Heat radiation structure and manufacturing method thereof

A technology of heat dissipation structure and manufacturing method, which is applied in the direction of modification by conduction and heat transfer, cooling/ventilation/heating transformation, semiconductor/solid-state device manufacturing, etc. problems, to achieve the effect of cost saving and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The heat dissipation structure provided by the present invention and its manufacturing method will be further described in detail below with reference to the accompanying drawings and embodiments.

[0028] see Figure 1-7 , the first embodiment of the present invention provides a method for manufacturing a heat dissipation structure, the steps of which include:

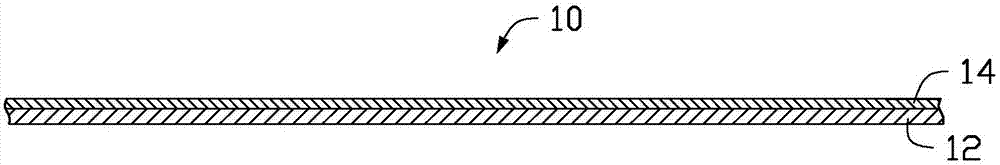

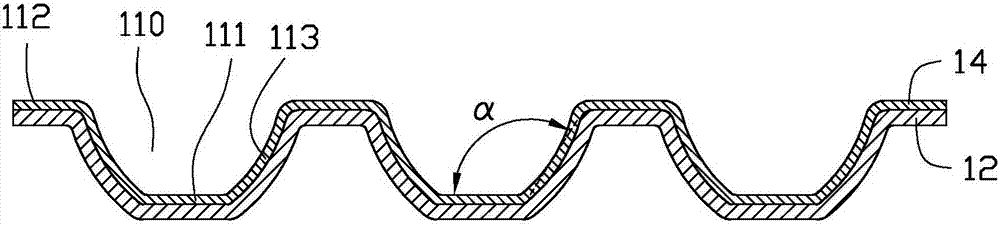

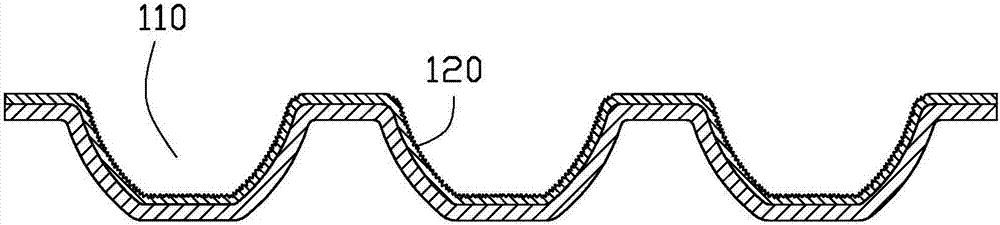

[0029] In the first step, a single-sided flexible copper-clad substrate 10 is provided and the single-sided flexible copper-clad substrate 10 is embossed to form at least one receiving groove 110 .

[0030] Please refer to figure 1 , the single-sided flexible copper-clad substrate 10 provided includes a base material layer 12 and a copper-clad layer 14 attached to the base material layer 12 , and the length of the base material layer 12 is equal to the length of the copper-clad layer 14 . The base material layer 12 has a thickness of 12-50 μm, and the copper clad layer 14 has a thickness of 12-140 μm. The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com