Replacement method of high-altitude vertical ripple compensator

A technology of corrugated compensator and replacement method, which is applied to expansion compensation devices for pipelines, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., to achieve the effects of strong practicability, safety assurance, and improved maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

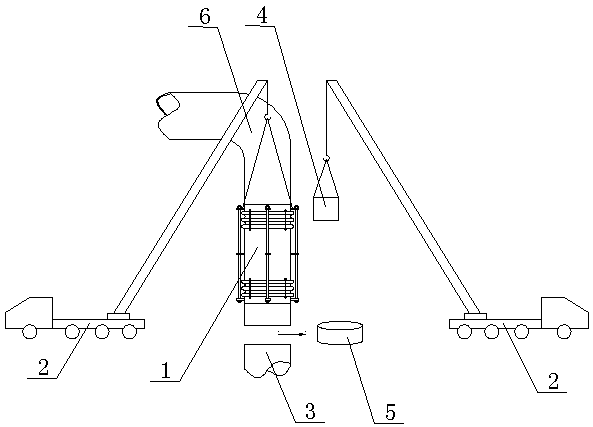

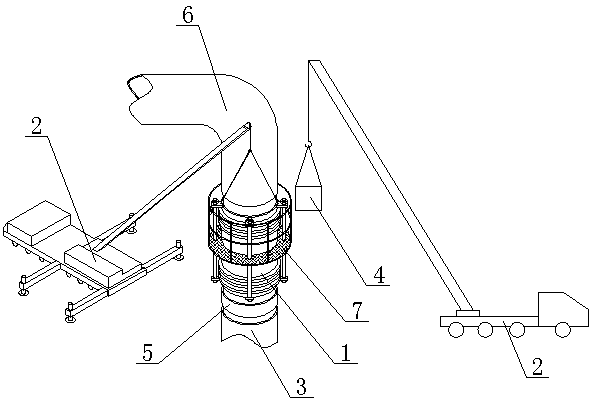

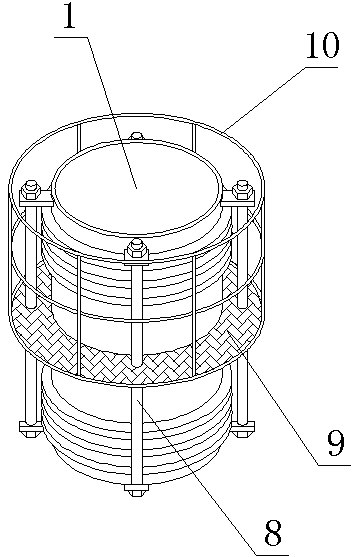

[0018] Such as Figure 1-3 As shown, a replacement method for a high-altitude vertical corrugated compensator includes the following steps:

[0019] A. Arrange cranes 2 on the open space on both sides of the high-altitude vertical corrugated compensator 1. The crane 2 is a truck crane. One crane 2 hangs the connecting pipe 3 connected to the lower end of the high-altitude vertical corrugated compensator 1. Another crane 2 Lift the cage 4 carrying the operator and make the cage 4 close to the connecting pipe 3 below. The operator uses gas welding to cut a pipe nipple 5 with a length of 450-550mm from the connecting pipe 3 below, and connects the pipe nipple 5 is drawn out, so that there is space when the high-altitude vertical corrugated compensator 1 is dismantled, hoisted and dropped.

[0020] B. Use one crane 2 to hang the lifting lugs on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com