Silicon carbide smelting waste gas collecting and purifying device

A waste gas collection and purification device technology, which is applied in the direction of gas treatment, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of large footprint, air pollution, and difficulty in sealing the sealing walls at both ends and the mobile cover. Achieve the effect of lowering the temperature and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

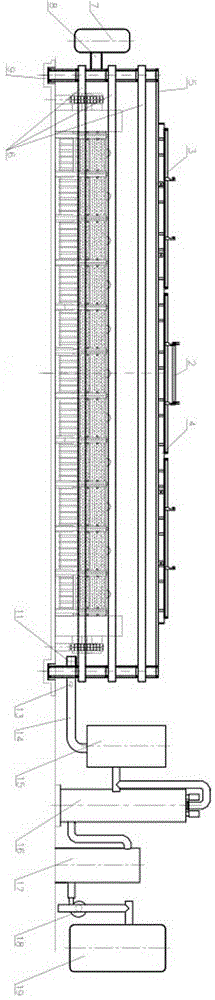

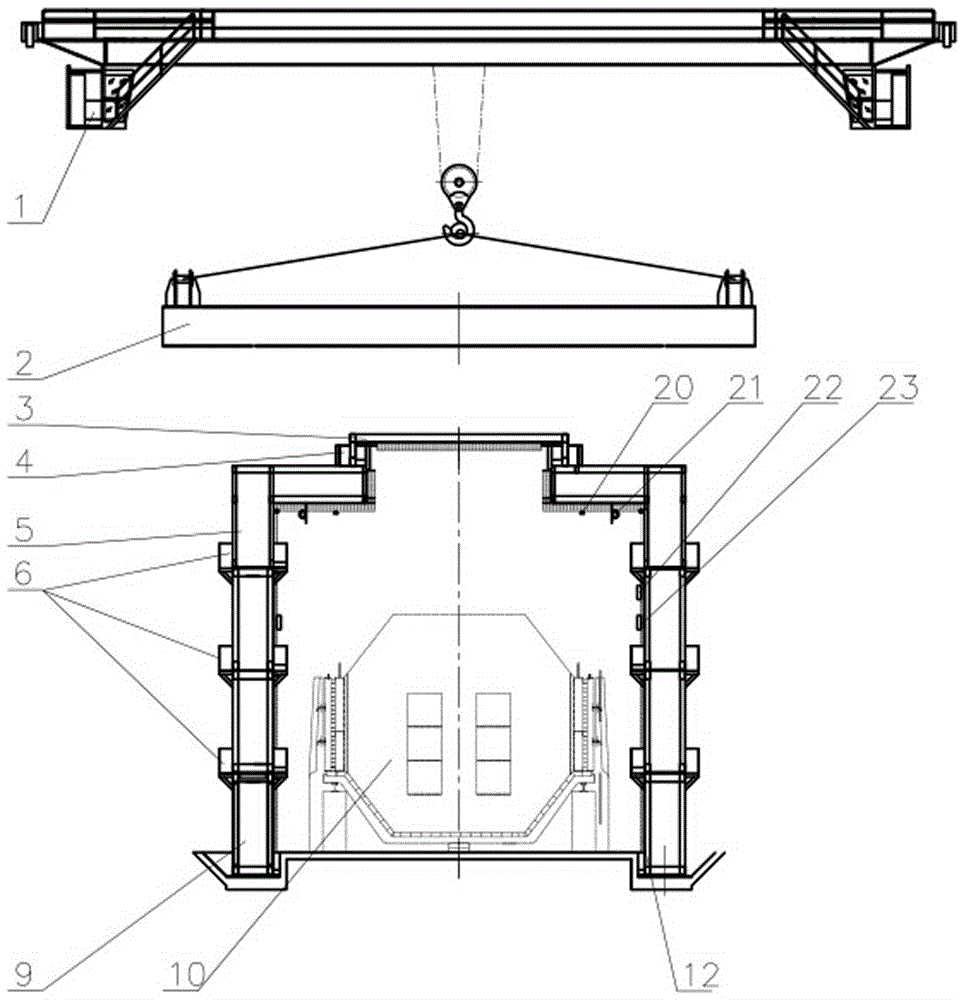

[0028] as attached Figure 1-2 As shown, the silicon carbide smelting waste gas collection and purification device includes a fully enclosed gas collecting hood for a silicon carbide smelting furnace. The silicon carbide smelting furnace 10 is arranged inside the gas collecting hood. The system 14 communicates with the desulfurization purification system through pipelines, the desulfurization purification system communicates with the exhaust fan 18 through pipelines, and the exhaust fan 18 communicates with the gas storage device 19 through pipelines; The body 9 and the upper cover body 5 are stacked horizontally, the second water seal groove 6 is set between the lower cover body 9 and the upper cover body 5 and between the lower cover body 9 and the bottom surface, and a pressure relief sealing device is set on the top of the upper cover body 5 .

[0029] The lower cover body 9 is evenly divided into three sections, and the second water seal groove 6 is set between the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com