Patents

Literature

63results about How to "Solve the replacement problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for exchanging tool of shield machine for tunnel construction

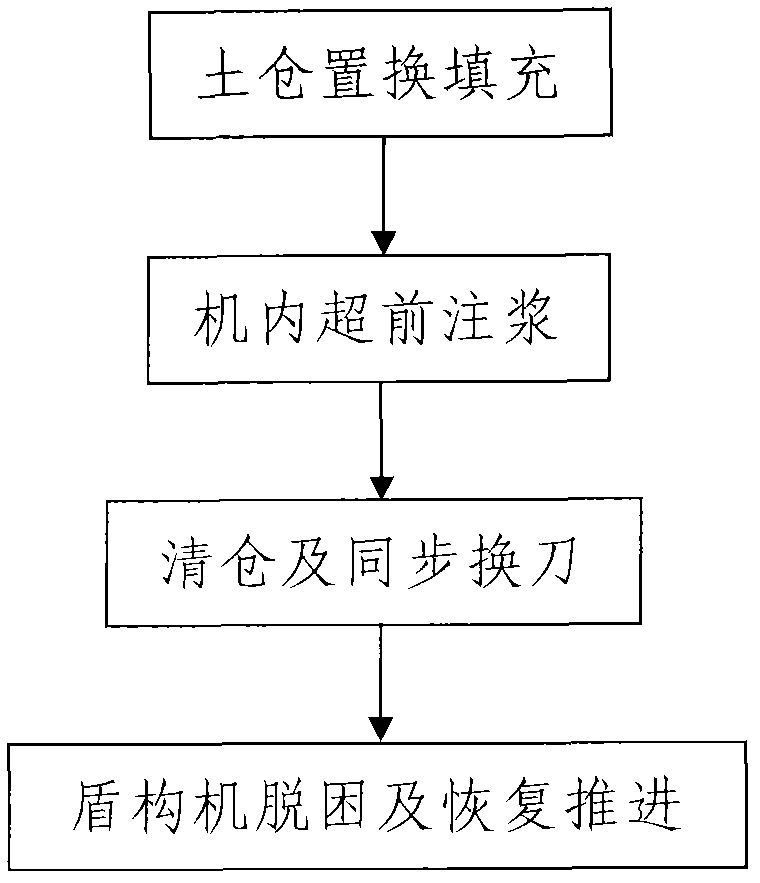

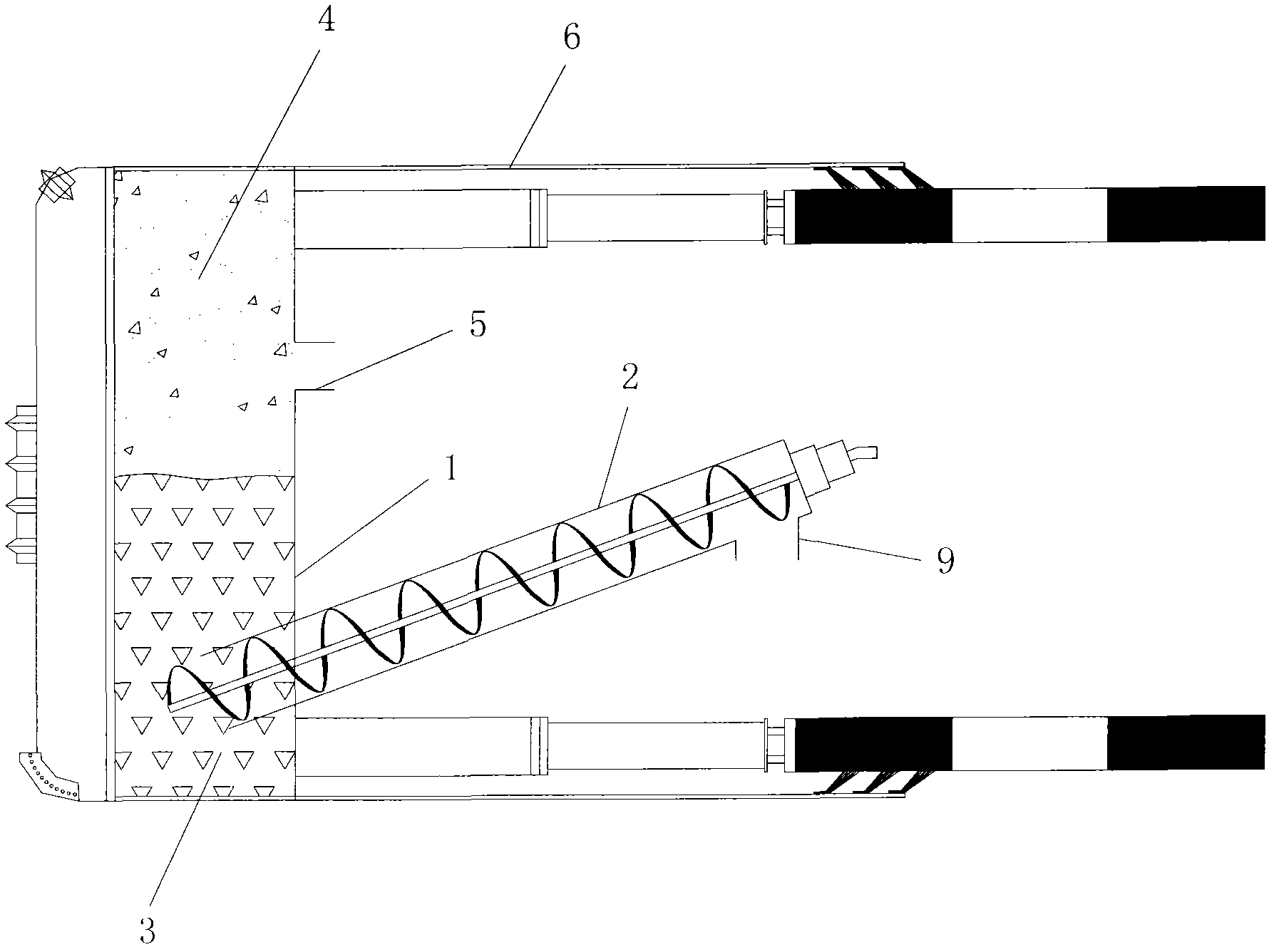

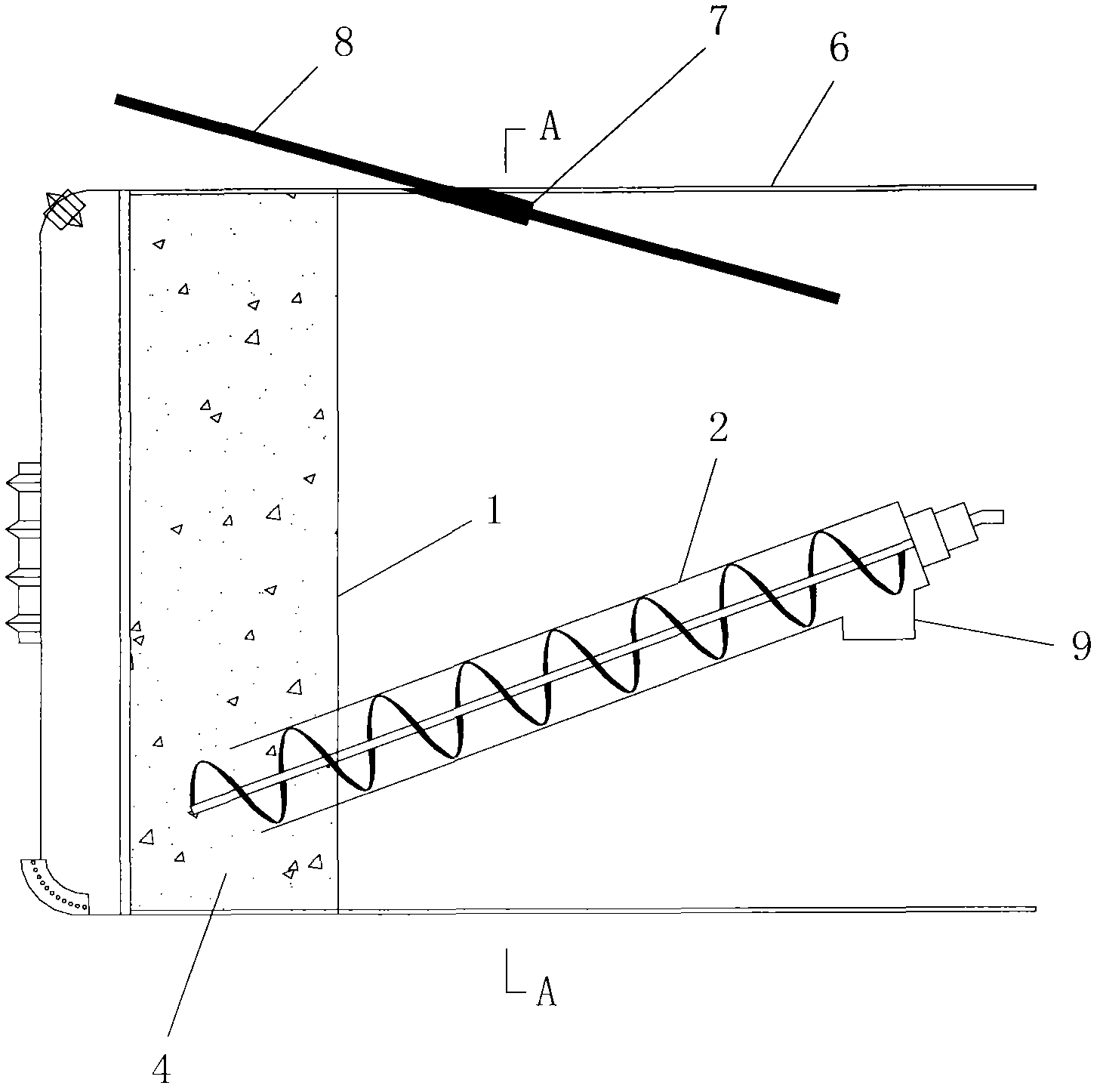

The invention discloses a method for exchanging a tool of a shield machine for tunnel construction, which comprises the steps of: (1) soil cabin replacement filling: performing the process of soil cabin replacement filling by using a spiral excavating machine and a slip casting system synchronously working with the spiral excavating machine; (2) advanced slip casting inside the machine: beating a plurality of slip casting pipes into the soil on the upper part of the shield machine from inner to outer inside the shield machine by respectively passing through a plurality of advanced geologic holes and then synchronously injecting cement paste into the soil on the upper part of the shield machine through the slip casting pipes by using a slip casting device till the cement paste cannot be injected any more; (3) cleaning cabin and exchanging tool synchronously: manually cleaning the cement plaster solidified inside the soil cabin and synchronously exchanging the tool mounted on the shield machine; and (4) getting rid of the difficult position of the shield machine and recovering the process. The method provided by the invention has the advantages of reasonable design, convenience for operation, low cost, high safety factor, good use effect and capable of solving the problem that the tool cannot be exchanged in the traditional tool exchanging mode under severe tool exchanging conditions.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

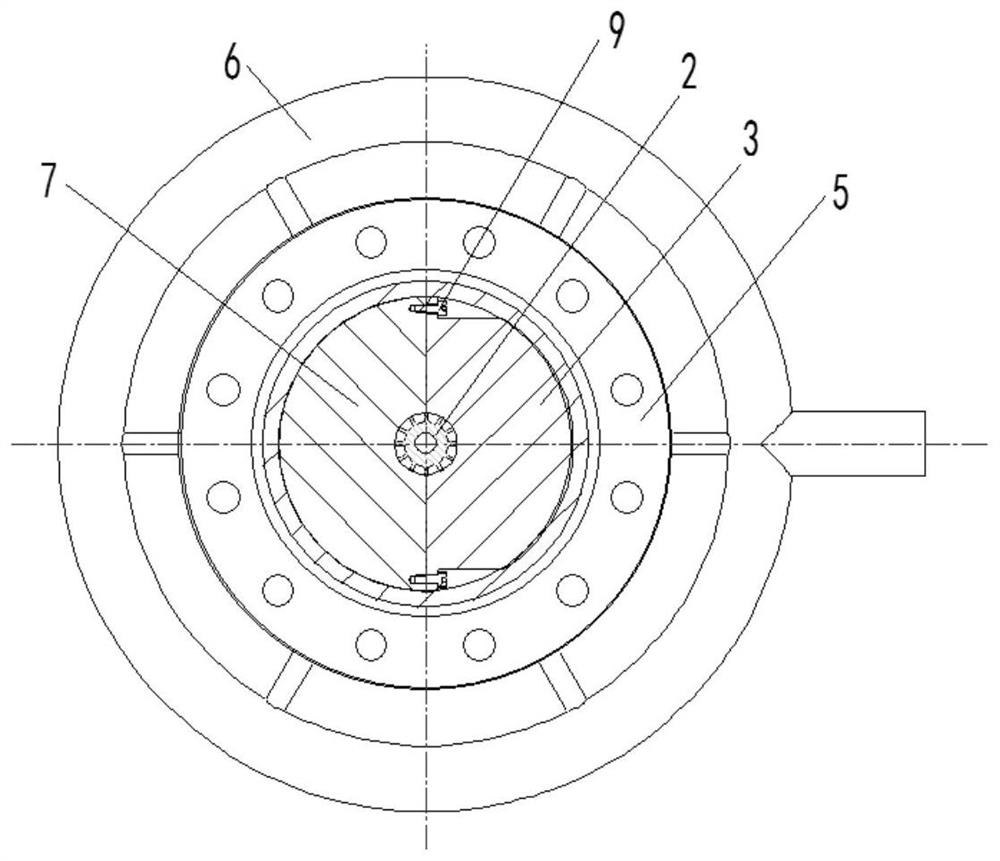

Tunnel face breast wall filter cake construction process for shield compressed air operations

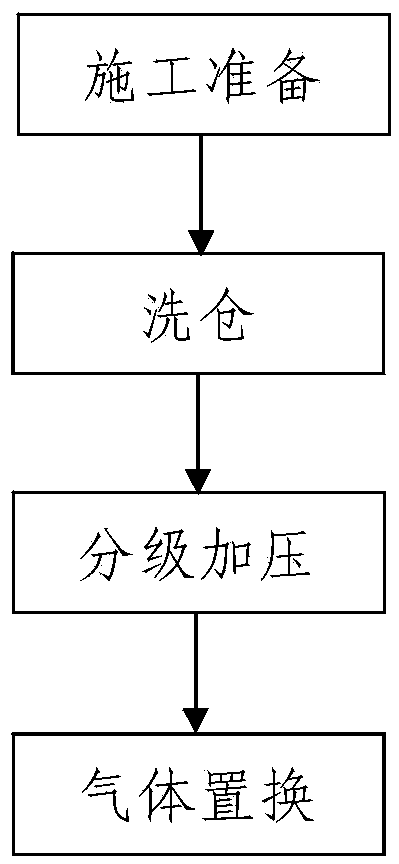

The invention discloses a tunnel face breast wall filter cake construction process for shield compressed air operations. The process includes the steps of 1, preparing for construction, namely connecting an injection system with a plurality of injection holes through an injection pipeline, which are arranged on the outer wall of the upper middle of an earth bin of a shield machine in the peripheral direction; 2, cleaning the bin, namely cleaning the earth bin of the shield machine by a screw conveyer and the injection system; 3, performing graded pressurization, namely performing graded pressurization, including primary pressurization, secondary pressurization, tertiary pressurization and quaternary pressurization, on the inside of the earth bin by the injection system; 4, performing air replacement, namely shutting down the injection system, and replacing bentonite slurry inside the earth bin by air. The construction process is reasonable in design, simple to operate, low in input cost, high in safety coefficient and good in using effect; the practical problem that under the tool-changing severe conditions of loose stratum at the shutdown position of the shield machine, poor self-stabilization capacity of tunnel face earth and the like, existing common tool changing methods fail in changing tools is solved.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

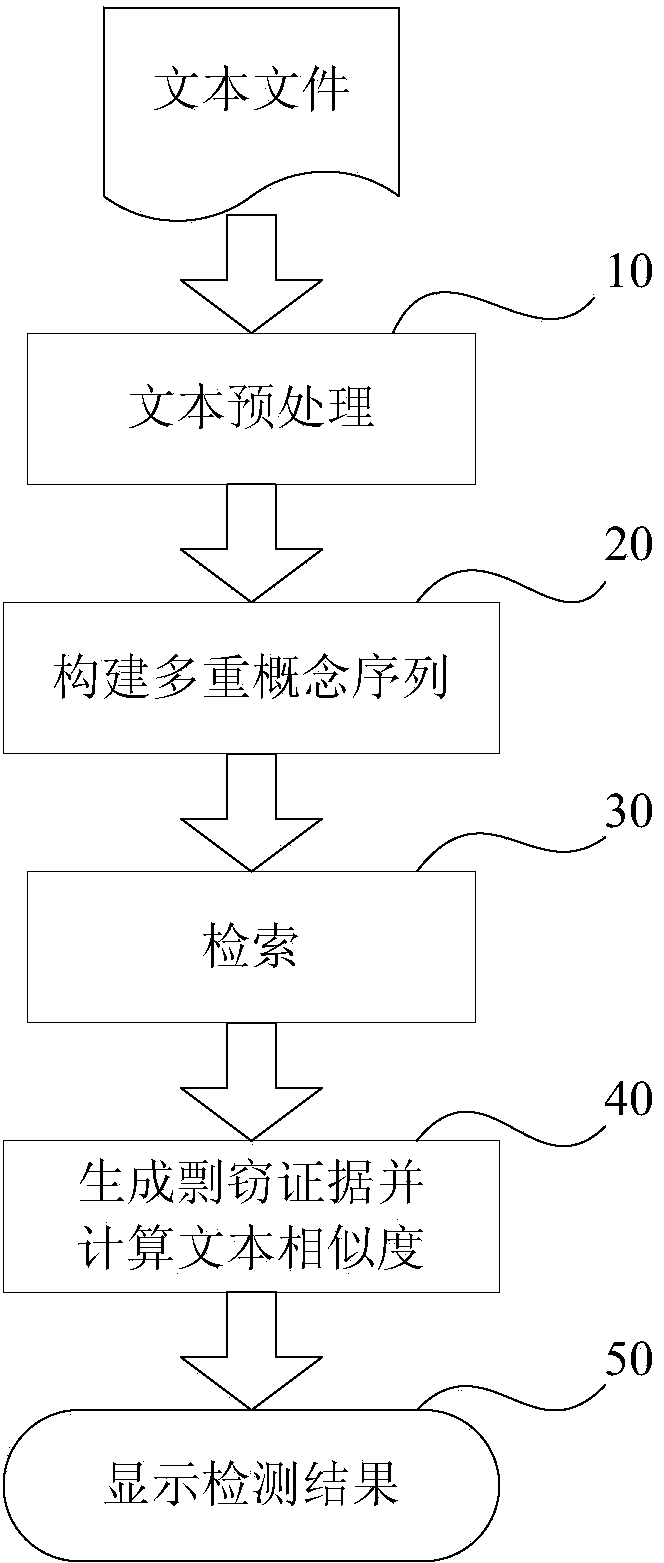

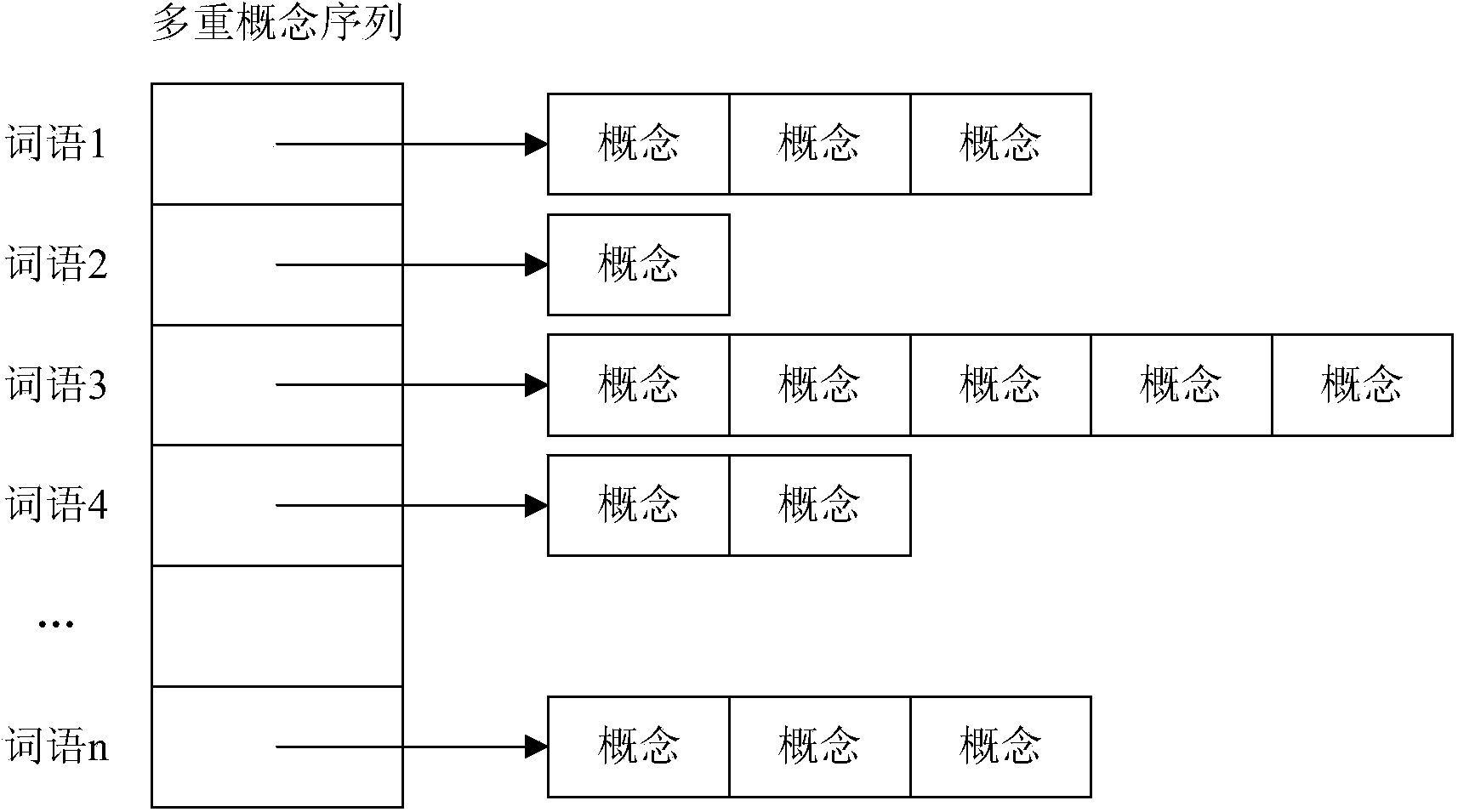

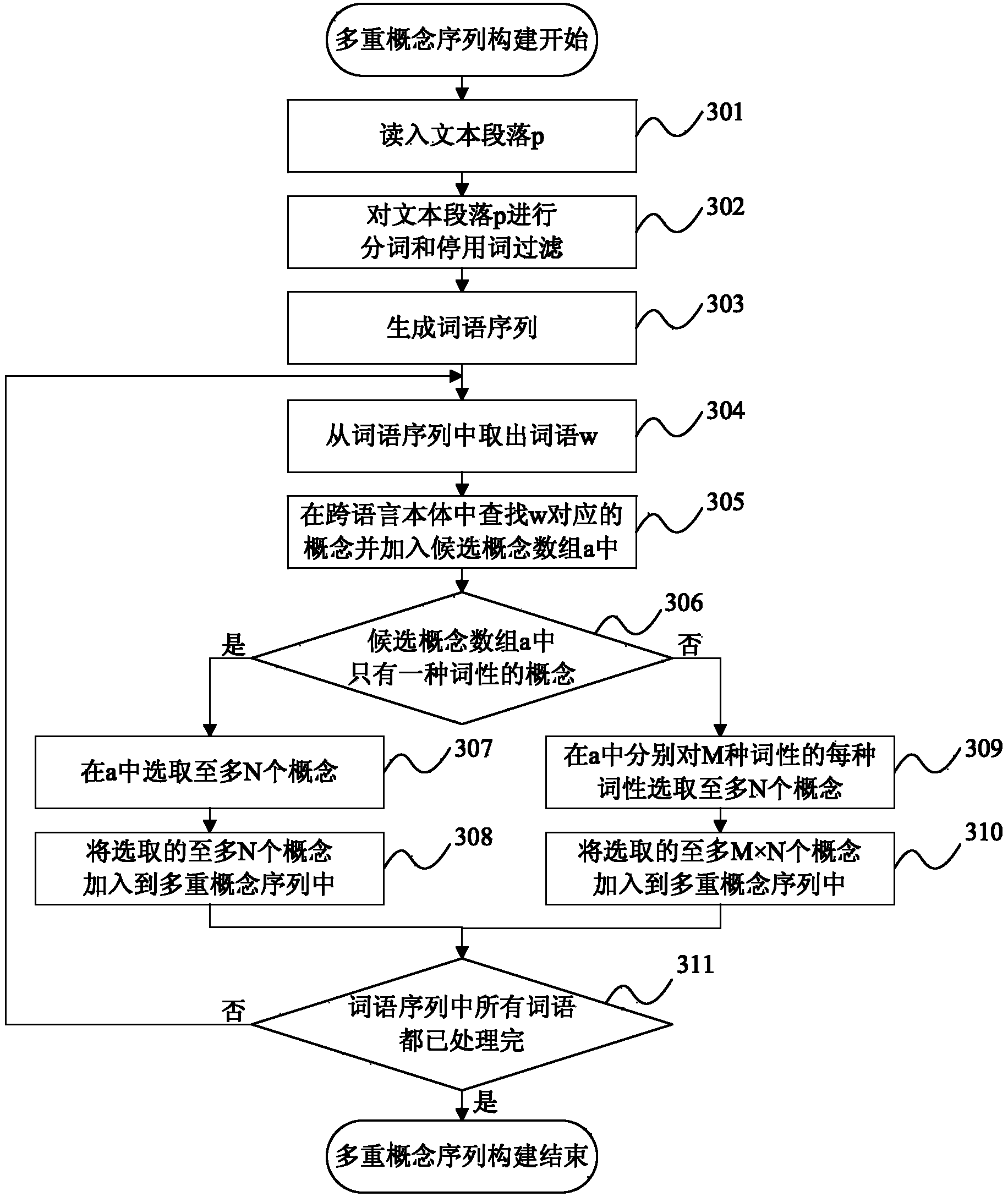

Cross-linguistic electronic text plagiarism detection system and detection method

ActiveCN103823862AFull searchSolve the replacement problemNatural language data processingSpecial data processing applicationsParagraphPlagiarism detection

The invention discloses a cross-linguistic electronic text plagiarism detection system and detection method. The cross-linguistic electronic text plagiarism detection method comprises the steps that paragraph division is carried out on an electronic text to be detected and a reference electronic text respectively to obtain a paragraph set to be detected and a reference paragraph set; concepts corresponding to terms in the paragraph set to be detected and the reference paragraph set are searched for according to a cross-linguistic body, and the paragraph set to be detected and the reference paragraph set are expressed as a multiple-concept sequence to be detected and a reference multiple-concept sequence according to the found concepts; the reference multiple-concept sequence having the most common concepts with the multiple-concept sequence to be detected is obtained through searching according to the multiple-concept sequence to be detected; the multiple-concept sequences are detected to generate a plagiarism evidence list; the plagiarism evidence list is combined and ordered to generate a detection result; the detection result is output and displayed. By means of the cross-linguistic electronic text plagiarism detection system and detection method, the built multiple-concept sequences can sufficiently search the electronic text to be detected and the reference electronic text, and further the detection accuracy is improved.

Owner:XI AN JIAOTONG UNIV

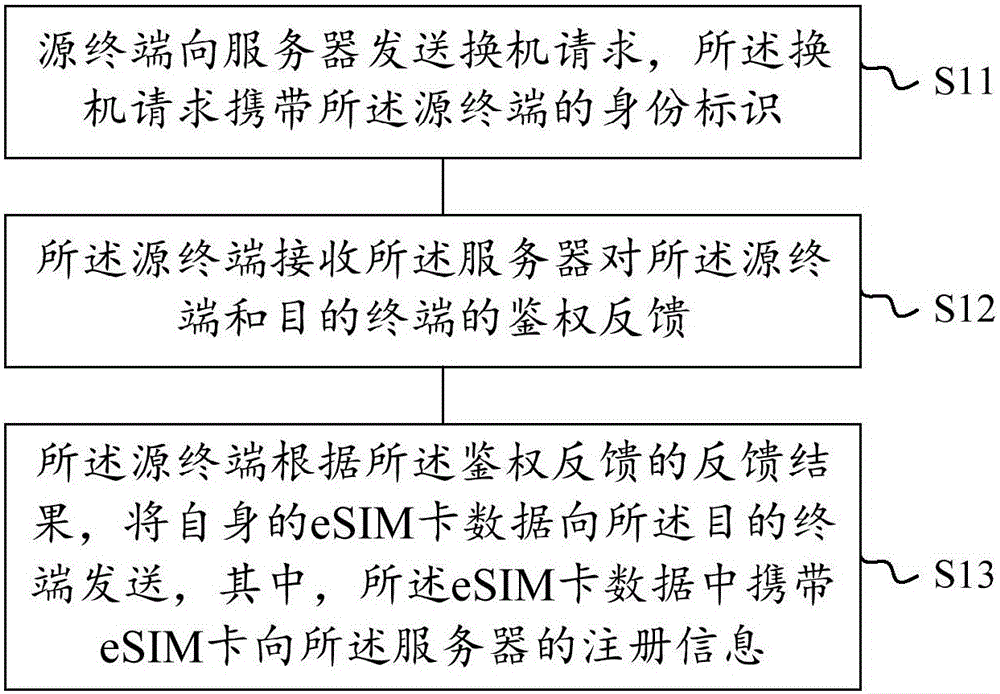

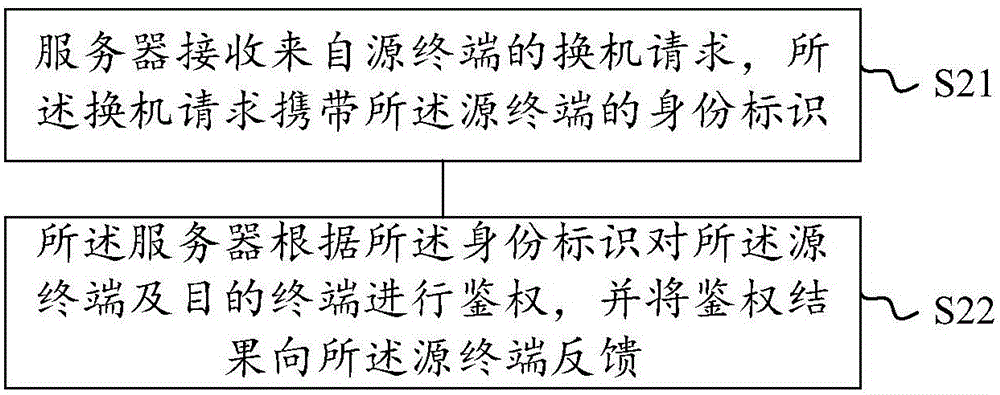

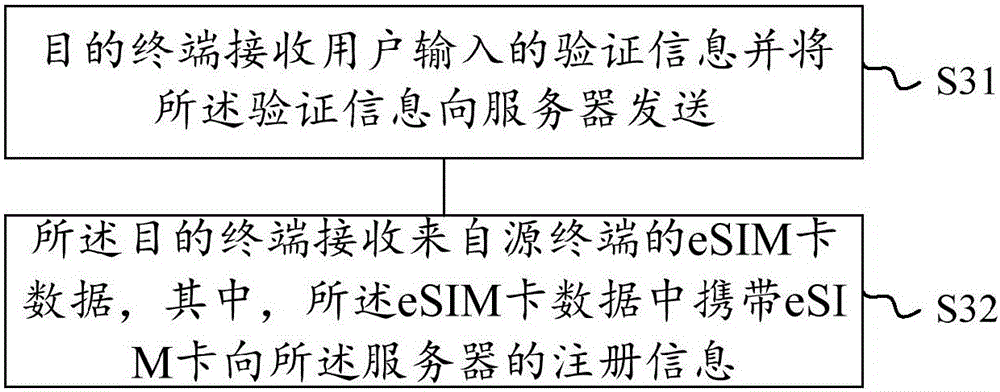

Machine changing method and device based on eSIM card, mobile terminal and server

InactiveCN105898733ASolve the replacement problemSwitch to achieveSecurity arrangementNetwork data managementComputer hardwareChange request

The invention discloses a machine changing method and device based on an eSIM card, a mobile terminal and a server, relates to the technical field of communication and solves the problem in the prior art that machine changing based on the eSIM card is inconvenient. The method comprises the steps that a source terminal sends a machine changing request to a server, wherein the machine changing request carries an identity identifier of the source terminal; the source terminal receives a right judging feedback of the server relative to the source terminal and a target terminal; and the source terminal sends eSIM card data of itself to the target terminal according to the feedback result of the right judging feedback, wherein the eSIM card data carries the registration information of the eSIM card to the server.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

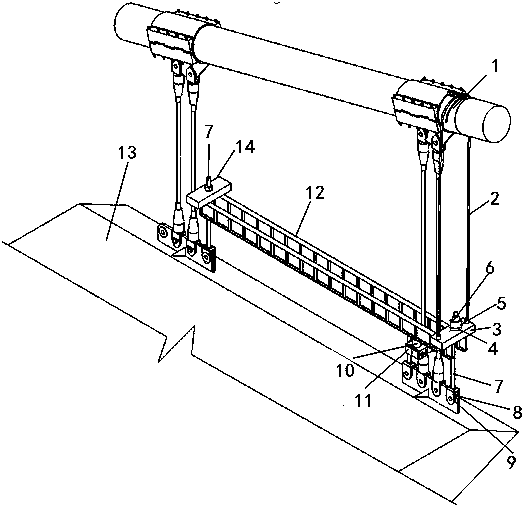

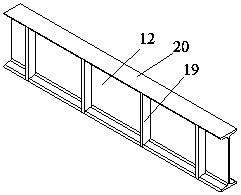

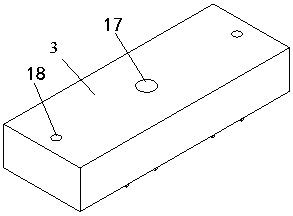

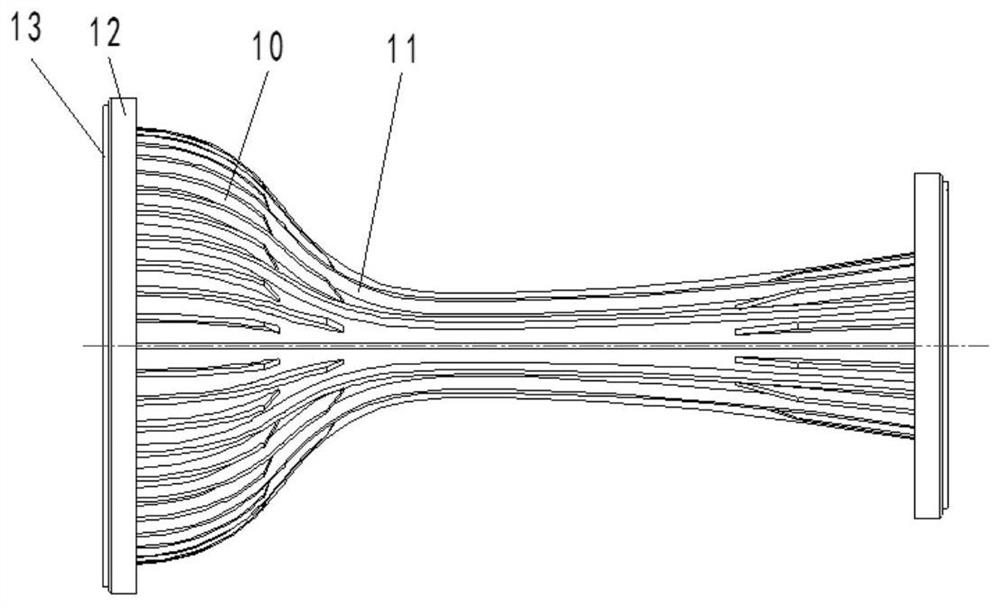

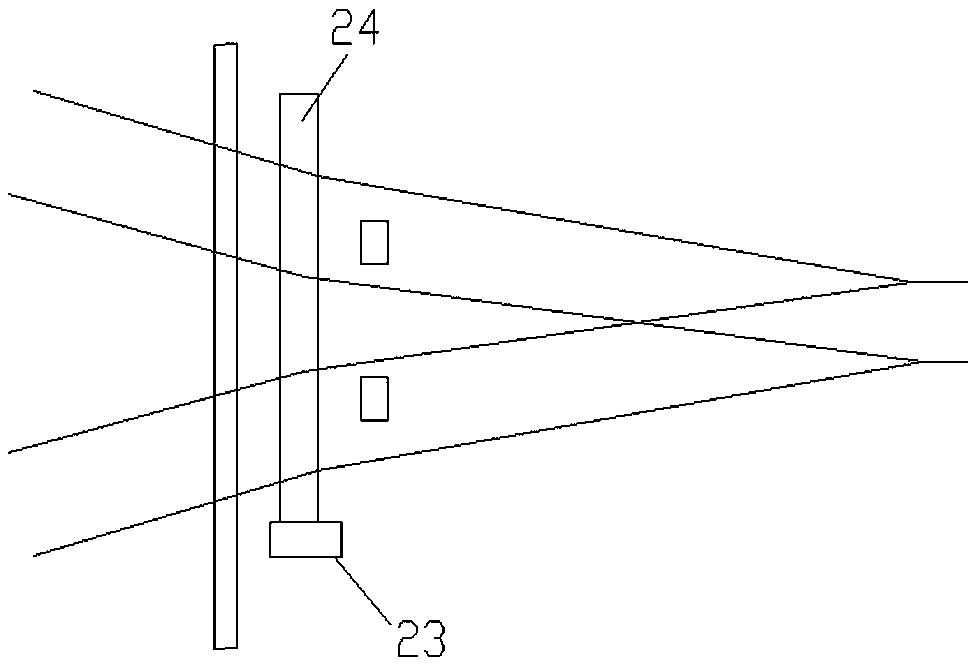

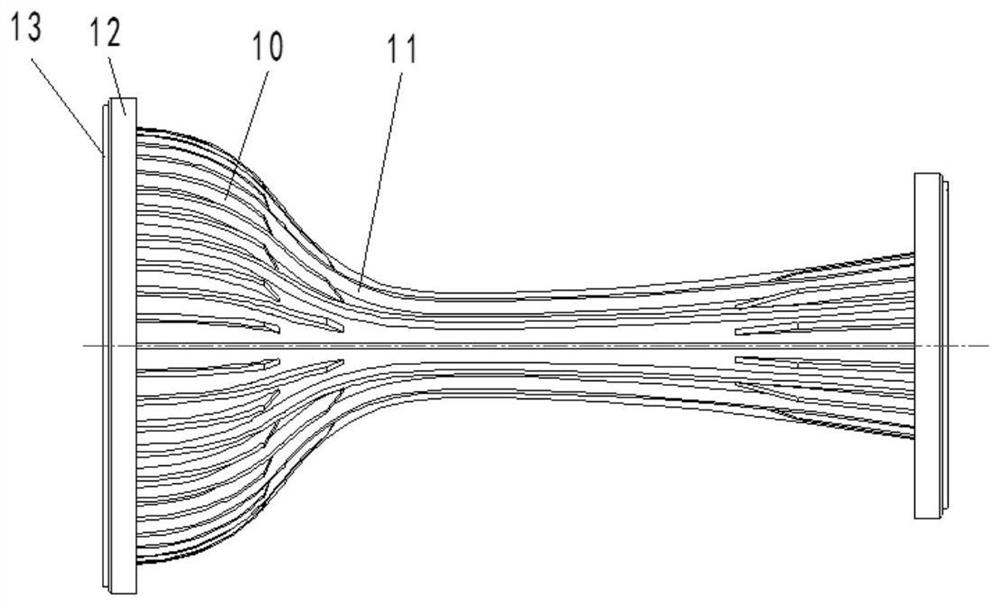

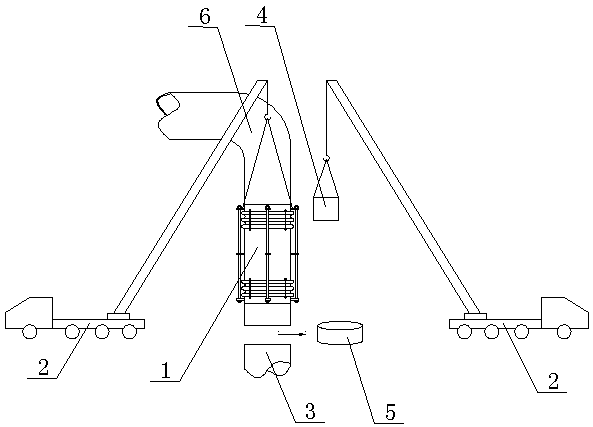

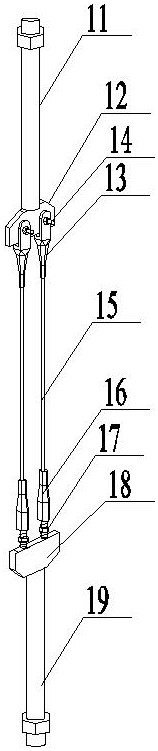

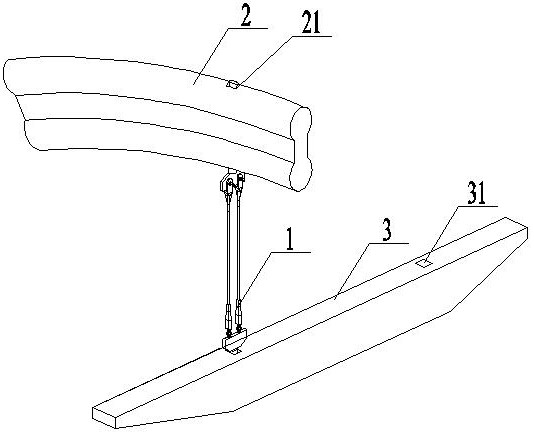

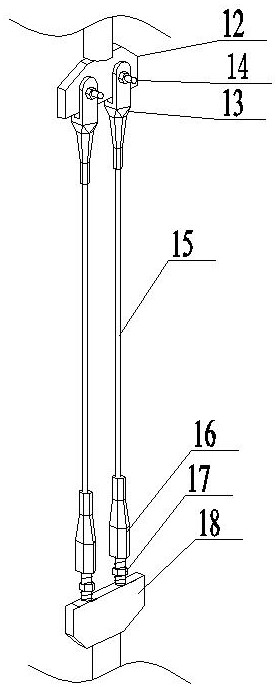

Straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables

PendingCN109487709ATemporary Cable Clamp LightEasy to install and constructBridge structural detailsBridge erection/assemblyInternal forcesSteel box girder

The invention discloses a straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables and belongs to the technical field of maintenance andreinforcement engineering of civil engineering suspension bridges. The straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables comprisesa main cable that is inclined; steel box girder (13) is arranged blow the main cable; lugs are arranged on the upper surface of the steel box girder (13); the main cable is provided with a pluralityof permanent cable clamps; the top end of a permanent cable is connected with each permanent cable clamp; the bottom end of each permanent cable is connected with one lug; each lug is provided with apinhole. The straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables helps solve the problem that cables are difficult to change when each cable lug of a suspension bridge has only one hanging hole, the fact that multiple-point lifting is carried out change one cable is avoided, aerial operation quantity is low, construction is simple, and the line shape and internal force of existing suspension bridge main cables and stiffening beams are less perturbed.

Owner:HOHAI UNIV +1

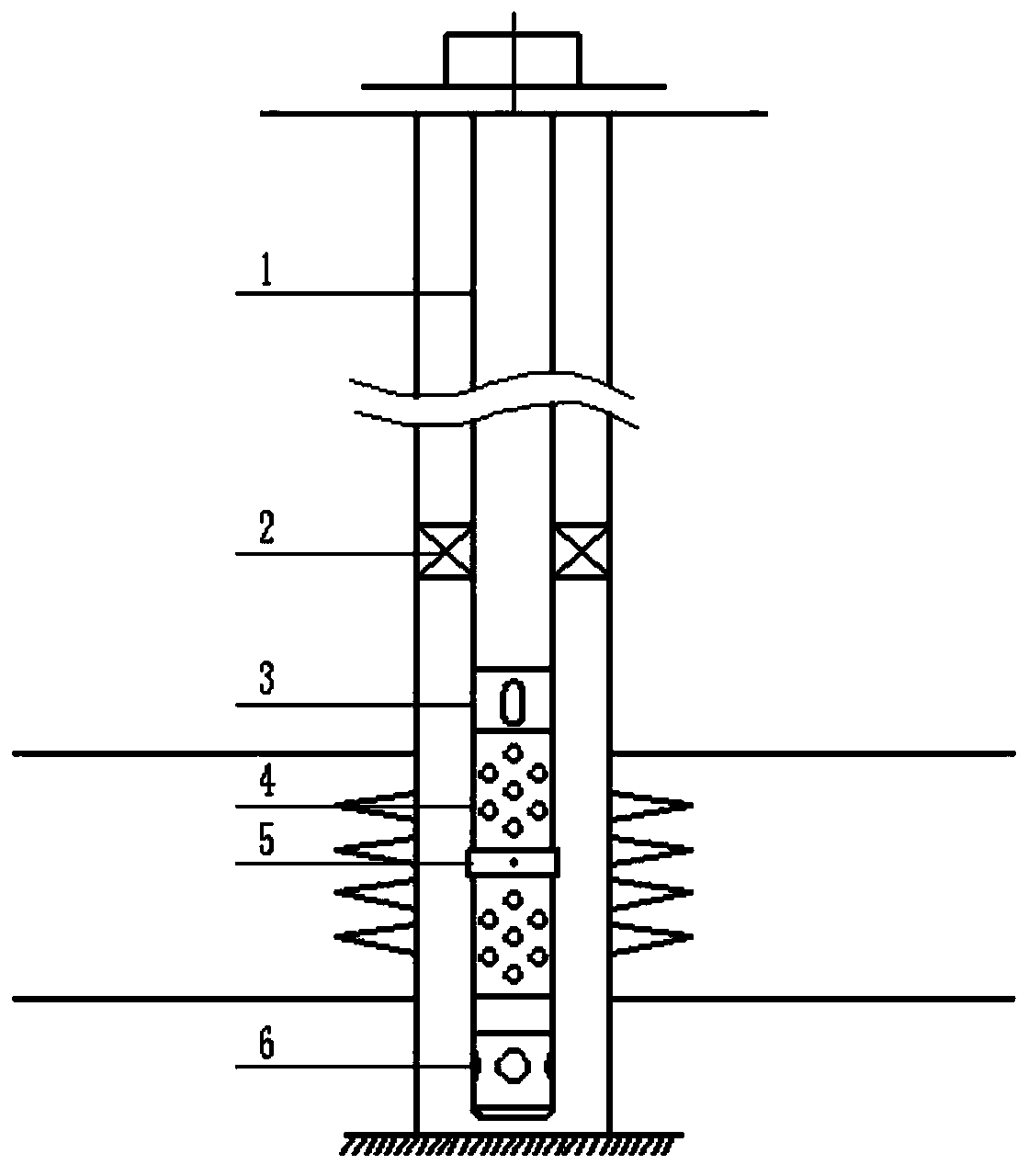

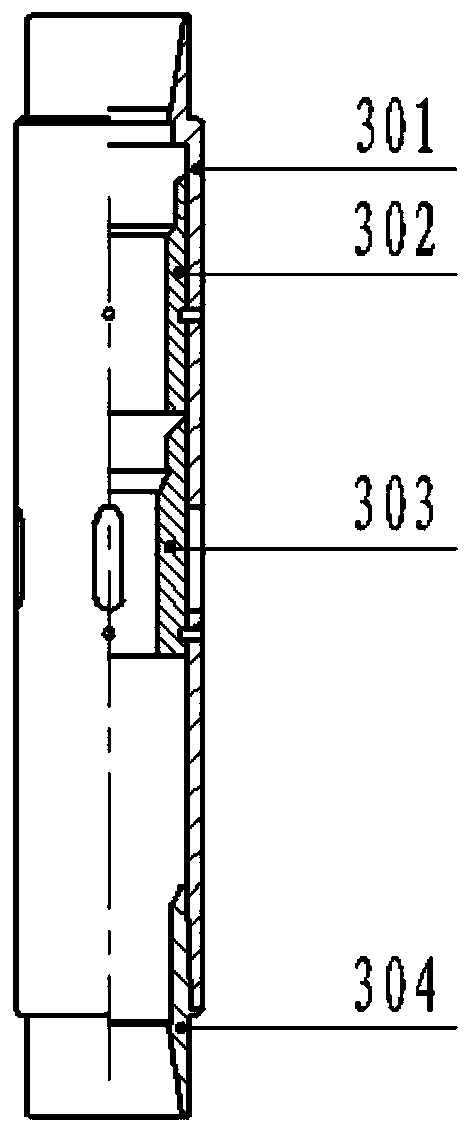

High-temperature and high-pressure oil-gas well multifunctional fracturing completion pipe string and construction process

PendingCN111088973AReduce construction riskShort construction periodDrilling rodsFluid removalGeotechnical engineeringUltra high pressure

The invention discloses a high-temperature and high-pressure oil-gas well multifunctional fracturing completion pipe string and a construction process thereof. The high-temperature and high-pressure oil-gas well multifunctional fracturing completion pipe string comprises an oil pipe, a packer, a closable fracturing sliding sleeve, a temporary plugging sand control screen pipe and a bottom mud displacement valve which are connected from top to bottom in sequence. High-pressure sealing safety joints are mounted on the part, below the packer, of the completion pipe string at intervals of a distance. The packer is internally provided with a shear pin. The closable fracturing sliding sleeve comprises an outer sleeve, an upper sliding sleeve and a lower sliding sleeve. The middle portion of theouter sleeve is transversely provided with a plurality of sand blasting holes. The upper sliding sleeve and the lower sliding sleeve are both of a cylindrical structure. The height of the upper sliding sleeve and the height of the lower sliding sleeve are greater than that of the sand blasting holes. The upper sliding sleeve and the lower sliding sleeve are arranged on the inner wall of the outersleeve and can slide along the inner wall to open and close the sand blasting holes. The temporary plugging sand control screen pipe comprises a base pipe. A pipe body of the base pipe is uniformly provided with a plurality of holes. Temporary plugging sand prevention filter parts are mounted in the holes of the base pipe. Through the high-temperature and high-pressure oil-gas well multifunctionalfracturing completion pipe string, a fracturing section can be opened and closed, and the problems of mud displacement, transformation and sand control completion of deep and super-deep high-pressureand superhigh-pressure oil-gas wells are solved better.

Owner:新疆恒智伟业石油工程技术开发有限公司

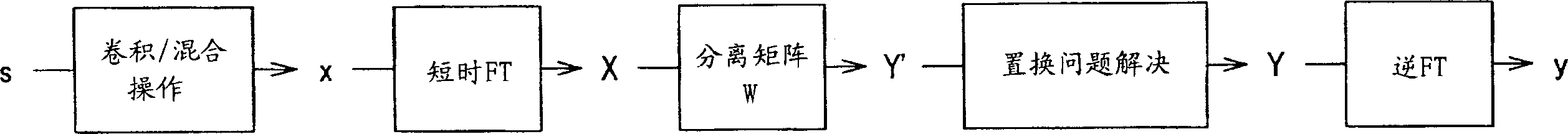

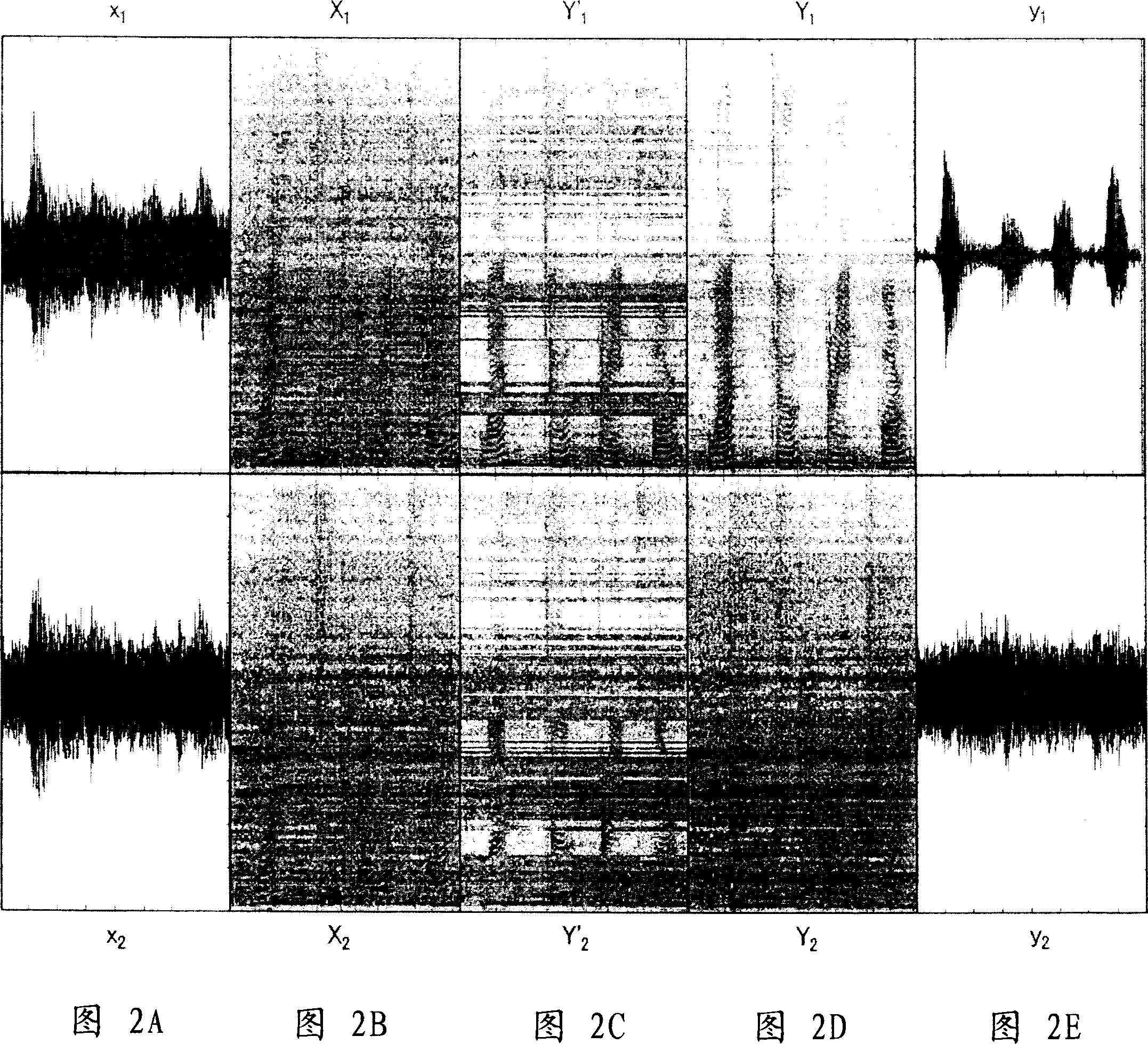

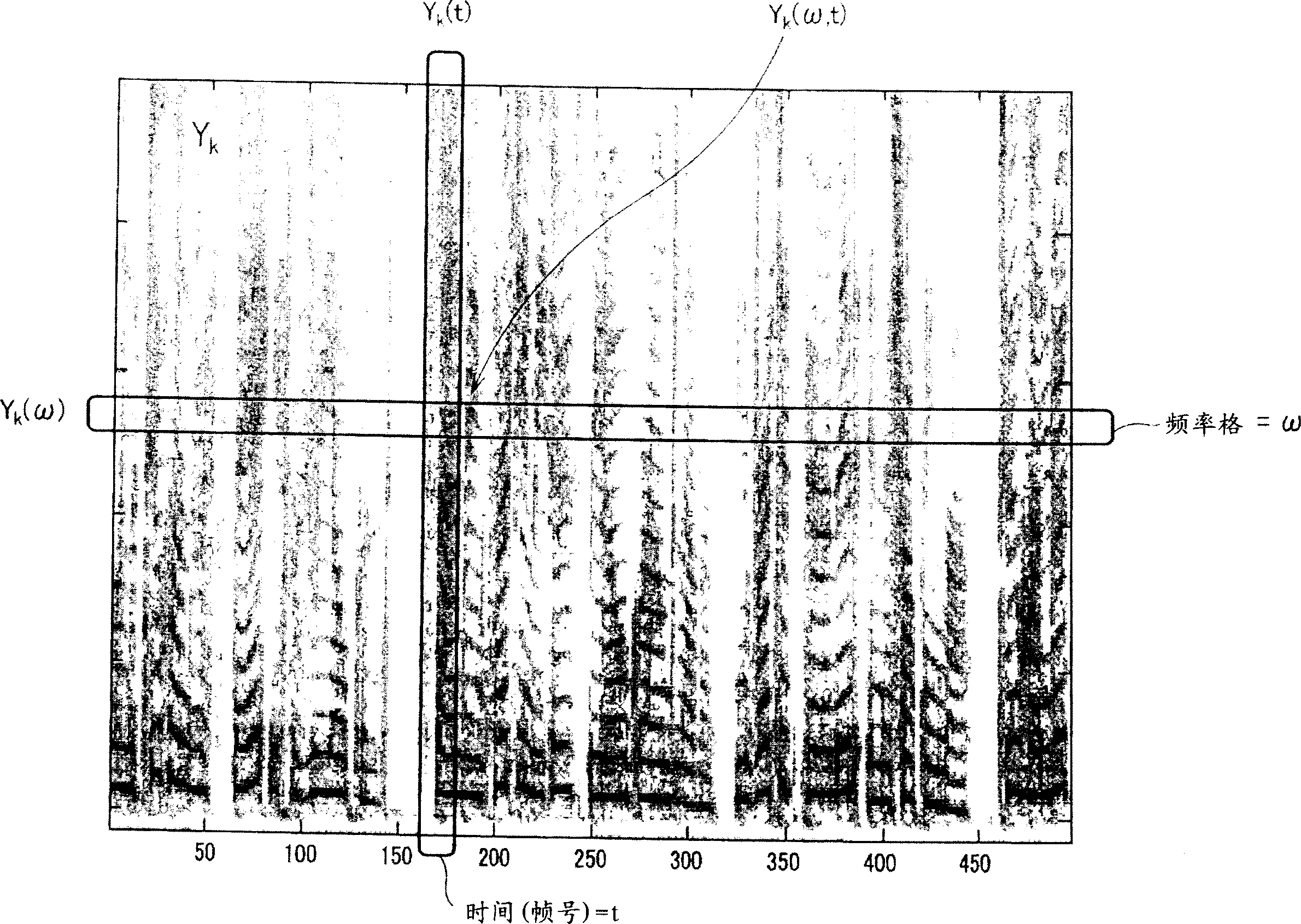

Audio signal separation device and method thereof

InactiveCN1897113ASolve the replacement problemAdaptive networkDigital technique networkTime domainFrequency spectrum

When independent component analysis is used to separate each of a plurality of signals mixed in an audio signal, it is possible to solve the permutation problem with high accuracy without utilizing knowledge about the original signal or information about microphone positions or the like. A short-time Fourier transform component generates a spectrogram of the observed signal from the observed signal in the time domain. The signal separating means separates the spectrogram of the observed signal into spectrograms of the individual signals to generate spectrograms of the separated signals. The permutation problem solving means calculates a scale corresponding to a degree of permutation, such as Kullback-Leiblar information calculated by using a multidimensional probability density function, or multidimensional kurtosis, from substantially the entirety of the spectrogram of the separated signal. Based on this scale, the signal at each frequency bin of the spectrogram of the separated signal is swapped between channels to solve the permutation problem.

Owner:SONY CORP

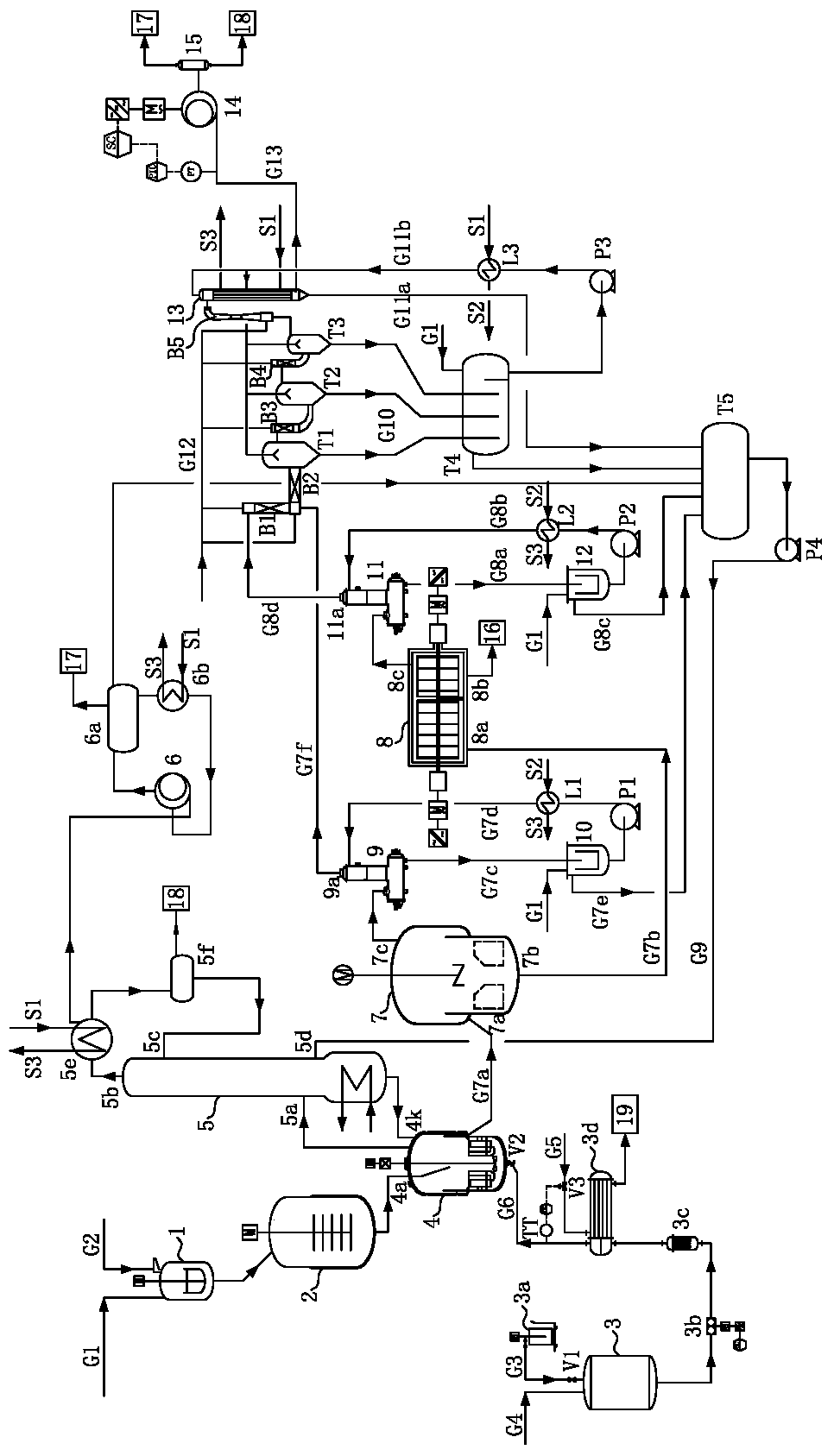

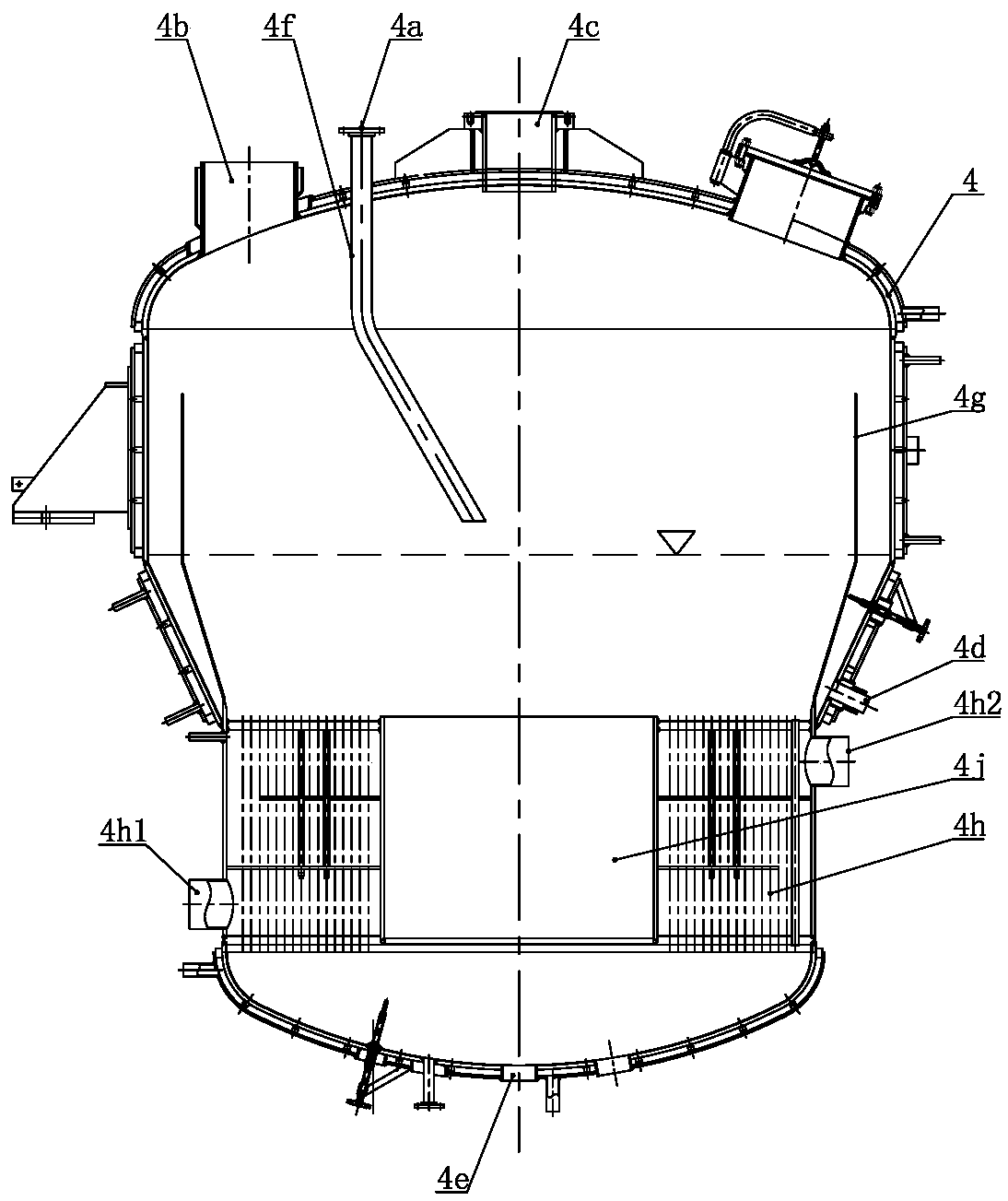

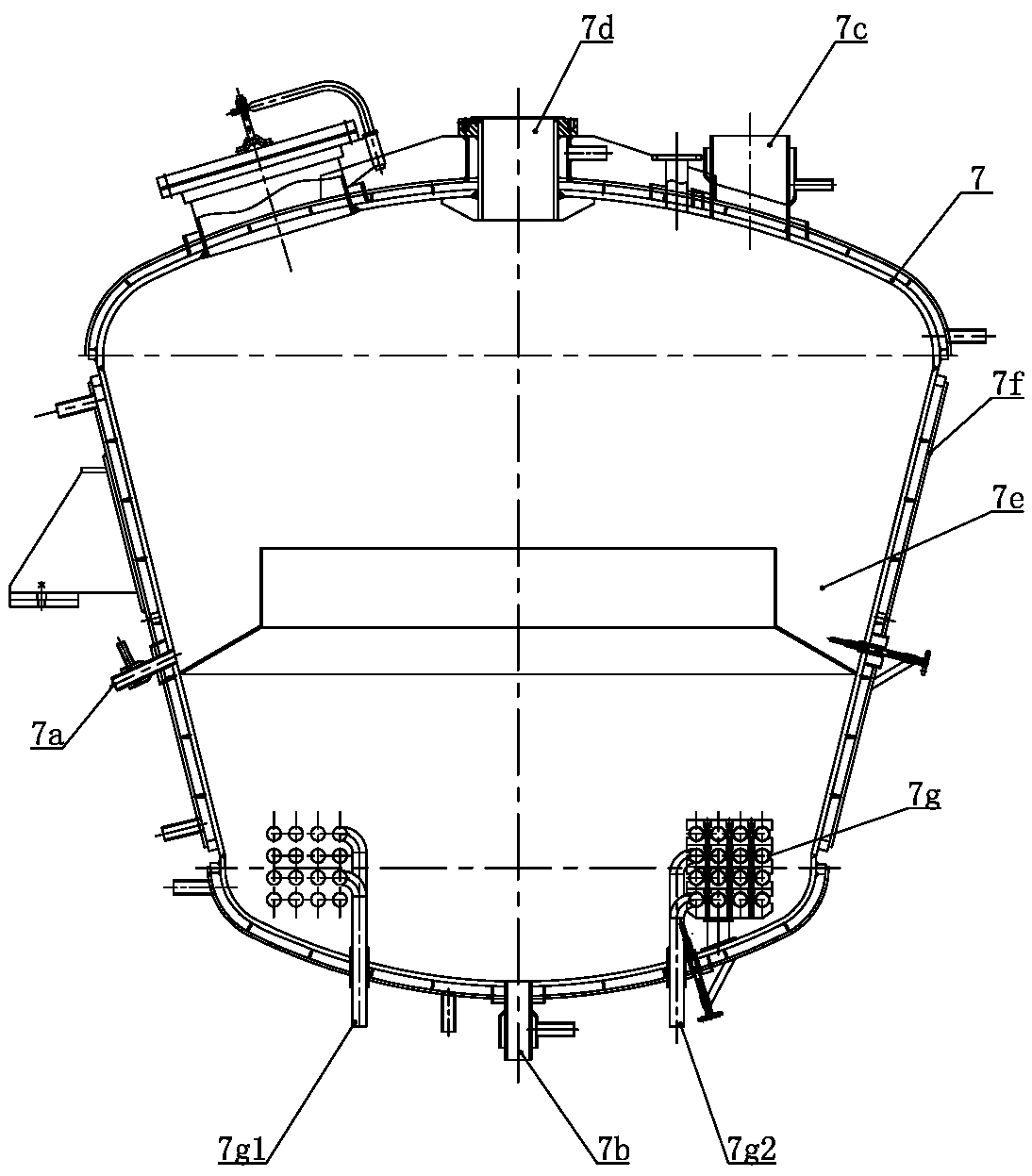

PBT(polybutylene terephthalate) esterification reaction system

PendingCN109529753AEasy to transportAvoid contactChemical/physical/physico-chemical stationary reactorsFeed devicesReactive systemSlurry

The invention relates to a PBT (polybutylene terephthalate) esterification reaction system, which comprises a slurry finished product tank, a catalyst tank, an esterification reaction kettle, a pre-condensation reaction kettle and a final condensation reaction kettle, wherein a discharging opening of the slurry finished product tank is connected with a slurry inlet of an esterification kettle; a discharging opening of the esterification kettle is connected with a feeding opening of a pre-condensation kettle; a discharging opening of the pre-condensation kettle is connected with a feeding opening of the final condensation kettle; a catalyst inlet arranged at the bottom of the esterification reaction kettle is provided with a catalyst bottom injection valve; a barrel pump outlet built in a catalyst barrel is connected with a feeding opening of the catalyst tank through a barrel pump output pipe; an air inlet on the top of the catalyst tank is connected with a nitrogen pipe; a dischargingopening of the catalyst tank is connected with an inlet of a catalyst metering pump; an outlet of the catalyst metering pump is connected with a material inlet of a catalyst heater through a catalystfilter; a material outlet of the catalyst heater is connected with an inlet of the catalyst bottom injection valve through a catalyst bottom injection pipe. The catalyst of the system does not need to be mixed with BDO (1,4-butanediol) for preparation; hydrolysis or pipeline blockage is not liable to occur; the continuous production can be ensured.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

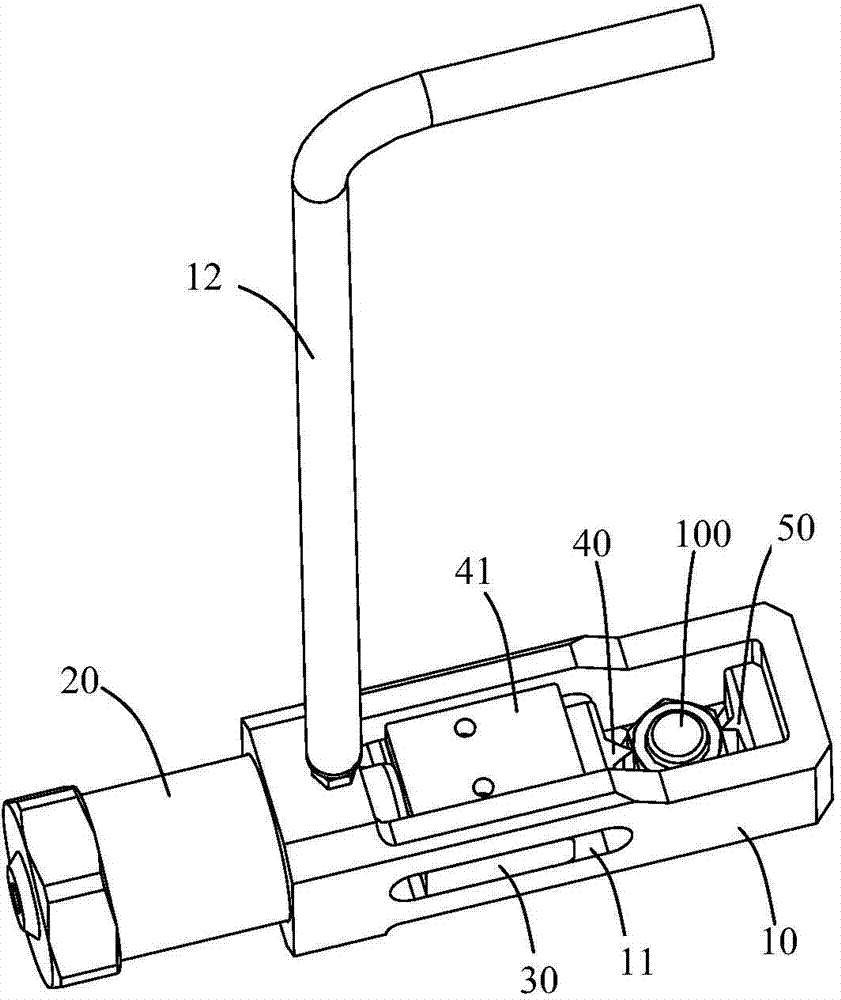

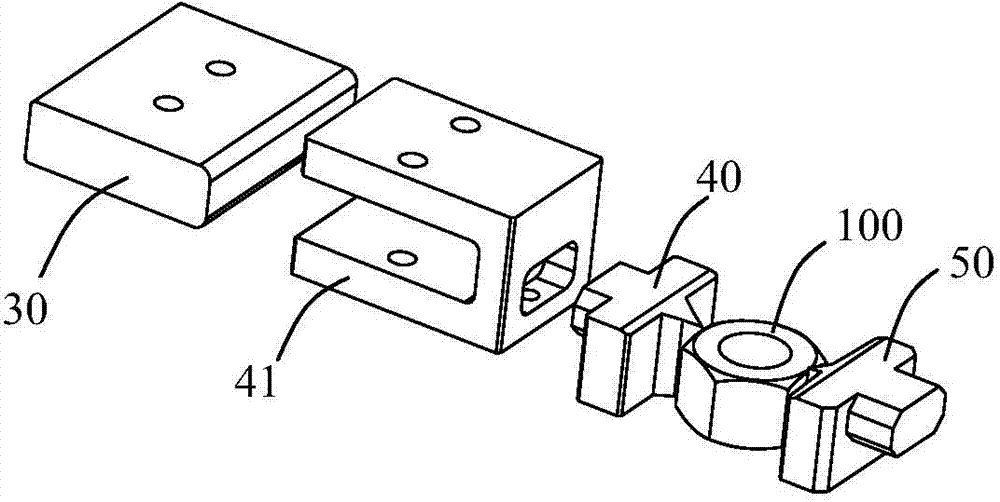

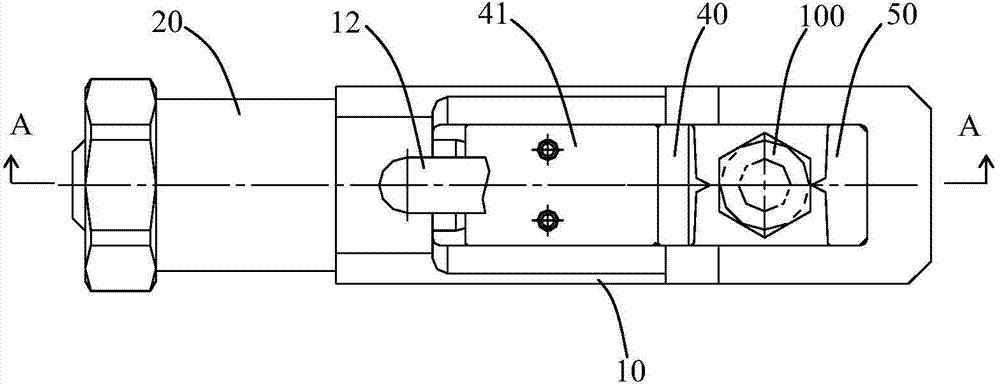

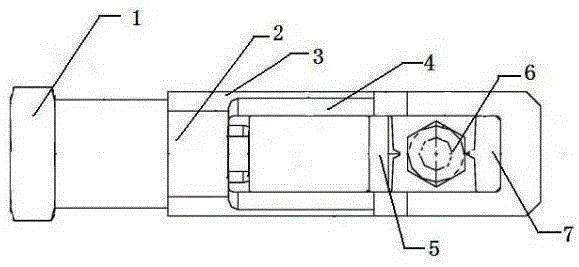

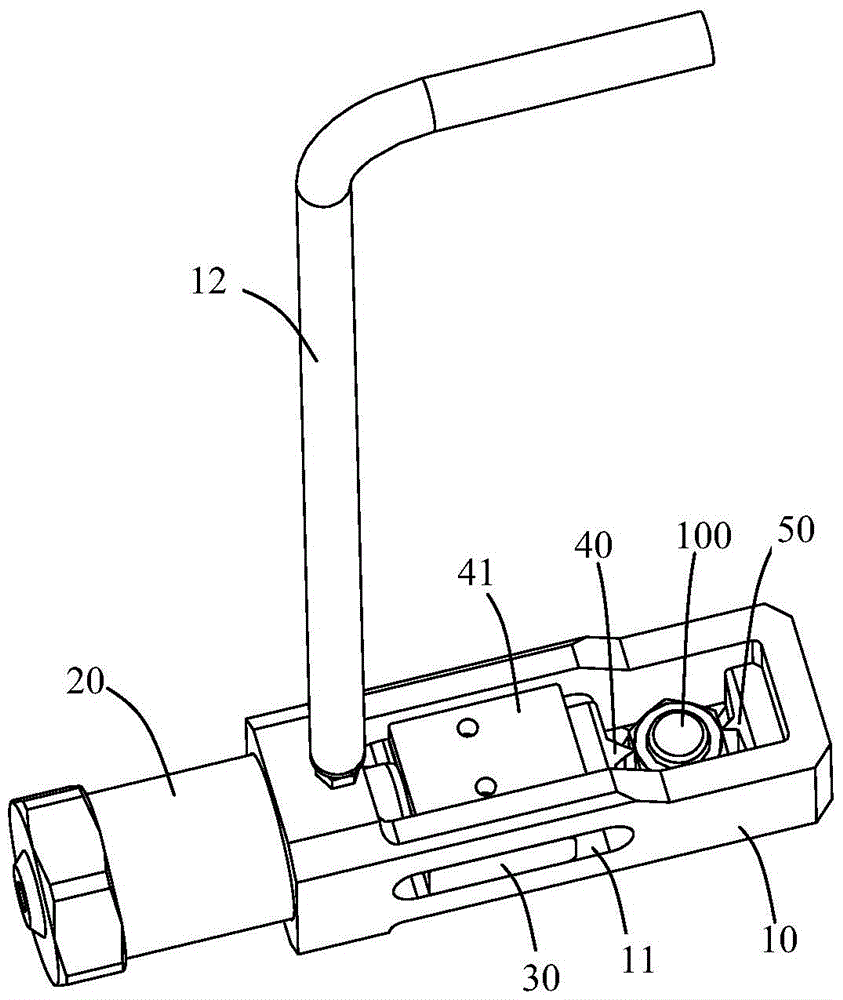

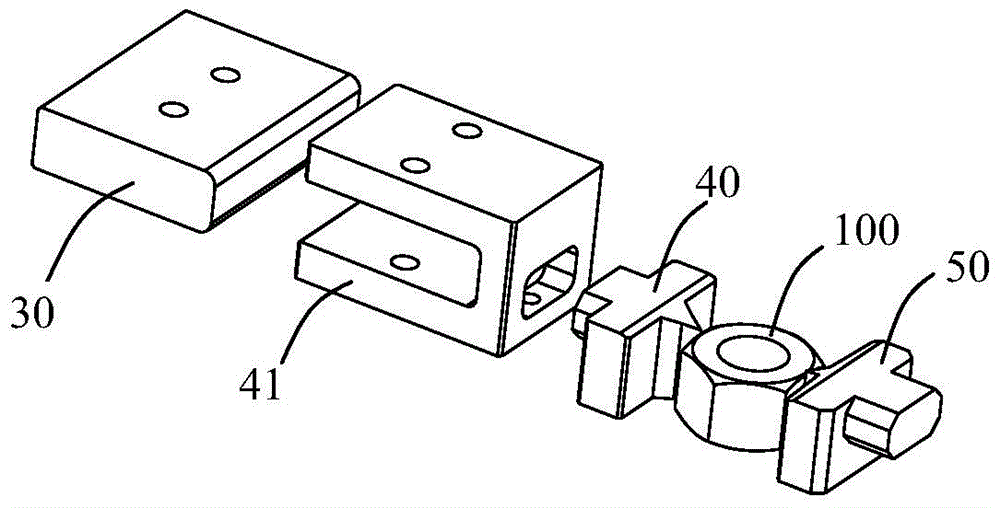

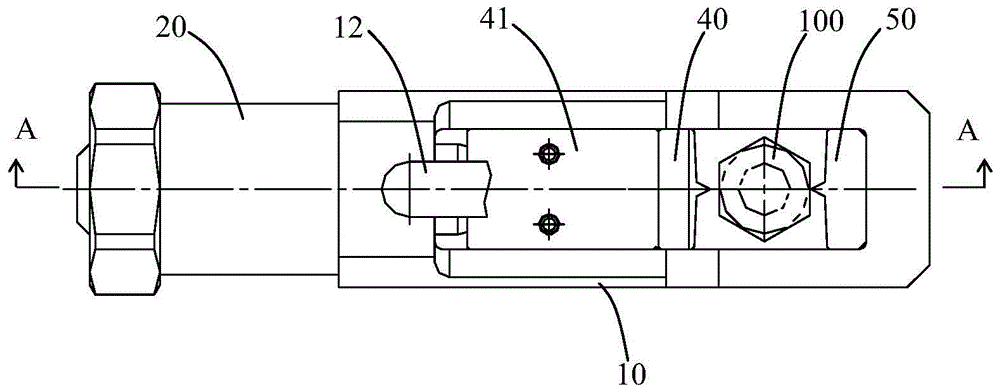

Nut splitter

ActiveCN103692148ATroubleshoot disassemblySolve the replacement problemPortable handheld shearing machinesMetal working apparatusHydraulic cylinderEngineering

The invention relates to a nut splitter, which comprises a main body frame, a hydraulic cylinder, a sliding block, a movable knife and a fixed knife, wherein the hydraulic cylinder is fixedly installed on the main body frame; the main body frame is provided with one pair of guide slots; two ends of the sliding block are matched with the guide slots and are respectively arranged in the guide slots; two ends of the sliding block can slide in the guide slots; the sliding block and the piston rod of the hydraulic cylinder are fixedly connected; the movable knife is fixedly connected with the sliding block; the fixed knife is fixedly installed on the main body frame. According to the nut splitter disclosed by the invention, fire and electricity are not used, bolt screw threads are not damaged, and therefore the difficulty of disassembling and replacing bolts and nuts can be conveniently, quickly, safely and efficiently solved.

Owner:上海瑞纽机械股份有限公司

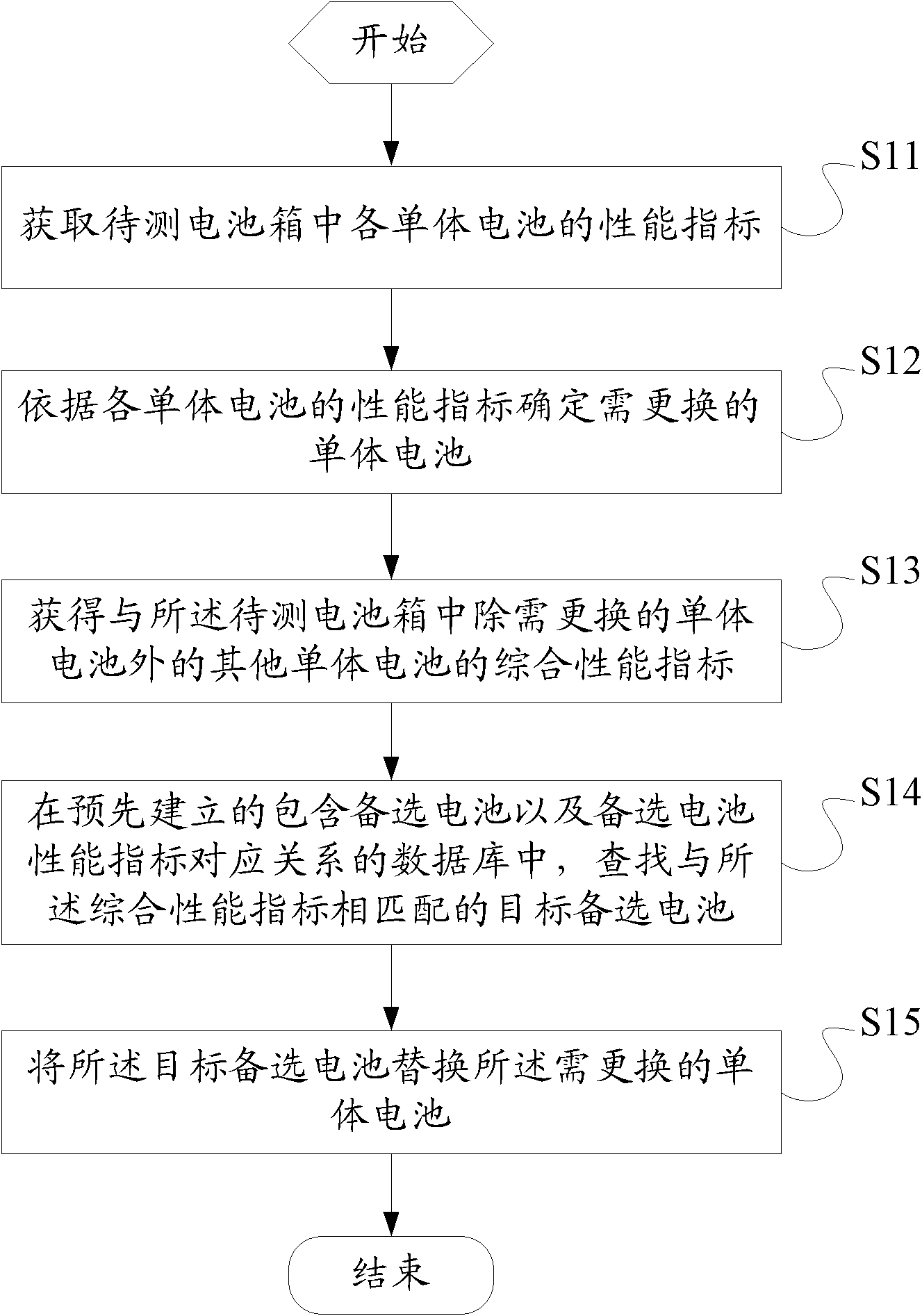

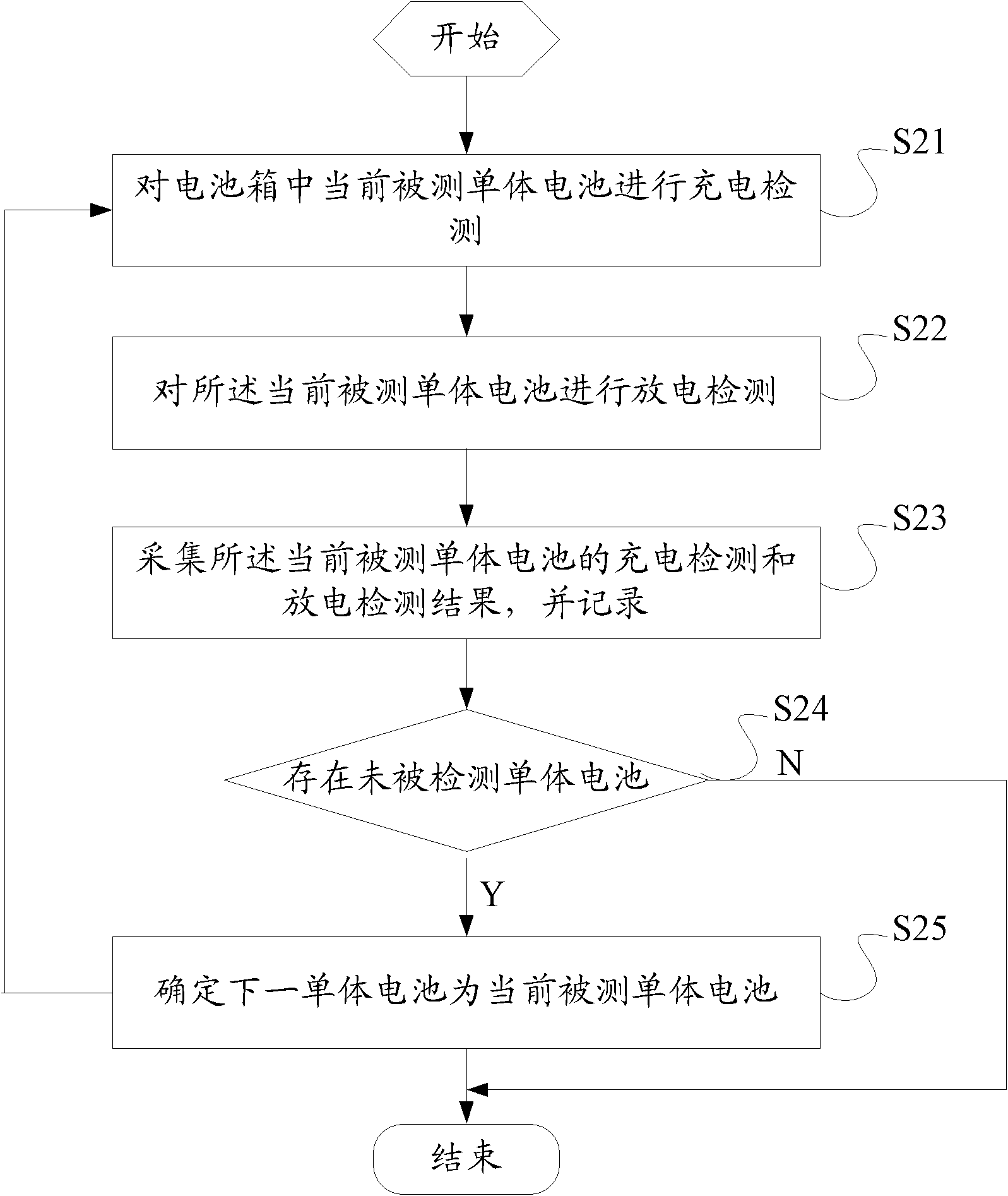

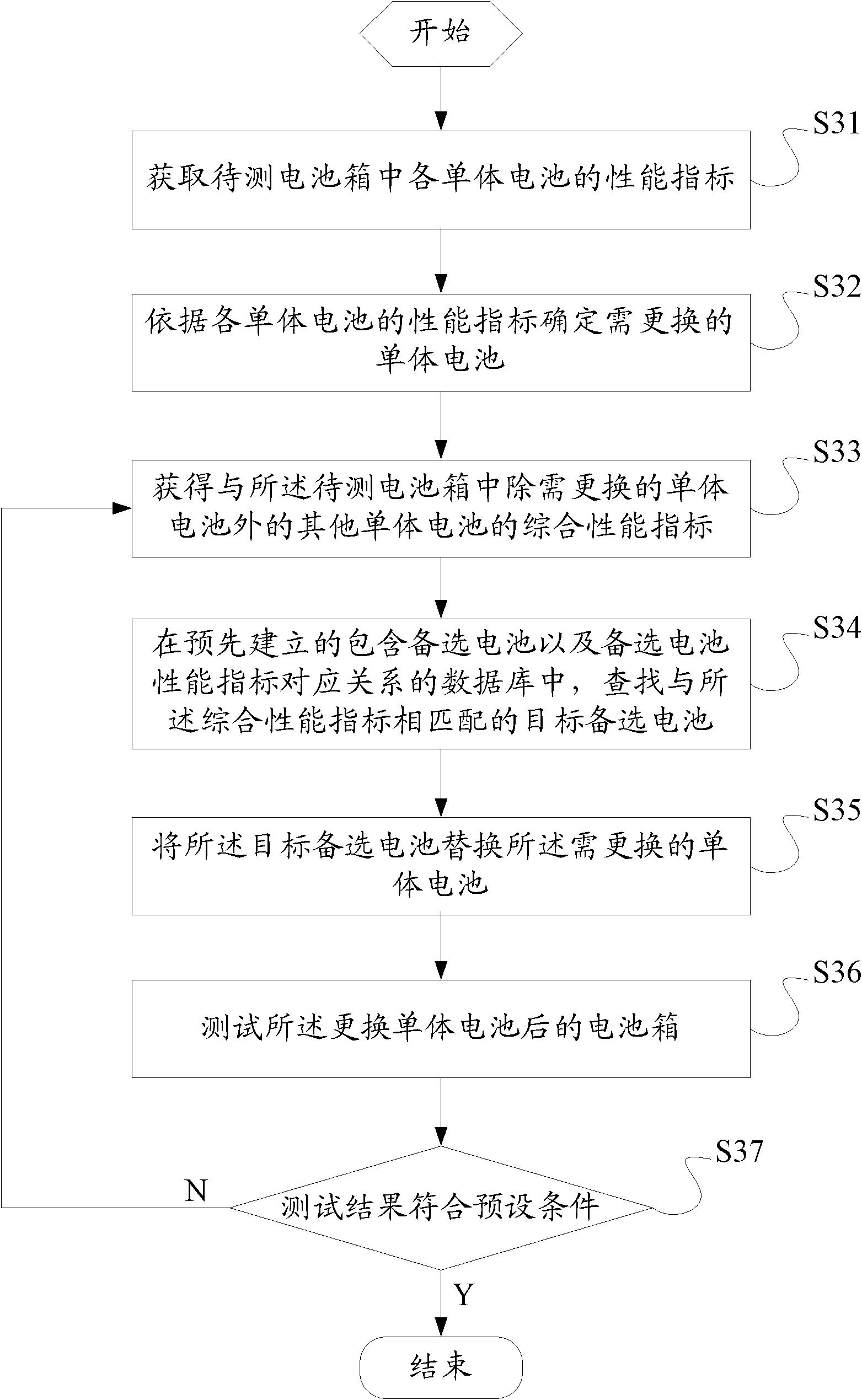

Battery replacement method and device

InactiveCN102867998AExtended service lifeSolve the replacement problemElectrical testingSecondary cells servicing/maintenancePerformance indexReplacement method

The invention discloses a battery replacement method and a device. The method comprises the following steps of: acquiring performance index of each single battery in a battery box to be measured; determining the single battery which needs replacement according to the performance index of each single battery; acquiring comprehensive performance index of other single batteries in the battery box except the single battery which needs replacement; searching a target alternative battery which matches with the comprehensive performance index in a pre-established database containing the alternative battery and the alternative battery performance index correspondence; and replacing the single battery which needs replacement with the target alternative battery. According to the battery replacement method disclosed by the embodiment, the replacement problem of a single pack and pack battery in a battery box is solved well, the whole battery box needn't to be replaced, the service life of an entire battery pack is raised, and operation cost of a battery pack is reduced.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD HANGZHOU POWER SUPPLY CO +2

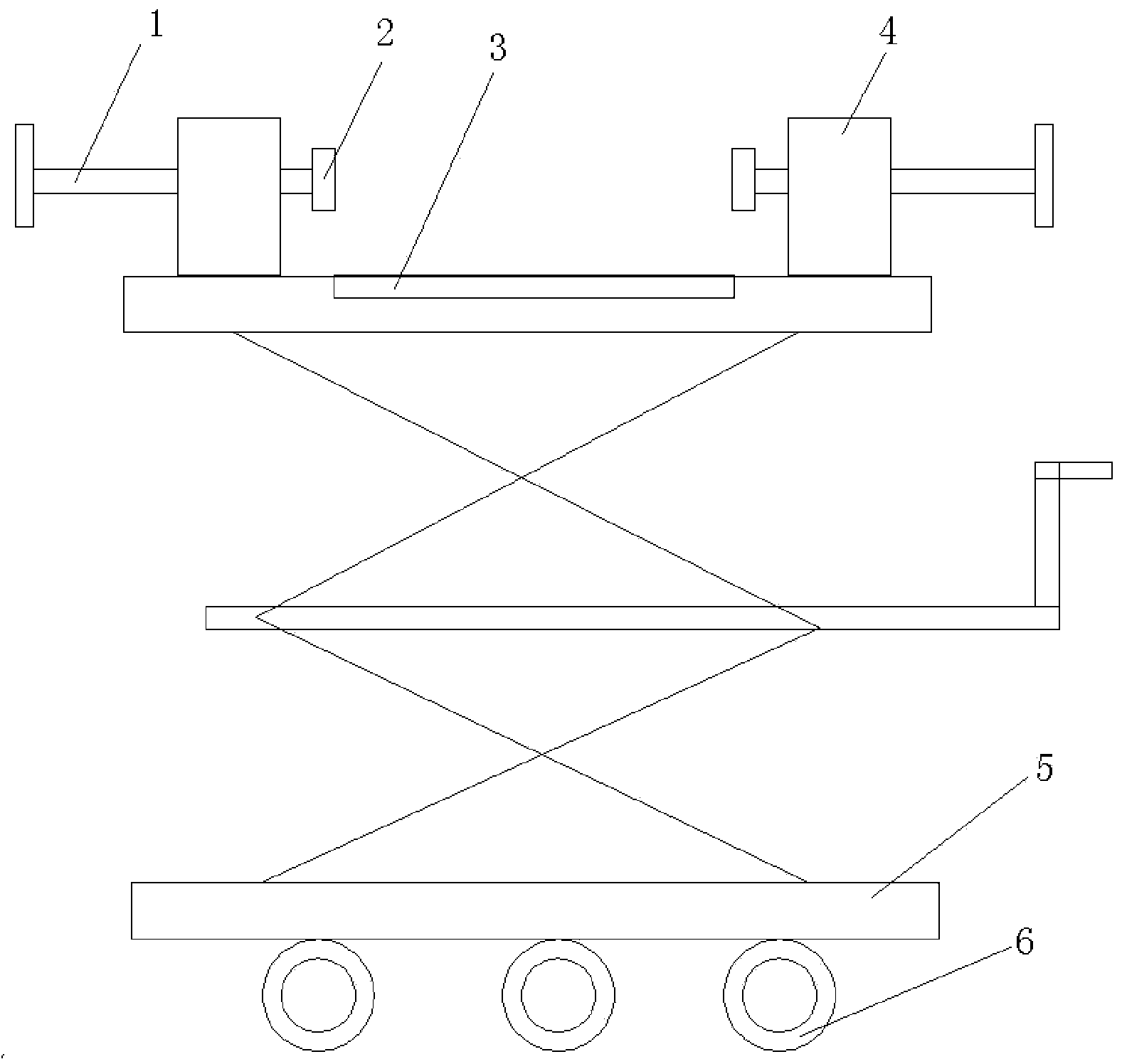

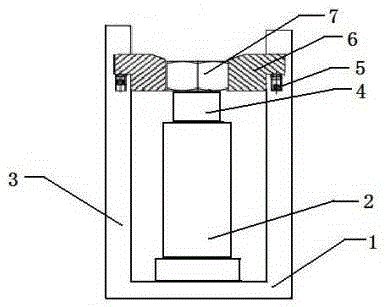

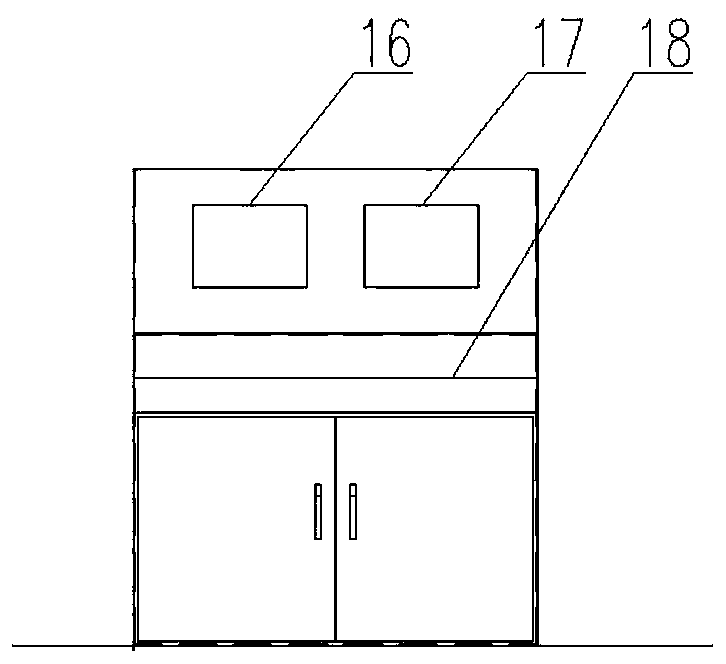

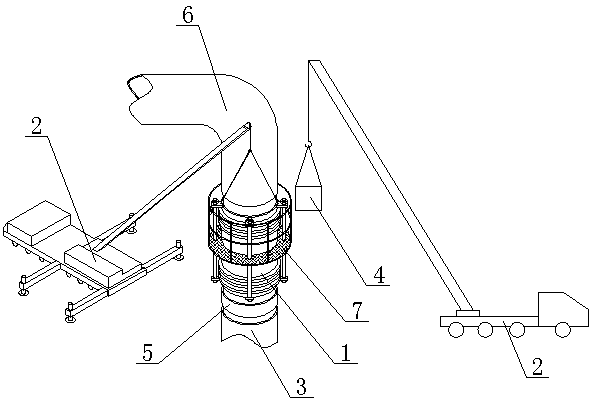

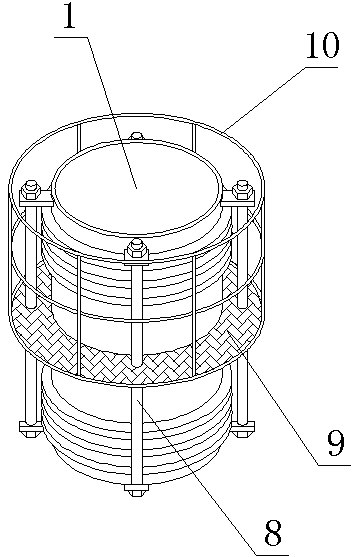

Motor replacement device of valve outer air cooling system

InactiveCN103434976AEliminate equipment hazardsShort time spentLifting framesElectric machineryAir cooling system

The invention relates to a motor replacement device of a valve outer air cooling system. The motor replacement device is characterized by comprising a manual lifting platform (5), wherein; a universal wheel (6) is arranged at the bottom of the manual lifting platform (5); at least two positioning frames (4) are arranged on the top of the manual lifting platform (5); each positioning frame (4) is provided with an adjusting screw rod (1); one end of each adjusting screw rod (1) is provided with a rotating handle, and the other end of the adjusting screw rod (1) penetrates through the positioning frame (4) to be connected with a motor fixed clamping sleeve (2); the adjusting screw rods (1) and the positioning frames (4) are in threaded connection. The motor replacement device disclosed by the invention solves can be used for solving the problem of field motor replacement, eliminatinges the equipment hidden danger and bringings the safety benefit; the motor replacement device disclosed by the invention proves that only 1.6 hours are needed to replace one air blower by being tried in the field, thereby greatly reducing the motor replacement time; the motor replacement device can ensure the safe and stable operation of a direct-current system and can be used for replacing the abnormal motor in time.

Owner:STATE GRID CORP OF CHINA +1

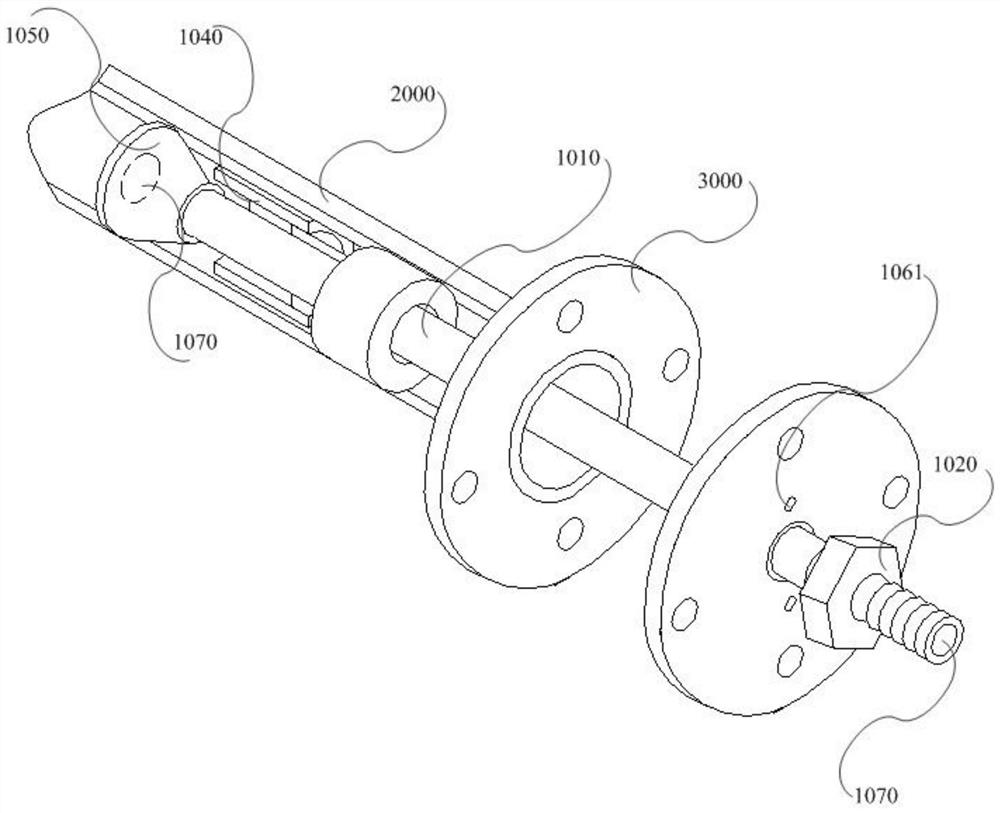

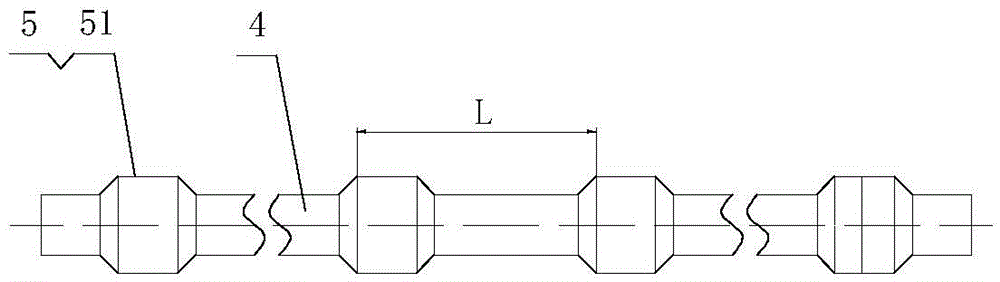

Pipeline welding and plugging device

PendingCN112344126AImprove the efficiency of welding operationsImprove efficiencyFlanged jointsPipe elementsSlag (welding)Mechanical engineering

The invention provides a pipeline welding and plugging device, and relates to the technical field of pipeline welding. The pipeline welding and plugging device provided by the invention is used for plugging a pipeline when a preset flange and the pipeline are welded. The pipeline welding and plugging device comprises a pull rod, wherein an expansion head is connected to the first end of the pull rod, and an air guide hose is connected to the second end; and a screwing nut sleeves the second end of the pull rod, and the pull rod and the expansion head fixed to the pull rod axially move relativeto the pipeline by rotating the screwing nut so as to seal the pipeline. By using the pipeline welding and plugging device, the safety of welding operation is facilitated. Impurities such as high-temperature welding slags can be prevented from entering the to-be-connected pipeline, and the service life of the pipeline can be prolonged.

Owner:PETROCHINA CO LTD

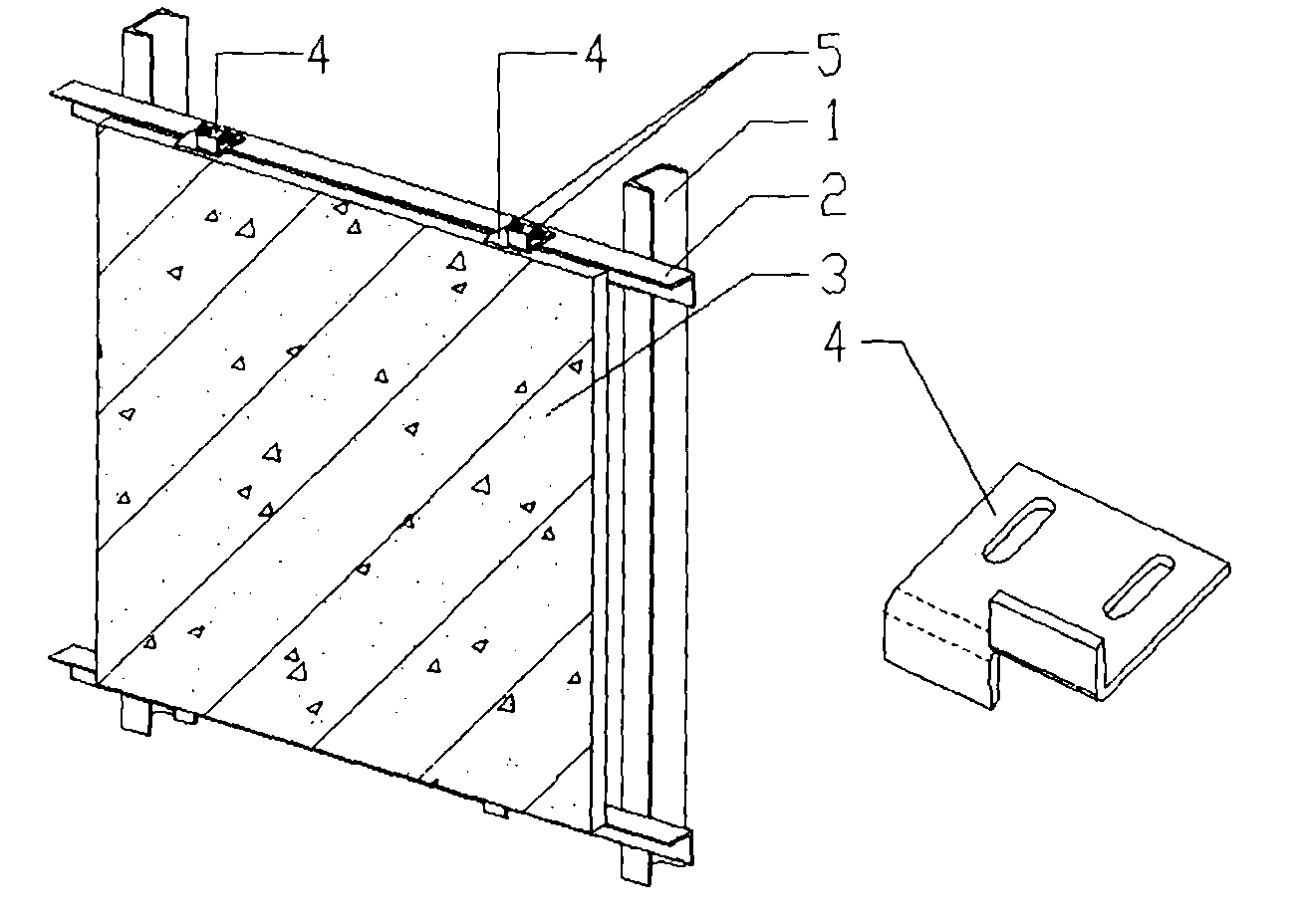

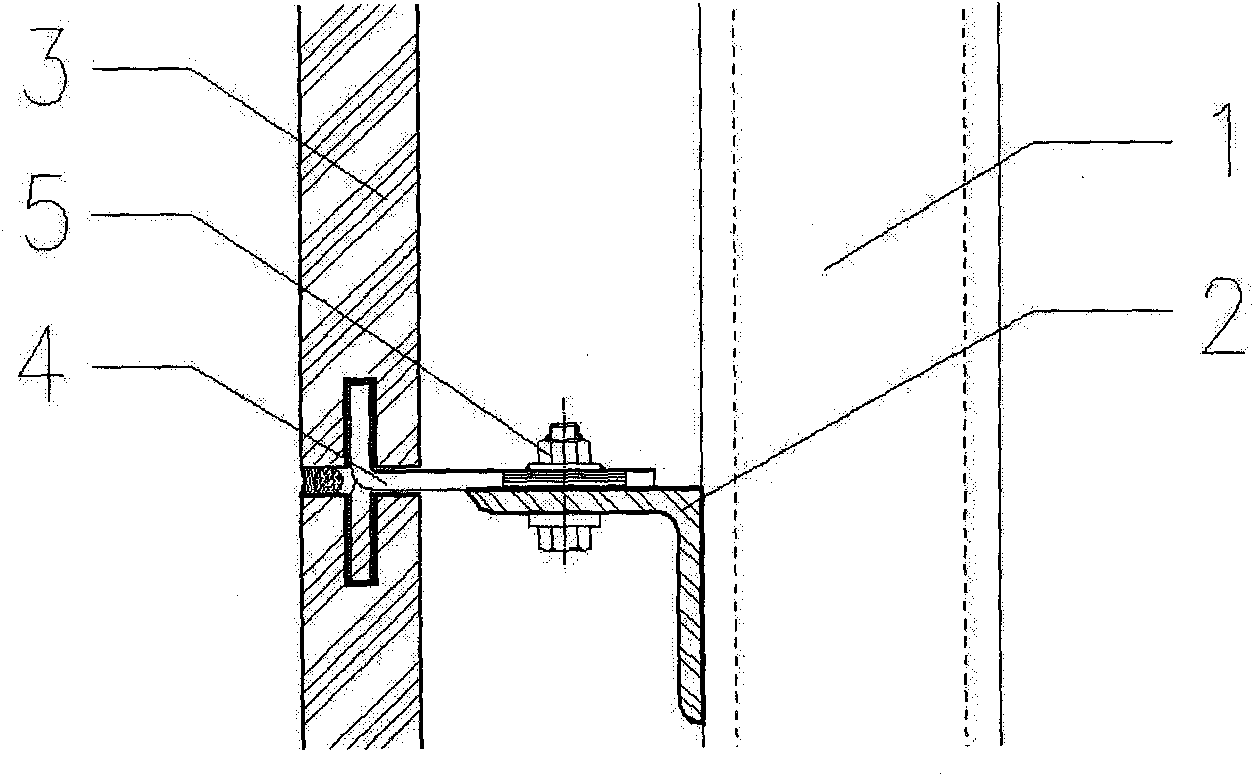

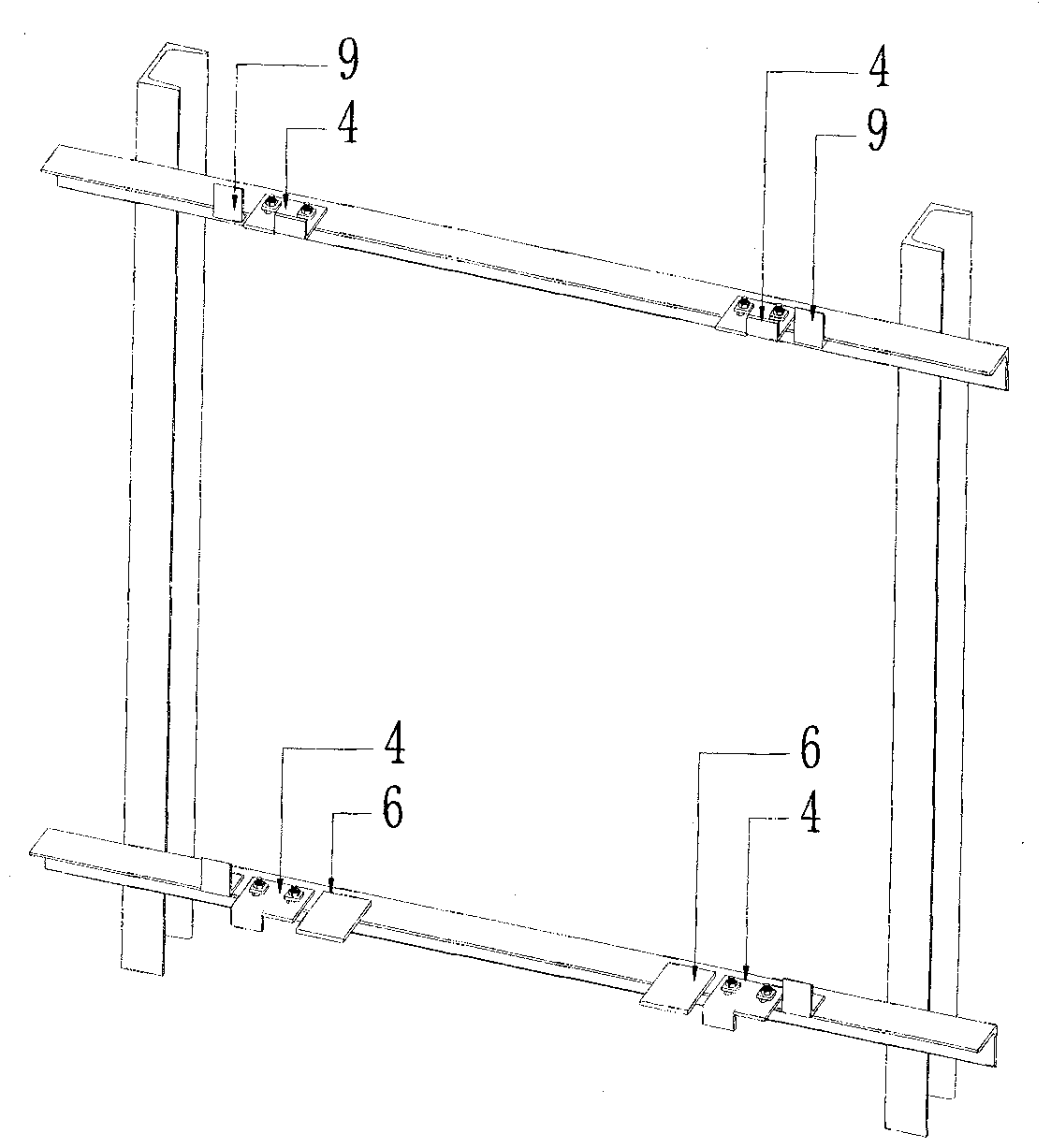

Method for removing clamp strip type stone plates

The invention provides a method for removing clamp strip type stone plates, which is characterized by cutting the corresponding parts of original butterfly clamp strips (4) for fixing the stone, welding two supporting plates (6) on a cross beam on the lower part of a stone panel (3) to bear the gravity of the stone and horizontally restricting the stone with clamp strips (8) with grooves and internal clamp strips (9). The method is simple and effective, dispenses with changing the form of the common clamp strip type structure, is strong in applicability and greatly saves the engineering cost.

Owner:ZHONGSHAN SHENGXING

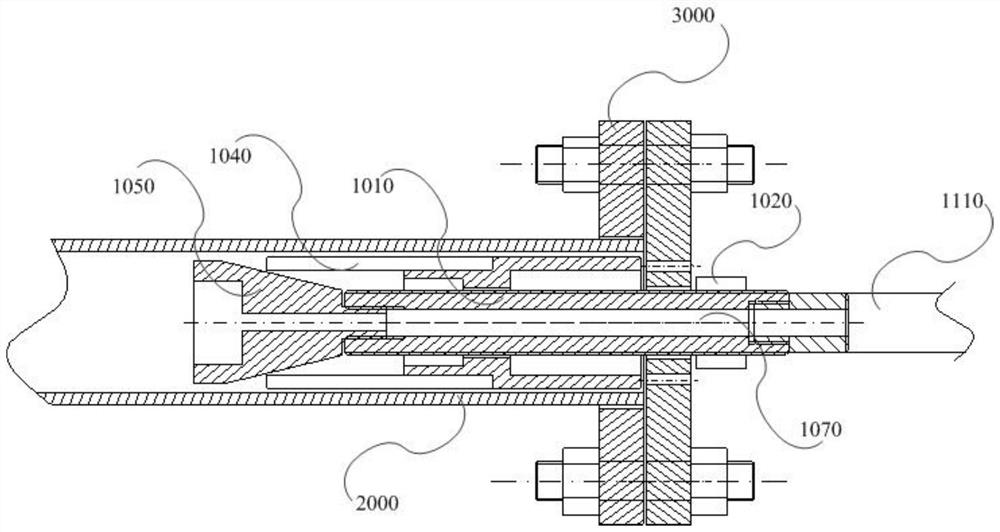

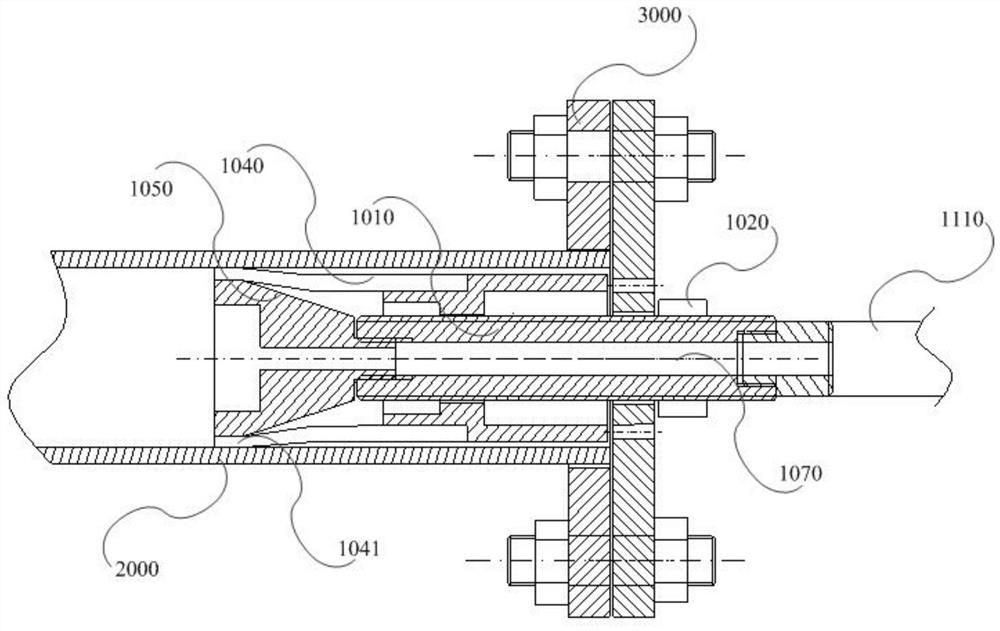

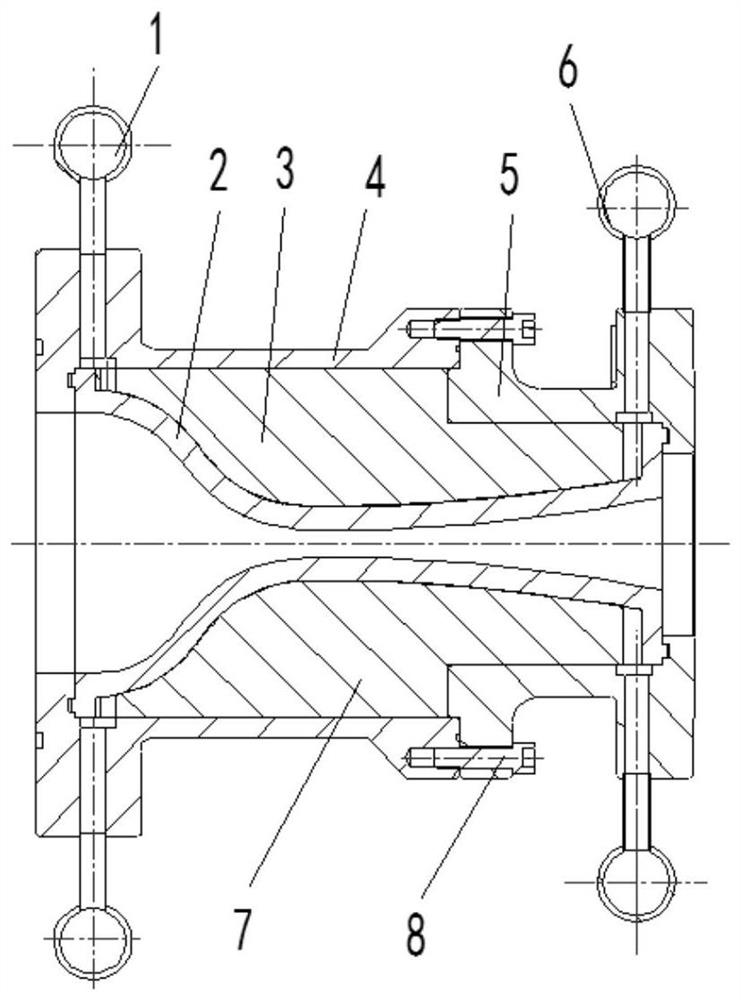

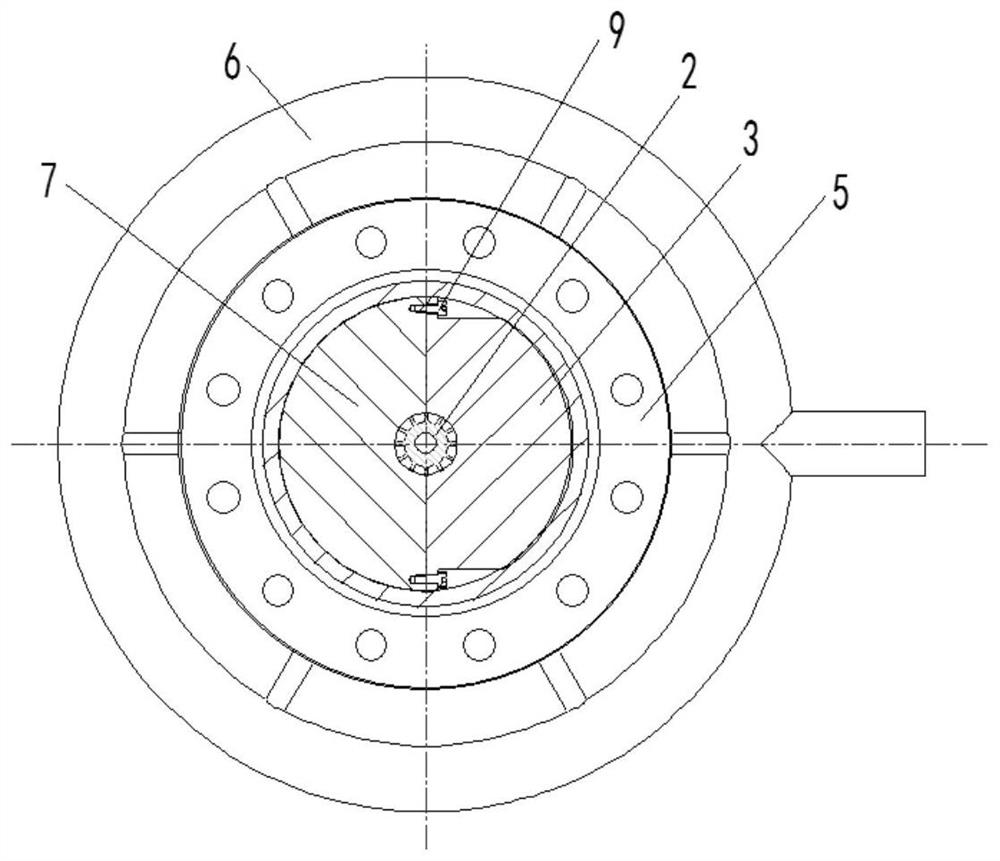

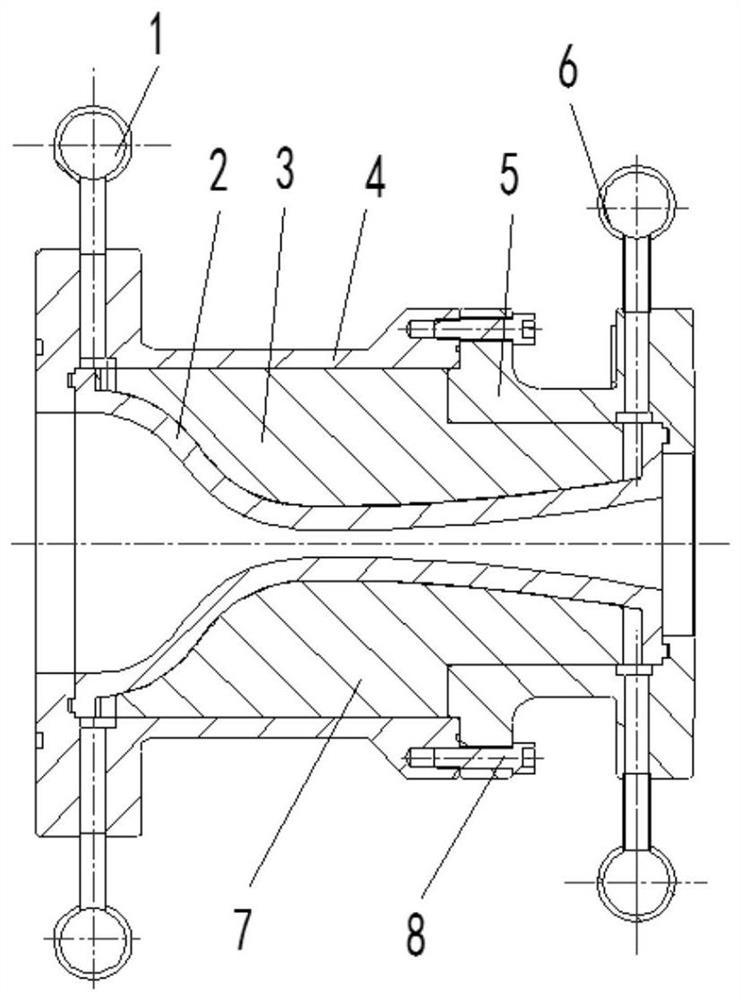

Structure of water-cooling throat of high-Mach-number molded surface spray pipe for hypersonic wind tunnel

ActiveCN112727860ASimple manufacturing processLow manufacturing costAerodynamic testingFluid dynamicsPhysicsMetal cylinder

The invention discloses a structure of a water-cooling throat of a high-Mach-number molded surface spray pipe for a hypersonic wind tunnel. The structure comprises a first water channel lining block and a second water channel lining block, wherein the first water channel lining block and the second water channel lining block are installed on the outer side of a throat inner shell and fixed to the throat inner shell through lining block connecting screws; a first outer shell and a second outer shell are combined to form the water-cooling throat section of the high-Mach-number spray pipe; the throat inner shell is an axisymmetric funnel-shaped metal cylinder; a water channel and a water channel separation rib are arranged outside the throat inner shell; and bosses used for sealing are arranged on the outer side faces of cylindrical tables at the two ends of the throat inner shell respectively. The throat section of the structure is of a full-assembly structure, a welding procedure is omitted, and the influence of welding residual stress on deformation of the throat section in the using process is eliminated; and the throat inner shell can be replaced, the maintenance cost after damage in the using process is reduced, the later machining period is shortened, and high-pressure and high-temperature sealing is reliable.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Full-automatic nut disassembly device

InactiveCN106737406ATroubleshoot disassemblySolve the replacement problemMetal-working hand toolsElectricityHydraulic cylinder

The invention discloses a full-automatic nut disassembly device. The full-automatic nut disassembly device is characterized by comprising a driving cylinder, a driving cylinder piston, a mounting frame, a mounting base, a mobile tool bit, a nut and a fixed tool bit, and further comprises a driving device, a mounting fixed device and a disassembly device; the driving device is the driving cylinder; the driving cylinder can be a hydraulic cylinder or a pneumatic cylinder; a piston of the driving cylinder is fixedly connected with the mobile tool bit on the mounting base through the mounting frame; the mobile tool bit is movably mounted in the mounting base; the fixed tool bit is fixedly mounted at the other end of the mounting frame; and an operation station for nut disassembly is between the fixed tool bit and the mobile tool bit. The full-automatic nut disassembly device has the advantages of: no use of fire, no use of electricity, no damage of bolt screw threads, convenience, speediness, safety, and efficient solution of the disassembly and replacement difficulties of bolts and nuts.

Owner:康容榕

Replacement method for vertical mill main speed reducer in cement raw material grinding system

InactiveCN104607282AGuaranteed repair qualitySolve the replacement problemGrain treatmentsReducerReplacement method

The invention discloses a replacement method for a vertical mill main speed reducer in a cement raw material grinding system. The replacement method is characterized by comprising the following steps: (1) jacking up a grinding roller in a mill, installing a protective sleeve, drawing a cross central line in the mill, and aligning the intersection with the central point of a millstone; (2) marking longitudinal and transverse parting midpoints of the speed reducer on a foundation slab, and measuring a sealing gap between the speed reducer and a bottom plate of a material scraping bin, with 8 points on the uniform side (b);( / b) (3) removing attachment bolts for the millstone and the speed reducer; (4) uniformly jacking up the millstone by using three 200-ton hydraulic jacks; and (5) removing an anchor bolt of the speed reducer, filling the speed reducer with a rolling rod by using a jack and the like. The replacement method has the beneficial effects that as the key replacement technology for the mill main speed reducer is developed on the basis of making reference to the experience in installation of the main speed reducer, the technology well solves the difficulty of replacement of the raw material main speed reducer, ensures the maintenance quality of the vertical mill, shortens the construction period, and reduces the construction cost.

Owner:ANHUI WUHU CONCH CONSTR & INSTALLATION ENG

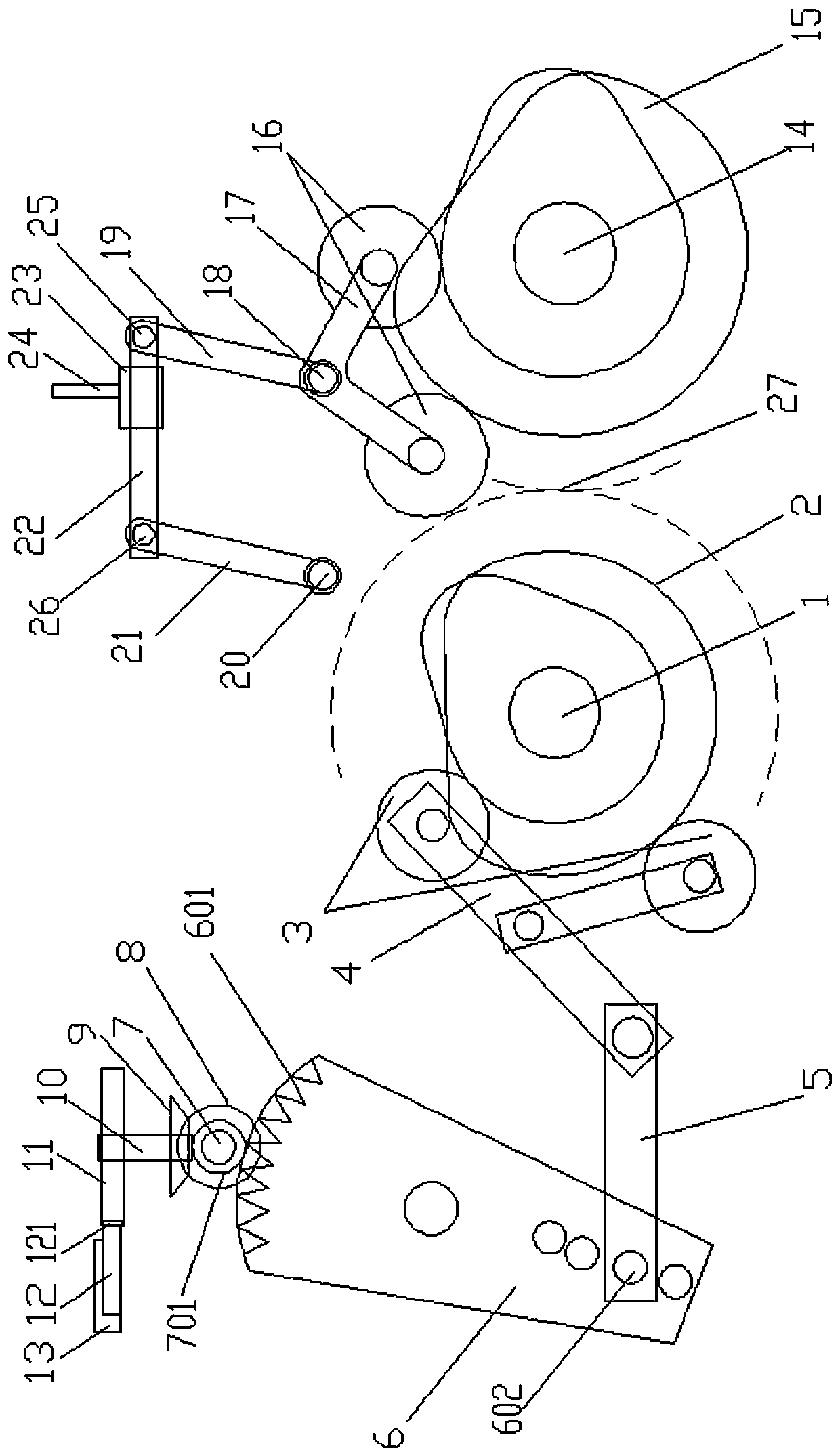

Parallel beating-up and weft insertion mechanism

The invention relates to a parallel beating-up and weft insertion mechanism. A beating-up driving swing arm is connected to a beating-up driving shaft in a penetrating mode; a beating-up fixed strokereciprocating mechanism drive is connected with the beating-up driving swing arm; a beating-up follow-up shaft and a beating-up driving shaft are respectively connected with the lower end of a beating-up follow-up swing arm and the lower end of a beating-up active reed pin in a penetrating mode; a connecting line of the beating-up driving shaft and the beating-up follow-up shaft, the beating-up active reed, the beating-up follow-up swing arm and a main follow-up swing arm connecting rod constitute a parallelogram; the main follow-up swing arm connecting rod is connected with a reed base with areed in a penetrating mode; a weft insertion fixed stroke reciprocating mechanism drive is connected with the lower end of a weft insertion gear arm via a weft insertion swing arm; an arc gear part on the upper part of the weft insertion gear arm is engaged with a gear part on a gear shaft; and the gear shaft is connected with a rapier fluted disc in a penetrating mode via an input bevel gear anda rapier drive shaft to drive the strip-shaped gear engagement on a rigid rapier in a rigid rapier track base. The mechanism can use fell weft insertion weaving and reed parallel beating-up, therebyeffectively simplifying a reed structure and the manufacturing cycle and cost, and conveniently achieving variety replacement.

Owner:JIANGSU YOUCHENG CNC TECH CO LTD

Method of quickly preparing aerogel by accelerating solvent extraction

The invention discloses a method of quickly preparing aerogel by accelerating solvent extraction. The method comprises the following steps of: (1) mixing and diluting a fixed quantity of inorganic silicon source and water, adding a fixed amount of acid to form salt-bearing silicasol, and obtaining gel after a period of time, (2) accelerating the solvent extraction of the gel obtained in step (1) with an organic solvent aqueous solution of which a concentration is increased with time, and (3) drying the gel obtained in step (2). The method of preparing the aerogel is simple in procedure, shortin production cycle and low in energy consumption, and the aerogel product has the characteristics of complete structure, low heat conductivity coefficient and high mechanical strength.

Owner:浙江岩谷科技有限公司

A structure for water-cooled throat of high Mach number surface nozzle in hypersonic wind tunnel

ActiveCN112727860BReduce deformation effectsSimple preparation processAerodynamic testingFluid dynamicsThroatWelding residual stress

The invention discloses a structure for a water-cooled throat of a high Mach number surface nozzle in a hypersonic wind tunnel, comprising a first water channel lining block and a second water channel lining block; the first water channel lining block and the second water channel lining block are installed On the outside of the throat inner shell, the first waterway lining block and the second waterway lining block are fixed on the throat inner shell through the lining block connecting screws; the combination of the first outer shell and the second outer shell forms the water-cooled throat section of the high Mach number nozzle; inside the throat The shell is an axisymmetric funnel-shaped metal cylinder, and the outside of the throat inner shell is provided with water channels and water channel dividing ribs, and the outer surfaces of the cylindrical platforms at both ends of the throat inner shell are respectively provided with bosses for sealing. The throat section of the structure adopts a fully assembled structure without welding process, which eliminates the influence of welding residual stress on the deformation of the throat section during use; the inner shell of the throat can be replaced, reducing the maintenance cost after damage during use , shorten the post-processing cycle, and the high-pressure and high-temperature seal is reliable.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Hydraulic ejection nut disassembly mechanism

InactiveCN106737405ASimple structureReduce volumeMetal-working hand toolsElectricityHydraulic cylinder

The invention discloses a hydraulic ejection nut disassembly mechanism. The hydraulic ejection nut disassembly mechanism is characterized by comprising a fixed mounting frame, a jacking driving cylinder, side columns, an extension piston, fixed bolts, fixed clamping blocks and a nut, and further comprises a fixed fixture, the fixed mounting frame and the jacking driving cylinder; the fixed mounting frame is U-shaped; the jacking driving cylinder is arranged in the middle position of the fixed mounting frame; the extension piston of the jacking driving cylinder is abutted against a nut core position; two fixed clamping blocks are located on two sides of the nut; the fixed clamping blocks are arranged on the inner sides of the side columns on two sides of the fixed mounting frame through the fixed bolts; and the driving cylinder can be a hydraulic cylinder or a pneumatic cylinder. The hydraulic ejection nut disassembly mechanism has the advantages of: simple structure, small size, convenience in carrying, no use of fire, no use of electricity, no damage of bolt screw threads, convenience, speediness, safety, and efficient solution of the disassembly and replacement difficulties of bolts and nuts.

Owner:梁芳歌

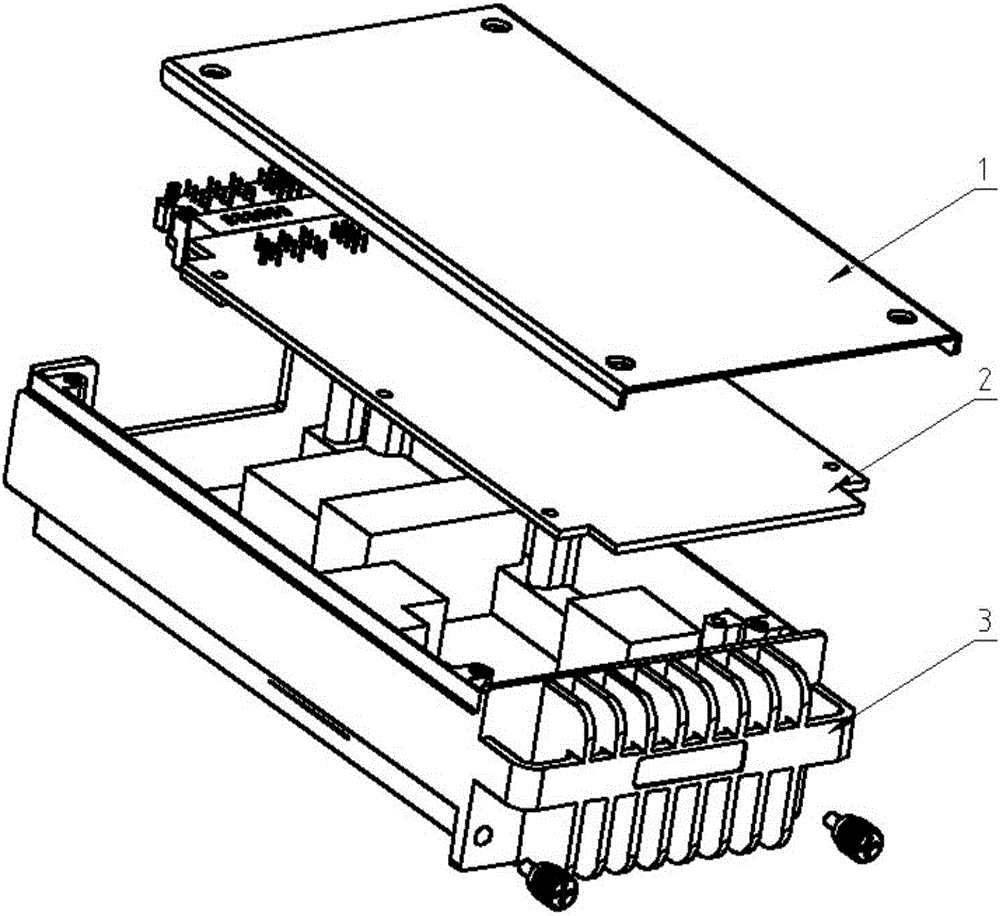

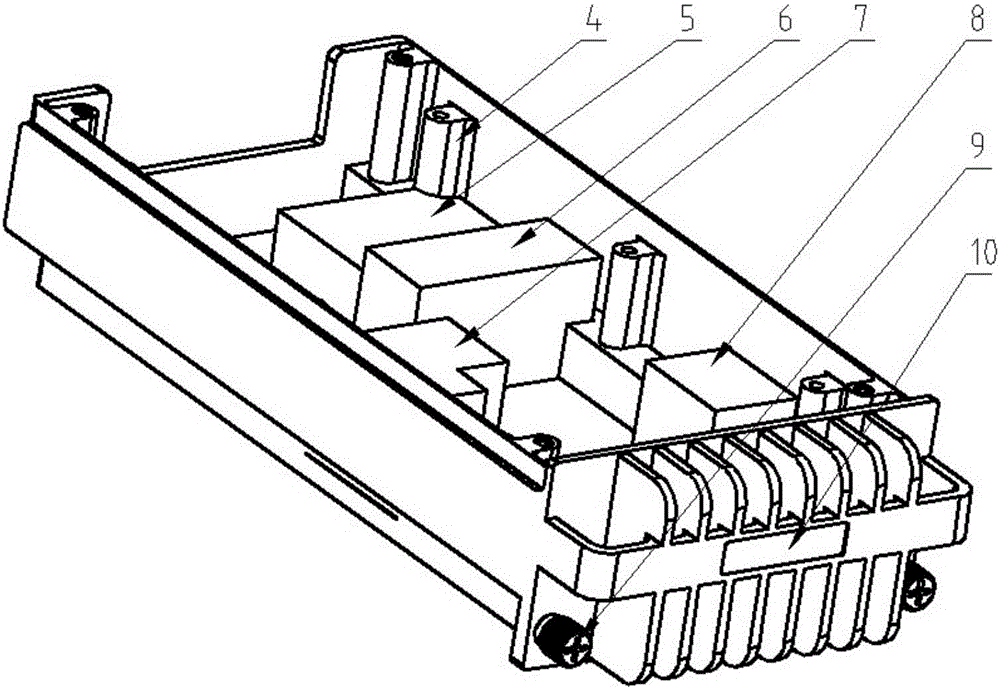

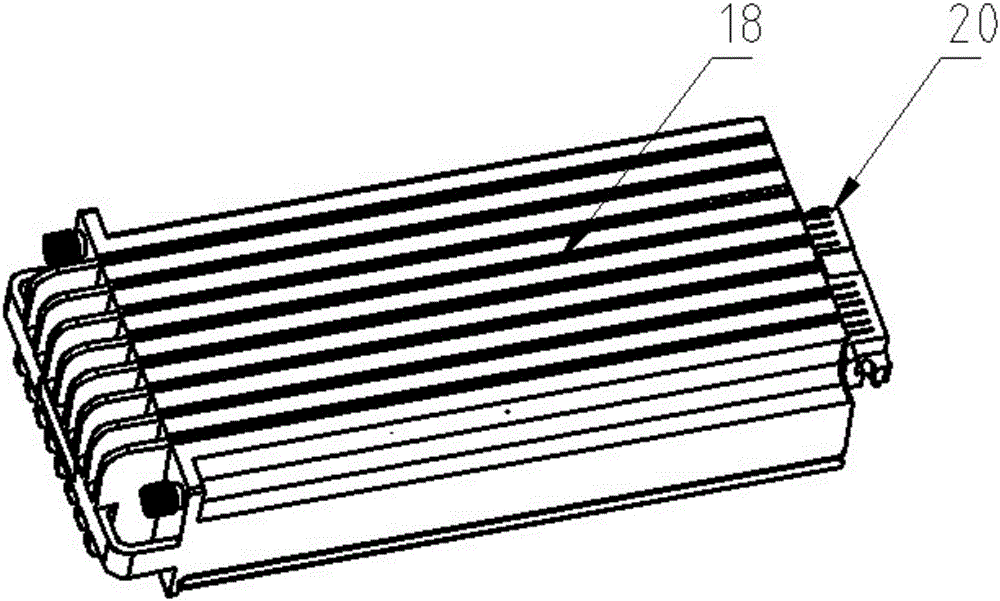

Plug-in heat dissipation power module

PendingCN107181392AEfficient conductionImprove cooling effectCooling/ventilation/heating modificationsPower conversion systemsThermodynamicsHeat conducting

The invention relates to a plug-in heat dissipation power module, the innovations of which are that the plug-in heat dissipation power module comprises a module cover plate, a PCB card and a module housing assembly, the PCB card is fixedly connected with the module housing assembly, and the module cover plate is fixedly connected with the module housing assembly; and the module housing assembly includes a module heat dissipation housing and a plurality of heat conducting blocks disposed in the module heat dissipation housing, and the PCB card is arranged above the plurality of heat conducting blocks. The invention provides a universal power module carrier, which can load a PCB card with various functions to facilitate realization and interchange of the various functions and is suitable for modular application.

Owner:CHANGZHOU BORI ELECTRIC POWER AUTOMATION EQUIP

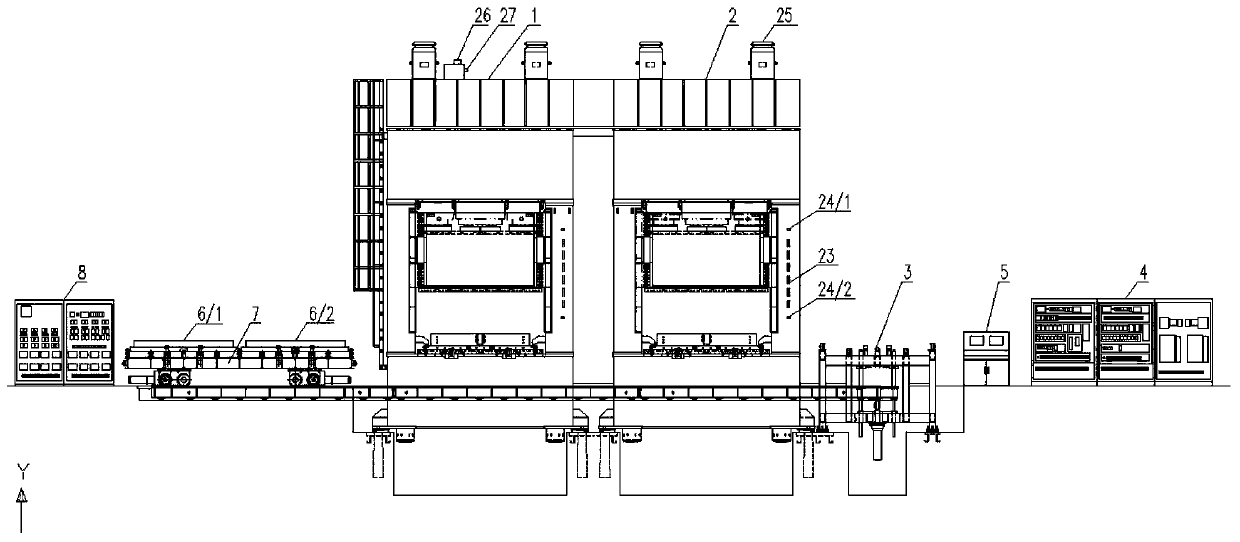

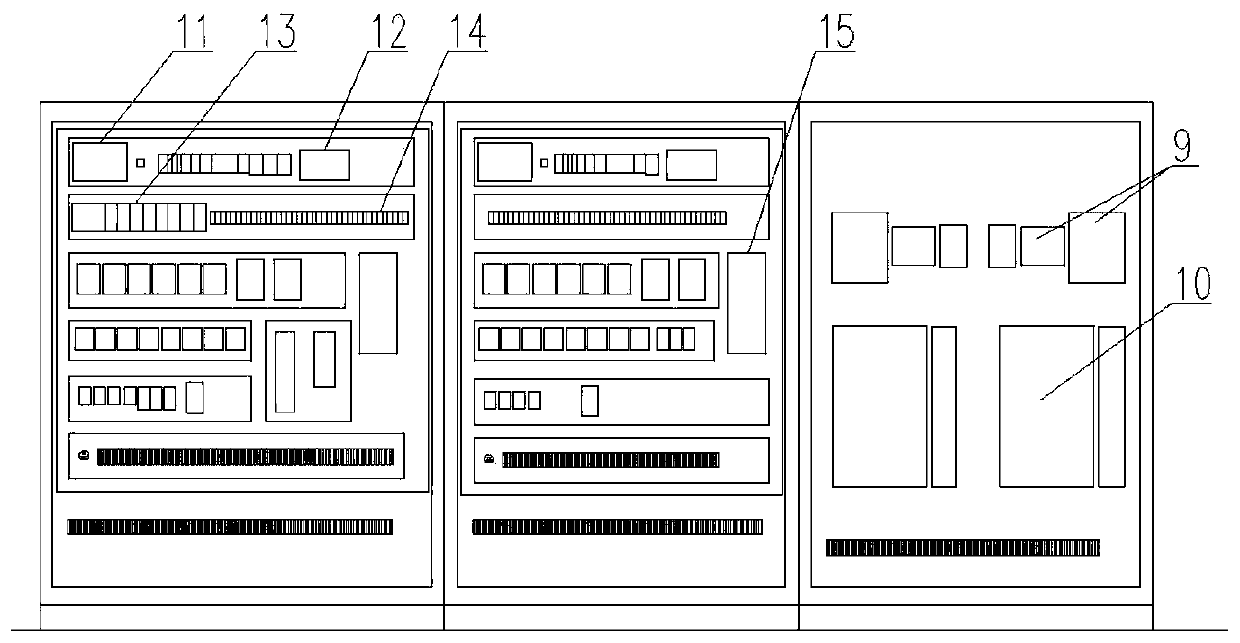

Electrical control system of multi-zone temperature and pressure follow-up control hydraulic machine

ActiveCN111399571AAvoid flawsAvoid damageSimultaneous control of multiple variablesFrequency changerCold formed

The invention discloses an electrical control system of a multi-zone temperature and pressure follow-up control hydraulic machine. The system comprises a hydraulic control electrical cabinet, a heating control electrical cabinet, an oil cooler, a thermal forming hydraulic machine body special for composite materials, a cold-forming hydraulic machine body special for composite materials, a composite material special demolding hydraulic machine, a composite material special hydraulic machine hydraulic station, a mold drawing trolley, a mold changing trolley, a piano type operation table, a centralized operation panel, a displacement sensor, a pressure sensor, an absolute value encoder, a PLC module installed in an electrical cabinet, an intermediate relay, an SEW frequency converter, an electromagnetic valve and a human-computer interface. In the whole process of molding and demolding of the composite material, according to the influence of the temperature on parameters and raw materials, the whole production process of the product is automated through the measures of partitioned heating, change of the heating temperature along with time and change of the pressure along with the temperature, and the percent of pass of the product is greatly improved.

Owner:HEFEI HAIDE HYDRAULIC PRESS

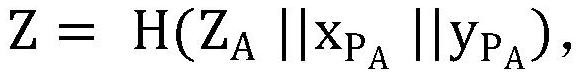

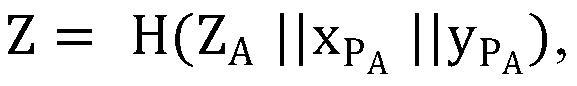

Key seed matrix and certificateless anti-collision key generation method based on matrix

PendingCN114065188AEasy key managementImprove efficiencyRandom number generatorsDigital data authenticationCryptosystemKey generation

The invention discloses a key seed matrix and a certificateless anti-collision key generation method based on the key seed matrix. The key generation method comprises the following steps: a key generation center generating a 200-bit random number; calculating a public key of the equipment part according to the random number; the key generation center calculating a ZA value according to the equipment identifier and the public key seed matrix, and calculating a Z value according to the ZA value and the partial public key of the equipment; selecting and adding eight elements according to the coordinate of the Z value mapped to the private key seed matrix to obtain an equipment identification private key, and calculating an equipment identification public key according to the equipment identification private key; the key generation center calculating an equipment complete public key according to the equipment identification public key, and calculating an equipment complete private key according to the random number and the equipment identification private key; and after the complete equipment public key and the complete equipment private key are obtained, the key generation center issuing the key pair to the equipment end through the secure channel. According to the method, the advantages of a combined public key technology and a certificateless cryptosystem are combined, and the problems between the combined public key technology and the certificateless cryptosystem are solved.

Owner:鄂尔多斯市迪曼森密码科技有限公司

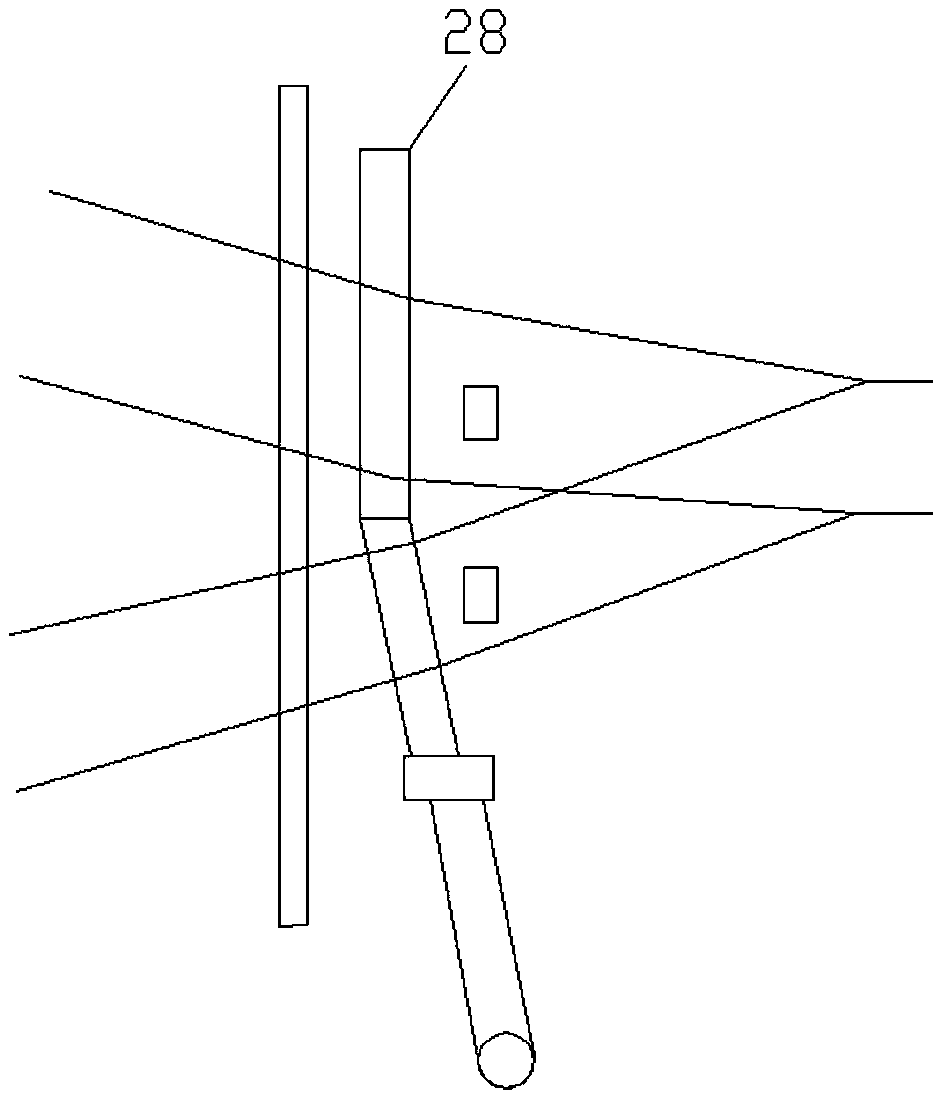

Replacement method of high-altitude vertical ripple compensator

InactiveCN107763304AShorten maintenance periodImprove maintenance efficiencyPipe laying and repairPipeline expansion-compensationEngineeringRapidity

The invention discloses a replacement method of a high-altitude vertical ripple compensator. The method comprises the steps of firstly, cutting a short section of a connecting pipeline below the high-altitude vertical ripple compensator, then cutting, so that the high-altitude vertical ripple compensator is separated from the upper connecting pipeline, removing the waste high-altitude vertical ripple compensator, manufacturing a circular installation platform outside a new high-altitude vertical ripple compensator at the same time, then lifting the new high-altitude vertical ripple compensatoron the line, welding the new high-altitude vertical ripple compensator with the upper connecting pipeline, and finally, backfilling and welding the short section of the connecting pipeline, so that the replacement purpose of the ripple compensator can be realized. According to the replacement method, the problem of replacing the high-altitude vertical ripple compensator without an overhaul platform at high altitude is solved, the overhaul period is shortened, the overhaul efficiency is improved, the labor intensity of maintenance workers is greatly reduced, the safety of the maintenance workers is effectively guaranteed in an overhaul process, and the replacement method has the advantages of rapidity and convenience in replacement, high safety, easiness in implementation and high practicability.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

nut cutter

ActiveCN103692148BTroubleshoot disassemblySolve the replacement problemPortable handheld shearing machinesMetal working apparatusHydraulic cylinderEngineering

The invention relates to a nut splitter, which comprises a main body frame, a hydraulic cylinder, a sliding block, a movable knife and a fixed knife, wherein the hydraulic cylinder is fixedly installed on the main body frame; the main body frame is provided with one pair of guide slots; two ends of the sliding block are matched with the guide slots and are respectively arranged in the guide slots; two ends of the sliding block can slide in the guide slots; the sliding block and the piston rod of the hydraulic cylinder are fixedly connected; the movable knife is fixedly connected with the sliding block; the fixed knife is fixedly installed on the main body frame. According to the nut splitter disclosed by the invention, fire and electricity are not used, bolt screw threads are not damaged, and therefore the difficulty of disassembling and replacing bolts and nuts can be conveniently, quickly, safely and efficiently solved.

Owner:上海瑞纽机械股份有限公司

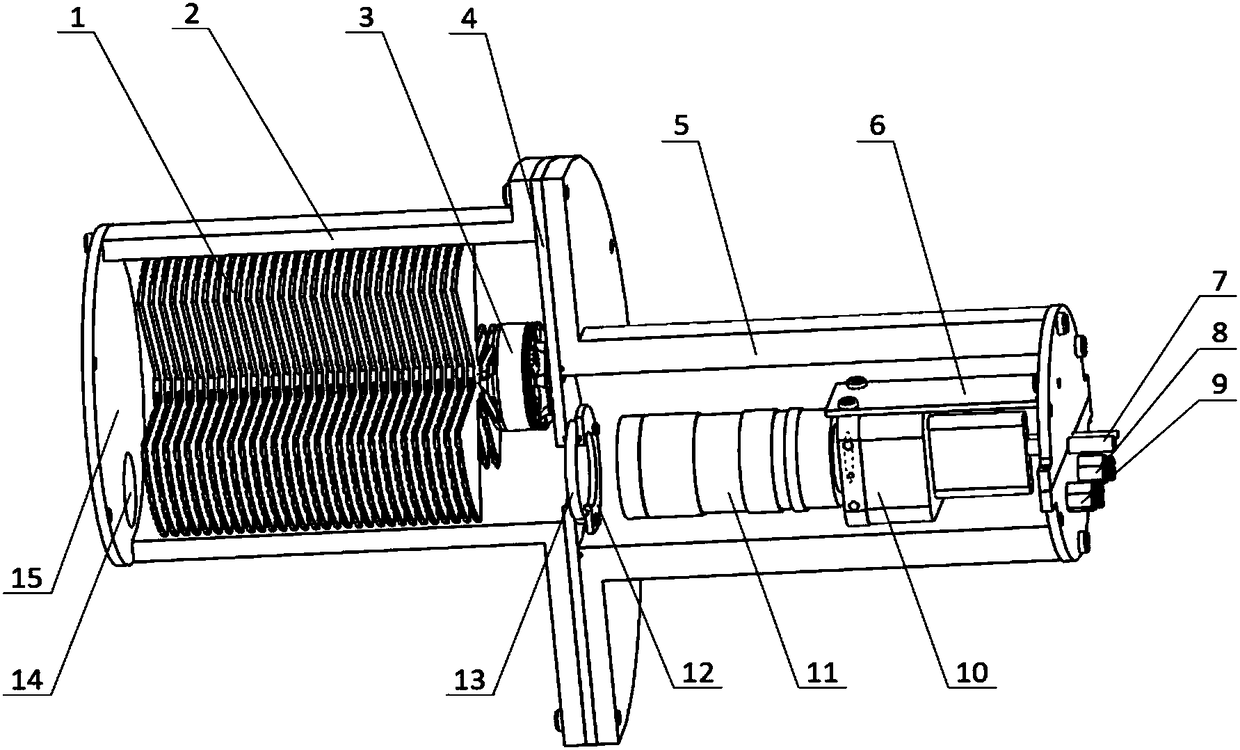

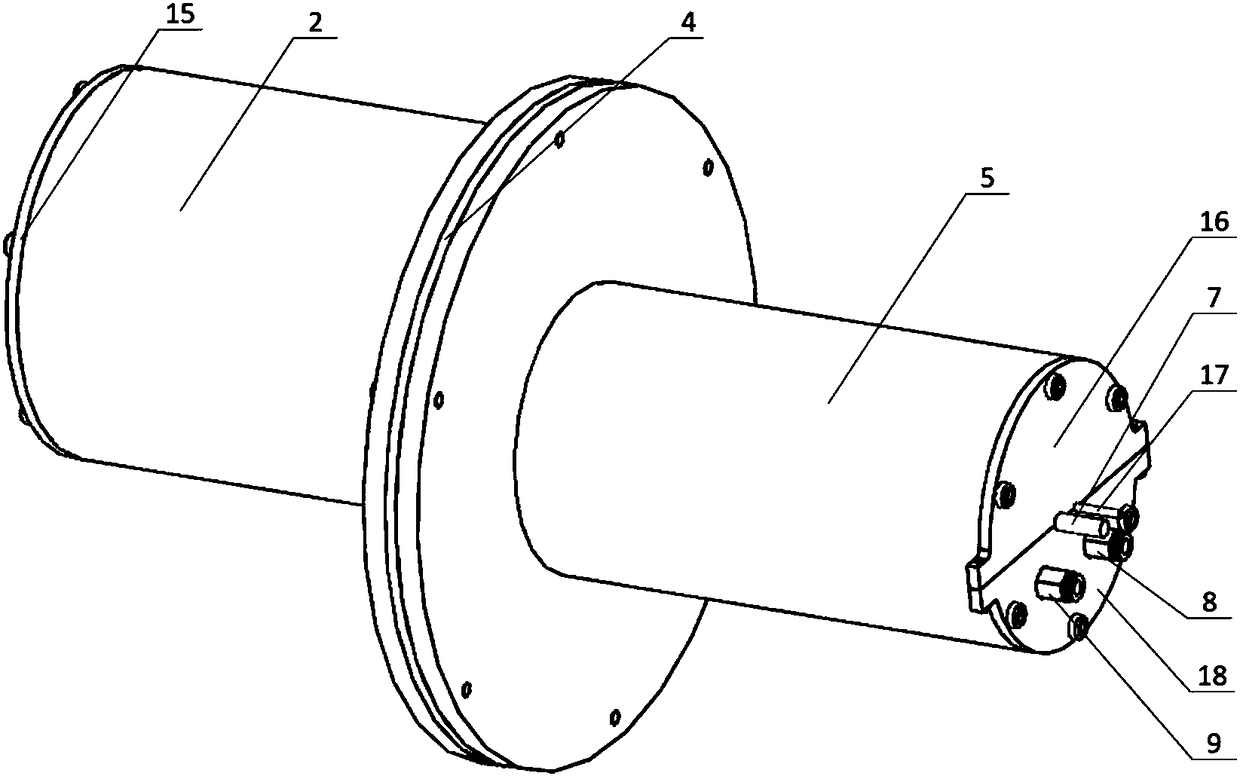

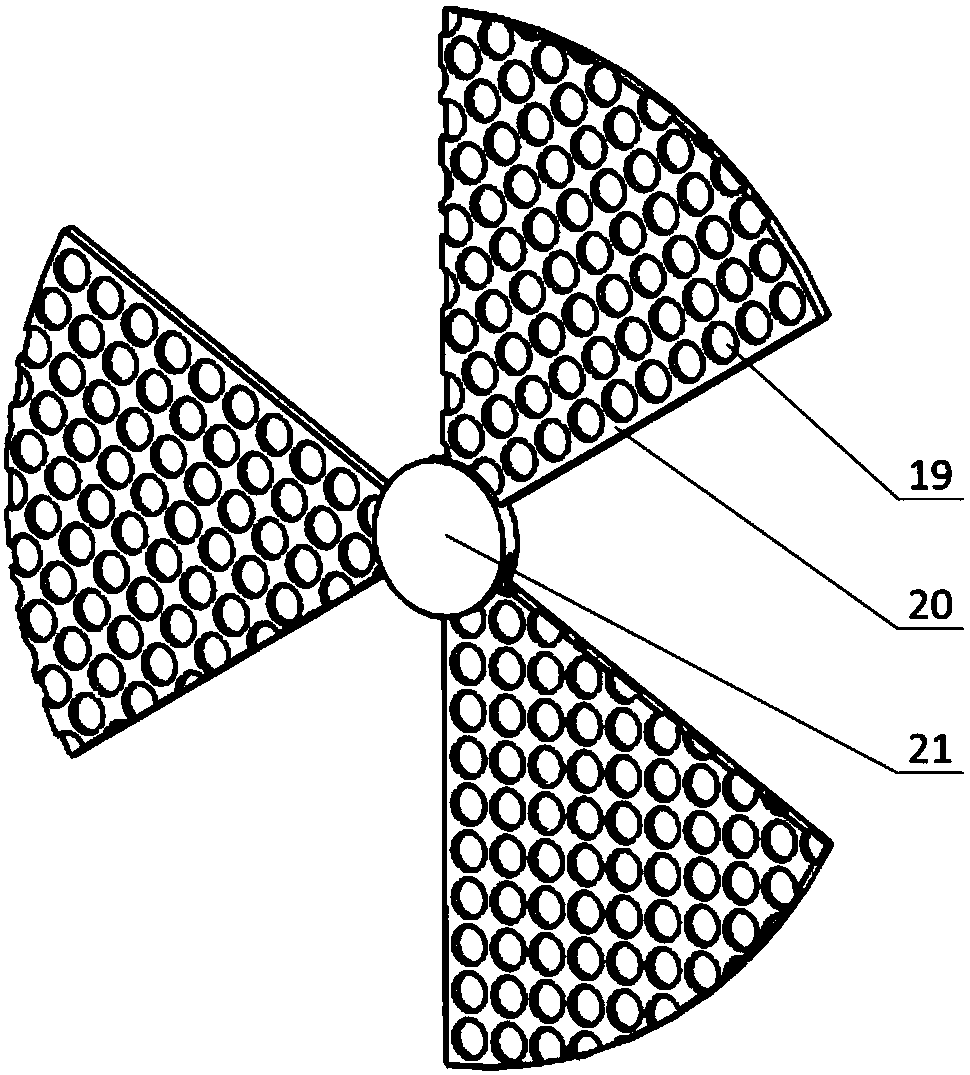

Electron beam forming and manufacturing visual monitoring system preventing metal vapor pollution

ActiveCN108174161AImprove adsorption capacityVisual monitoring worksTelevision system detailsColor television detailsVisual monitoringElectron beam machining

The invention relates to an electron beam forming and manufacturing visual monitoring system preventing metal vapor pollution, and belongs to the technical field of electron beam forming and manufacturing monitoring. The monitoring system comprises a metal vapor anti-pollution system, an optical observation system and a camera cooling sleeve; a motor is used to drive a group of adsorption fan blades to rotate at high speed to effectively adsorb the metal vapor generated during an electron beam processing process, so as to prevent the metal vapor from contaminating optical components in the visual monitoring system, thereby realizing the stable and reliable monitoring of the electron beam processing process. By controlling the exposure trigger time of an industrial camera in the visual monitoring system, synchronous imaging is performed when two adjacent fan blades successively pass through an optical axis of a lens, so as to prevent the fan blades from blocking a light path. The monitoring system is simple in structure and low in cost, and is suitable for performing effective visual monitoring on any processing process with stronger metal vapor pollution.

Owner:TSINGHUA UNIV

Method for rapidly preparing aerogel by accelerating solvent extraction in normal pressure

ActiveCN108862285ALow costSolve the replacement problemSilicon compoundsOrganic solventUltimate tensile strength

The invention discloses a method for rapidly preparing aerogel by accelerating solvent extraction in a normal pressure. The method comprises the following steps: (1) enabling a quantitative inorganicsilicon source to be mixed with water and diluting, adding quantitative acid, forming saliferous silica sol, and forming gel after a period of time; (2) performing accelerated solvent extraction on the gel obtained in the step (1) by using organic solvent water solution of which concentration is increased along with time; (3) performing the accelerated solvent extraction on the gel obtained in thestep (2) by mixed liquid of a water-containing organic solvent and an organosilicon compound; and (4) drying the gel obtained in the step (2) in the normal pressure. The provided method for preparingthe aerogel is simple in process, short in production period, and less in energy consumption. An aerogel product of the method has the characteristics of complete structure, low heat conductivity coefficient, and good mechanical strength.

Owner:浙江岩谷科技有限公司

Novel replacement structure for reinforced concrete through arch bridge suspender and replacement method thereof

ActiveCN111996930AReach the theoretical cable force valueGuaranteed unchangedBridge erection/assemblyBridge strengtheningBridge engineeringReinforced concrete

The invention discloses a novel replacement structure for a reinforced concrete through arch bridge suspender and a replacement method thereof, belongs to the technical field of bridge engineering, and aims to solve the problems that a single suspender of a reinforced concrete through arch bridge needs to be replaced by means of a temporary tensioning and dragging device, the bridge traffic needsto be interrupted, and time and labor are wasted. The structure comprises a suspender, an arch rib and a cross beam, the suspender is arranged between the arch rib and the cross beam, the suspender isa double-suspender component, the double-suspender component comprises a first anchor rod, a first cable distributing plate, a suspender unit, a second cable distributing plate and a second anchor rod which are sequentially arranged from top to bottom, a suspender anchor head is arranged between the suspender unit and the first cable distributing plate, and a screw sleeve is arranged between thesuspender unit and the second cable distributing plate. The method comprises primary replacement and secondary replacement. The suspenders can be replaced one by one through portable equipment, the stress reasonability of a bridge structure can be guaranteed, and great convenience is brought to cable replacement construction.

Owner:兰州交通大学工程检测有限公司

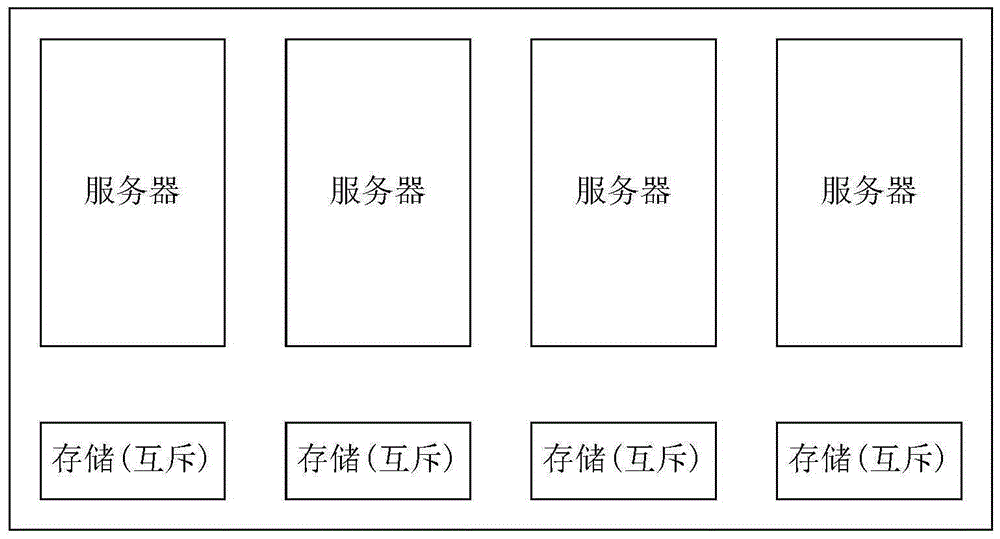

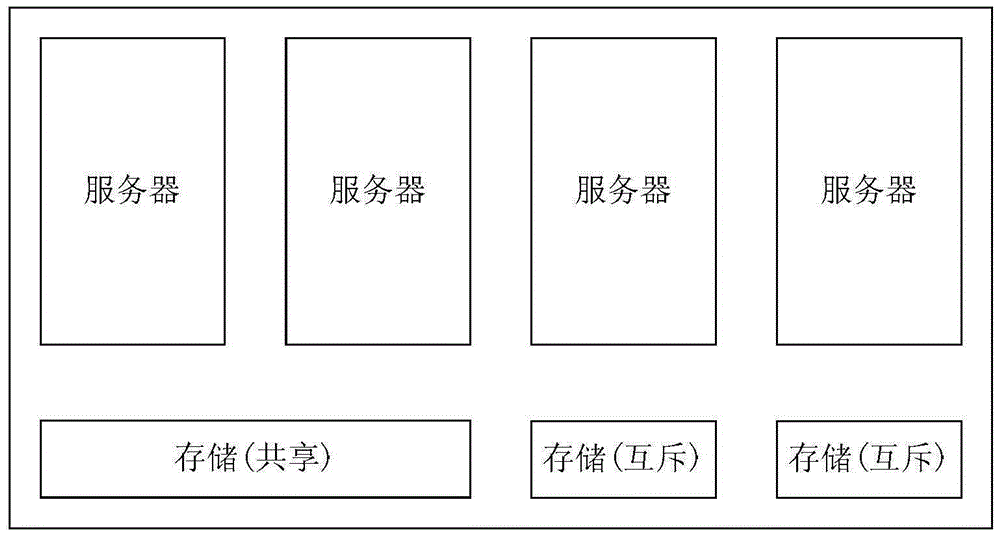

Multiple types of storage media coexistence system as well as method and apparatus for performing file operation

InactiveCN105183368ASolve the replacement problemLoad balancingInput/output to record carriersSpecial data processing applicationsOperating systemComputer hardware

The present invention provides a multiple types of storage media coexistence system as well as a method and an apparatus for performing a file operation. The multiple types of storage media at least comprise one or more first storage media and one or more second storage media. The method comprises: screening out a file that meets a thermalization trigger condition according to access statistic information of each file stored in the system; and periodically copying the file that meets the thermalization trigger condition, and if an absolute value of a difference value of predetermined performance parameters of the first storage media and the second storage media is greater than a preset threshold, preferentially copying the file that meets thermalization trigger condition to a predetermined storage medium with a high performance parameter . The present invention provides a file operation scheme applicable to the multiple types of storage media coexistence system.

Owner:ZTE CORP

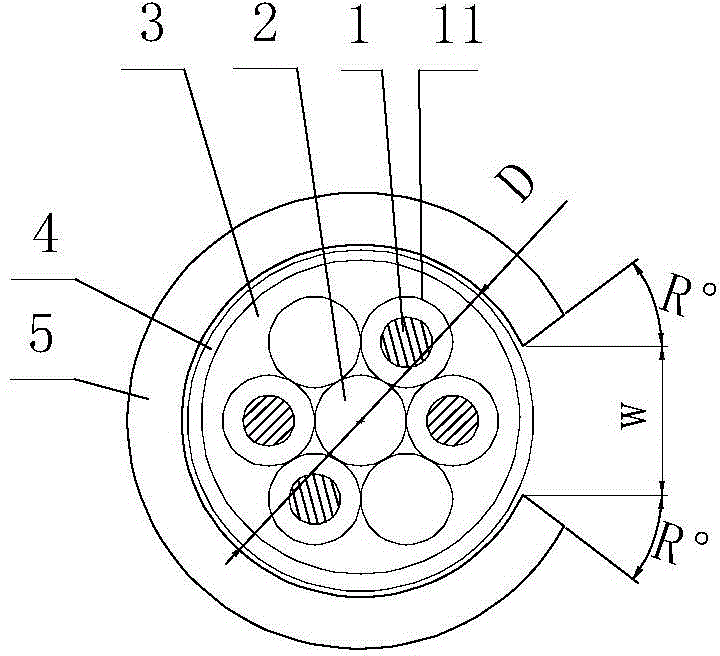

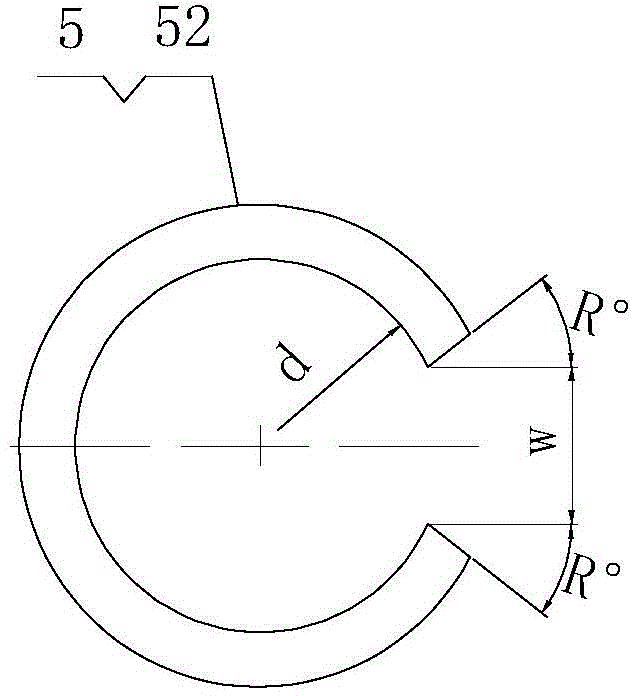

Calibration cable based on geological detection and application thereof

InactiveCN104464923ASolve the difficult problem of length calculationSimple structureFlexible cablesFlexible conductorsElectrical conductorNatural disaster

The invention provides a calibration cable based on geological detection and application of the cable. The cable comprises a cabled core composed of multiple conductors and a tensile strength component. A sheath layer is arranged outside the cabled core in an extruded mode, calibration rings are arranged on the sheath layer at an equal interval of L, the outer diameter of the sheath layer is D, the inner diameter of each calibration ring is d, and the surfaces of the calibration rings are red or of other marking colors and are made of rubber. According to the technical scheme, products are manufactured according to operation procedures of a manufacturing process, and a segment of the calibration cable is selected from the finished cable at will for detection. The calibration cable overcomes the defects that an existing detection cable has no calibration distance, and is not suitable for deep geological condition detection or cannot precisely finish geological detection tasks, the length of the cable needs to be designed and calculated when geological conditions of a certain depth are detected, the service life of the cable is influenced, and detection cost is increased. The calibration cable is especially suitable for being used on instruments and equipment for geological condition detection in places where earthquakes, debris flow, landslide and other natural disasters frequently occur.

Owner:湖南华菱线缆股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com