System accorded with OPC standard for monitoring remote configuration

A configuration monitoring and remote technology, applied in the transmission system, digital transmission system, electrical program control, etc., to achieve seamless integration, ensure correctness, and expand openness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

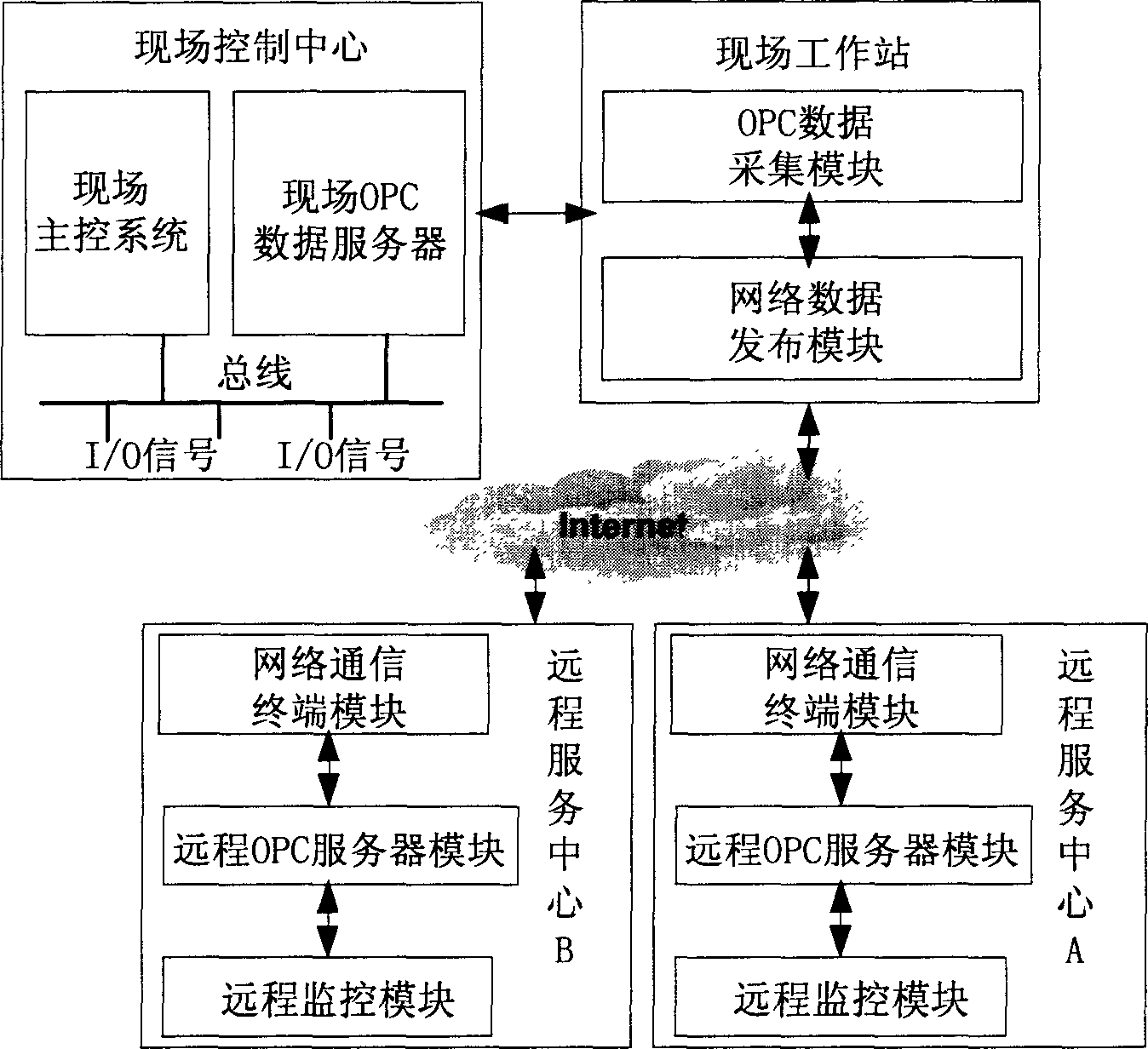

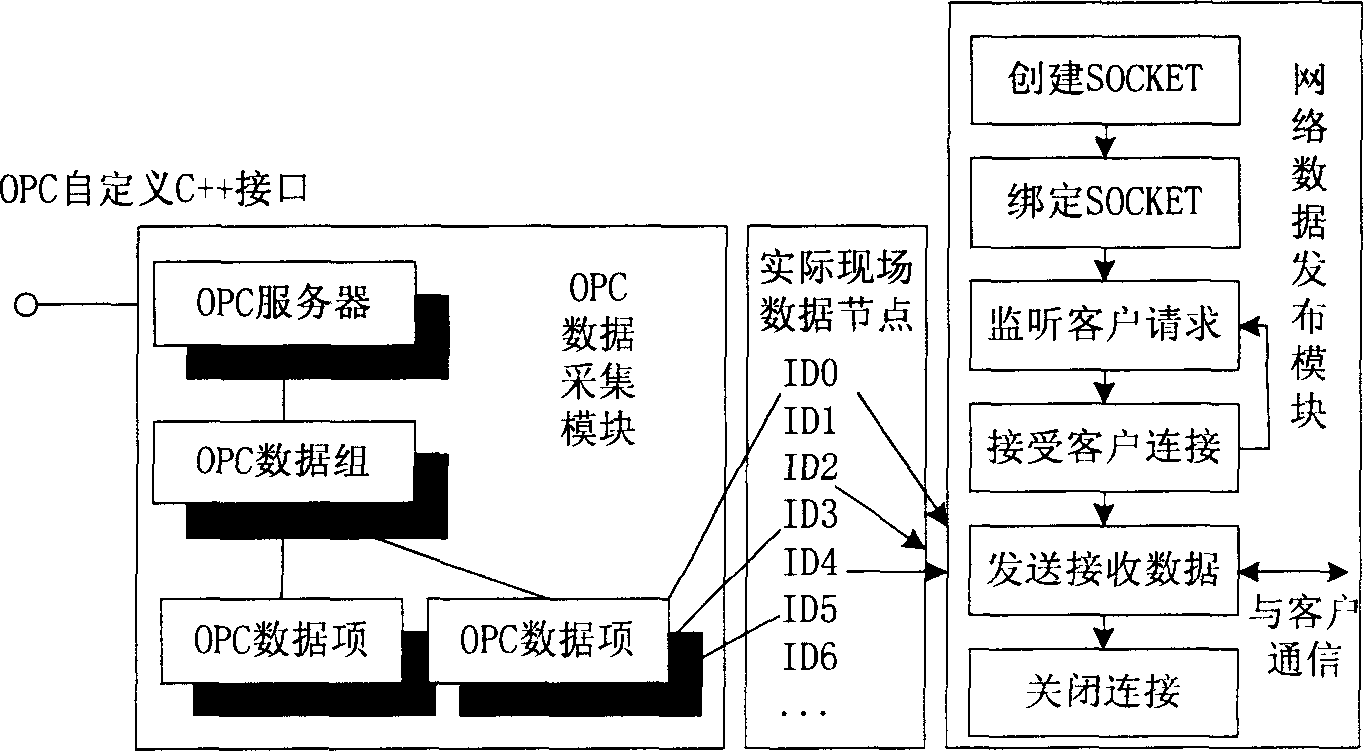

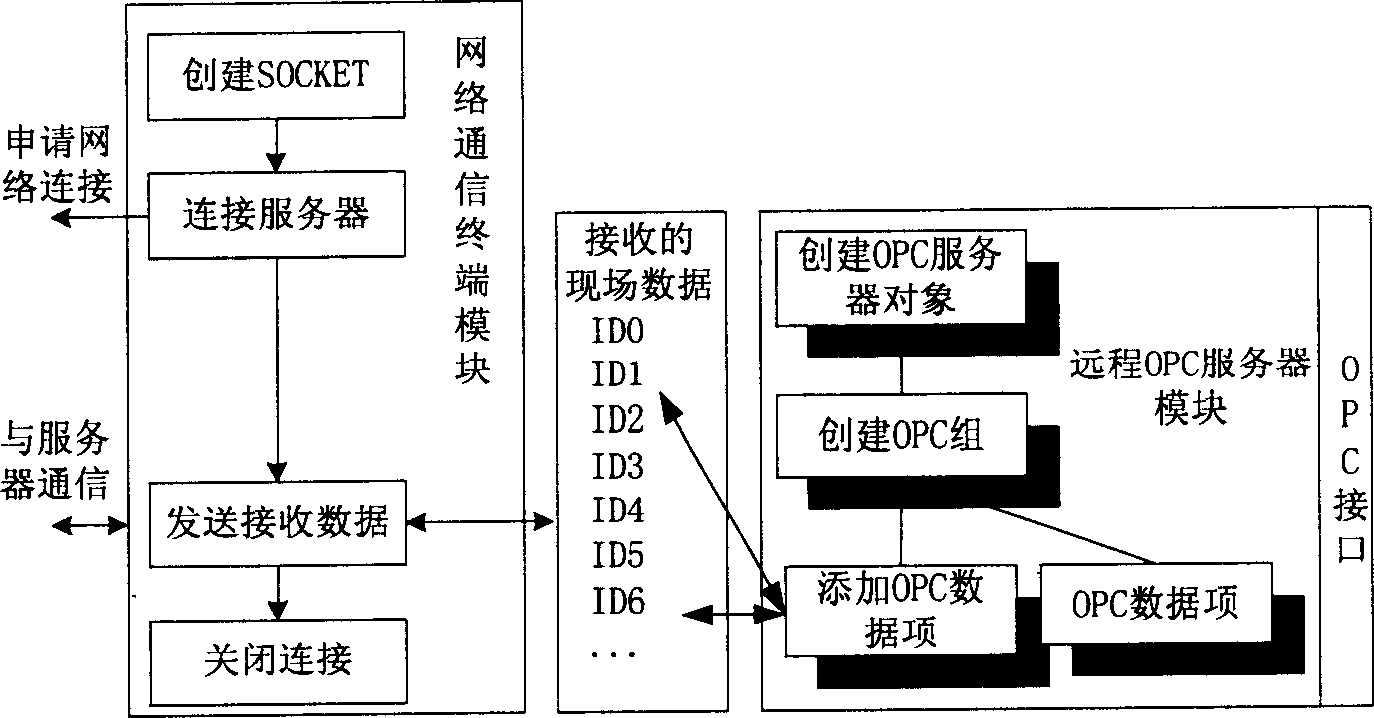

[0049] The idea of the invention is to realize the remote transfer of the OPC data interface through the OPC technology conforming to the industrial standard and the Internet network technology, that is, to transfer the OPC interface on site to the remote service center. The whole system can be integrated with the distributed FF field bus supporting OPC interface, and can also be integrated with the German Siemens PROFIBUS bus to realize remote monitoring of field devices without affecting the original field monitoring. details as follows:

[0050] Such as figure 1 As shown, it includes on-site control center, running on-site main control system and on-site OPC data server, providing OPC interface of on-site data to the upper monitoring system; it also includes on-site workstation and remote service center, of which: in the on-site control center, on-site ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com