Method of evaporating sample injecting inducted by dielectric barrier discharge microplasma

A technology of dielectric barrier discharge and micro-plasma, which is applied in the direction of plasma, electrical components, analytical materials, etc., can solve the problems that the sampling efficiency depends on the chemical form of the analytical elements, is expensive, and has poor reproducibility, so as to improve the efficiency of sample introduction , cheap production, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

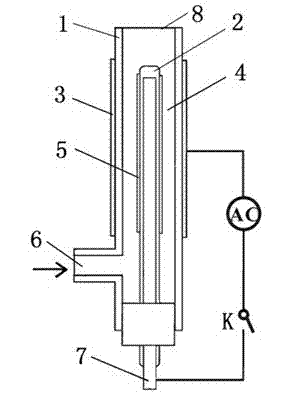

[0023] Embodiment 1: The structure of the dielectric barrier discharge device that needs to be prepared in the method of the present invention is as follows figure 1 As shown, it includes power supply, switch K, two insulating dielectric layers and two electrodes. The two insulating dielectric layers are concentric cylindrical tube structures made of ordinary glass. The inner diameter of the cylindrical tube 1 is 16mm, the inner diameter of the inner cylindrical tube 2 is 4mm, the distance between the glass cylindrical tubes of the two insulating medium layers is 5mm, the discharge chamber 4 is between the two insulating medium layers; the outer electrode 3 is wrapped in the outer layer Outside the cylindrical tube 1, the inner electrode 7 is inserted into the inner cylindrical tube 2, and the two electrodes are connected to the power supply. The outer cylindrical tube 1 is also provided with an air inlet 6, and the steam outlet 8 is located at the discharge one end of the roo...

Embodiment 2

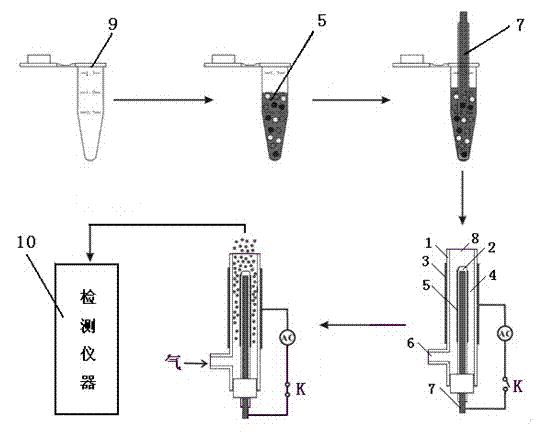

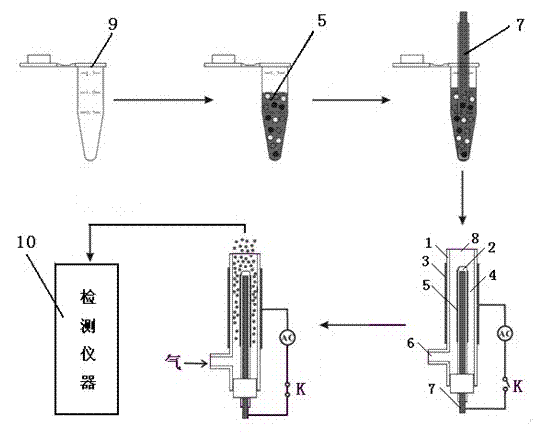

[0028] Embodiment 2: apply the method of the present invention to measure cadmium in the aqueous solution, the dielectric barrier discharge device that produces micro-plasma takes common glass as insulating medium, and the length of inner and outer cylindrical tubes is 30 mm, and the thickness is 2 mm. The inner diameter of the layer cylindrical tube 1 is 10mm, the inner diameter of the inner layer cylindrical tube 2 is 4mm, and the distance between the glass cylindrical tubes of the two insulating medium layers is 1mm; the carrier gas is a mixed gas of He and hydrogen, and the proportion of hydrogen is 2%; The carrier gas flow rate is 400ml / min; the sampling volume is 6μL. The power supply is a small ozone generating power supply with an input of 220V, the rated power is 18W, and the frequency is 50Hz; the signal is detected by an atomic fluorescence photometer, according to figure 2 The analysis procedure is to measure cadmium in aqueous solution, and its linear range is 1-...

Embodiment 3

[0029] Embodiment 3: application method of the present invention measures thimerosal in the vaccine, the dielectric barrier discharge device that produces micro-plasma adopts cylindrical structure, uses quartz as insulating medium, and the length of inner and outer cylindrical tubes is 80 mm, the thickness is 0.5 mm, the inner diameter of the outer cylindrical tube 1 is 10 mm, the inner diameter of the inner cylindrical tube 2 is 4 mm, and the distance between the glass cylindrical tubes of the two insulating medium layers is 2.5 mm; Ar is the carrier gas, and the carrier gas flow The speed is 1000ml / min; the sampling volume is 6μL. The power supply is 10000V, 30KHz; the signal is detected by inductively coupled plasma mass spectrometry, according to figure 2 The analytical procedure is used to determine thimerosal in vaccines, and its linear range is 1-100 ng / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com