Patents

Literature

80results about How to "To achieve the purpose of safe production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

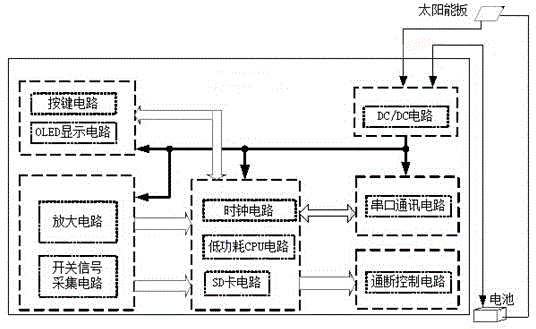

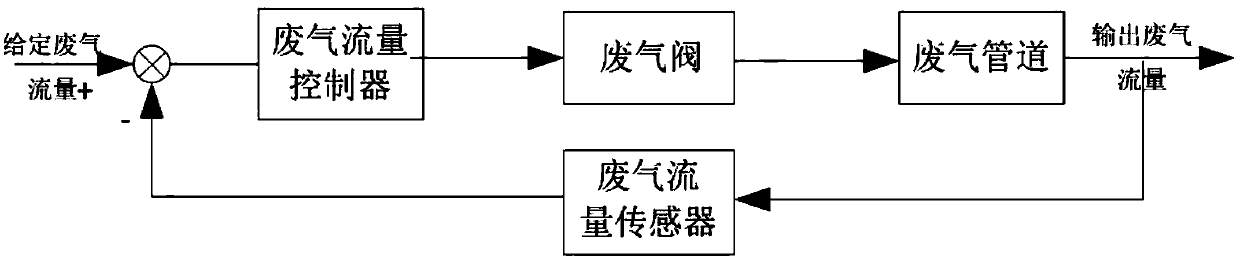

Gas production control method for natural gas well and intelligent controller

ActiveCN105545262ARealize intelligent controlTo achieve the purpose of safe productionFluid removalProcess engineeringControl valves

The invention discloses a gas production control method for a natural gas well and an intelligent controller and mainly solves the problems of low measurement precision, high labor cost and the like with the conventional gas production control method for the natural gas well. The gas production control method for the natural gas well comprises the following steps: (1) presetting control valve opening data corresponding to different gas well casing pressure, oil pressure and flow; (2) acquiring gas well casing pressure, oil pressure and flow data; (3) controlling the control valve to be opened to the corresponding opening according to the acquired casing pressure, oil pressure and flow data. The gas production control method can realize intelligent control and is convenient to implement and high in control precision.

Owner:CHENGDU KESI SAIDE TECH CO LTD

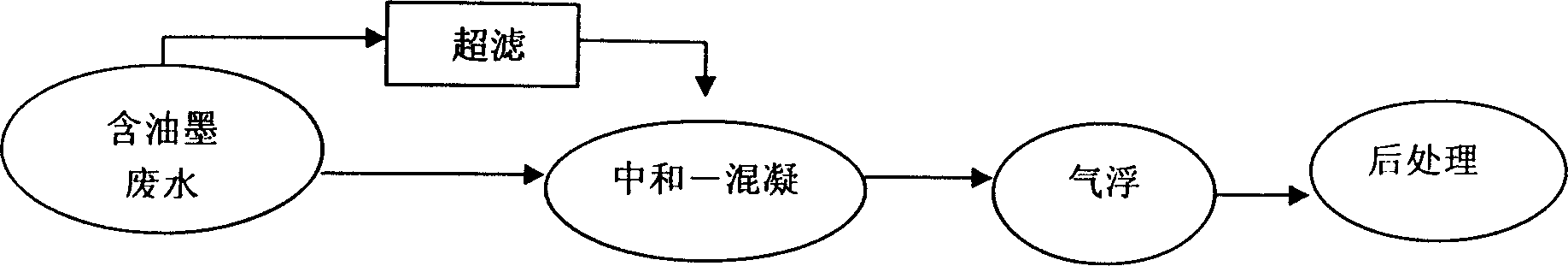

Waste water treatment agent for novel gravure note printing

InactiveCN1736896AAvoid corrosionSmooth responseWater/sewage treatment by flocculation/precipitationSolventUltrafiltration

Owner:SHANGHAI BANKNOTE PRINTING +1

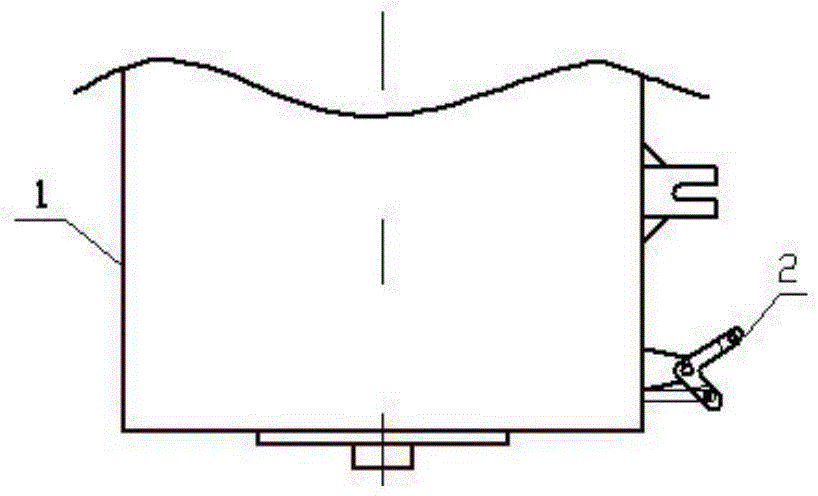

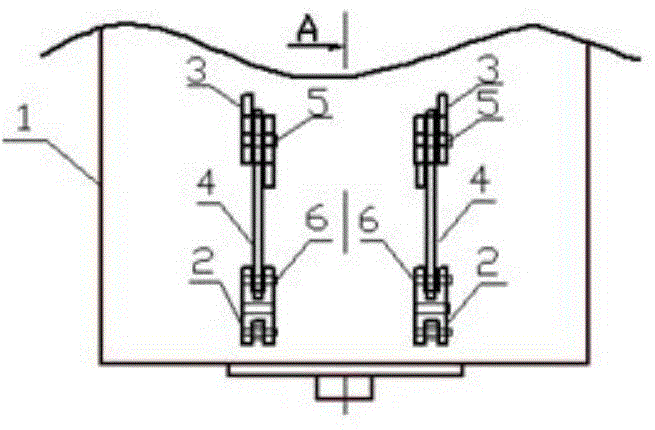

Steam styling cabinet for wig production

The invention discloses a steam styling cabinet for wig production. The steam styling cabinet comprises a styling device and a steam circulating device; the styling device comprises a cabinet body, an electric rotating device and a plurality of support plates arranged in the cabinet body, the upper portion of the left side inside the cabinet body and the lower portion of the right side inside the cabinet body are provided with an air outlet and an air inlet respectively, a condensation device is arranged at the air outlet, the electric rotating device is installed on the outer side of the cabinet body and electrically connected with a controller, the controller is electrically connected to an operation panel arranged outside the cabinet body, the support plates are arranged in parallel and are of a rectangular structure, the back ends of the support plates are fixedly provided with shafts, and the left ends of the shafts penetrate through the cabinet body to be connected to the electric rotating device; the steam circulating device comprises a combustion chamber, a steam pipeline, a water storage tank and a circulating fan. The steam styling cabinet solves the problems that due to the fact that hair curling pipes in a steam styling cabinet cannot rotate, hair is unevenly heated, and the curling effects achieved after styling are inconsistent and also solves the energy waste problem.

Owner:太和县嘉泰发制品有限公司

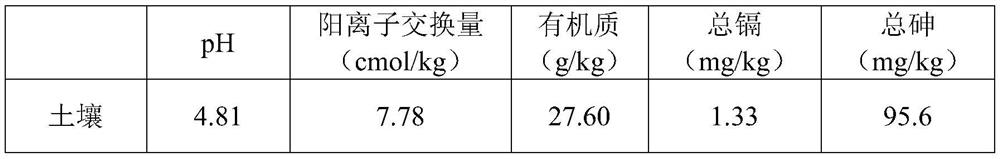

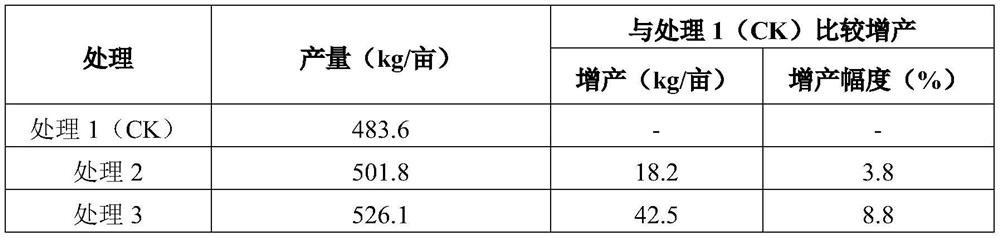

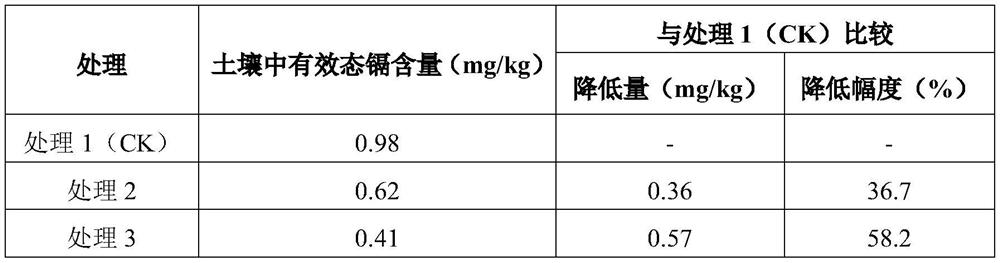

Soil conditioner for treating cadmium and arsenic combined pollution of farmland and application method of soil conditioner

PendingCN112939696AReduced bioavailabilityLarge specific surface areaAgriculture tools and machinesFertilising methodsSoil scienceSoil remediation

The invention relates to the field of farmland soil remediation, in particular to a soil conditioner for treating farmland cadmium and arsenic combined pollution and an application method of the soil conditioner. The soil conditioner is prepared from the following components in percentage by mass: 50%-60% of modified charcoal, 10%-30% of reduced iron powder, 10%-30% of calcium magnesium phosphate fertilizer and 10%-30% of sepiolite. When the soil conditioner is applied, the soil conditioner is uniformly mixed with water through a stirring box to form slurry, then the slurry is sprayed into a rice field through slurry spraying equipment, and then the soil conditioner is fully mixed with soil through ploughing. The soil conditioner provided by the invention can effectively reduce the bioavailability of cadmium and arsenic in farmland soil, reduce the content of cadmium and arsenic in agricultural products produced in a cadmium and arsenic combined pollution farmland, and avoid secondary pollution in the use process.

Owner:湖南中米环保科技有限公司

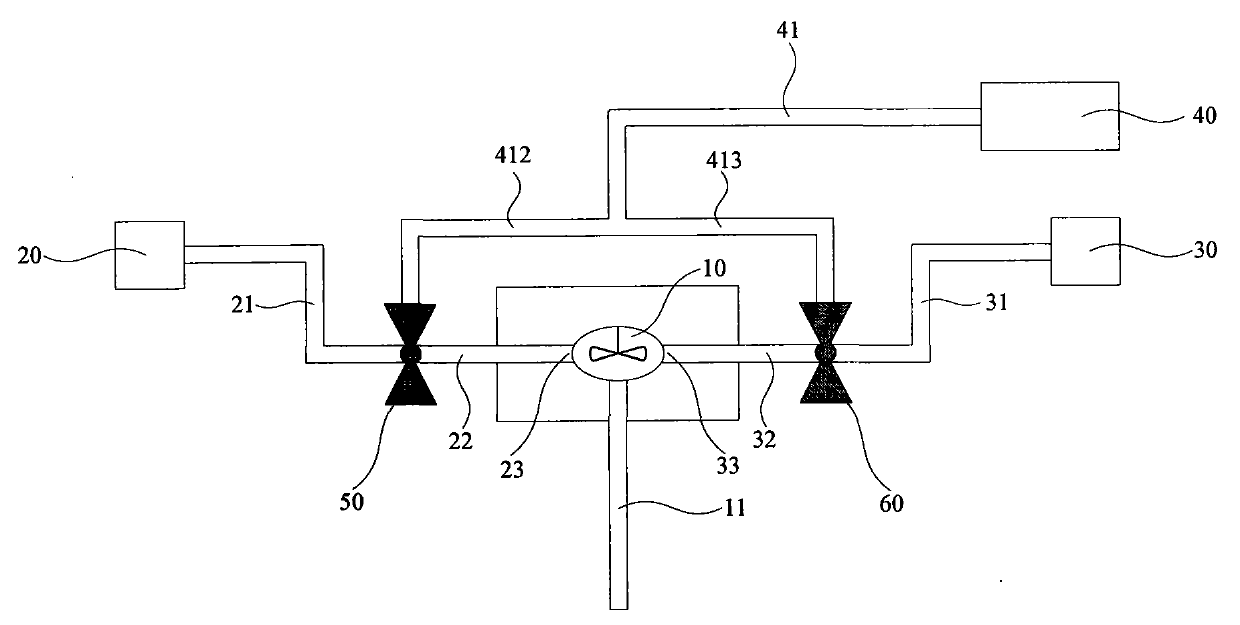

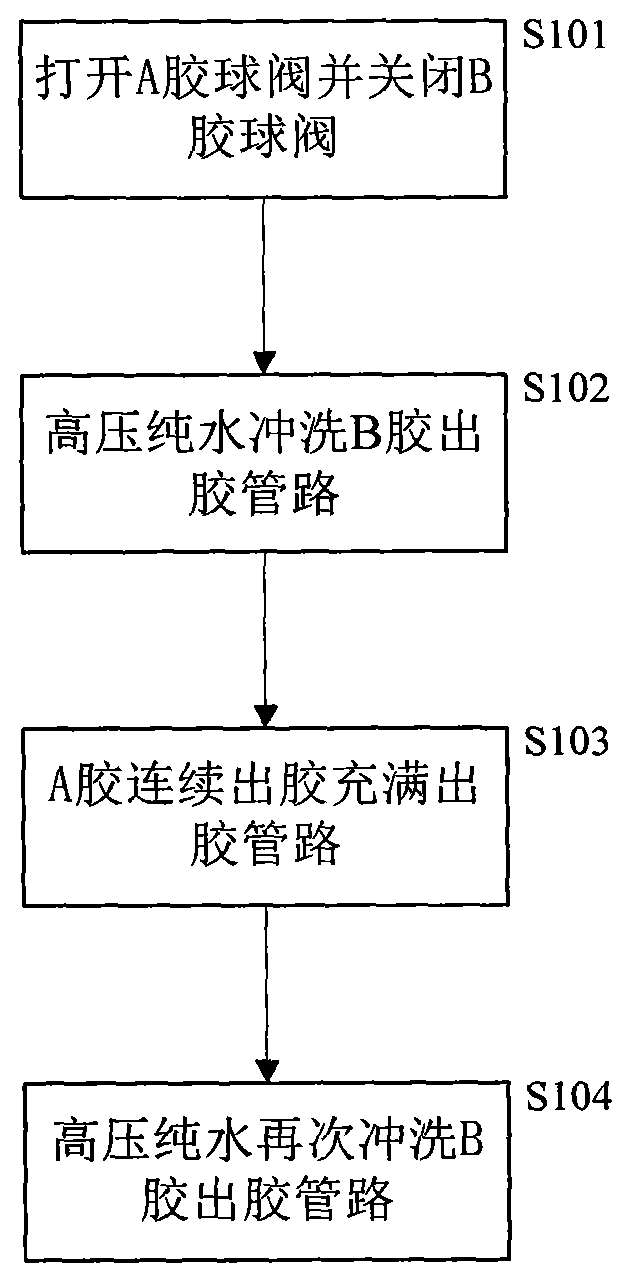

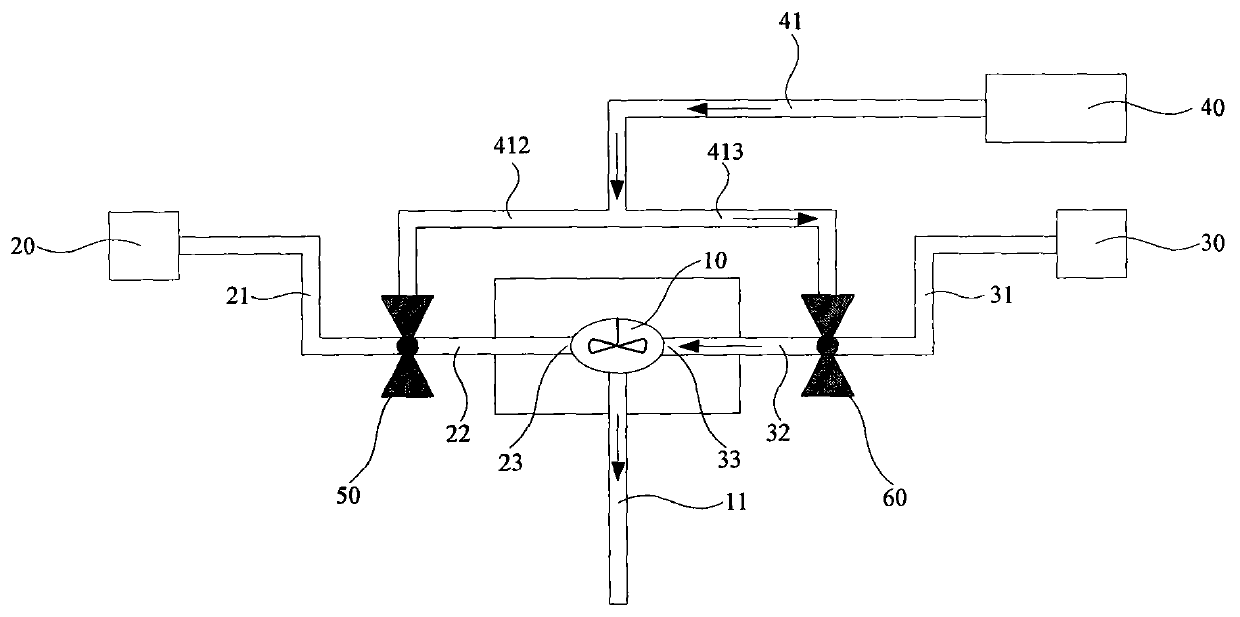

A and B adhesive filling device and method for keeping adhesive discharge state thereof

InactiveCN103785564AResidue reductionPrevent solidificationLiquid surface applicatorsHollow article cleaningAdhesiveWater storage tank

The invention discloses an A and B adhesive filling device and a method for keeping an adhesive discharge state thereof. The adhesive filling device comprises an A adhesive container, an A adhesive discharge pipeline, a B adhesive container, a B adhesive discharge pipeline, an A adhesive ball valve, a B adhesive ball valve, an adhesive mixer, an adhesive discharge pipeline, a water storage tank and a water discharge pipeline. Water in the water storage tank can flow into the adhesive discharge pipeline via the water discharge pipeline, the A adhesive ball valve, the B adhesive ball valve, the A adhesive discharge pipeline, the B adhesive discharge pipeline and the adhesive mixer. The method includes steps of a, opening the A adhesive ball valve and closing the B adhesive ball valve; b, flushing the B adhesive discharge pipeline by the aid of high-pressure water; c, continuously discharging A adhesive and filling the adhesive discharge pipeline with the A adhesive; d, flushing the B adhesive discharge pipeline by high-pressure water again. The A and B adhesive filling device and the method for keeping the adhesive discharge state thereof have the advantages that the A adhesive and B adhesive can be prevented from being solidified in the adhesive discharge pipeline, and the excellent A and B adhesive discharge state can be kept.

Owner:APOLLO PRECISION (FUJIAN) LIMITED

Silicon carbide smelting waste gas collecting and purifying device

InactiveCN106178757AEasy to liftEnsure stabilityGas treatmentUsing liquid separation agentPositive pressureSmelting process

The invention discloses a silicon carbide smelting waste gas collecting and purifying device. The device comprises a fully-closed gas collecting hood of a silicon carbide smelting furnace, the silicon carbide smelting furnace is arranged in the gas collecting hood, one end of the gas collecting hood is communicated with a recycling pipeline system, the recycling pipeline system is communicated with a desulphurization and purification system through a pipeline, the desulphurization and purification system is communicated with an exhaust fan through a pipeline, and the exhaust fan is communicated with a gas storage device through a pipeline; the gas collecting hood is composed of a lower hood body and an upper hood body which are horizontally overlaid, second water sealing tanks are arranged between the lower hood body and the upper hood body and arranged between the lower hood body and the bottom face respectively, and a pressure relieving and sealing device is arranged at the top of the upper hood body. According to the device, collection is conducted through the fully-closed gas collecting hood, and the whole system runs under the micro-positive pressure, the zero pressure and the micro-negative pressure and is closed and not leaked; the hood bodies are divided into multiple sections, the lower hood body sections are installed in an interchanged mode, hoisting is convenient, the desulphurization and purification system can completely remove H2S generated in the smelting process, and collected CO can be directly reutilized without being treated.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

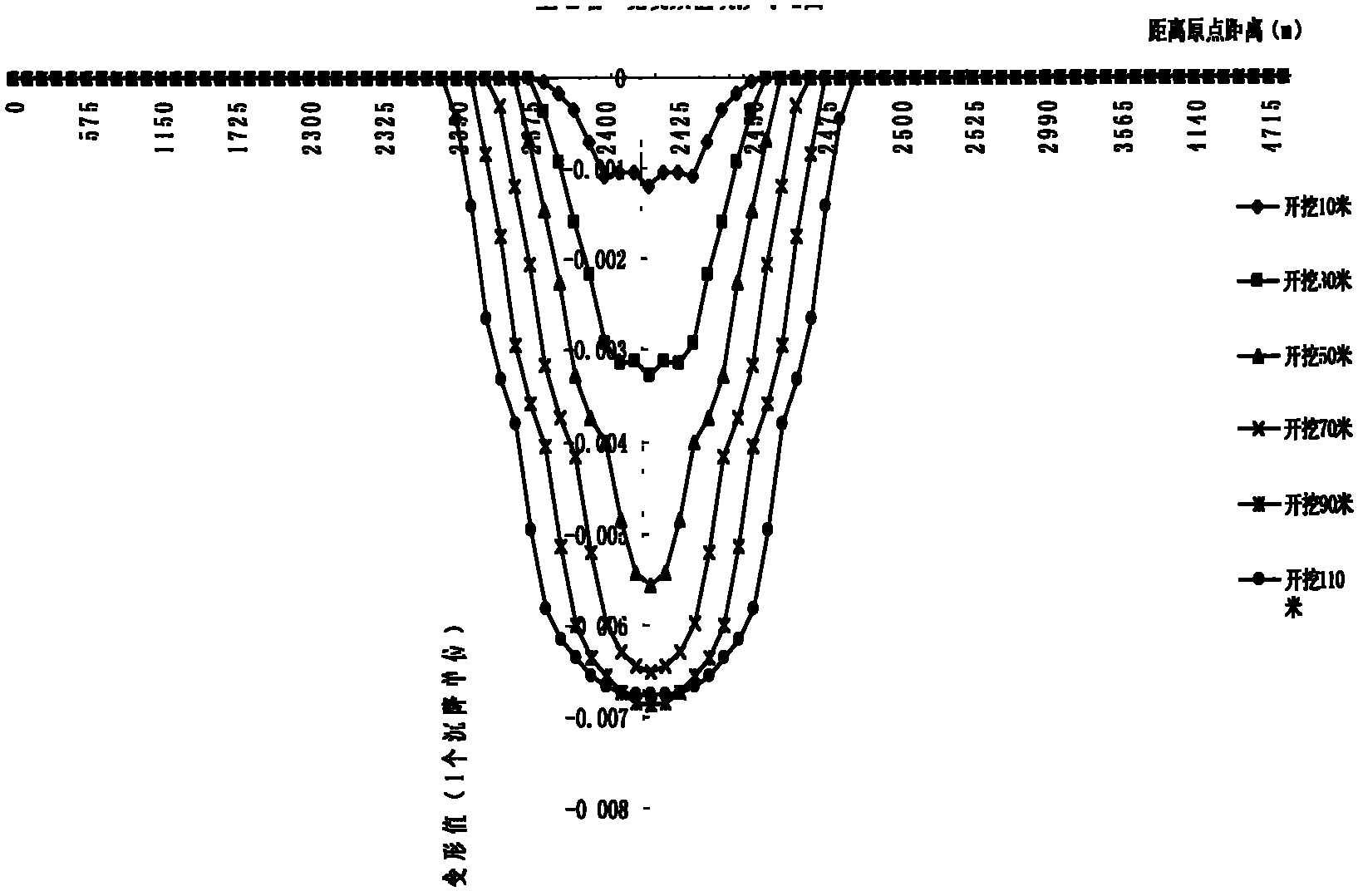

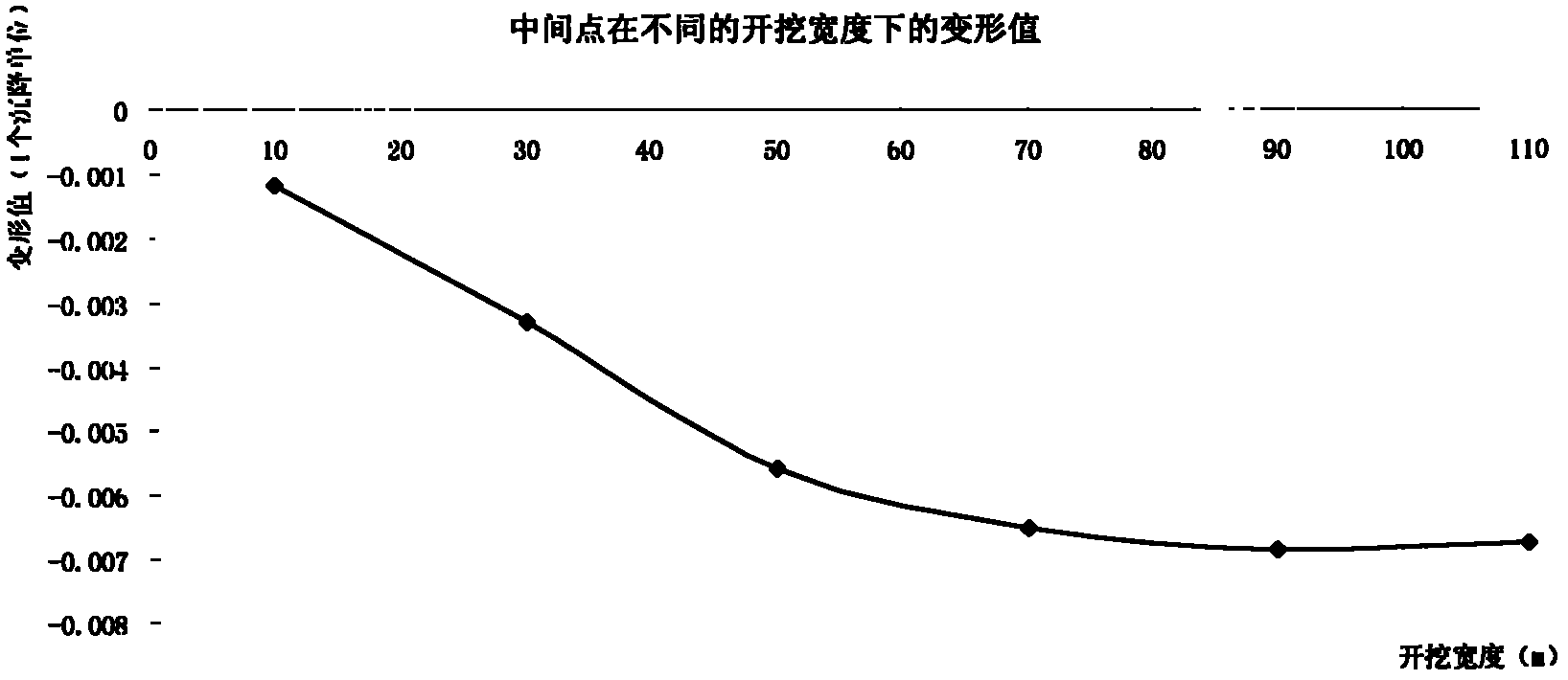

Technology for controlling deformation of slope rock mass

InactiveCN102194251AImprove slope stabilityTo achieve the purpose of safe production3D modellingClassical mechanicsEngineering

The invention provides a technology for controlling deformation of a slope rock mass and solves the problem on the critical excavating width due to a three-dimensional slope effect generated by slope strip mining, a slope stability coefficient calculation formula taking the three-dimensional slope effect into consideration is provided, and thereby the slope deformation can be reduced and the stability of the slope is improved by a three-dimensional deformation control method and the aim of safely producing is achieved.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

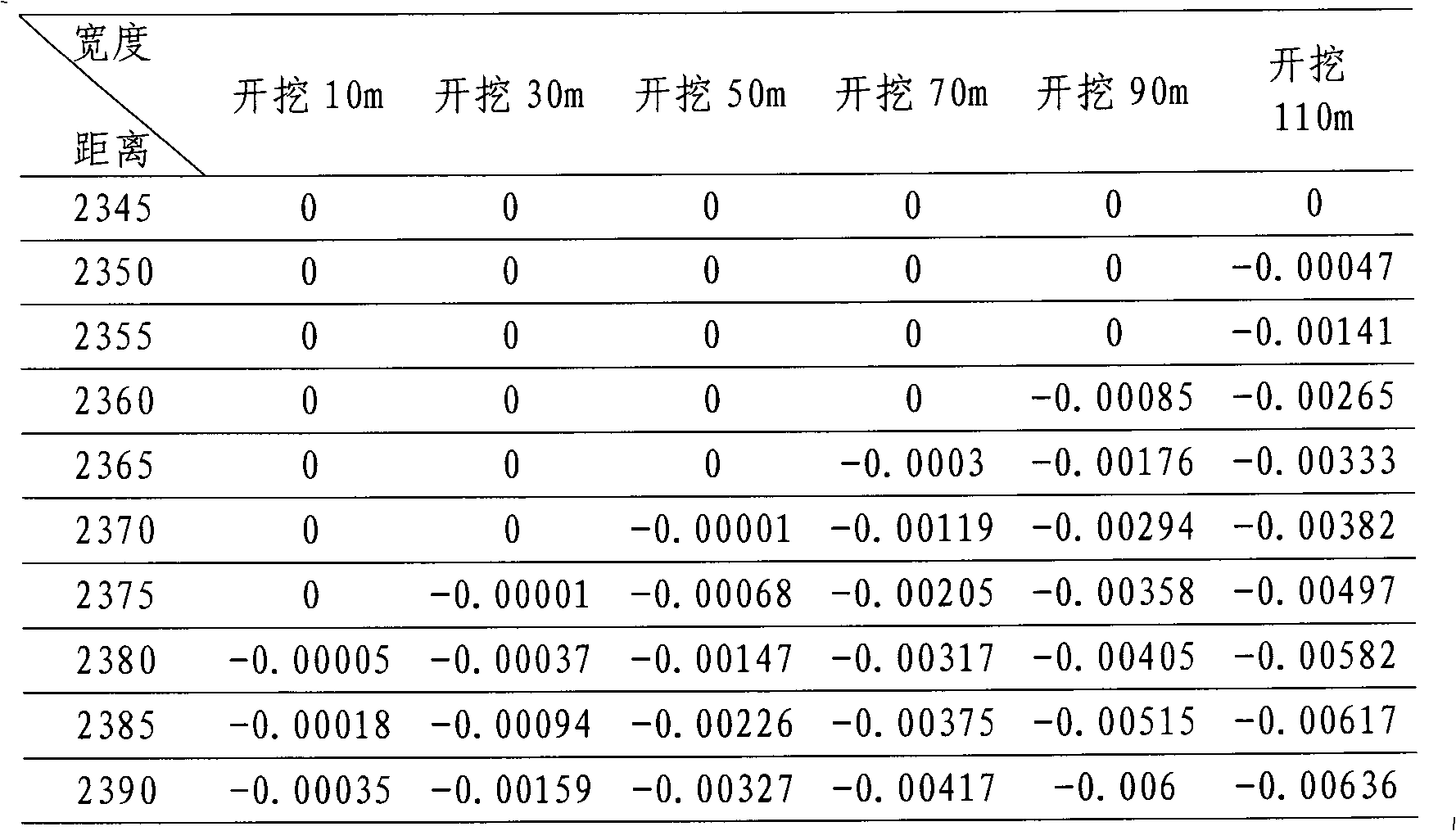

Energy concentration shell for permafrost excavation

InactiveCN107218851AImprove excavation efficiencyReduced excavation efficiencyBlasting cartridgesPermafrostPunching

The invention discloses an energy concentration shell for permafrost excavation, and relates to the technical field of blasting. The problems that an existing energy concentration shell cannot give consideration to the radiation and directing effects both, and is not suitable for permafrost excavation are solved. According to the technical scheme, the energy concentration shell for permafrost excavation comprises a shell, a fusing device, a separating plate and an energy concentration cover, and the fusing device is arranged in the center of the top of the shell; the energy concentration cover made of metal materials is arranged in the shell, the position between the energy concentration cover and the shell is filled with explosive, and the separating plate is horizontally arranged in the explosive below the top of the shell; and the upper section of the energy concentration cover is a spherical arc cover ring, and the lower section of the energy concentration cover is in a circular truncated cone shape and is connected with the bottom of the shell. The energy concentration cover is matched with the separating plate, the explosive performance reaches the radiation and directing dual spreading effects, punching can be carried out in permafrost, the hole bottom is in a kettle shape after blasting is carried out, explosive kettle method blasting next time is facilitated, the explosive using rate is improved, the number of drilled holes is remarkably decreased, the permafrost excavation efficiency is improved, and in addition, the safety is improved.

Owner:SINOHYDRO FOUND ENG

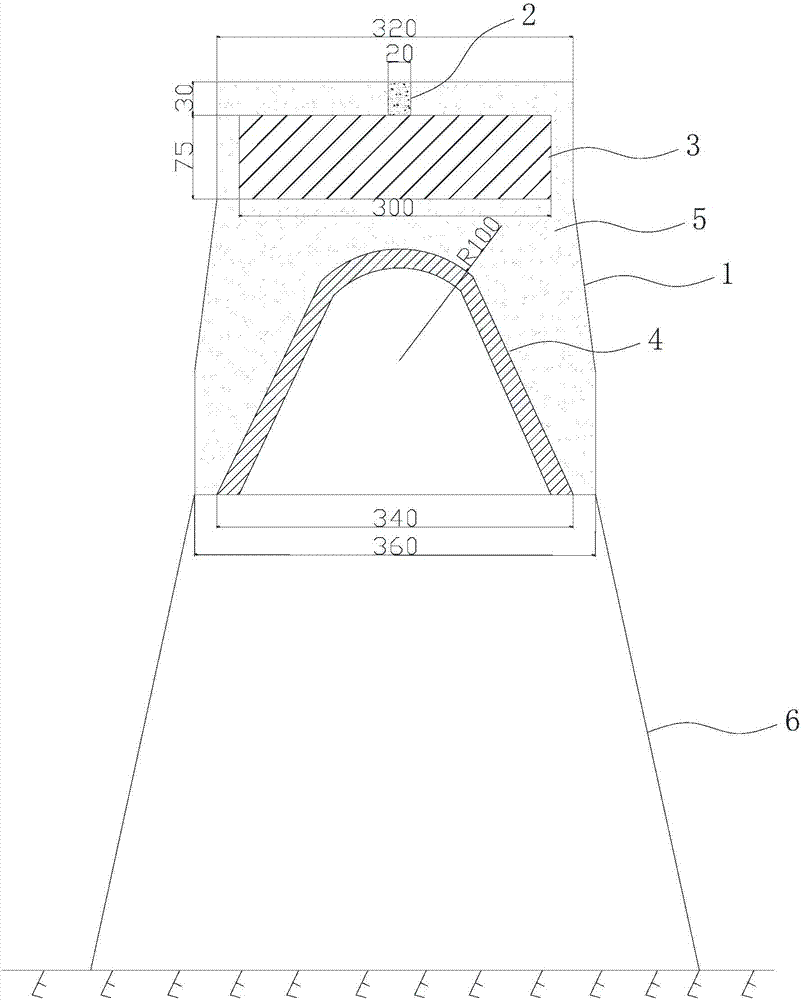

Industrial waste gas incinerator

InactiveCN109099445APrevention of Exhaust ExplosionsControl environmental pollutionIncinerator apparatusIndustrial wasteExhaust fumes

Owner:XUZHOU NORMAL UNIVERSITY

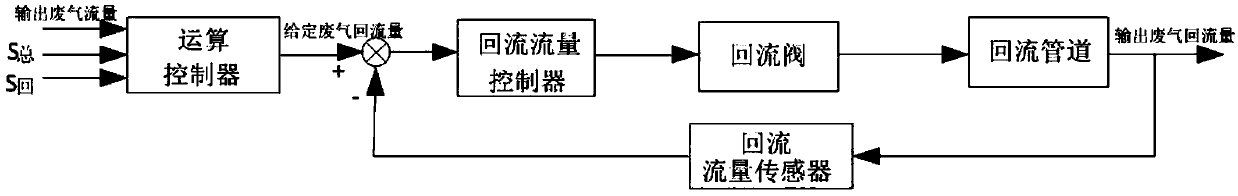

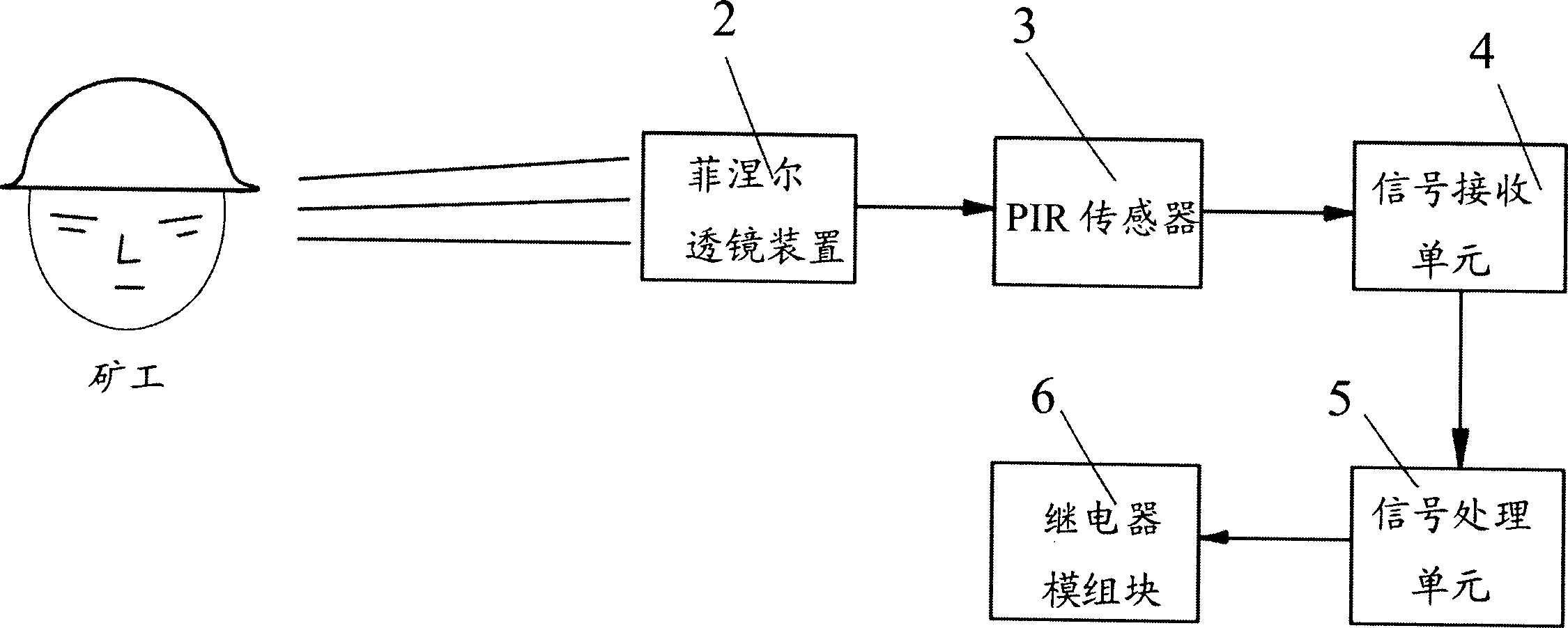

Safety monitoring and preventing system of man and vehicle in oblique transportation in mine well

InactiveCN1818345AGuarantee personal safetyTo achieve the purpose of safe productionMining devicesComputer moduleLength wave

A safe monitoring protective system for human and vehicles in slanting mine laneway that comprise the infrared detector, the signal gatherable module which connect with the infrared detector by the data electric cable, the signal processing module which connect with the signal gatherable module by the data electric cable, and the relay module which operate and control the transportationed equipments in the laneway. The infrared detector comprise PIR sensor which can translate the wavelength 7 to 12 um of infrared signal into electric signal and can inhibit the nature white light, and lens equipment which can divide the cautionary area into some bright areas and dark areas and refract or reflect the pyroelectric infrared signal to sensor.

Owner:北京中矿电力电子技术有限公司

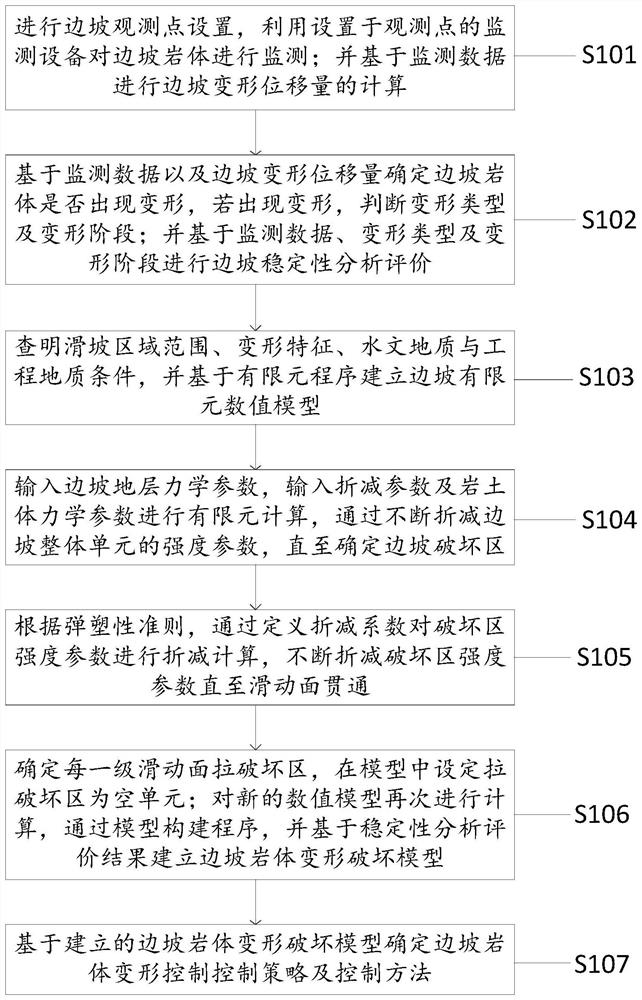

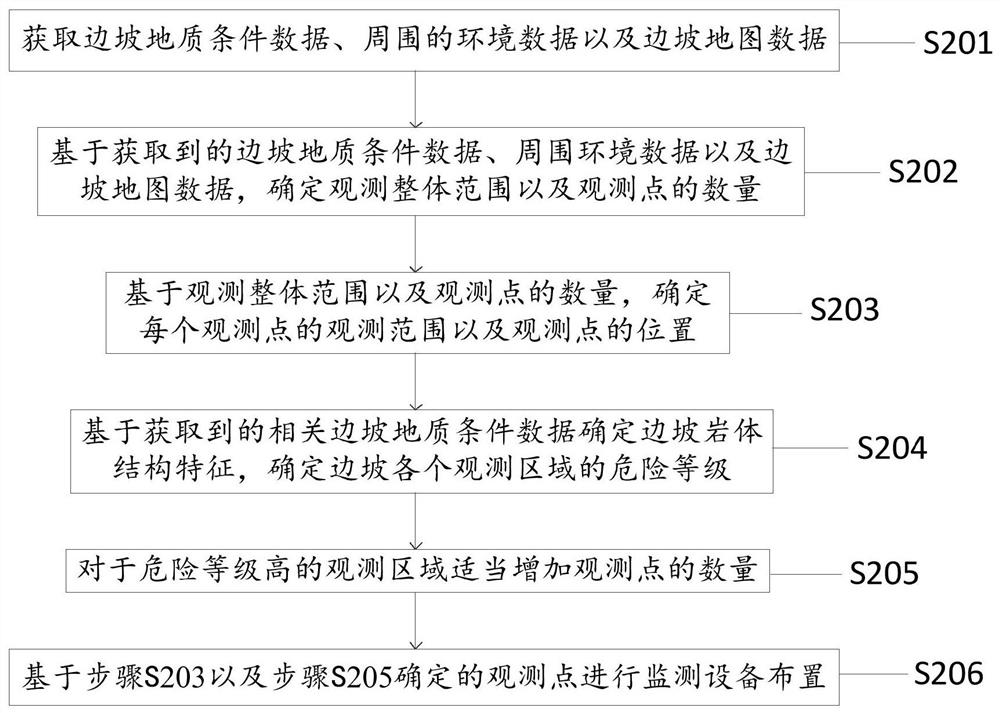

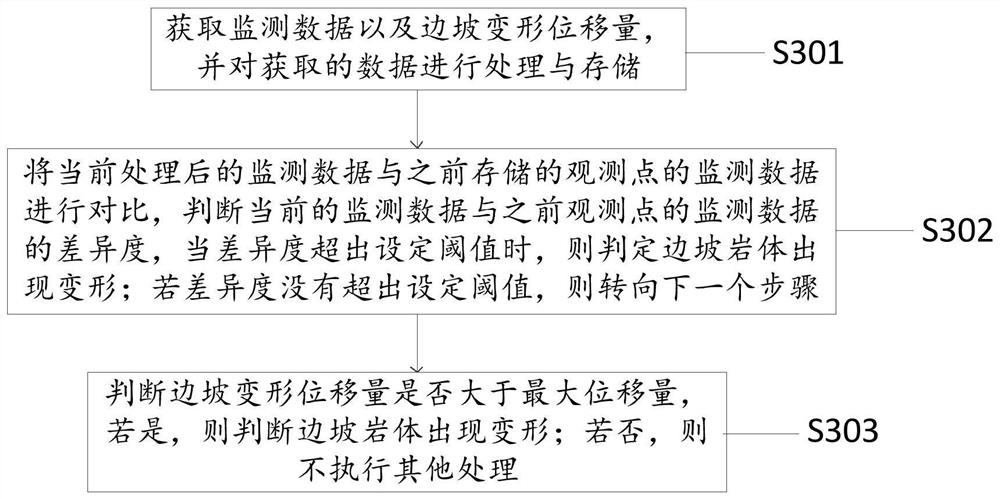

Slope rock deformation control method, computer program product and readable storage medium

ActiveCN112507438AReduce displacementImprove stabilityGeometric CADClimate change adaptationSlope stability analysisObservation point

The invention discloses a slope rock mass deformation control method, a computer program product and a readable storage medium, and the method comprises the steps: setting slope observation points, monitoring a slope rock mass through monitoring equipment, and calculating the slope deformation displacement based on the monitoring data; determining whether the slope rock body deforms or not based on the monitoring data and the slope deformation displacement, and judging a deformation type and a deformation stage; analyzing and evaluating the slope stability based on the monitoring data, the deformation type and the deformation stage; establishing a slope rock mass deformation and failure model based on a stability analysis and evaluation result; and determining a slope rock mass deformationcontrol strategy and a control method based on the established slope rock mass deformation damage model. By the adoption of the method, slope deformation can be effectively controlled, slope deformation displacement is reduced, slope stability is improved, and the purpose of safe production is achieved.

Owner:GUANGZHOU METRO DESIGN & RES INST

Method of quickly preparing aerogel by accelerating solvent extraction

The invention discloses a method of quickly preparing aerogel by accelerating solvent extraction. The method comprises the following steps of: (1) mixing and diluting a fixed quantity of inorganic silicon source and water, adding a fixed amount of acid to form salt-bearing silicasol, and obtaining gel after a period of time, (2) accelerating the solvent extraction of the gel obtained in step (1) with an organic solvent aqueous solution of which a concentration is increased with time, and (3) drying the gel obtained in step (2). The method of preparing the aerogel is simple in procedure, shortin production cycle and low in energy consumption, and the aerogel product has the characteristics of complete structure, low heat conductivity coefficient and high mechanical strength.

Owner:浙江岩谷科技有限公司

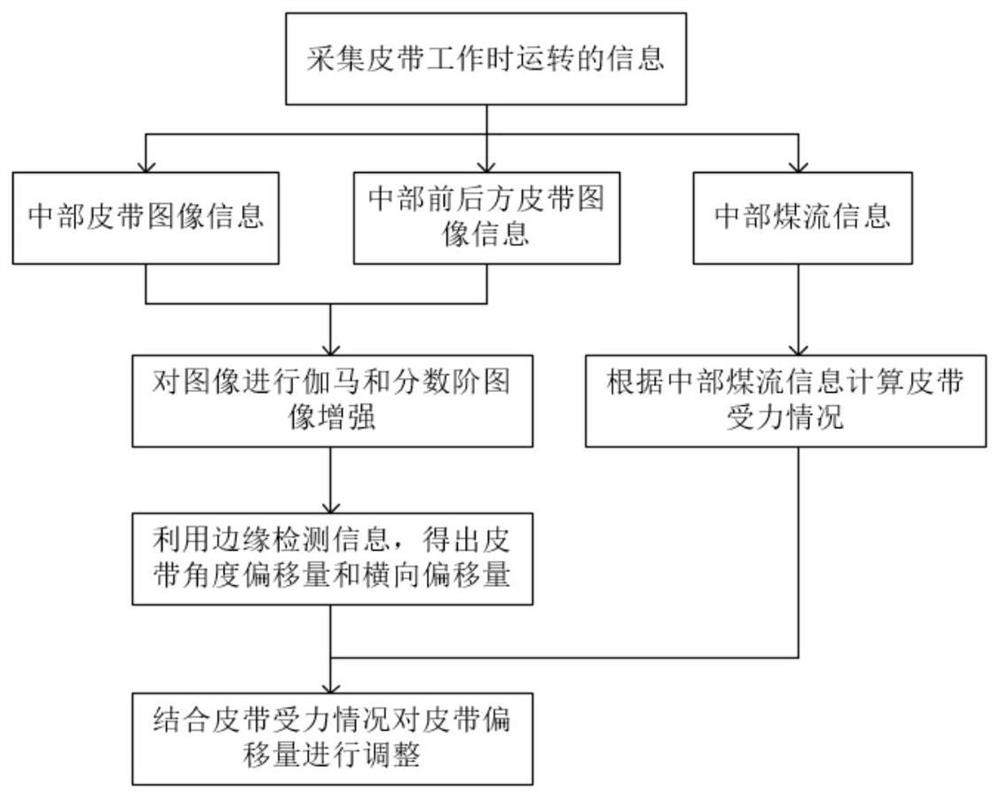

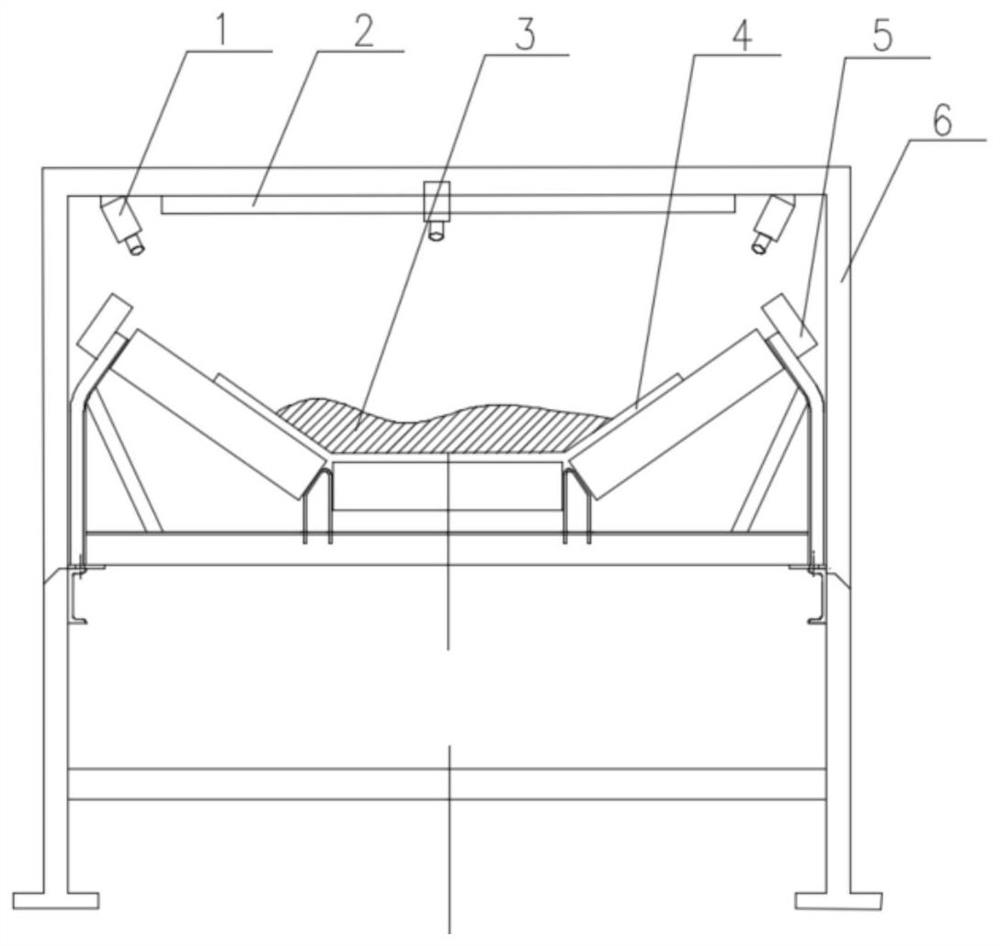

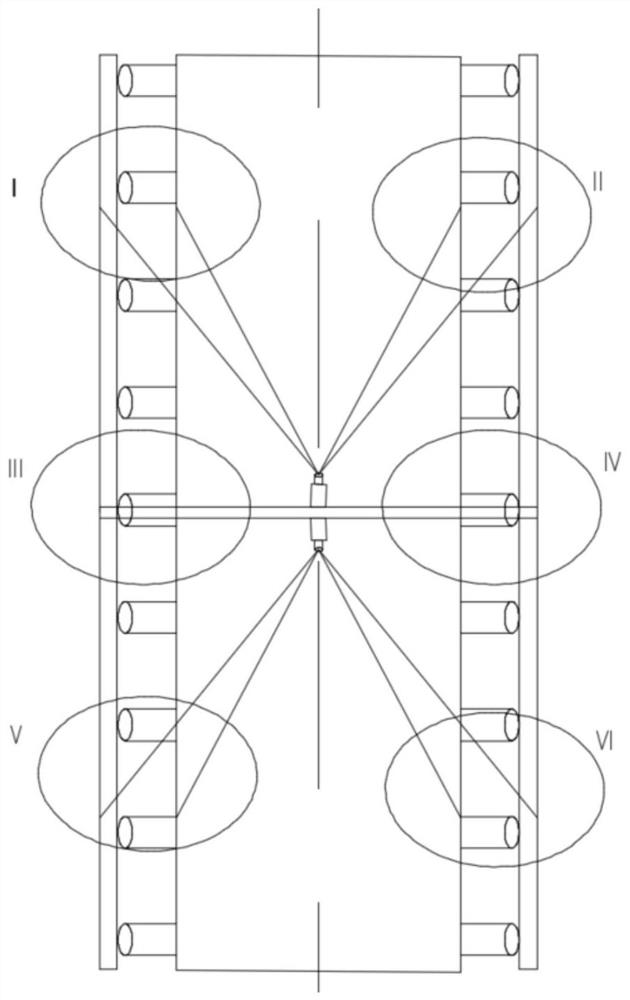

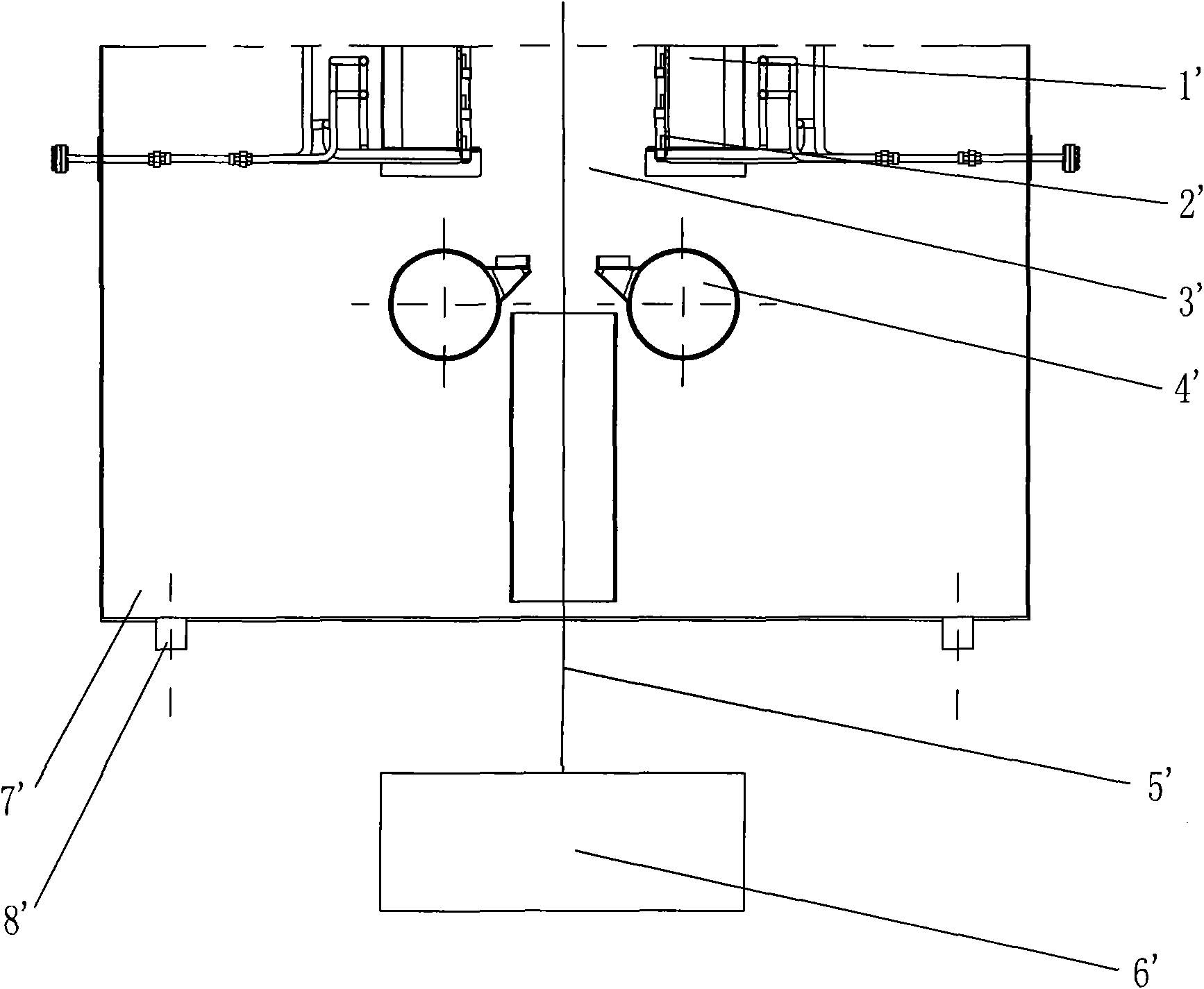

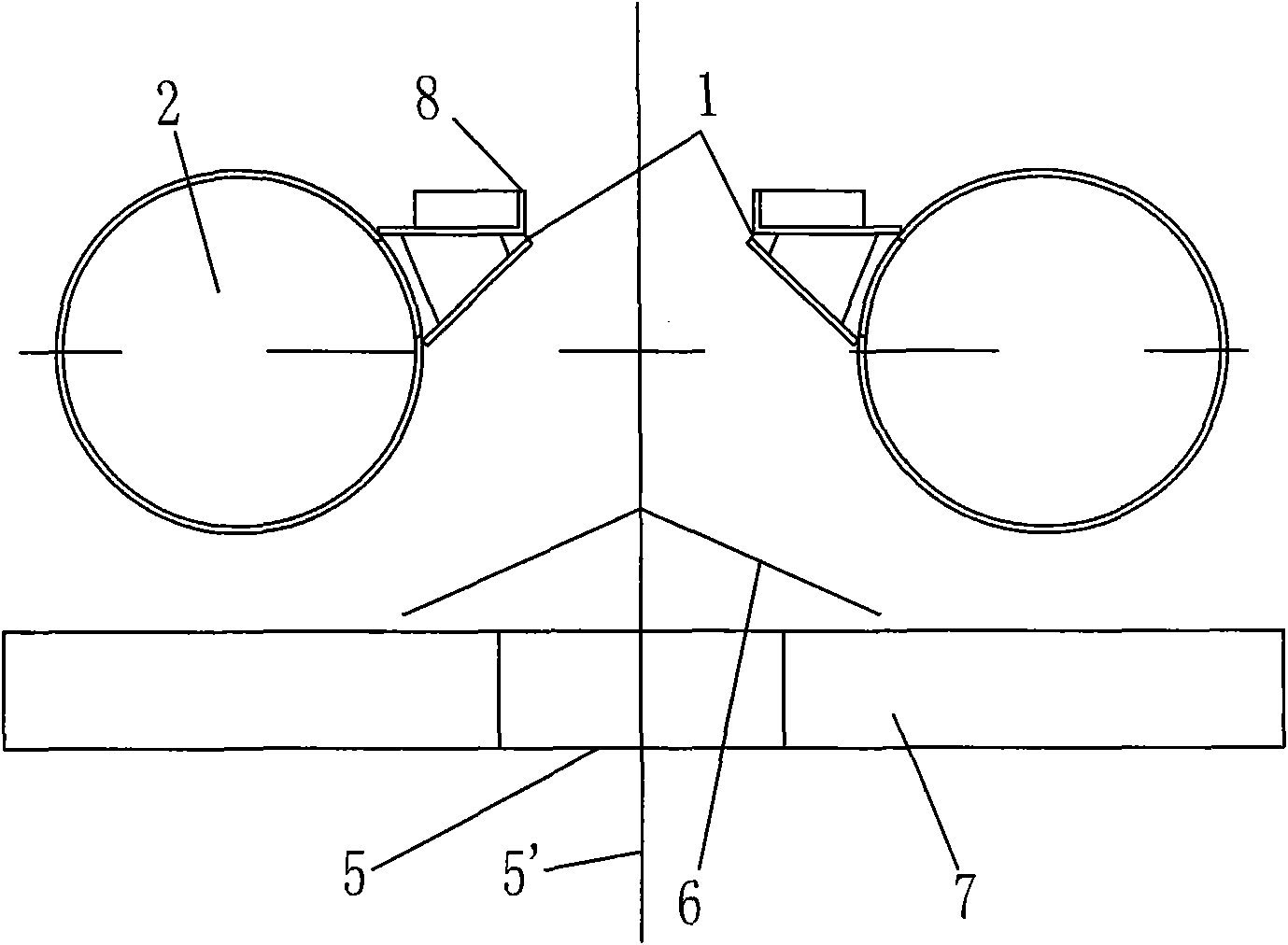

Belt conveyor deviation detection device and automatic adjustment method

ActiveCN113772364ATo achieve the purpose of safe productionEfficient detectionConveyorsControl devices for conveyorsControl theoryVisual perception

The invention discloses a belt conveyor deviation detection device and an automatic adjustment method. The belt conveyor deviation detection device comprises a visual detection module and a carrier roller control module. The automatic adjustment method comprises the steps that firstly, the visual detection module installed in the middle of a belt conveyor is used for obtaining middle belt operation images, middle front and rear operation images and middle coal flow information when the belt conveyor works, gamma and fractional orders are used for image enhancement processing, Canny edge detection is conducted on the processed images so as to obtain carrier roller and belt edge information; the deviation angle is calculated through the front and rear carrier rollers in the middle of a belt and a belt edge straight line, and then the transverse deviation amount is detected according to information obtained through middle edge detection; the stress condition of the belt is calculated according to belt middle coal flow information obtained by a line laser camera of the visual detection module, and finally belt deviation is corrected in real time through the carrier roller control module according to the belt stress condition and the deviation amount, so that the deviation amount of the belt is effectively detected in time and adjusted in time. According to the belt conveyor deviation detection device and the automatic adjustment method, the purpose of coal conveying safety production is achieved.

Owner:CHINA UNIV OF MINING & TECH

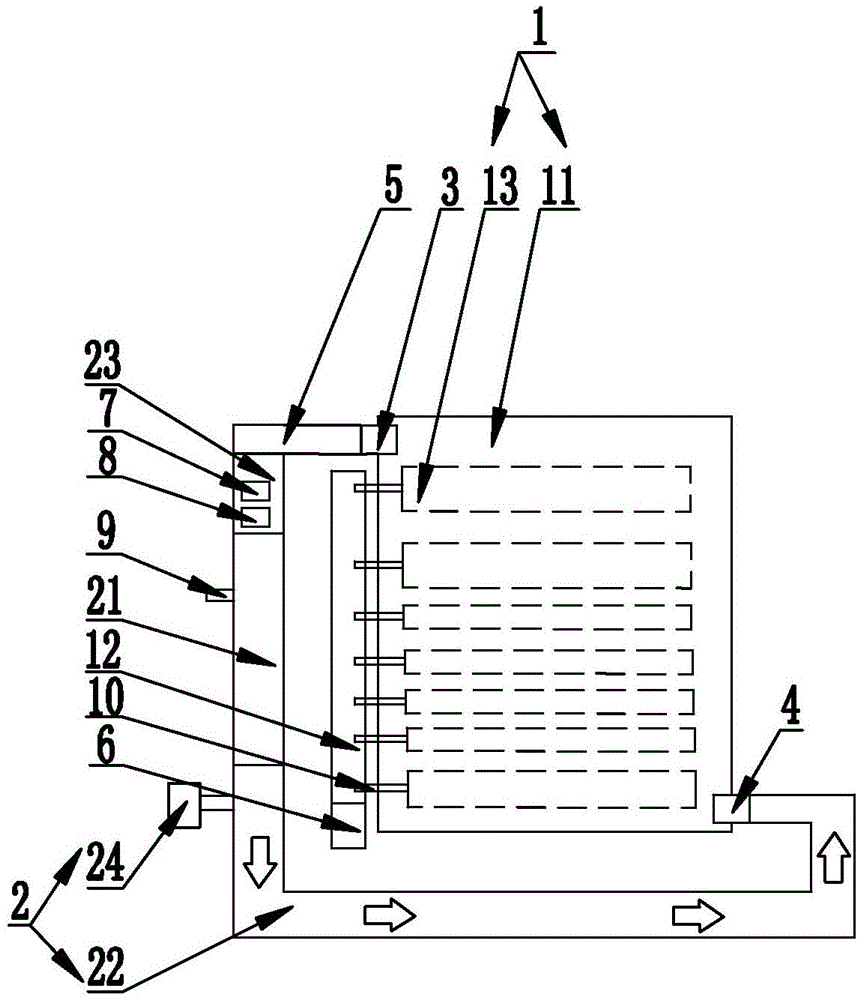

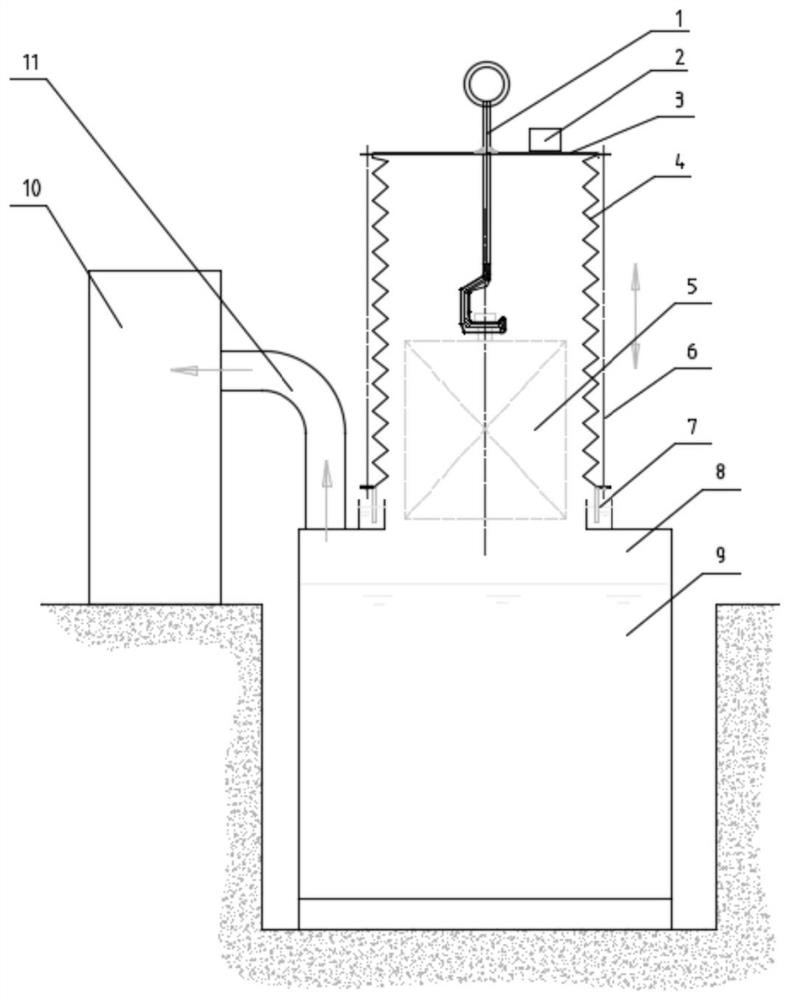

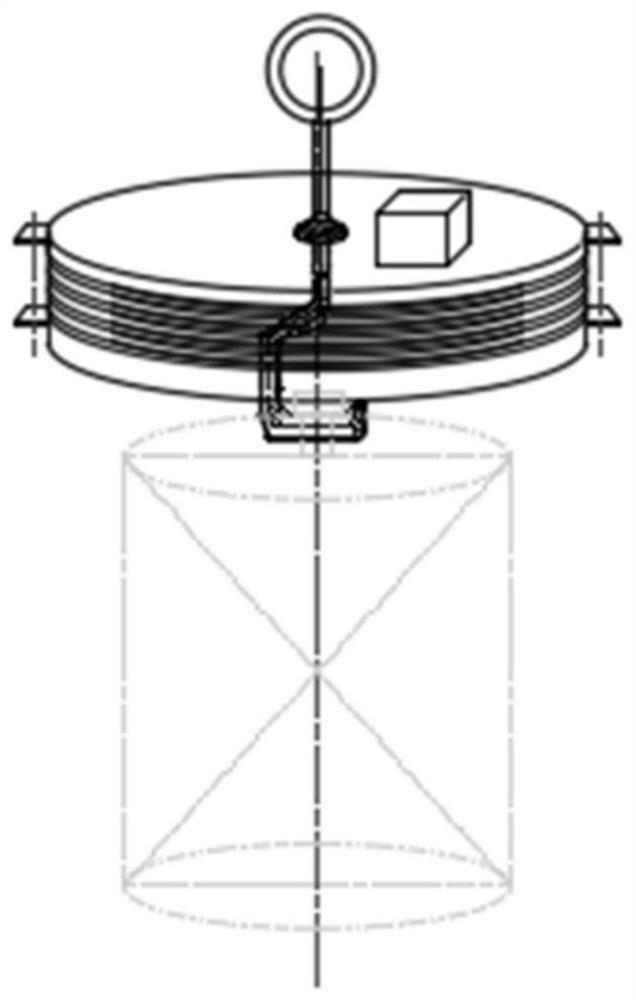

Bottom sealing device of band steel aerosol cooling device

ActiveCN101876003AGood sealing effectSimple equipmentFurnace typesHeat treatment furnacesAir knifeZinc

The invention relates to a bottom sealing device of a band steel aerosol cooling device, which comprises an air knife (1), an air knife cylinder (2), an air inlet (3), a stretching mechanism (4), a band steel inlet (5), a water collecting sump (7), and a watertight shuttle (8). The water collecting sump (7) is a square ring shaped sump which comprises an inclined bottom plate (70), a water outlet (71), an inner square plate (72), a outer plate (73), a bottom plate (74) and an inner arc-shaped plate (75); and the nozzle of the air knife is a ring-shaped nozzle which comprises an upper air nozzle (11), a lower air nozzle (12), a lower arc-shaped air nozzle (13), a side air nozzle (14) and an upper arc-shaped air nozzle (15). The bottom sealing device of the band steel aerosol cooling device has the advantages of good sealing effect, simple equipment and stable working, can reduce equipment maintenance load, has high promotion value in the field of quick aerosol cooling after plating, and can be applied to hot galvanizing, aluminum and zinc hot dipping and zinc layer alloying production lines, and also be suitable to other occasions needing aerosol cooling.

Owner:BAOSHAN IRON & STEEL CO LTD

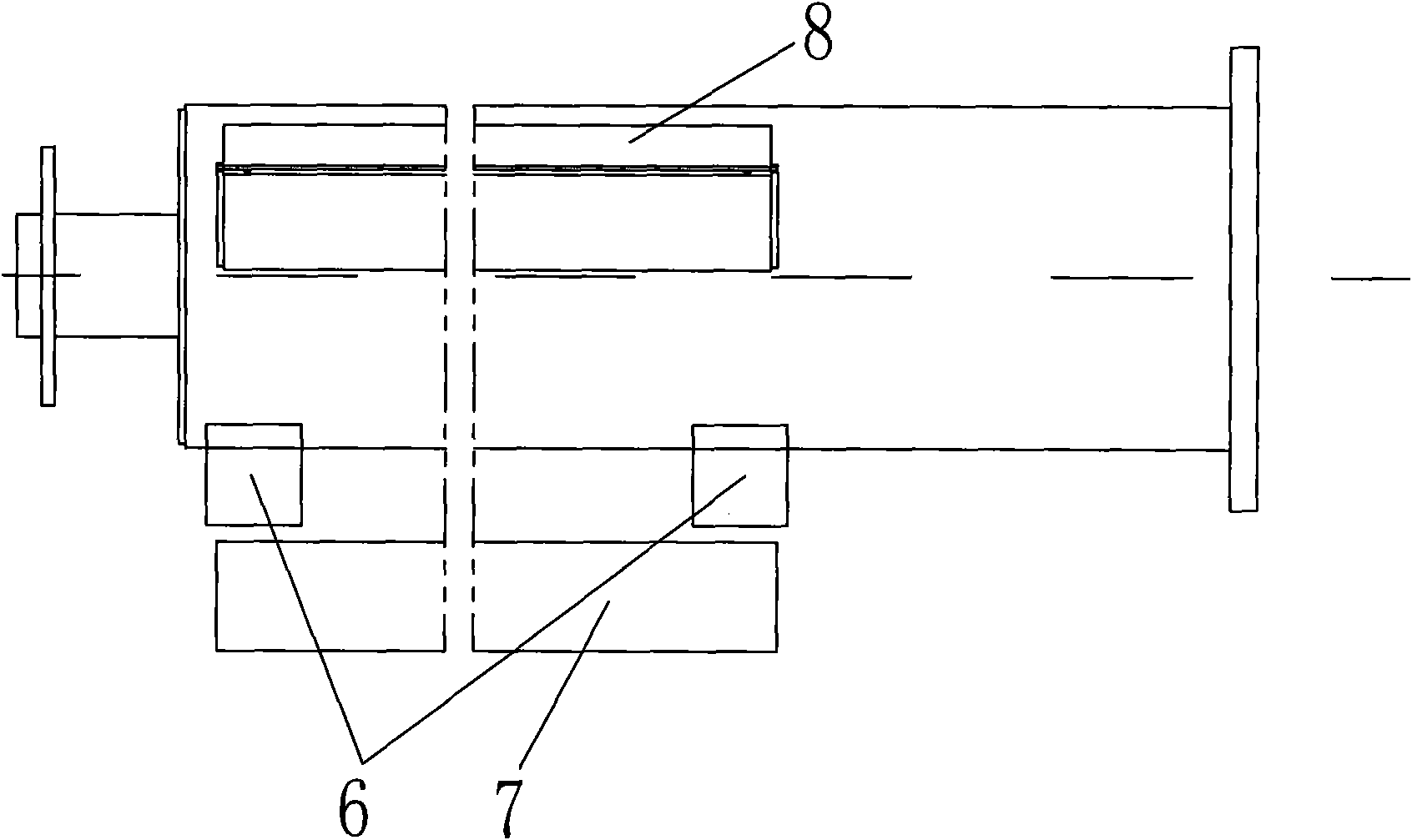

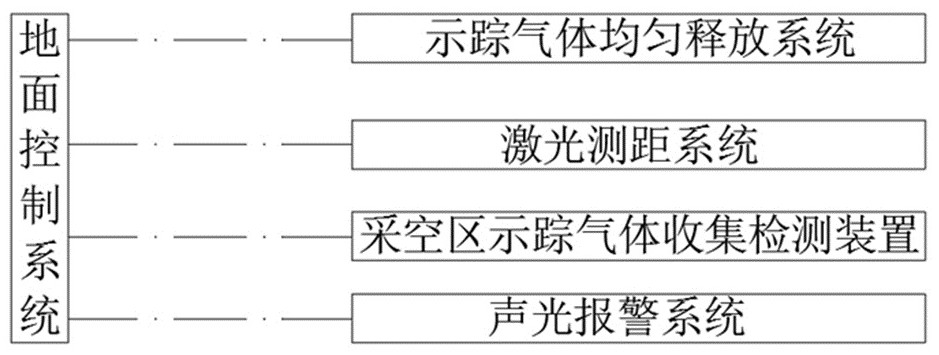

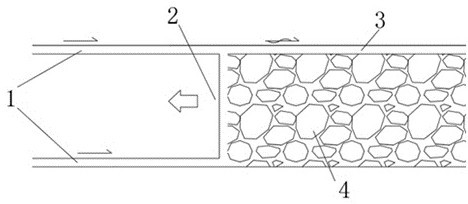

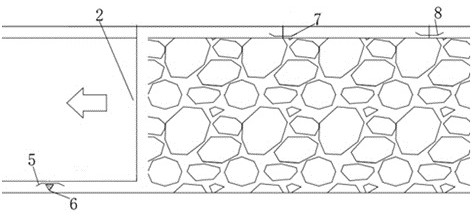

System and method for detecting goaf air leakage under gob-side entry retaining mining in real time

PendingCN112362248AEasy to analyzeTo achieve the purpose of safe productionDetection of fluid at leakage pointAnalysing gaseous mixturesControl systemEnvironmental engineering

The invention belongs to the technical field of underground coal mine ventilation. Goaf air leakage is a nature important link of coal of an existing goaf, however, existing goaf air leakage amount detection is large in manpower consumption and long in detection time, the underground goaf air leakage situation cannot be obtained as soon as possible, goaf management cannot be judged in time. The invention provides a system and method for detecting goaf air leakage under gob-side entry retaining mining in real time. Tracer gas is released in a goaf, mixed gas of the goaf is collected and detected, the contained tracer gas is detected and analyzed, data is transmitted to a ground control system, sound-light alarm is triggered when the air leakage reaches a set threshold value; the installation positions and serial numbers of tracer gas release devices are adjusted according to advancing of a working face, unmanned operation starting is achieved, manpower is saved, the safety in the production process is improved, and the production cost is effectively reduced.

Owner:TAIYUAN UNIV OF TECH

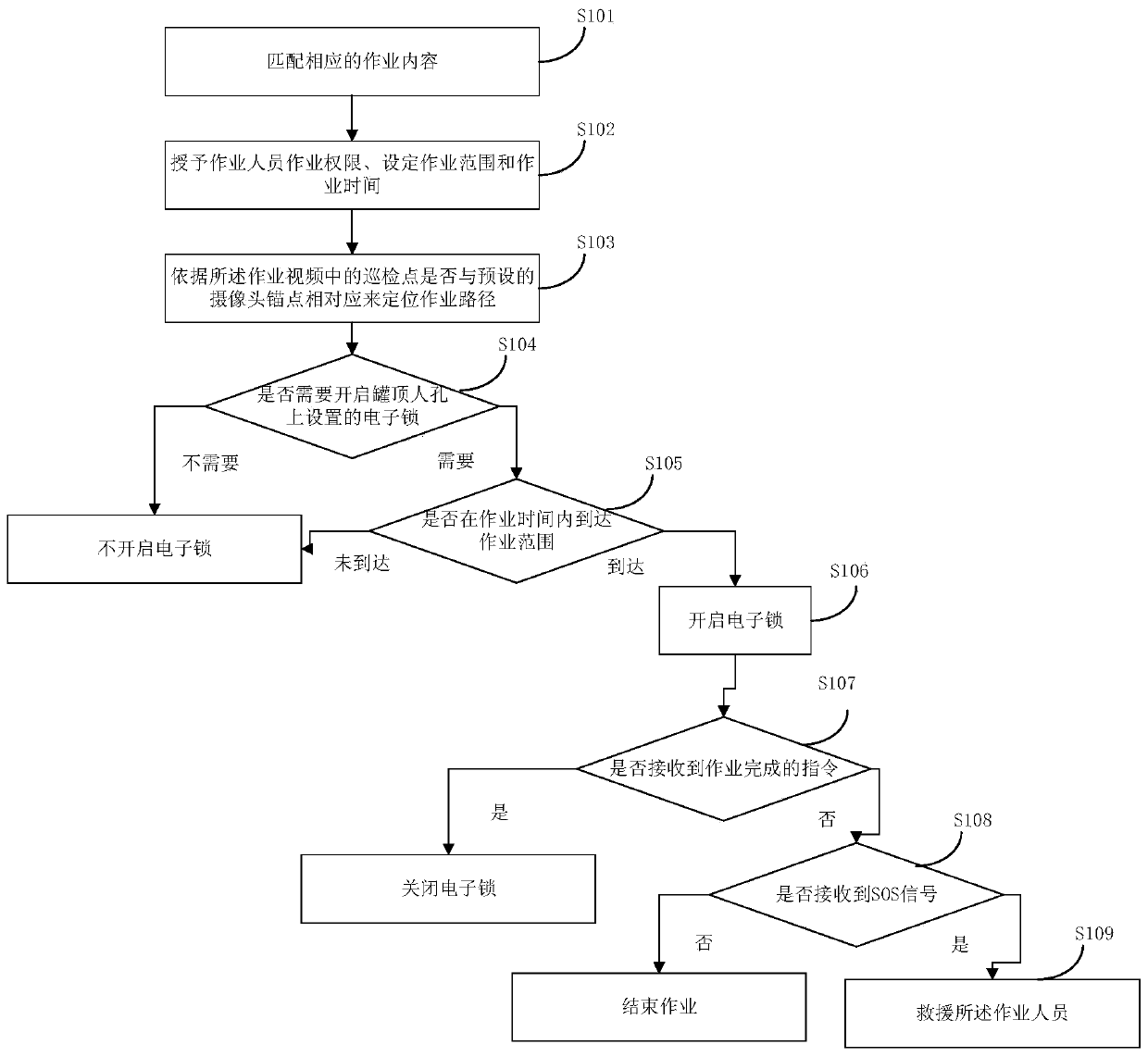

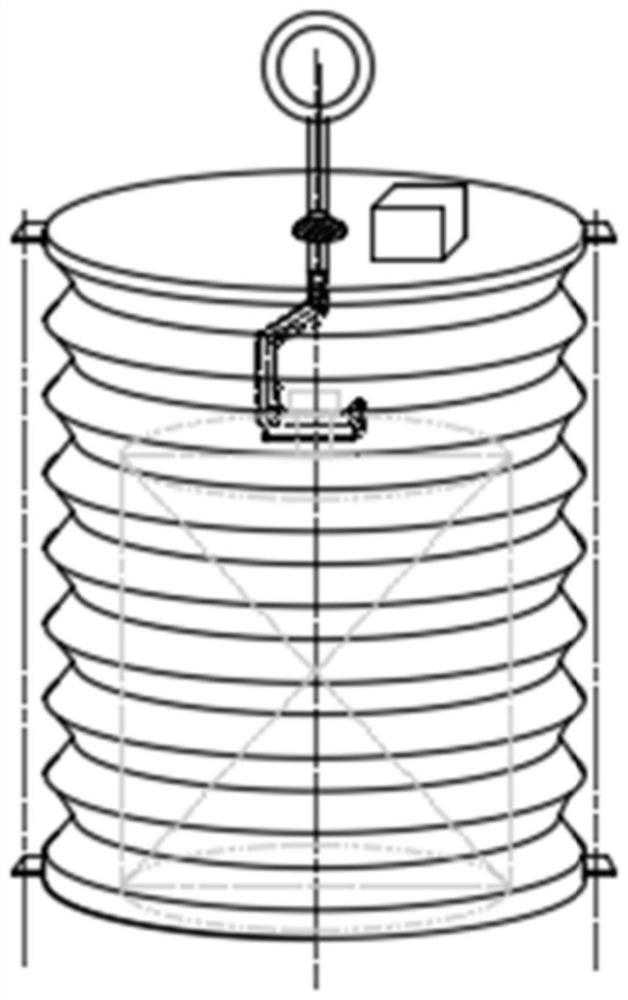

Tank top operation management method and system

ActiveCN110248155ATo achieve the purpose of safe productionClosed circuit television systemsIndividual entry/exit registersOperation timeAnchor point

The invention discloses a tank top operation management method and system, and the method comprises the steps: receiving a tank top operation instruction, and carrying out the matching of corresponding operation contents; according to the operation content, granting operation authority to an operator, and setting an operation range and operation time; receiving an operation video shot by the video inspection instrument, and positioning an operation path according to whether an inspection point in the operation video corresponds to a preset camera anchor point or not; judging whether an electronic lock arranged on the tank top manhole needs to be opened or not according to the operation content; if the electronic lock needs to be unlocked, judging whether the operator reaches the operation range within the operation time or not according to the operation path; if yes, opening the electronic lock, and an operator can enter the manhole; if an operation completion instruction is received, closing the electronic lock; and judging whether the SOS signal is received or not in the operation time, and if the SOS signal is received, rescuing an operator according to the SOS signal. Therefore, tank top operation can be carried out intelligently and safely.

Owner:普瑞特机械制造股份有限公司

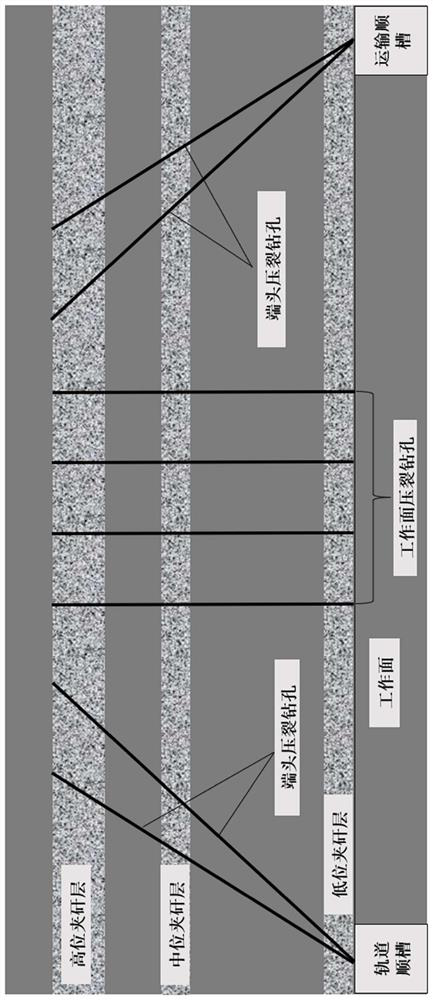

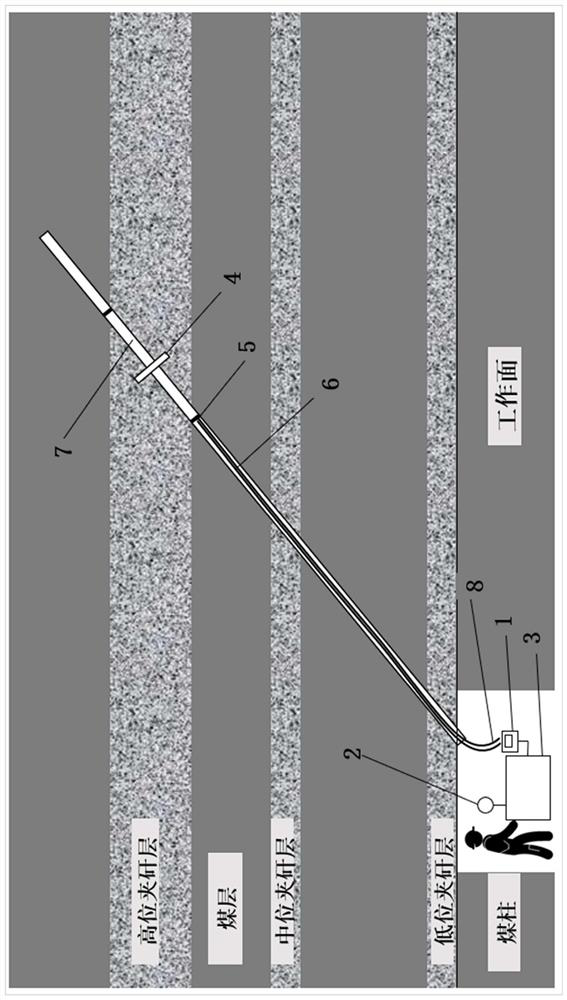

Networked presplitting technology for high-position dirt band layer of extra-thick coal seam based on hydraulic fracturing

PendingCN113982583AImprove fraudIncreased crack densityUnderground miningFluid removalMining engineeringHydraulic fracturing

The invention discloses a networked presplitting technology for a high-position dirt band layer of an extra-thick coal seam based on hydraulic fracturing. The networked presplitting technology comprises the following steps that a top coal structure of a fully mechanized caving face is observed; top coal fracturing parameters of the fully mechanized caving face are determined; fracturing drilling construction and grooving are conducted on top coal of the fully mechanized caving face; the fully mechanized caving face fracturing drill hole is subjected to drill hole sealing; high-pressure hydraulic fracturing is performed on the top coal of the fully mechanized caving face; the hydraulic fracturing effect of the fully mechanized caving face is analyzed; the step of conducting fracturing drilling construction and slotting on the top coal of the fully mechanized caving face comprises the steps that a plurality of fracturing drilling holes perpendicular to the top face of the fully mechanized caving face are formed in the top coal of the fully mechanized caving face; a plurality of fracturing drill holes which deflect towards the working face by an angle are formed in the top face of the rail gate road and the top face of the transportation gate road; and a plurality of transverse cutting grooves are formed in the part, located in the high-position dirt band layer, of the fracturing drill hole. Therefore, the high-position thick and hard dirt band layer in the coal seam can be pre-split and crushed, effective mining of the coal seam above the dirt band layer is achieved, and waste of resources is reduced.

Owner:陕西旬邑青岗坪矿业有限公司 +1

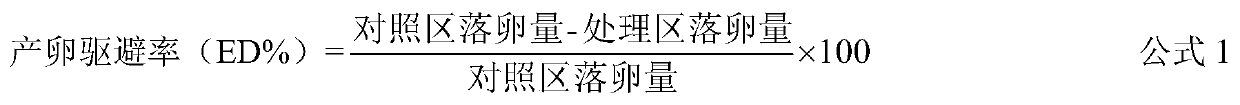

Conopomorpha sinensis bradley adult stage and egg stage collaborative prevention and control method

ActiveCN109874810AReduce egg dropReduce the pressure of prevention and treatmentBiocidePest repellentsPesticidePopulation

The invention discloses a conopomorpha sinensis bradley adult stage and egg stage cooperative prevention and control method. The method comprises the following steps of: spraying litchi and longan fruit trees with a conopomorpha sinensis bradley adult repellent at a conopomorpha sinensis bradley adult stage; and spraying the fruit trees with a conopomorpha sinensis bradley egg killing agent in theconopomorpha sinensis bradley egg period. The conopomorpha sinensis bradley adult stage and egg stage cooperative prevention and control method provided by the invention is researched and developed according to the characteristic that prevention and control cannot be carried out in the larval stage and the pupa stage of the conopomorpha sinensis bradley through a laboratory and orchard verification test. By means of the method, the number of pest populations can be effectively controlled, use of chemical pesticides is greatly reduced, the prevention and control effect is guaranteed, the influence on the environment is reduced to the maximum extent, the yield and quality of litchi and longan are greatly improved, and the purpose of safe production of litchi and longan is achieved.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI

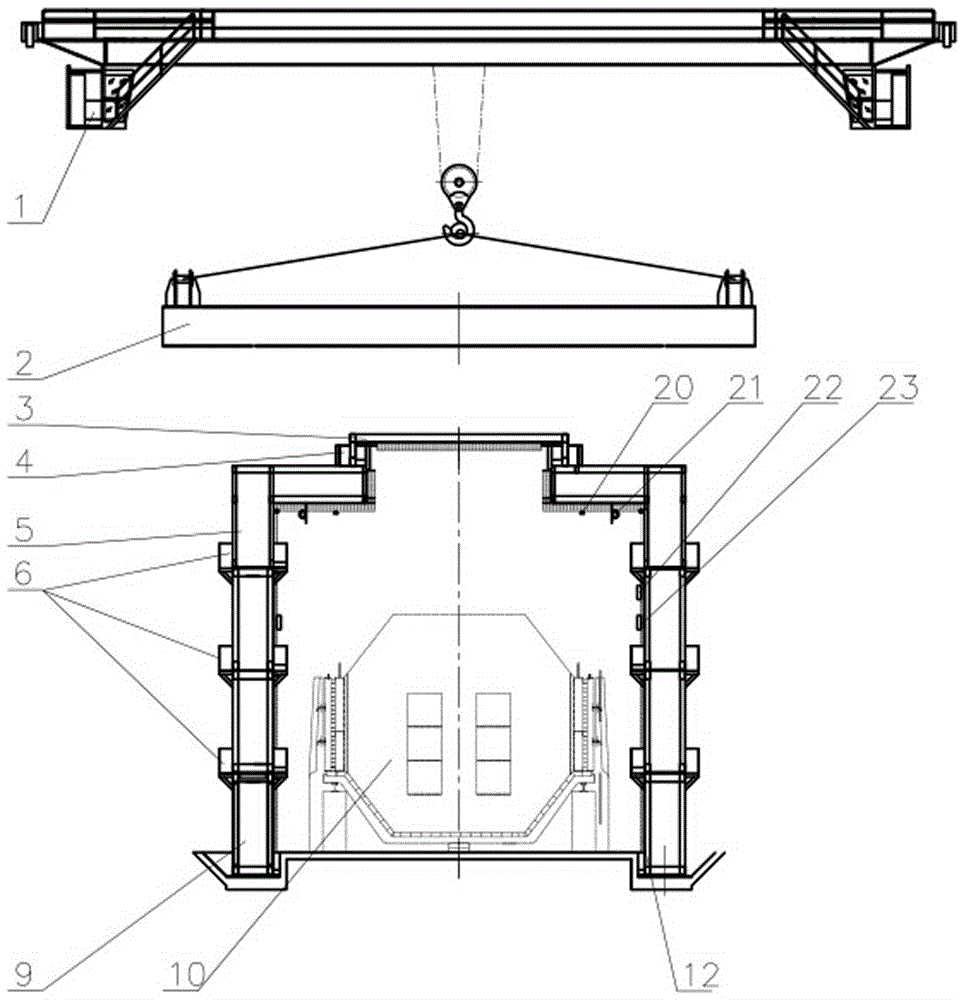

Safety precaution system for gantry crane

InactiveCN104817020APrevent collapseTo achieve the purpose of safe productionSafety gearInformation transferEmbedded system

The present invention discloses a safety precaution system for a gantry crane. The safety precaution system comprises displacement sensors, a central processing unit, cameras and an electromagnetic valve, wherein the displacement sensors are respectively arranged on the two support legs of the gantry crane and for transmitting the collected support leg information to the central processing unit, the camera is used for collecting the information of the images on the front track and the rear track of the support legs and transmitting the collected image information to the central processing unit, the central processing unit judges the position of the support leg according to the position information of a plurality of the displacement sensors, judges whether the two support legs are positioned in the same horizontal direction, and judges whether the safety hidden danger exists on the track according to the image information collected by the cameras, the electromagnetic valve turns off the power of the gantry crane according to the command of the central processing unit, and when the central processing unit turns off the power of the gantry crane through the electromagnetic valve, the central processing unit concurrently controls the braking system of the gantry crane to compulsively brake so as to achieve the safe production.

Owner:苏勇

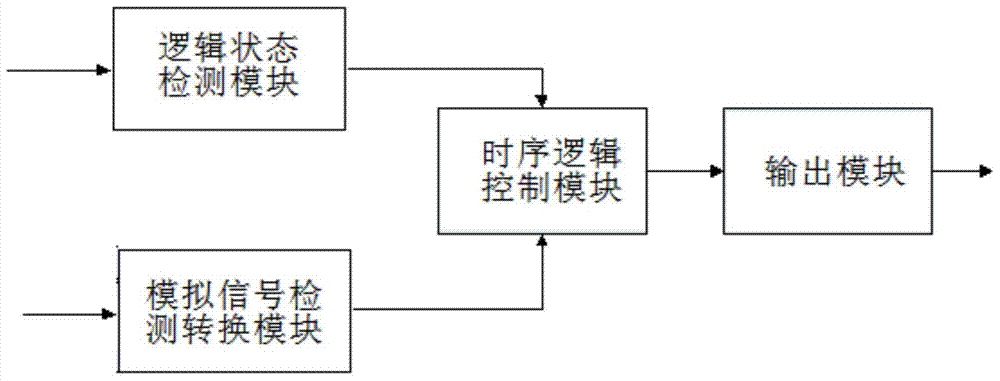

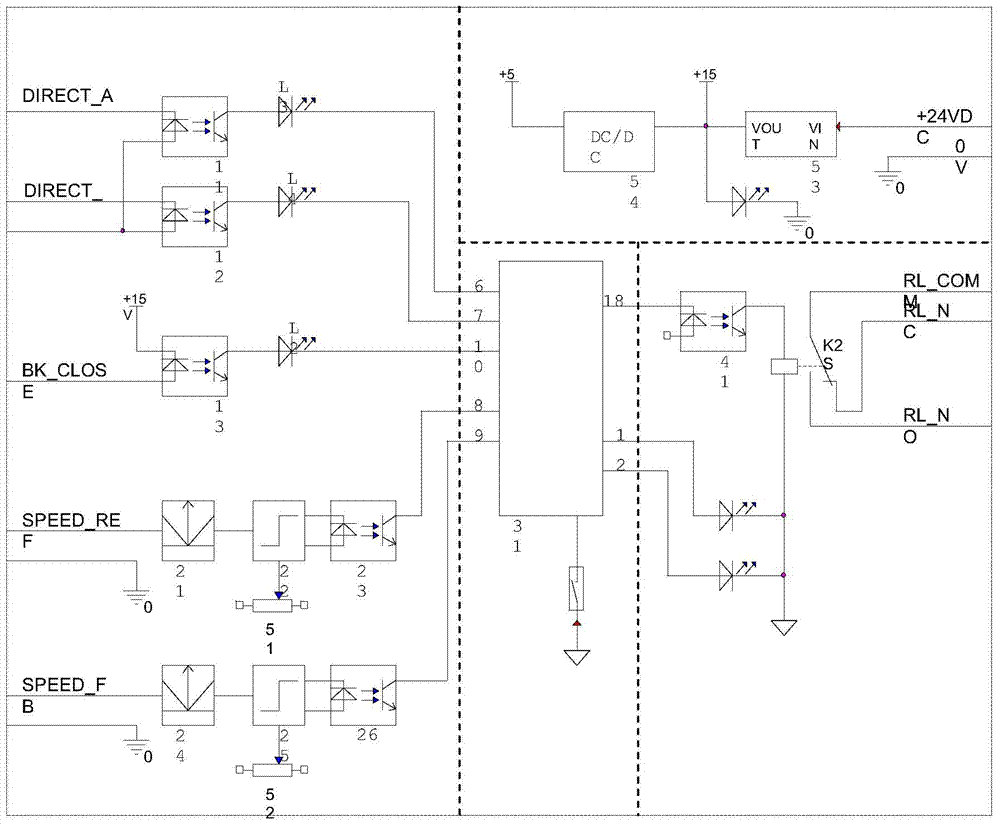

Brake control apparatus for crane analog quantity stator voltage-adjusting and speed-adjusting control system

ActiveCN104760888AEliminate hooksEliminate the defect of rolling carLoad-engaging elementsStator voltageAutomatic control

The present invention discloses a brake control apparatus for a crane analog quantity stator voltage-adjusting and speed-adjusting control system. The brake control apparatus comprises a logic state detection module, an analog signal detection conversion module, an output module and a sequential logic control module respectively connected with various modules, and the sequential logic control module judges the working state of the crane according to the logic level signal transmitted by the logic state detection module and the analog signal detection conversion module, generates a brake control signal according to the working state of the crane, and transmits the brake control signal to the output module to output. According to the present invention, the brake control apparatus can be directly used for the crane analog quantity stator voltage-adjusting and speed-adjusting control system, the brake control apparatus and the existing control system can automatically co-control the crane mechanical brake according to the predetermined rule under the condition of no influence on the completeness of the existing control system so as to eliminate the defects of hook slipping and crane slipping of the existing control system, such that the purport of safe production is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Biodegradable swelling slow releasing fertilizer and its manufacturing method

InactiveCN1297521CProvide evenlyReduce nitrosamine contentFertilizer mixturesRenewable resourcePetroleum

The present invention discloses a bio-degradable puffed slowly-released chemical fertilizer and its preparation method. Said method includes the following steps: pulverizing industrial and agricultural wastes and discards of tained old grain, etc., regulating quality, uniformly mixing the above-mentioned obtained material with chemical fertilizer, utilizing puffing process to prepare puffed material, further breaking to obtain granules whose grain size is 5-8mm, spraying oil foot and granulating so as to obtain the invented product.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

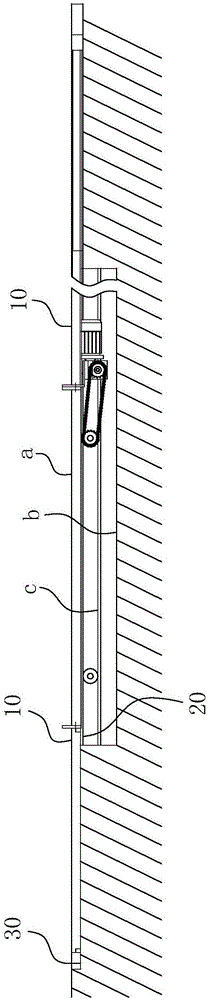

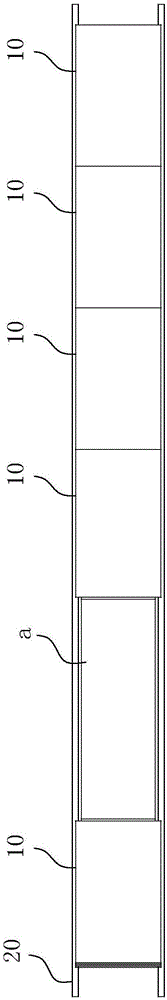

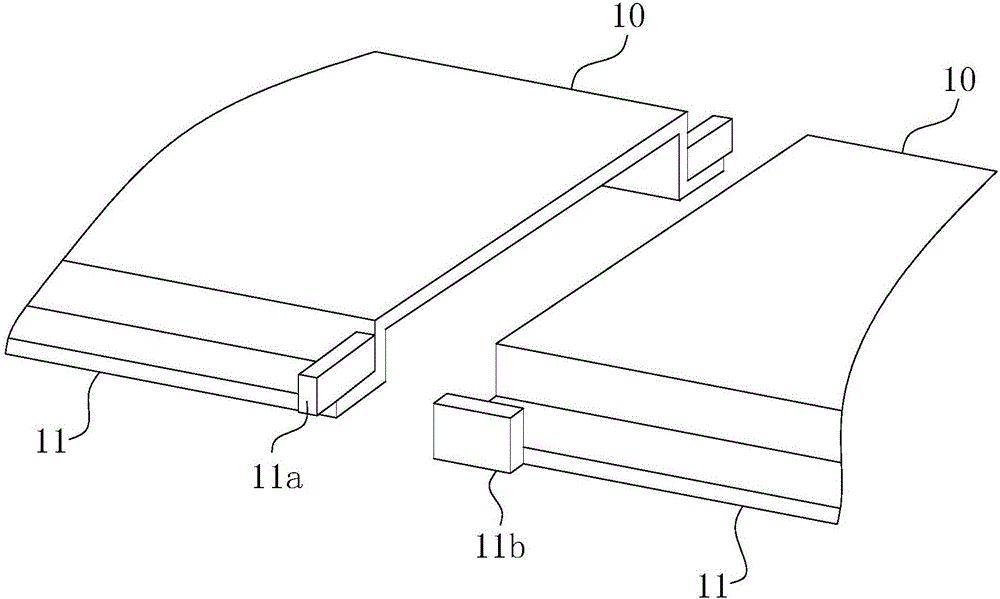

Automatic covering device for cover plates of wire drawing trolley trench

InactiveCN106703457AReliable retractionRealize the automatic cover effectArtificial islandsUnderwater structuresEngineeringSlide plate

The invention belongs to the technical field of safety protection in the varnished wire production industry and particularly relates to an automatic covering device for cover plates of a wire drawing trolley trench. The automatic covering device comprises a left cover plate component and a right cover plate component, and the left cover plate component and the right cover plate component are arranged at two ends of a transport trolley along an advancing direction of the transport trolley respectively. Each of the left cover plate component and the right cover plate component comprises slide plates, and the slide plates share rails with the transport trolley or slide in a reciprocated manner along a transport trolley operating path through independent slide rails. Placement spaces allowing placement of the slide plates in retracting action are reserved at two ends of the trench outside the transport trolley operating path, and one end, towards the transport trolley, of each slide plate extends along the length direction of the trench to be fastened to the corresponding end of the transport trolley. The automatic covering device has advantages of high automation degree, convenience and flexibility in mounting and low cost, seamless covering of the exposed trench can be realized in movement of the transport trolley, and accordingly safety production is guaranteed.

Owner:TONGLING JINGXUN SPECIAL ENAMELLED WIRE

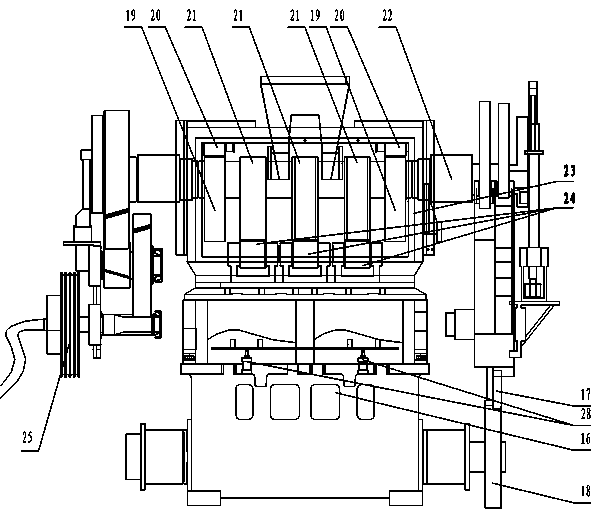

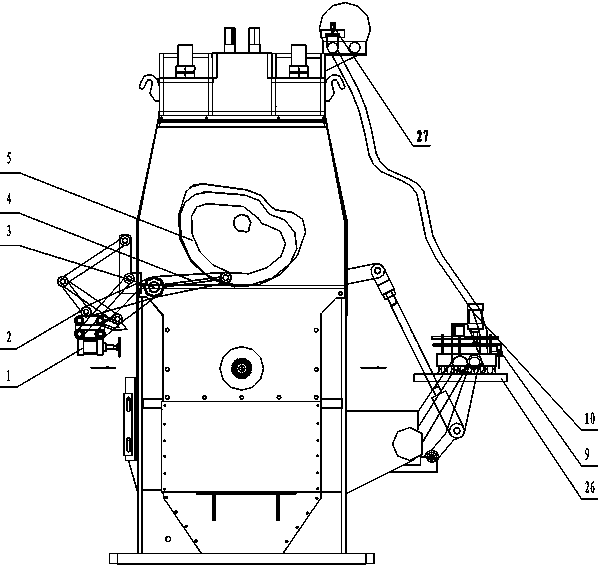

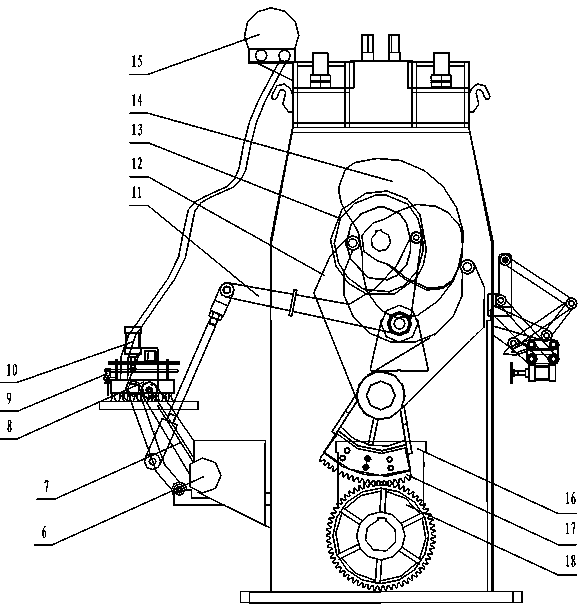

Full-automatic cam type double-die tile pressing machine

The invention discloses a full-automatic cam type double-die tile pressing machine which can produce safely and continuously. The full-automatic cam type double-die pressing machine comprises a rack, a main shaft is supported at the upper part of the rack, a pressing chamber is arranged at the lower part of the rack, an upper die and a lower die are arranged at the lower part of the pressing chamber, and a driving part, a blank feeding part, a pressing part and a pressing product discharging part are respectively arranged by taking the main shaft as a center. A control driving part consists of a control box, a frequency converter, a motor, a triangular belt and a pneumatic clutch. The blank feeding part consists of a main shaft grooved pulley, a roller wheel connecting rod, a connecting rod shaft, a crank connecting rod assembly and an air cylinder. The pressing part consists of the main shaft, a stoke cam and a lifting wheel, a pressing cam and a pressing wheel, a box body, a box body track, a workbench, a workbench driving gear, double cams of the main shaft, a shifting fork and a fan gear. The pressing product discharging part consists of a main shaft grooved pulley, a crank arm shaped like Chinese character 'qi' (means seven in English), a connecting rod, a connecting rod shaft, a tile sucking air cylinder, a punching air cylinder, a sucker and a fan.

Owner:宜兴市科力建材机械设备有限公司

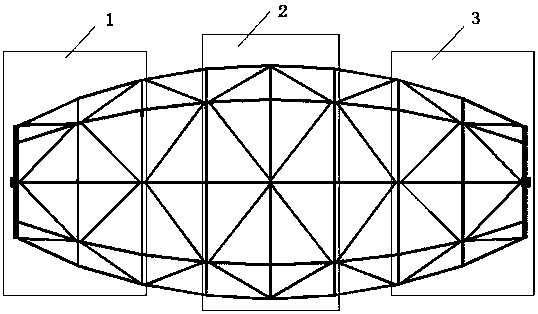

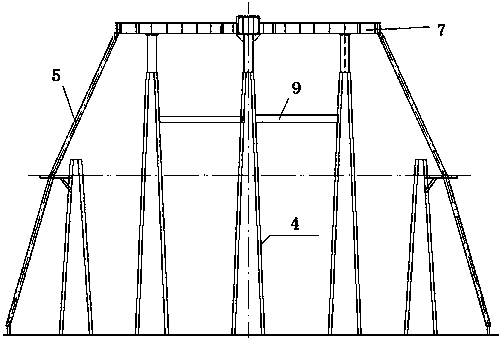

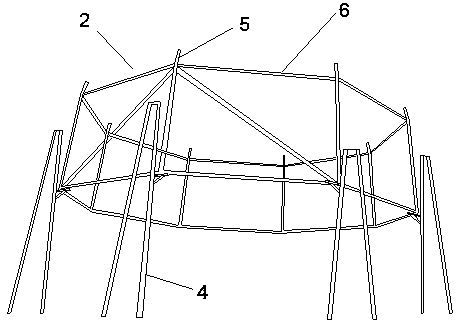

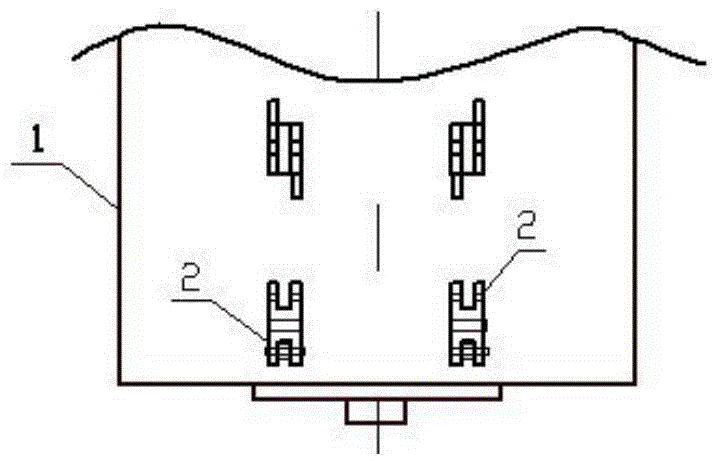

Deep-open-sea cage culture equipment infrastructure truss construction technology

ActiveCN110521649AAvoid continuous work at heightsTo achieve the purpose of safe productionClimate change adaptationPisciculture and aquariaMarine fishCage culture

The invention discloses a deep-open-sea cage culture equipment infrastructure truss construction technology, and relates to the technical field of building of pipe structure sea fish culture platforms. A truss is divided into three parts which are built separately, and then the three parts are integrally closed up; the truss is of an oval-shaped hollow structure formed through pipe connection andcomprises a front truss segment, a middle truss segment and a rear truss segment; the front truss segment and the rear truss segment are symmetrically arranged at the two ends of the middle truss segment. The truss construction technology comprises the following steps of firstly, making the front truss segment, the middle truss segment and the rear truss segment separately, then lifting the threemade segments onto a bed jig separately, and integrally closing up the front truss segment, the middle truss segment and the rear truss segment through the installation of bulk pipes. The technology has the advantages that continuous aerial work can be avoided, the purpose of safe production is achieved, during making, the three parts are separately built, and then integrated, the number of toolsand set-up scaffolds can be reduced, the building cost is lowered, the building period is shortened, and the building efficiency is improved.

Owner:SHANGHAI ZHENHUA HEAVY IND QIDONG MARINE ENG

Method for rapidly preparing aerogel by accelerating solvent extraction in normal pressure

ActiveCN108862285ALow costSolve the replacement problemSilicon compoundsOrganic solventUltimate tensile strength

The invention discloses a method for rapidly preparing aerogel by accelerating solvent extraction in a normal pressure. The method comprises the following steps: (1) enabling a quantitative inorganicsilicon source to be mixed with water and diluting, adding quantitative acid, forming saliferous silica sol, and forming gel after a period of time; (2) performing accelerated solvent extraction on the gel obtained in the step (1) by using organic solvent water solution of which concentration is increased along with time; (3) performing the accelerated solvent extraction on the gel obtained in thestep (2) by mixed liquid of a water-containing organic solvent and an organosilicon compound; and (4) drying the gel obtained in the step (2) in the normal pressure. The provided method for preparingthe aerogel is simple in process, short in production period, and less in energy consumption. An aerogel product of the method has the characteristics of complete structure, low heat conductivity coefficient, and good mechanical strength.

Owner:浙江岩谷科技有限公司

Method for preparation of propionic acid

InactiveCN1277801CHigh selectivityLow selectivityOrganic compound preparationCarboxylic compound preparationPropanoic acidOxygen

The invention relates to a process for preparing propionic acid by using acetone as raw material, using oxygen, air, or the gas mixture of oxygen and gas exhibiting inert property to the reaction as oxidant for oxidation reaction without the requirement of catalyst.

Owner:SINOPEC QILU CO

Fire extinguishing and smoke dust collecting device

PendingCN111876566AClosed QuenchingEfficient collectionDirt cleaningQuenching devicesEnvironmental engineeringWaste gas

The invention discloses a fire extinguishing and smoke dust collecting device comprising a telescopic section, a top cover, a grabbing device and a dust purifying device. A telescopic section is arranged on the lower surface of the top cover, is of a cylindrical structure and is coaxial with the top cover; the grabbing device is arranged on the top cover, and the grabbing end of the grabbing device is located in the telescopic section; and the top of a pit furnace quenching oil tank is connected with the dust purifying device. The device can effectively extinguish fire and collect smoke dust waste gas generated during quenching, the purpose of safe production is achieved, the collected smoke dust waste gas can be further purified subsequently, and the workshop environment is improved.

Owner:西安北恒材料科技有限公司

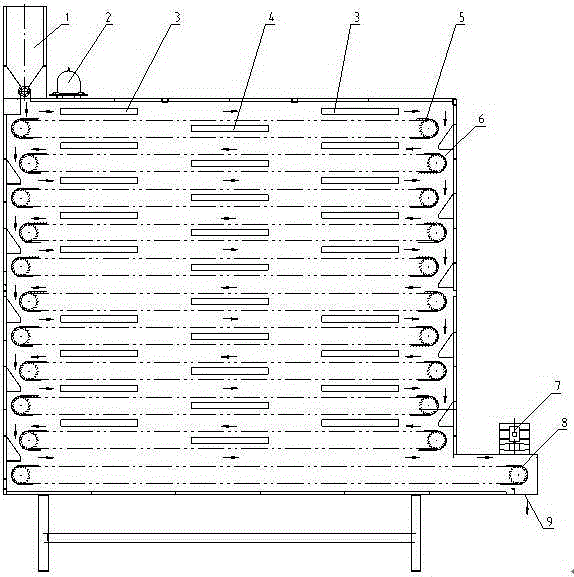

High-efficiency energy-saving grain drying machine

InactiveCN105325538ALarge amount of processingMeet the requirements of high drying efficiencyFood processingSeed preservation by dryingCold airAgricultural engineering

The invention provides a high-efficiency energy-saving grain drying machine. The high-efficiency energy-saving grain drying machine comprises a rack, an upper layer conveying chain board, middle conveying chain boards and a lower layer conveying chain board; the top of the rack is provided with a feeding bin which corresponds to the initial end of the upper layer conveying chain board inside the rack, a discharge opening is formed in the bottom end of the rack, the discharge opening corresponds to the tail end of the lower layer conveying chain board inside the rack, hot-air inlets and wet-air outlets are formed in the side face of rack, the length of the lower layer conveying chain board is larger than that of the upper layer conveying chain board and that of each middle conveying chain board, and a moisture removing cooling fan is arranged on the upper position of the extending section of the lower layer conveying chain board. By means of the high-efficiency energy-saving grain drying machine, drying treatment on different materials can be achieved, and the material treatment amount is increased; meanwhile, thermal drying treatment is conducted firstly, and then cold-air blast drying and cooling treatment is conducted, the normal temperature state of the materials is restored on the premise that drying is guaranteed, and the requirement for high drying efficiency is met.

Owner:新疆闰通天华机械设备有限公司

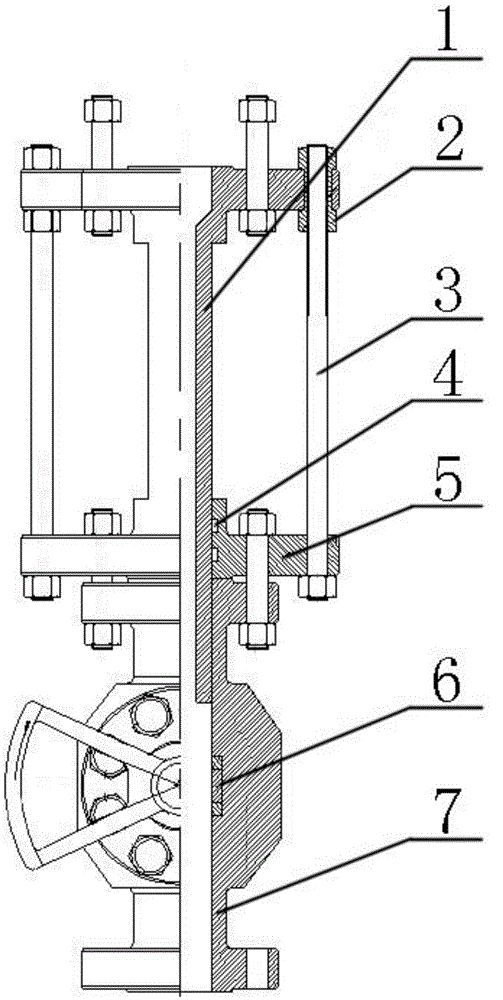

Main valve protector of shale gas production wellhead

InactiveCN105840130AAvoid scourExtended service lifeFluid removalSealing/packingFracturing fluidEngineering

The invention relates to a main valve protector for a shale gas production wellhead, which includes a valve body. The main valve protector for a gas production wellhead also includes a mandrel and a lower flange arranged below the mandrel. The lower end is arranged in the lower flange, and the lower flange is fixedly connected with the valve body by bolts, and the upper end of the mandrel is provided with an upper flange, and a plurality of positioning nuts are arranged on the upper flange. A displacement lead screw is provided between the positioning nut and the lower flange, and multiple sets of seals are provided on the inner wall of the lower flange. By passing the mandrel through the valve core when fracturing occurs, the fracturing fluid is prevented from washing the valve core, thereby improving the service life of the manual flat valve and reducing development costs. At the same time, the invention has a simple structure, is convenient for installation and operation, has a large diameter, reduces frictional resistance and construction pressure, and achieves the purpose of safe production.

Owner:SINOPEC CHONGQING FULING SHALE GAS EXPLORATION & DEV

Method for preventing steel ladle slide mechanism from being opened accidentally

InactiveCN104889375AUnique methodTo achieve the purpose of safe productionMelt-holding vesselsMolten metal conveying equipmentsHydraulic cylinderMolten steel

The invention relates to a method for preventing steel ladle slide mechanism from being opened, especially being opened accidentally. The method is characterized in that the method comprises following steps of before a steel ladle is baked, picking off a hydraulic cylinder from the steel ladle, installing supporting handrails, taking out the steel ladle after being smelt and then lifting the steel ladle to an assigned position; dismounting the supporting handrails from the steel ladle, assembling the hydraulic cylinder and finishing drainage of the steel ladle; and pouring the steel ladle, then dismounting the hydraulic cylinder from the steel ladle, assembling the supporting handrails and lifting the steel ladle back to a melting workshop. According to the invention, it can be avoided that a slide mechanism is opened caused by collision of external force during a lifting process of smelting or pouring of a steel ladle carrying molten steel, thereby achieving an objective of safe production.

Owner:KOCEL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com