Dust generating device

A technology of dust generation and dust, which is applied in the direction of dissolution, mixer, gas/steam and solid mixing, etc., can solve the problems that the amount of dust generated is difficult to control, and the amount of dust generated cannot be guaranteed and consistent, and achieves high precision and reliable output. Controlling and precise effect of dust volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

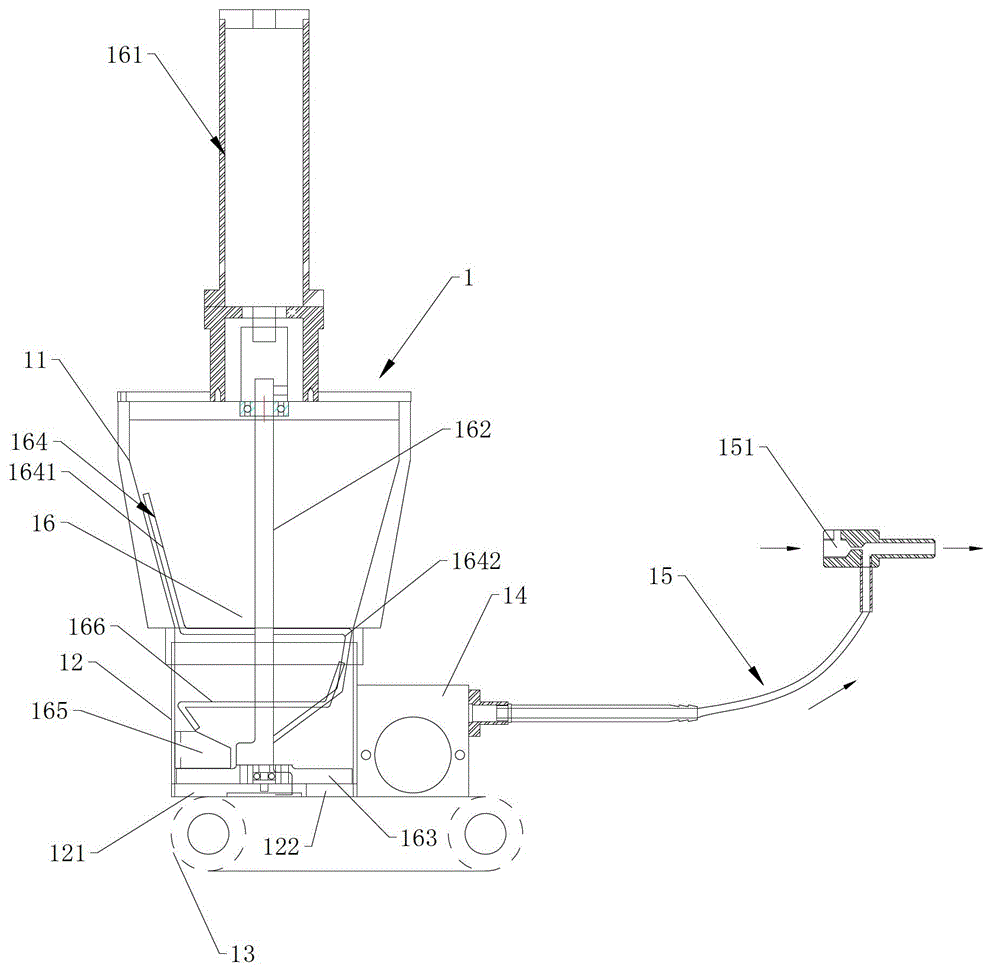

[0022] Such as figure 1 As shown, a dust generating device 1 includes a dust feeding hopper 11, a stirring output chamber 12, a belt conveying device 13, a dispersing reclaimer 14 and a dust outlet pipe 15. The dust feeding hopper 11 is detachably mounted on the stirring output The upper port of chamber 12 is convenient for installation and maintenance. The bottom plate 121 of the stirring output chamber 12 is provided with a discharge port 122, and the side wall of the stirring output chamber 12 is provided with a passage port communicating with the discharge port 122, wherein the bottom plate 121 is also detachably installed in the stirring output chamber 12 It can be seen that the bottom plate 121 can be selectively replaced according to the size of the discharge port 122, so as to ensure that the powder output is infinitely adjustable within a large numerical range. The du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com