Full-automatic cam type double-die tile pressing machine

A cam-type, fully automatic technology, applied in the direction of forming indenters, etc., can solve the problems of high labor intensity, troublesome operation, dangerous work and low efficiency of production workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

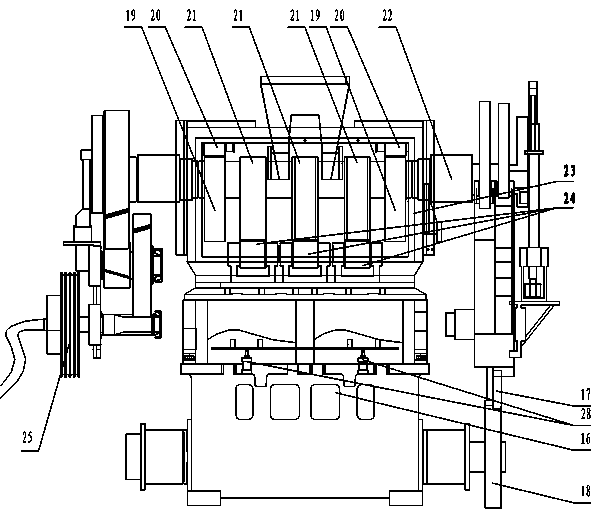

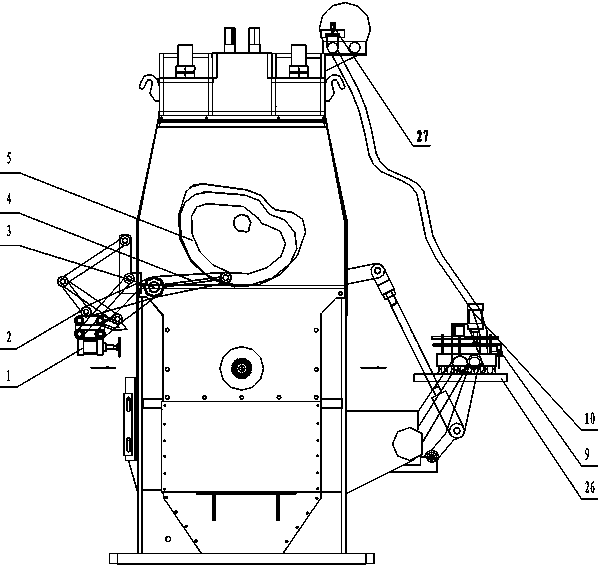

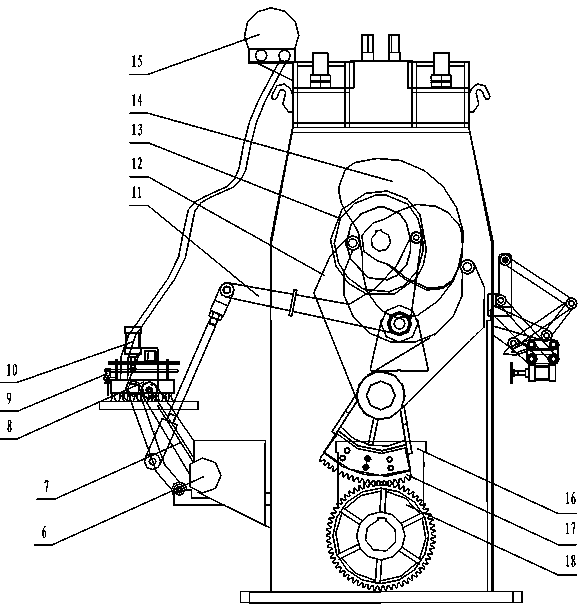

[0017] Such as Figure 1-Figure 3 Shown, the structure of the present invention is specifically as follows:

[0018] Electrical connection: the electrical connection between the control box and the main motor, the control box and the fan, the control box and multiple solenoid valves, the control box and the photoelectric switch, and the control box and the limit switch.

[0019] Pneumatic connection: air pump and pneumatic clutch, air pump and multiple solenoid valves, connection between solenoid valves and corresponding cylinders, air pipe connection between fan and suction cup.

[0020] Mechanical connection: the motor pulley is connected to the pulley of the pneumatic clutch 25 through 4 B belts, and the clutch 25 and the input shaft teeth are connected to the main shaft 22 after two-stage deceleration. The cams 19 and 21 on the main shaft 22 are connected with the casing 23 . One side of the main shaft 22 is connected with the tile advancing sheave 5, the roller con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com