Steam styling cabinet for wig production

A steam setting and wig technology, applied in wigs, applications, clothing, etc., can solve problems such as uneven heating of hair, inconsistent curling effect, and inability to rotate the curling tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

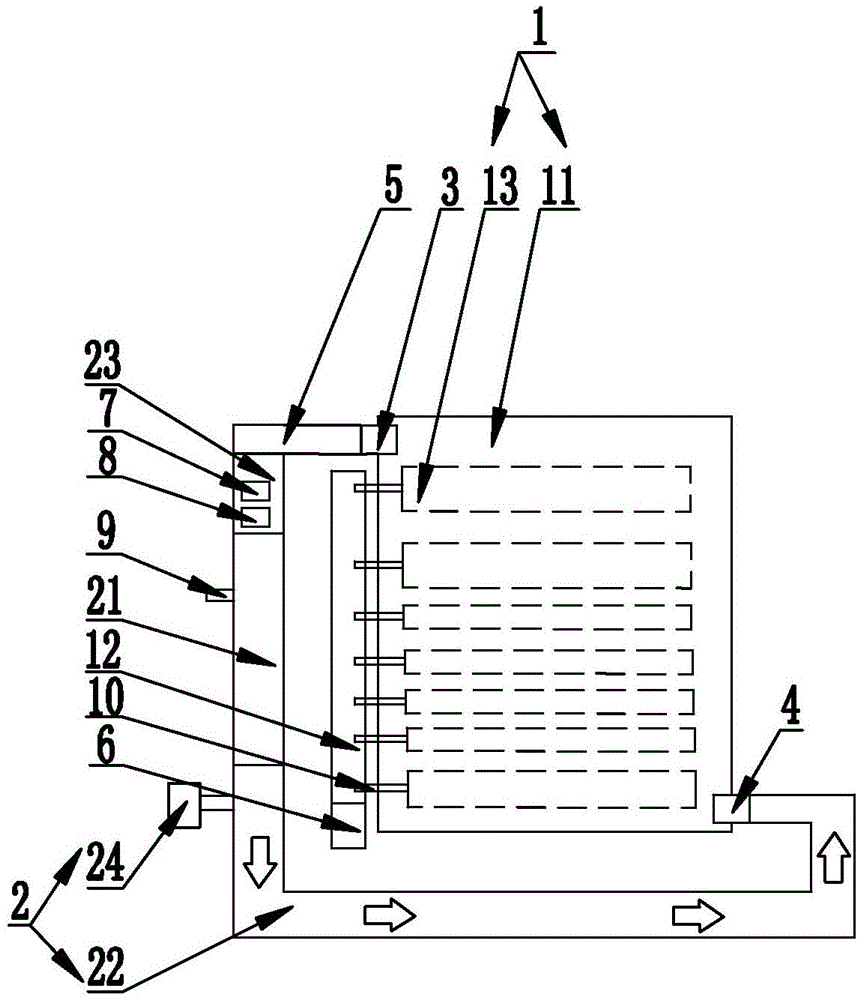

[0022] Such as figure 1 As shown, a steam setting cabinet for wig production includes a setting device 1 and a steam circulation device 2. The setting device 1 includes a cabinet body 11, an electric rotating device 12 and a support plate 13 in the cabinet body 11. The upper part on the left side and the lower part on the right side of the cabinet body 11 are respectively equipped with an air outlet 3 and an air inlet 4, the air outlet 3 is provided with a condensation device 5, and the electric rotating device 12 is installed on the outside of the cabinet body 11 , the electric rotating device 12 is electrically connected to a controller 6, and the controller 6 is electrically connected to an operation panel (not shown in the figure) outside the cabinet body 11, and several support plates 13 are arranged in parallel. The support plate 13 is a rectangular structure, the rear end of the support plate 13 is fixedly equipped with a shaft 10, and the left end of the shaft 10 passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com