High-efficiency energy-saving grain drying machine

A grain dryer, high-efficiency and energy-saving technology, applied in food processing, seeds preservation by drying, etc., can solve the problems of poor drying effect, unreasonable wet air outlet, and inability to provide materials at room temperature immediately, so as to meet the requirements of drying Efficiency, the effect of high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

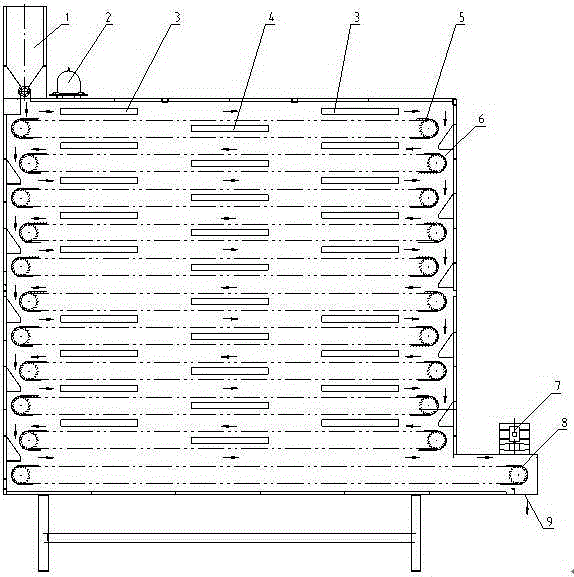

[0017] according to figure 1 The high-efficiency and energy-saving grain dryer includes a frame, an upper conveyor chain plate 5, a middle conveyor chain plate 6, and a lower conveyor chain plate 8. A feeding bin 1 is set on the top of the frame, and the feeding bin corresponds to the upper layer conveying inside the frame. The beginning of the chain plate 5, the bottom of the frame is provided with a discharge port 9, the discharge port corresponds to the end of the lower conveying chain plate 8 inside the frame, and the side of the frame is provided with a hot air inlet 3 and a wet air outlet 4, The length of the lower conveyor chain plate is longer than the middle upper conveyor chain plate and the middle conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com