Belt conveyor deviation detection device and automatic adjustment method

A belt conveyor and detection device technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as output instability, manpower and time input, and impact on coal mine production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

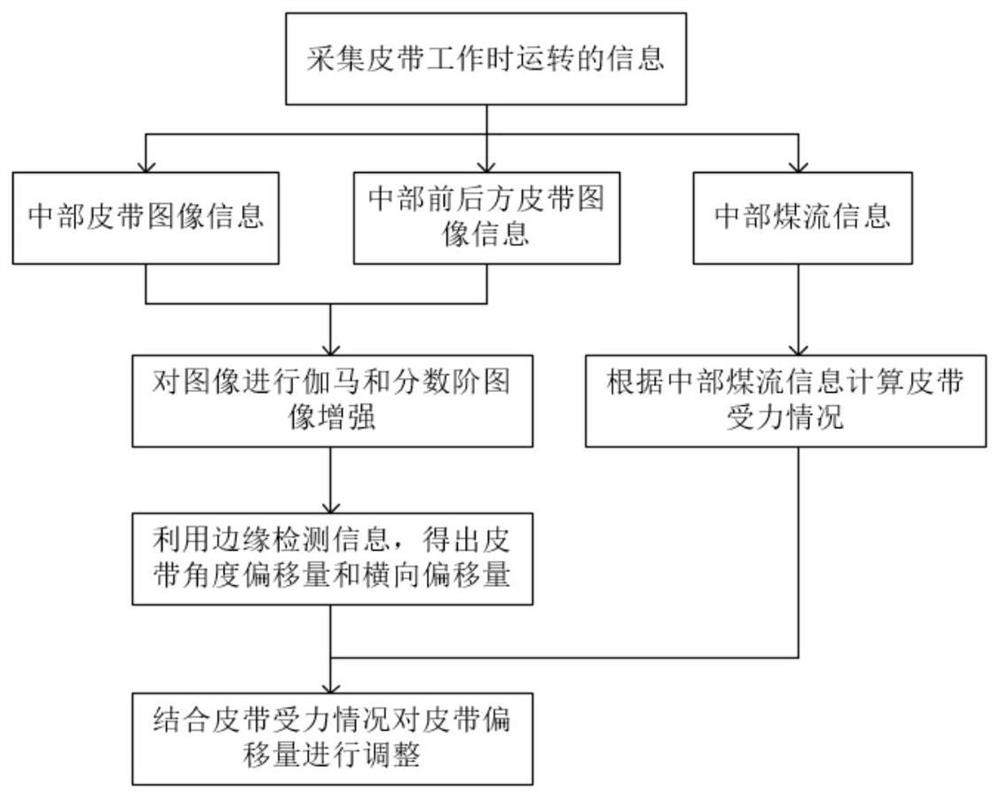

[0034] see Figure 2~4 , a belt conveyor deviation detection and automatic adjustment method, including

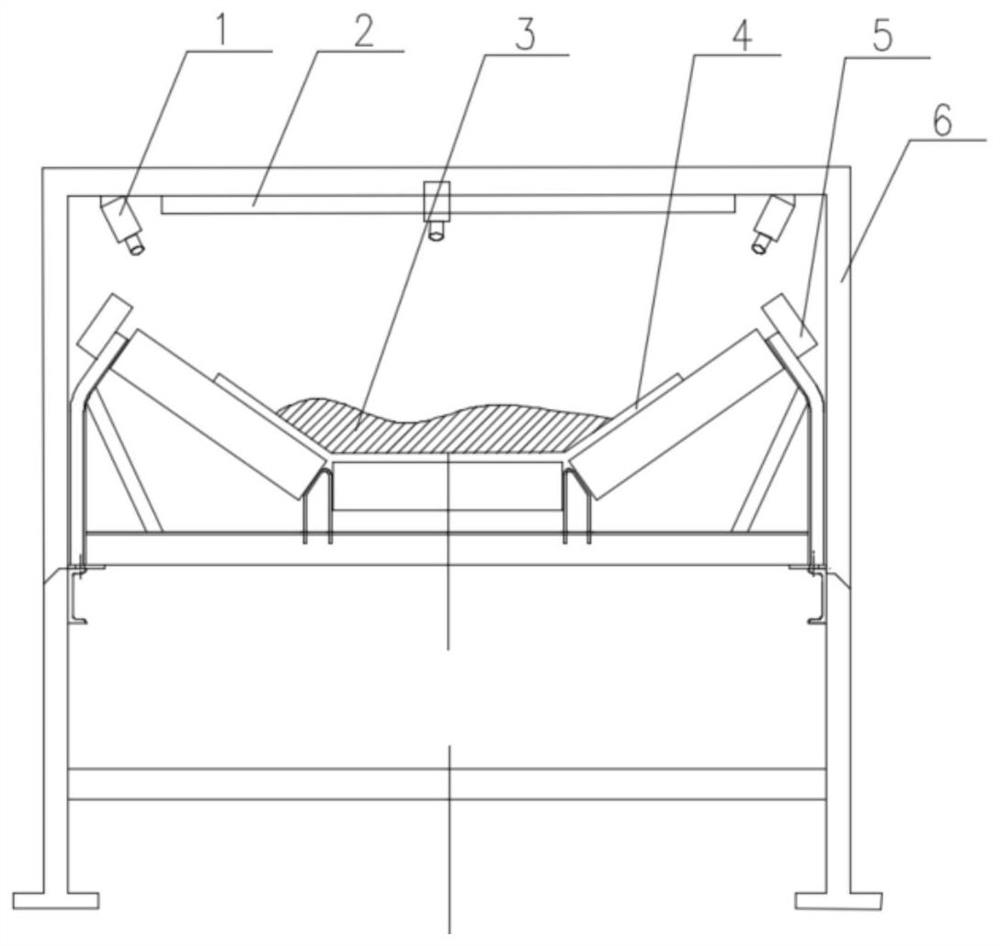

[0035] The visual inspection module is installed directly above the belt 4 in the middle of the belt conveyor, and it is composed of a carrier frame 6, a high-definition camera 1 and a line laser camera 2 installed on the carrier frame 6;

[0036] The idler adjustment module 5 is located on the inner side of the bearing frame 6 and is respectively arranged on both sides of the bottom of the belt 4 , and it is composed of a bearing bearing 8 and a mobile hydraulic cylinder 7 connected to both ends of the bearing bearing 8 .

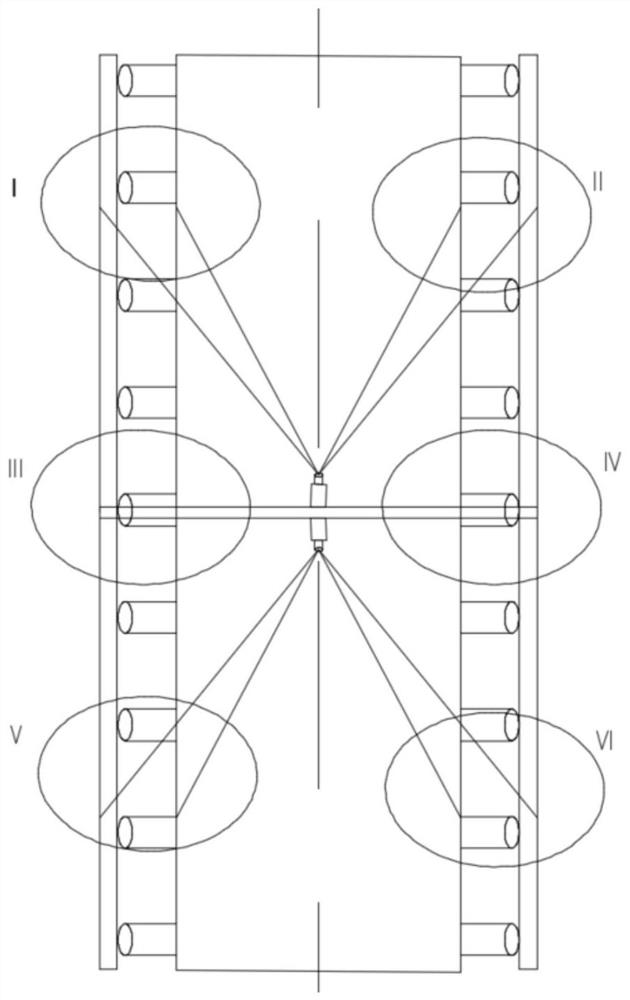

[0037] In the embodiment of the present invention, the high-definition camera 1 arranged on both ends of the visual collection module collects the left and right side edge images of the belt 4; the line laser rangefinder 2 in the middle is used to measure the top of the coal material 3 to the collection module The height h(u) of the frame; the front a...

Embodiment 2

[0039] see Figure 1~4 , an automatic adjustment method of a belt conveyor deviation detection device, the automatic adjustment method includes the following steps

[0040] Step S1: image data acquisition, four high-definition cameras 1 on the visual acquisition module collect the video image I when the belt is working; the middle line laser rangefinder 2 measures the distance from the coal material 3 to the 6 top beams of the bearing frame;

[0041] Step S2: Image data preprocessing, extracting key frames from the video image I obtained by the high-definition camera 1, and using gamma and fractional image enhancement on the frame image to obtain an image G; Height information for data denoising processing;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com