Centrifugal casting pouring unit

A technology of centrifugal casting and center position, applied in the field of centrifugal casting, can solve the problem of uneven laying of centrifugal casting pipes, and achieve the effect of improving quality and ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

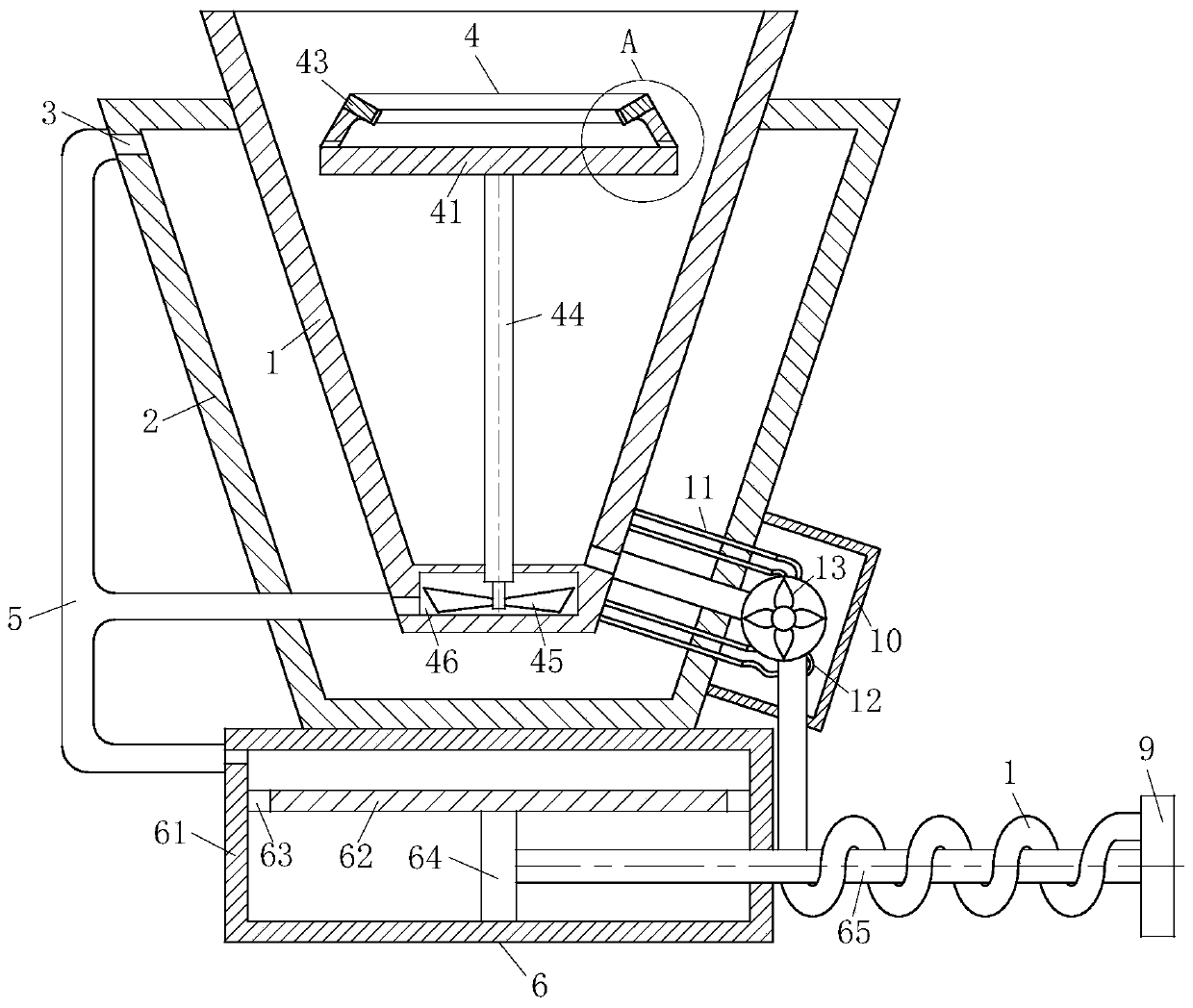

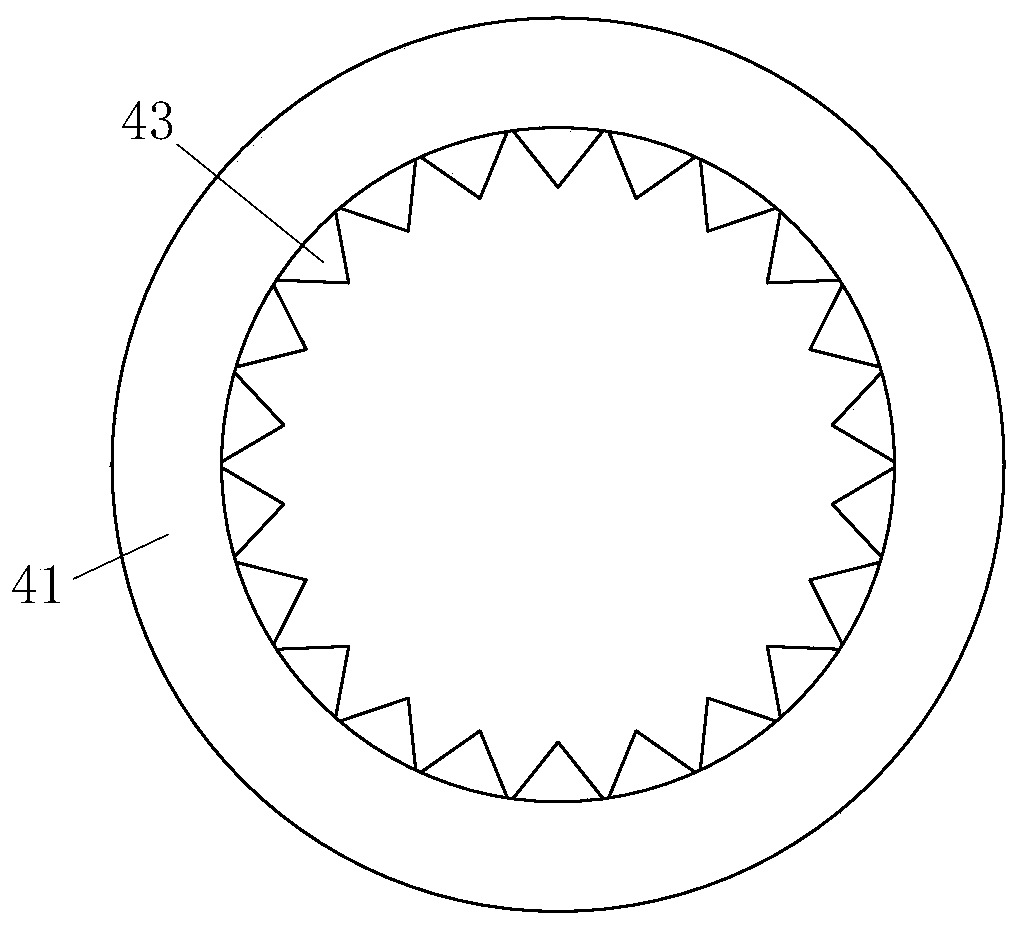

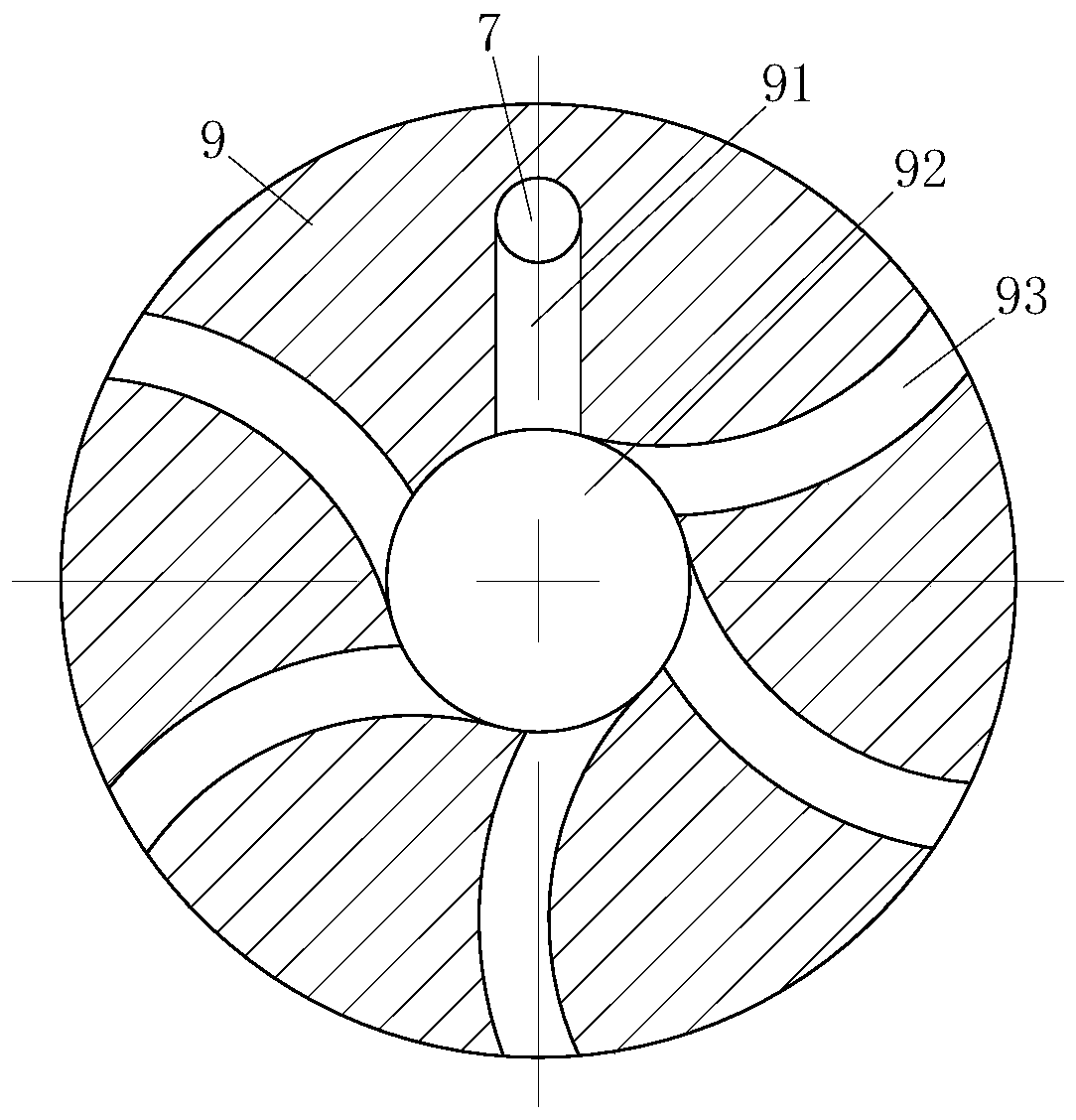

[0022] use Figure 1-Figure 5 A centrifugal casting pouring unit according to an embodiment of the present invention will be described as follows.

[0023] Such as figure 1 As shown, a centrifugal casting pouring unit according to the present invention includes an inner casting tank 1, an outer casting tank 2, a slag removal module 4 and a feeding module 6, and the inner casting tank 1 is fixedly connected to the inside of the outer casting tank 2 , the top height of the inner casting tank 1 is greater than the top height of the outer casting tank 2, and the outer casting tank 2 and the inner casting tank 1 are both unclosed and hollow at the top of a rounded platform structure; the bottom of the outer casting tank 2 is provided with a feeding Module 6, the feeding module 6 is used to send the casting liquid into the centrifugal casting tube; the feeding module 6 includes a feeding box 61, a partition 62, a piston 64 and a feeding rod 65, and the feeding box 61 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com