Blast furnace soaking furnace examination and repair method

A technology for simmering furnaces and blast furnaces, which is applied in the field of simmering furnace maintenance for blast furnaces, can solve the problems of long time for resumption of production and long maintenance period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

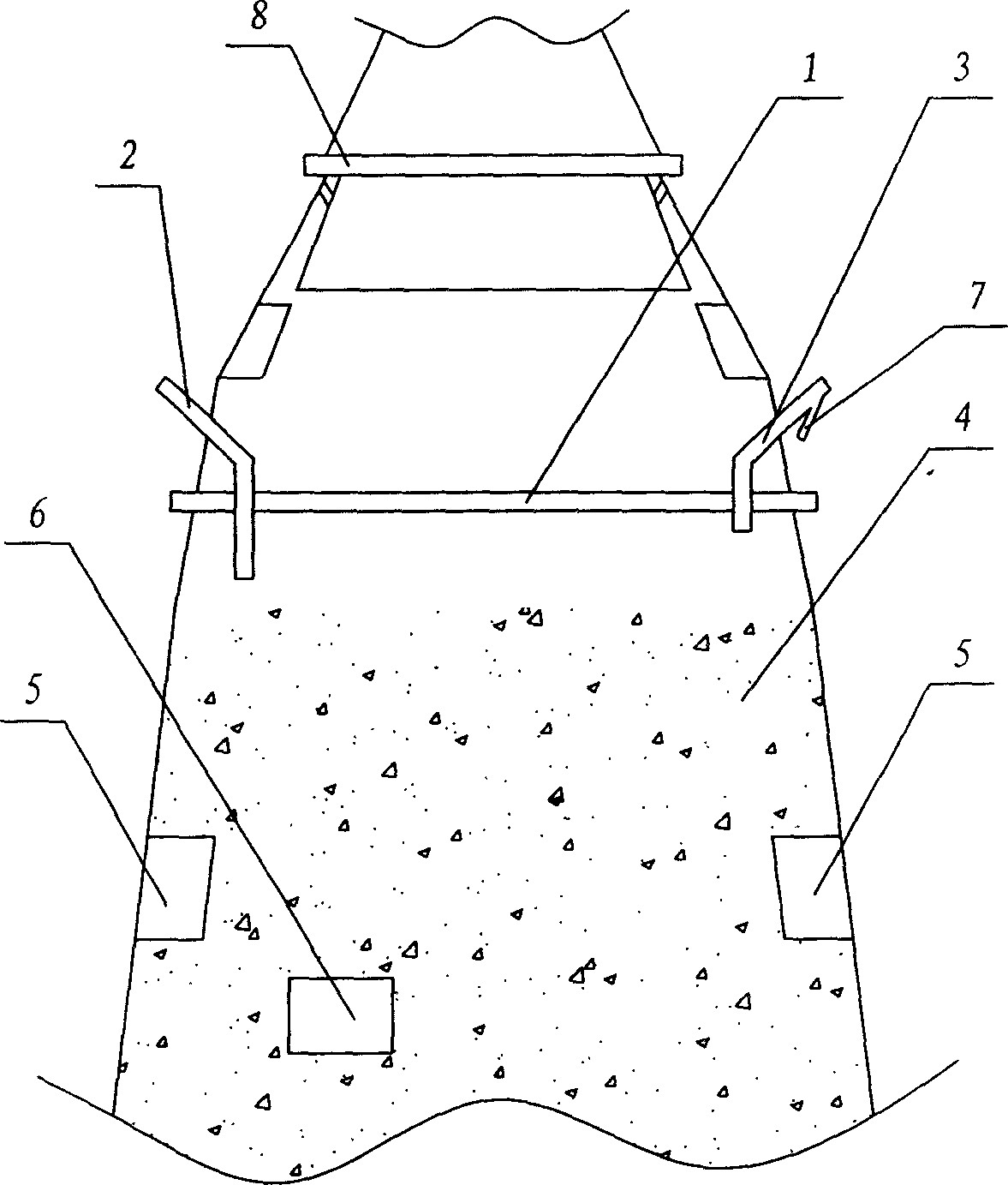

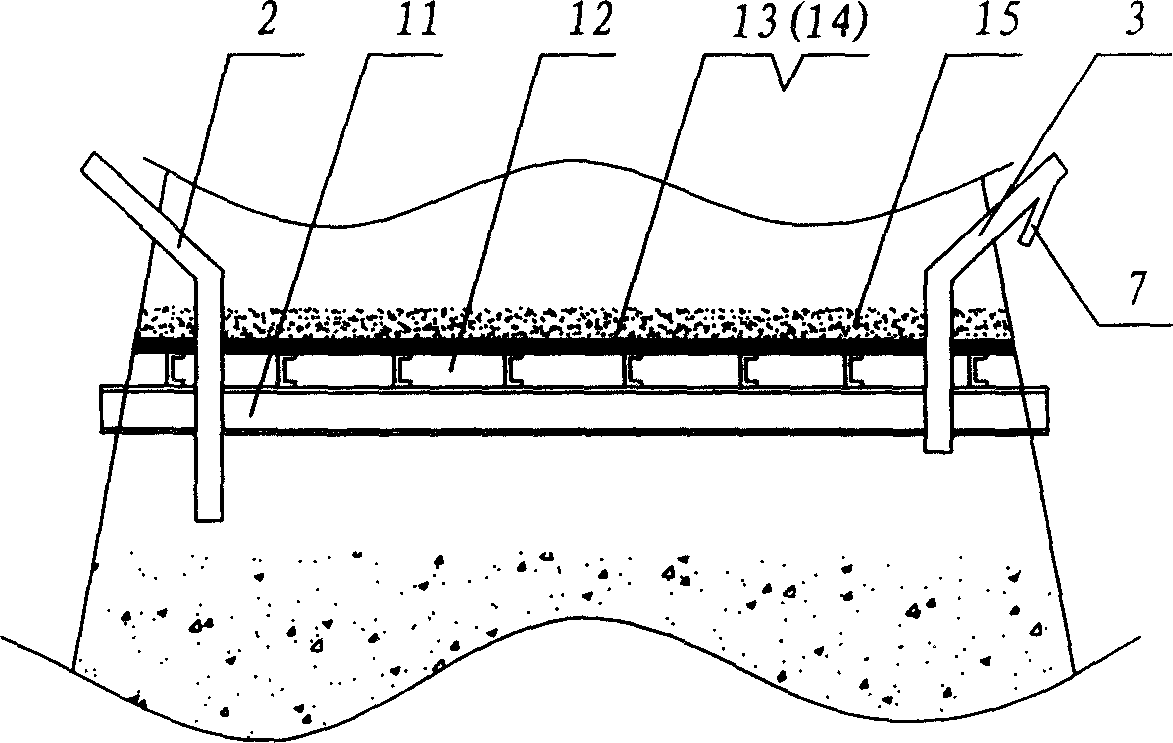

[0018] While implementing this method, you can refer to figure 1 , figure 2 , to help understand, where 1-working platform, 2-intake pipe, 3-outlet pipe, 4-burden material, 5-tuyere, 6-taphole, 7-compressed air pipe, 8-large flange of furnace top, 11 -I-beam support beam, 12-channel steel secondary beam, 13-steel plate, 14-asbestos cloth, 15 river sand.

[0019] Introduce in detail the concrete steps of blast furnace braising furnace maintenance method of the present invention below:

[0020] 1. First, determine the height of the material surface in the furnace so that the material surface in the furnace is 1.2-1.5 meters away from the bottom of the working platform to be built, and the height of the working platform is determined according to the maintenance site.

[0021] 2. When the furnace is not turned off and the wind is off, seal all the tuyere and taphole of the furnace with refractory mud.

[0022] 3. Open an access channel on the furnace wall for construction per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com