Patents

Literature

328results about How to "Prevent suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

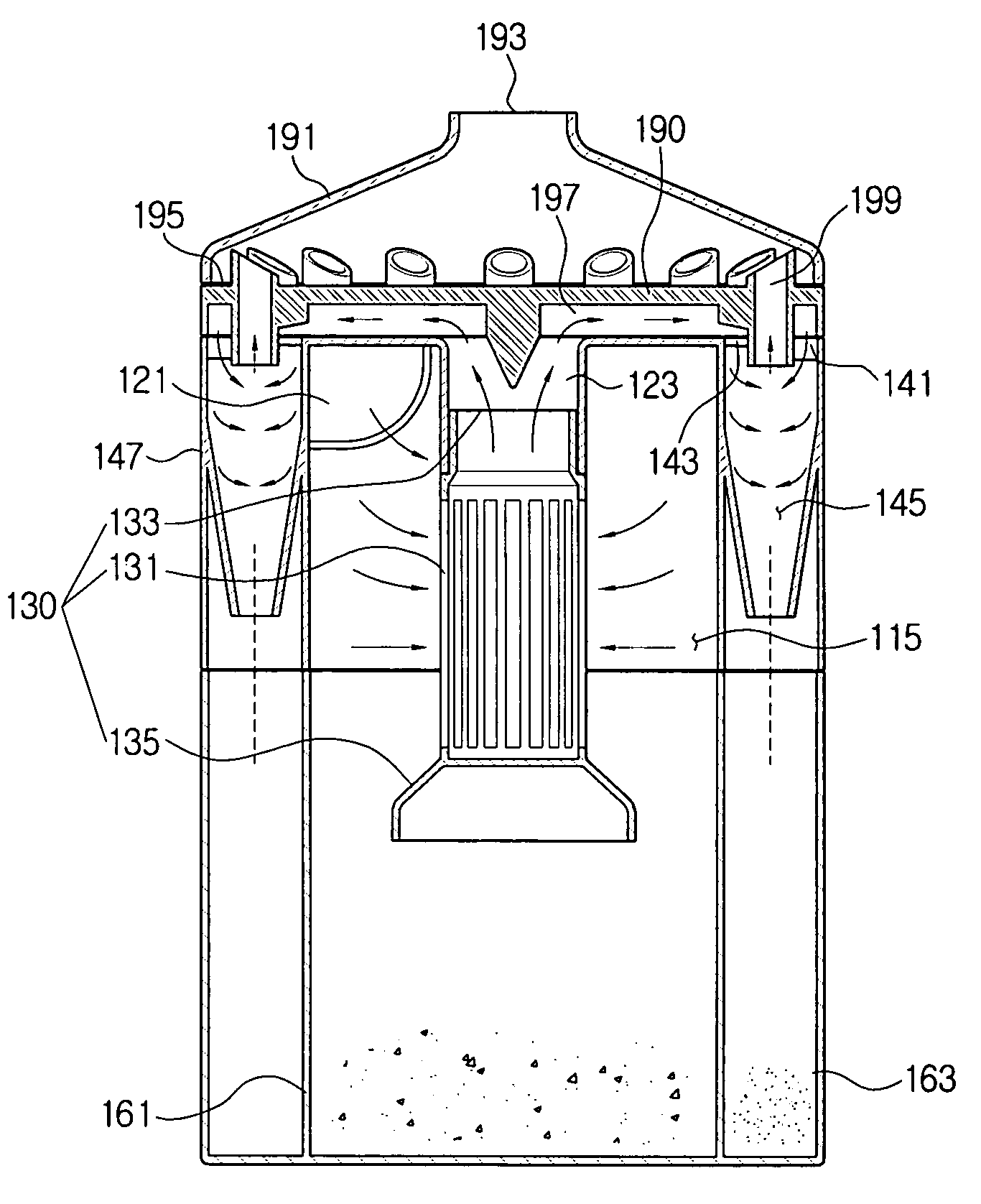

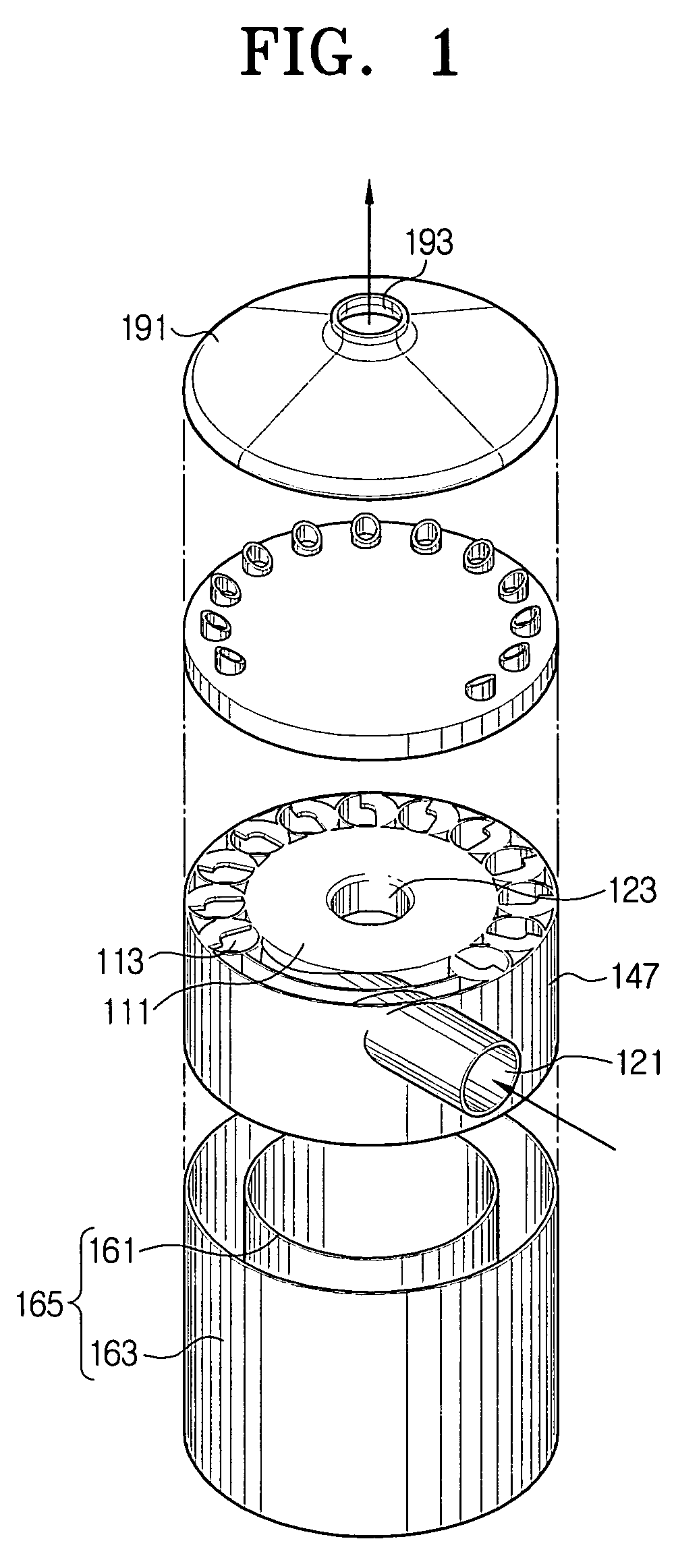

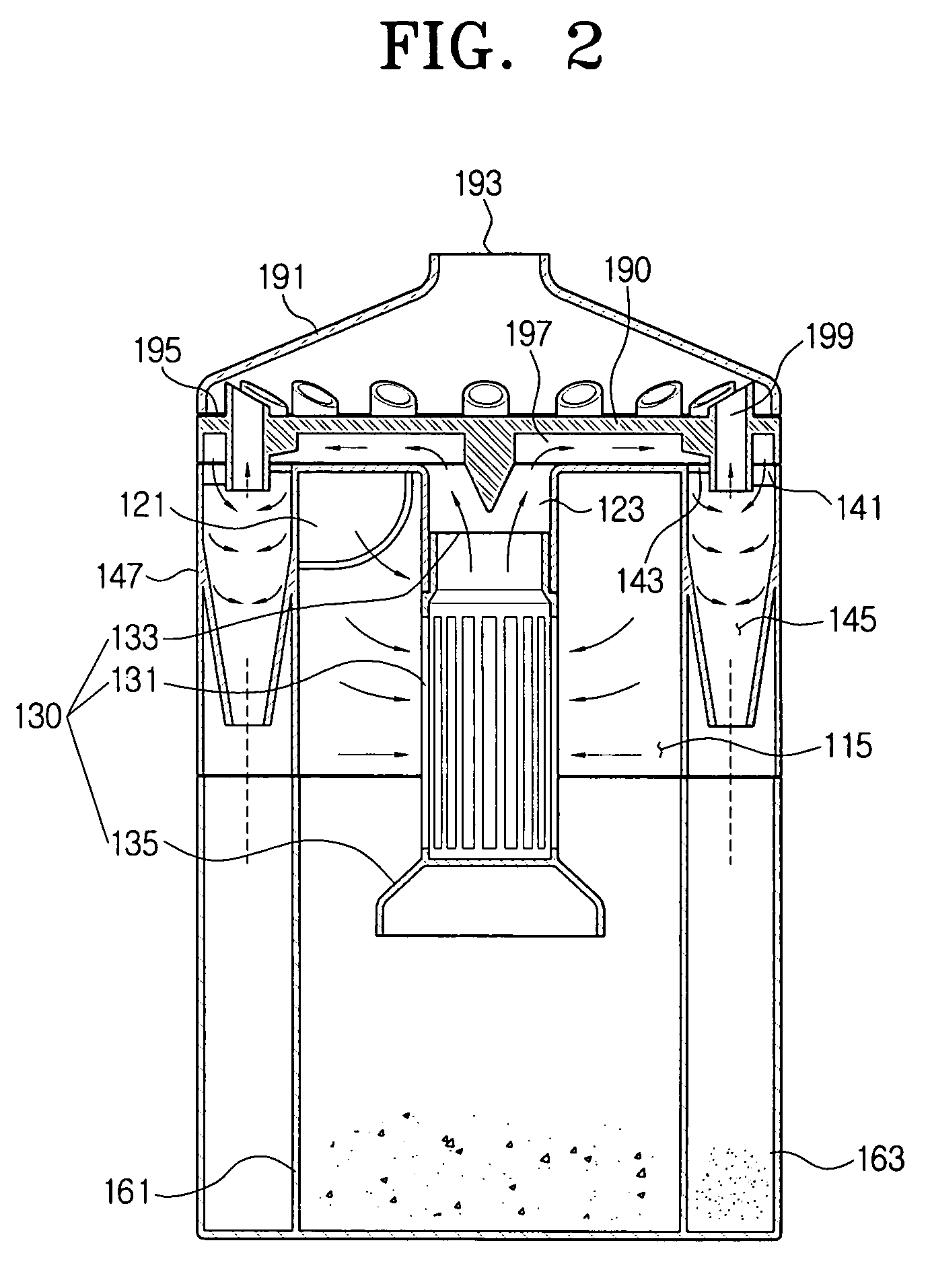

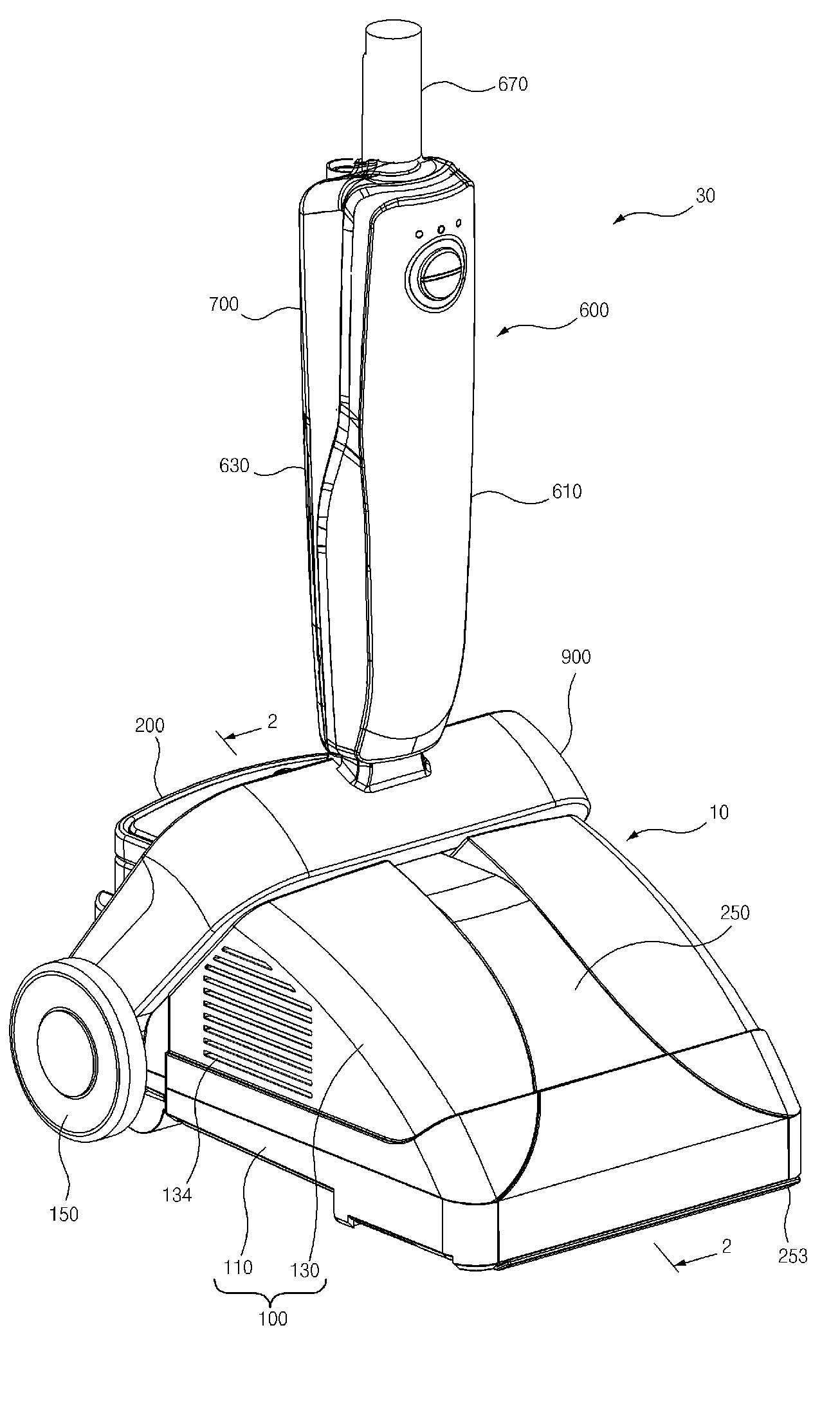

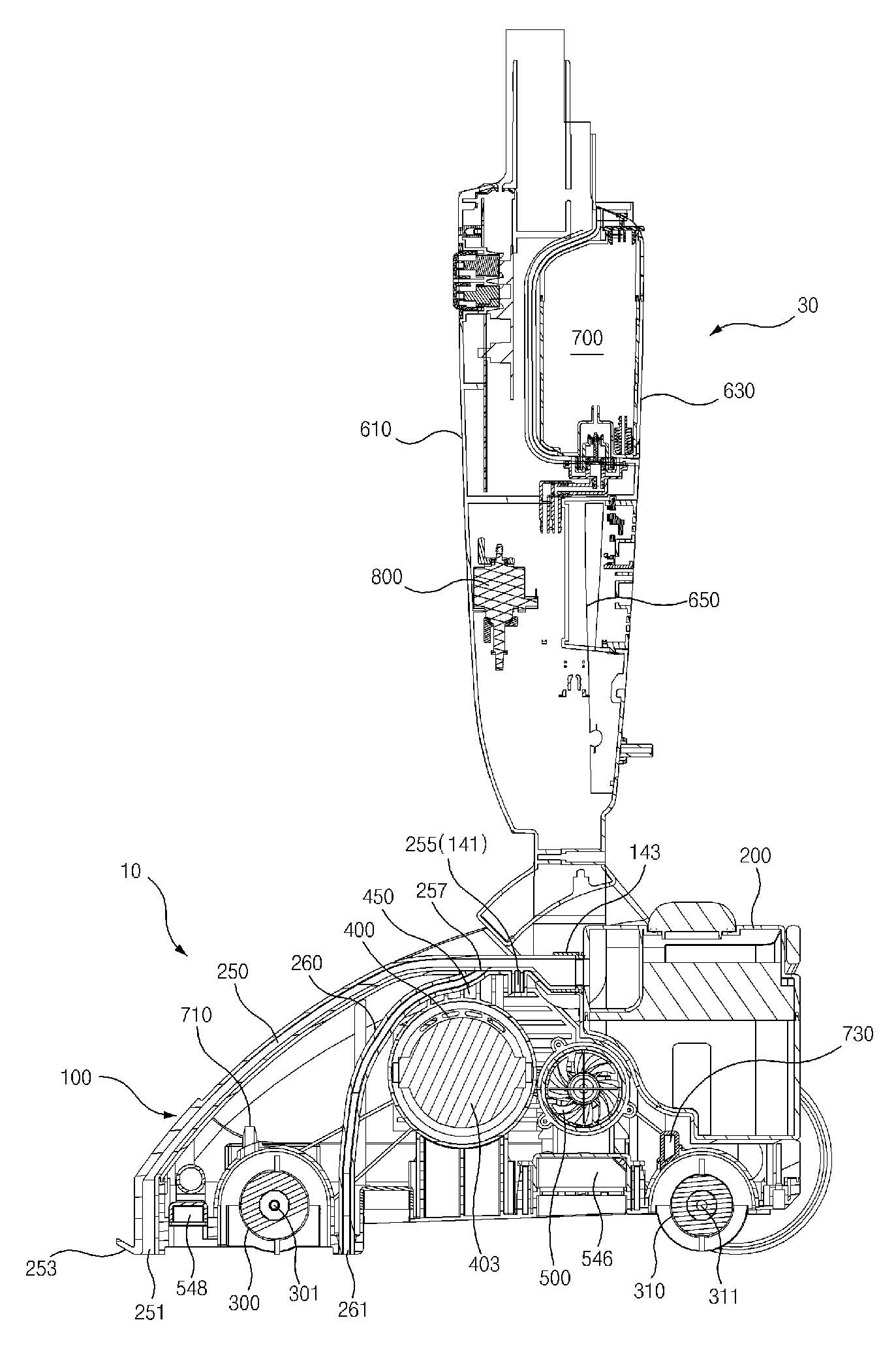

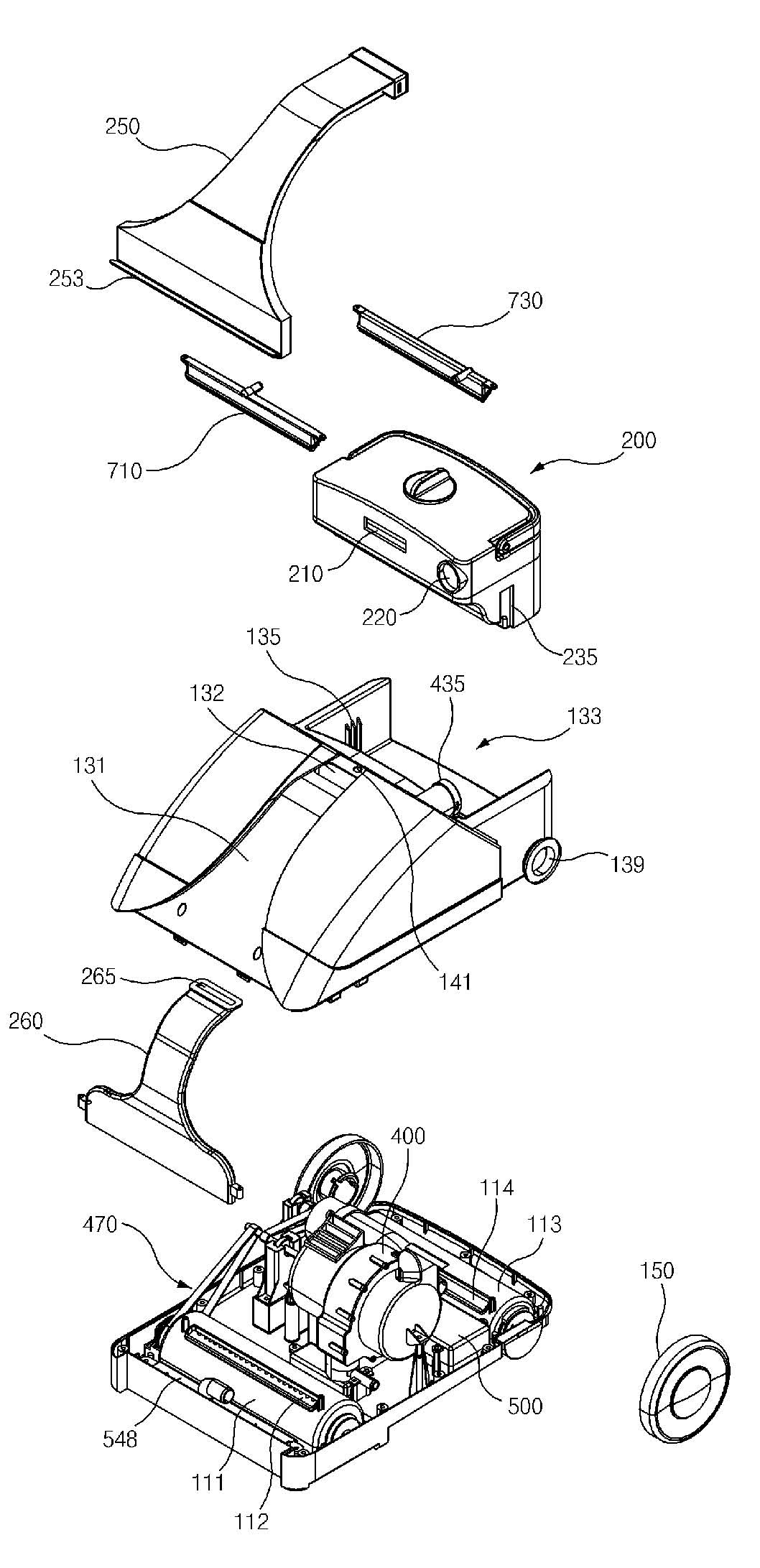

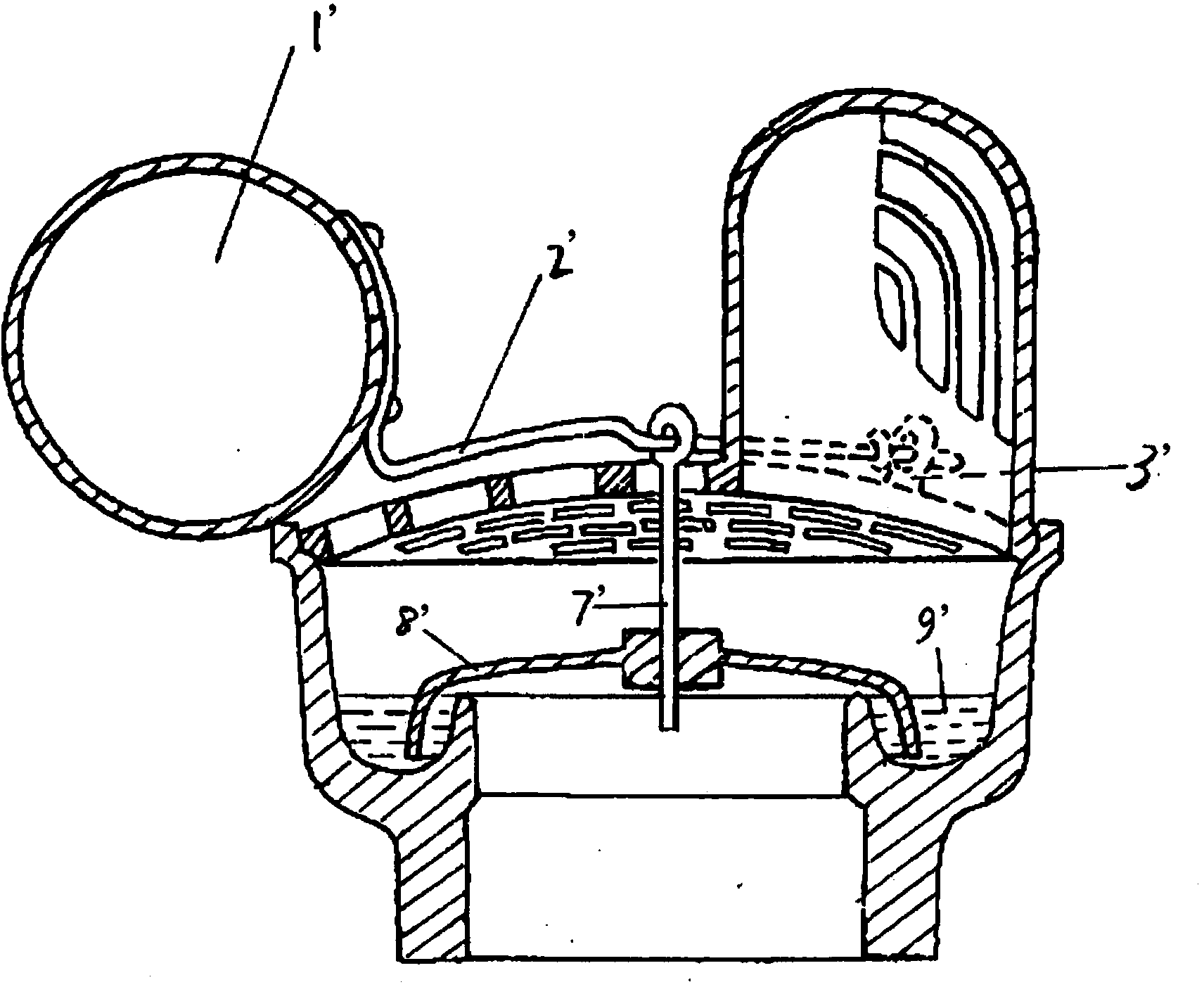

Cyclone dust separating apparatus and vacuum cleaner having the same

InactiveUS7361200B2Prevent suctionImprove efficiencyCleaning filter meansAuxillary pretreatmentCycloneSuction force

A cyclone dust separating apparatus and a vacuum cleaner with the same is disclosed. The cyclone dust separating apparatus includes a first cyclone for separating large dust particles from air, a plurality of second cyclones for separating minute dust particles from air via a centrifugal force after dust separation at the first cyclone, and a cover disposed on an upper portion of the first cyclone and the second cyclones. The cover includes a conical guide formed at a lower center to guide air discharged from the first cyclone into the second cyclones. Because drawn-in air is repeatedly cleaned by a plurality of cyclones, the cyclone dust separating apparatus can be provided with a compact structure, can provide an effective cleaning operation, and can prevent deterioration of a suction force.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

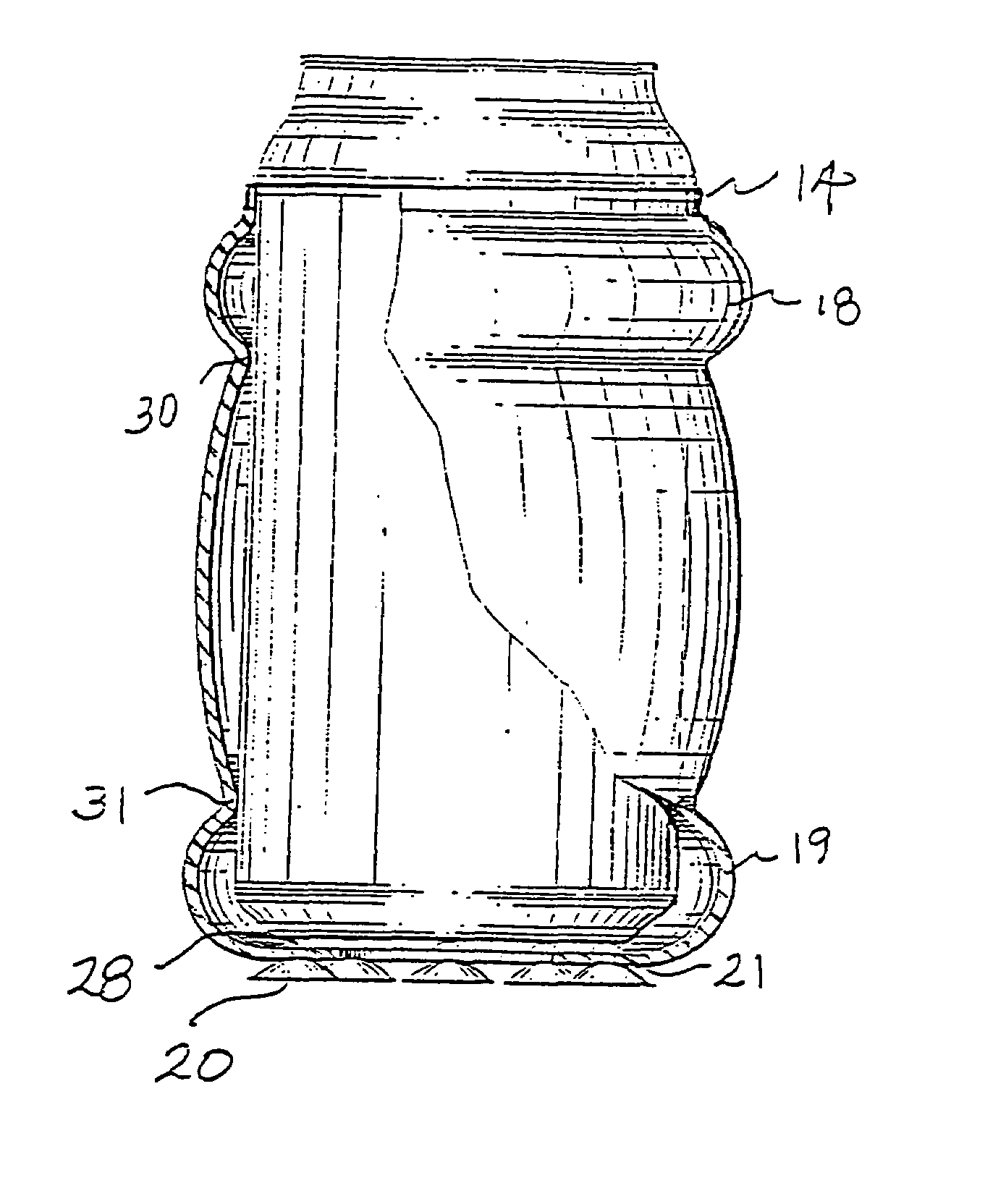

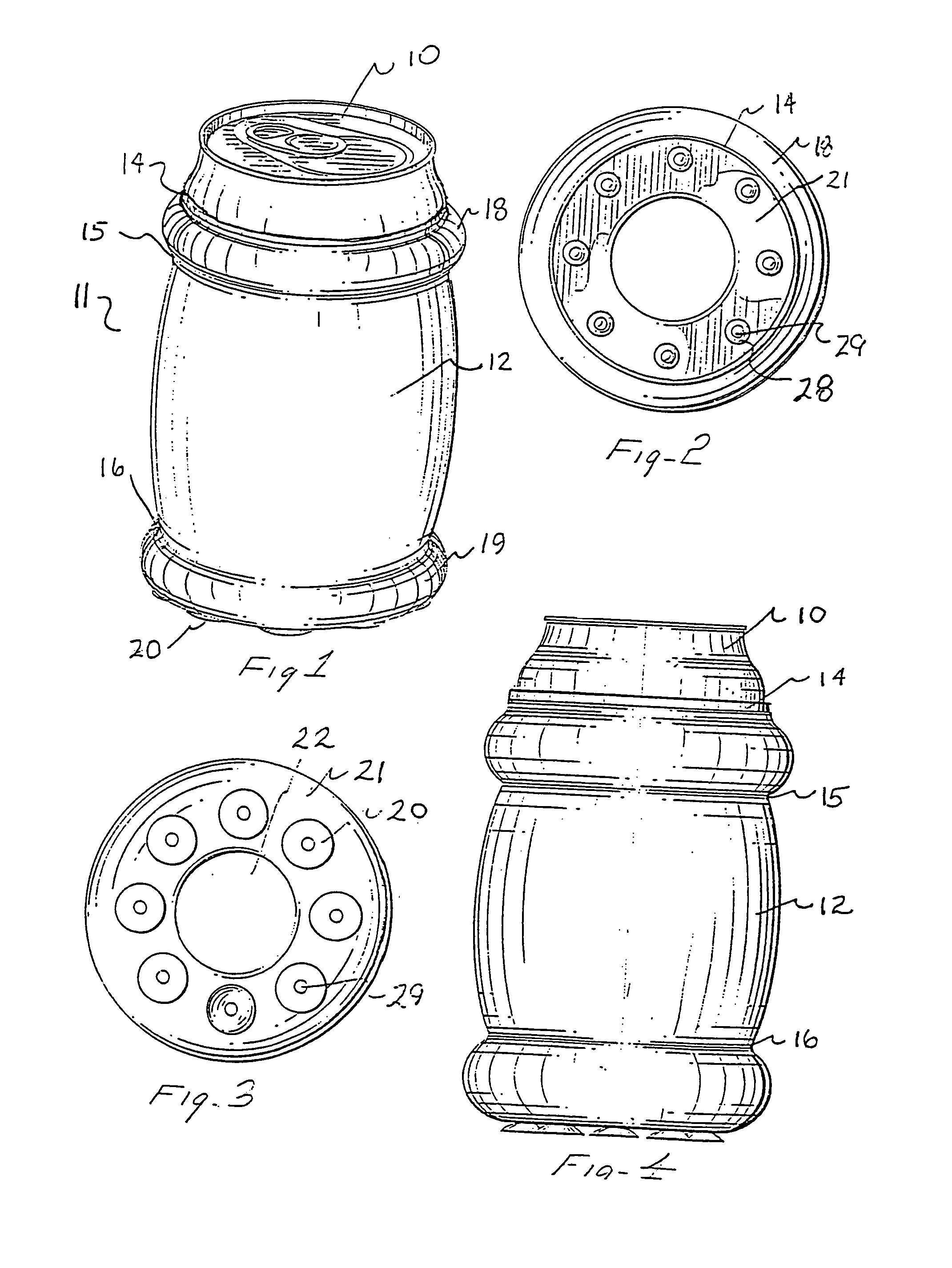

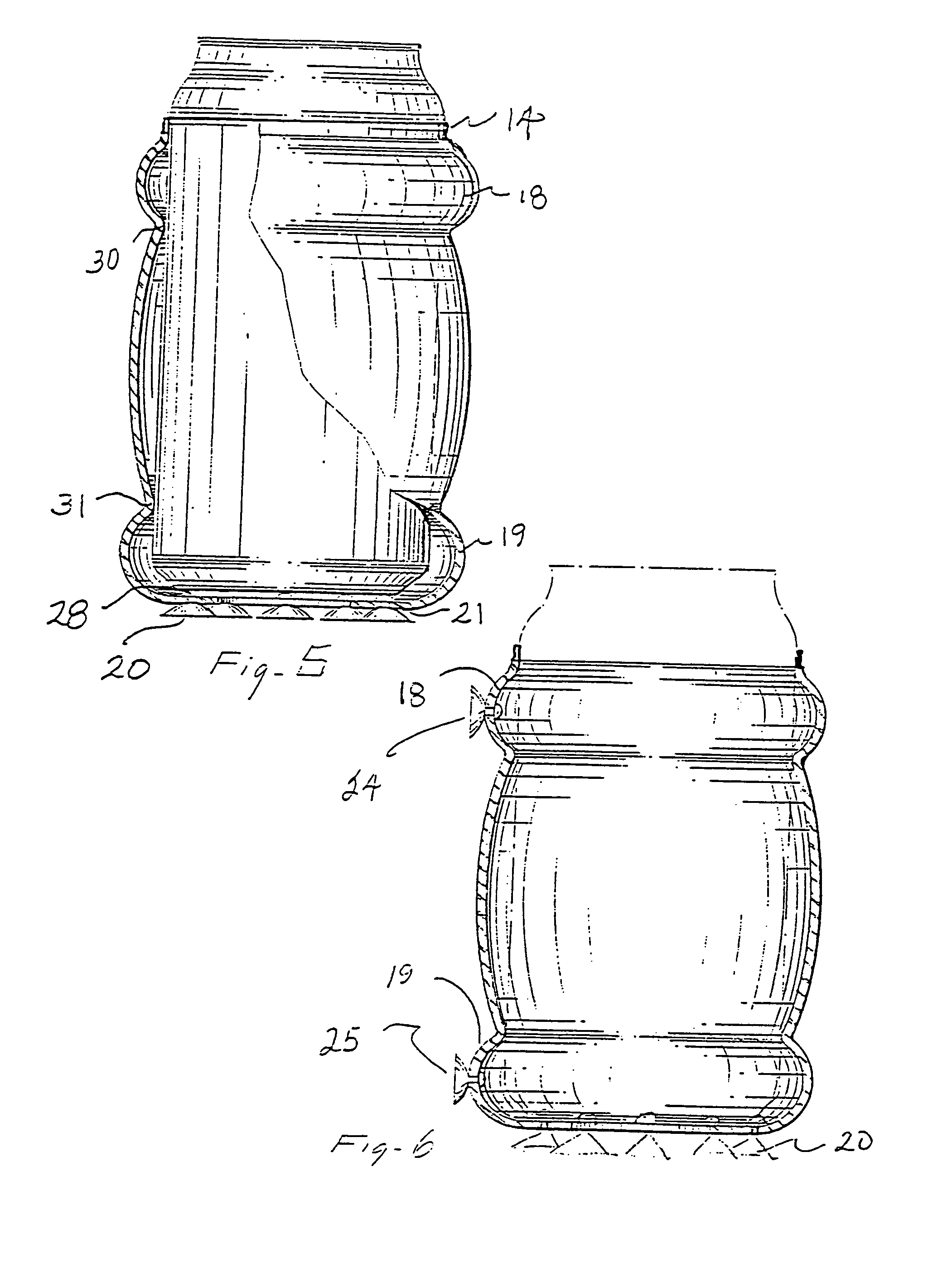

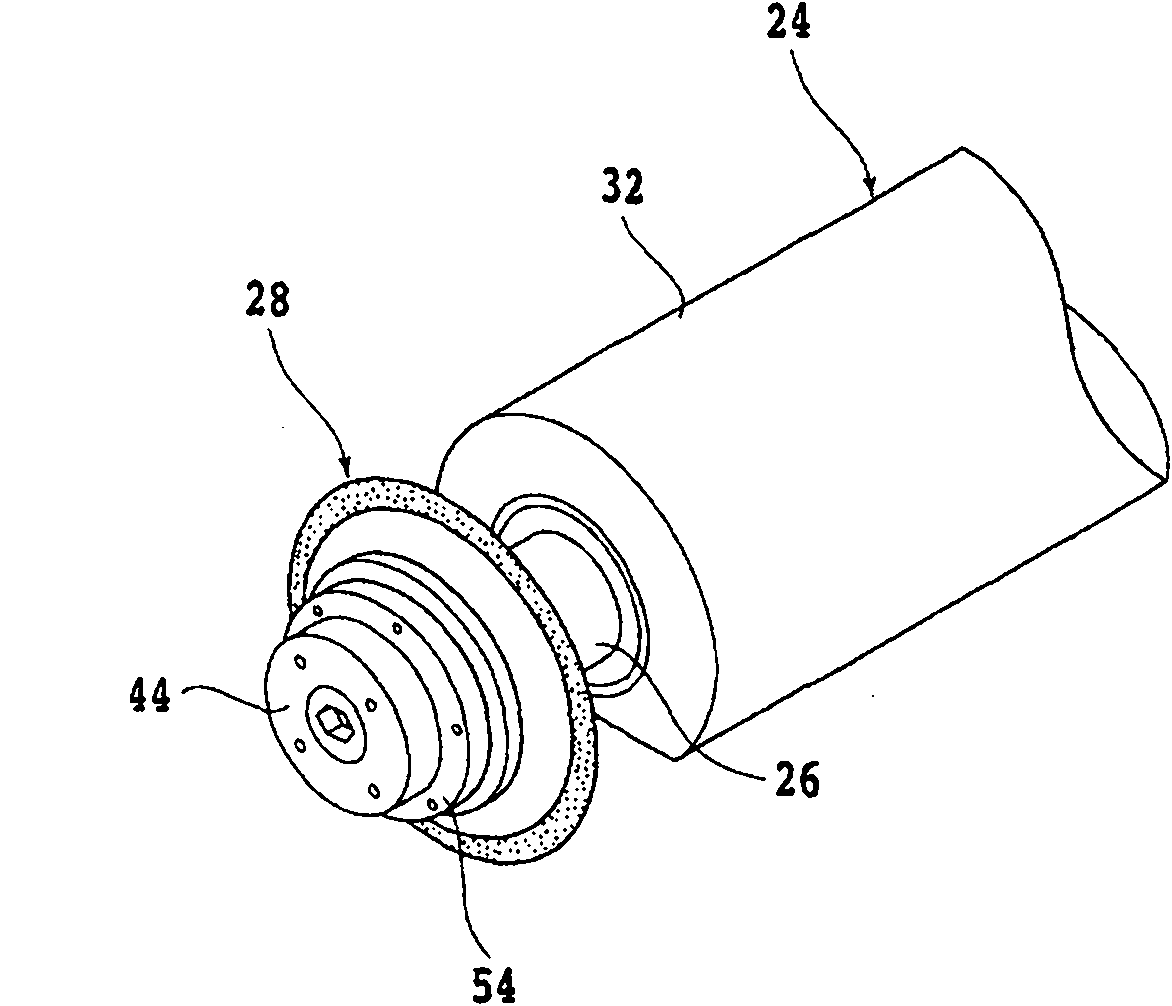

Insulating beverage container holder

InactiveUS7337915B1Maintain temperatureEasy to insertDomestic cooling apparatusLighting and heating apparatusSupport surfaceFlange

A holder for a beverage container wherein the insulating sleeve includes internal ribs proximate to the top and bottom for gripping the container. An inwardly extending flange at the bottom of the sleeve is provided with a plurality of suction cups for stable affixation to a support surface.

Owner:WELDON DANIEL

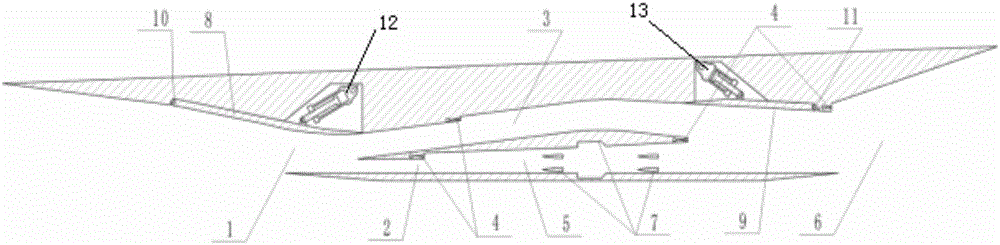

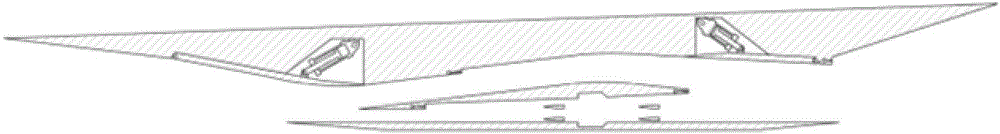

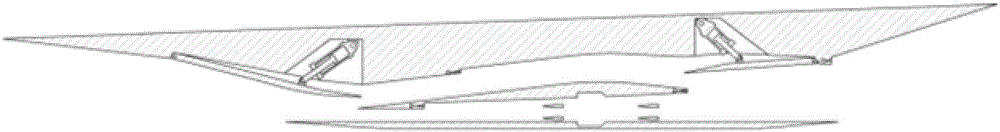

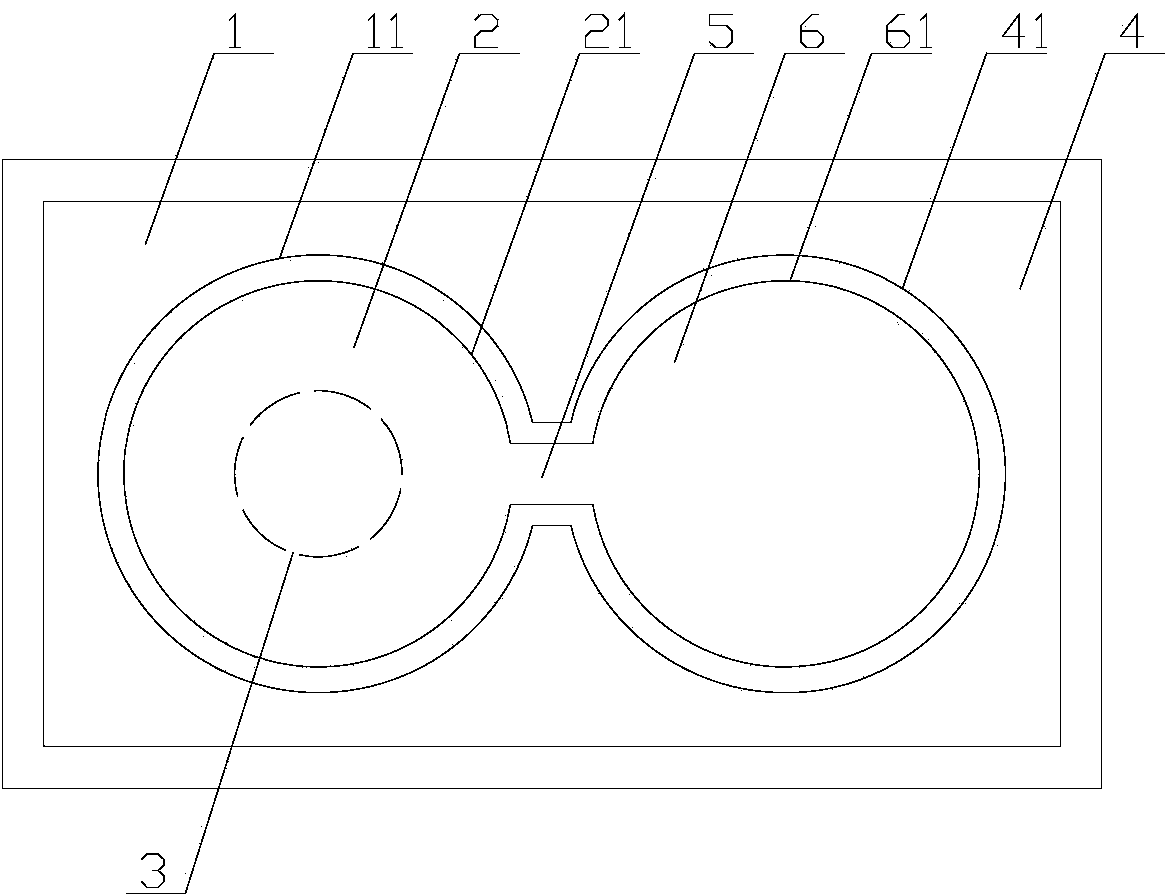

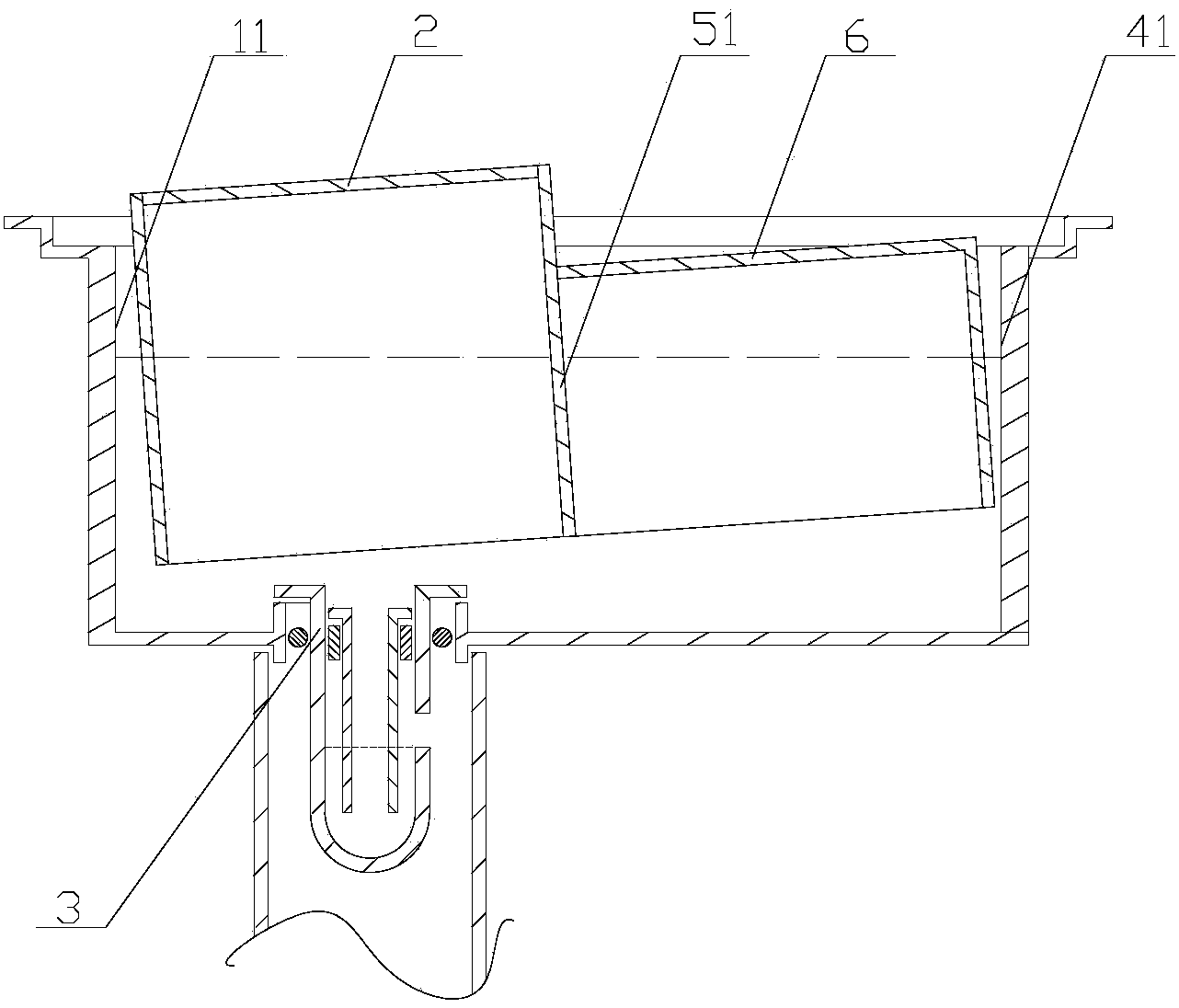

Double-channel variable geometry rocket base combined cycle engine

InactiveCN106150757AImprove adhesionMeet power needsGas turbine plantsRam jet enginesHigh-speed flightAirflow

The invention discloses a dual-channel variable-geometry rocket-based combined cycle engine, which adopts a dual-channel structure and realizes good work in a wide flight range through a partitioned combustion mode; the dual channels work simultaneously in a low-speed flight state to complete ejection mode and sub-stage The work in the low-speed section of the combustion mode; in the high-speed flight state, it is converted to the high-speed channel to work alone, and completes the work of the high-speed section of the sub-combustion mode and the super-combustion mode. The variable geometry method that the top pressure plate rotates around the rotating shaft is used to realize the adjustment of the small shrinkage ratio in the low-speed flight state and the large shrinkage ratio in the high-speed flight state, and meet the air capture and airflow compression requirements under different flight Mach numbers in a wide range of the engine. The binary mixed pressure inlet is adopted, the top pressure plate and the side plate of the inlet have good adhesion, and the mechanical dynamic seal is easy to realize, which is suitable for engineering applications; it meets the power requirements of different working modes of the aircraft. The top pressure plate and the conversion plate are respectively connected to the rotating shaft of the double fulcrum structure, the structure is rigid, and the high temperature sealing is easy to realize.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for producing circuit board thin plates

The invention discloses a method for producing circuit board thin plates. The technical scheme is characterized in that the method comprises the following steps that: conducting plating though holes; conducting outer layer circuit pattern transfer; conducting graph electric plating and etching; penetrating a string through locating holes of the circuit board thin plates, utilizing string beads to separate the circuit board thin plates, and plating the circuit board thin plates though the holes, after plating the circuit board thin plates through the holes, washing liquid medicine on the surfaces of the circuit board thin plates away by horizontally drawing the circuit board thin plates through a thick plate; conducting electric test; conducting routing; utilizing a plastic package tray to package a finished-product unit plate subjected to routing. From the procedure of layer circuit pattern transferring to the procedure of routing, the circuit board thin plates are compressed through pressing grooves by the adoption of a pig cage frame device to be transferred between the procedures. The method for producing the circuit board thin plate solves the problems that the circuit board thin plates are prone to plate adhesion, plate curving, plate clamping and plate fracture due to the fact that the circuit board thin plates are small in size. The method for producing circuit board thin plates is simple in process and stable in product quality.

Owner:广东依顿电子科技股份有限公司

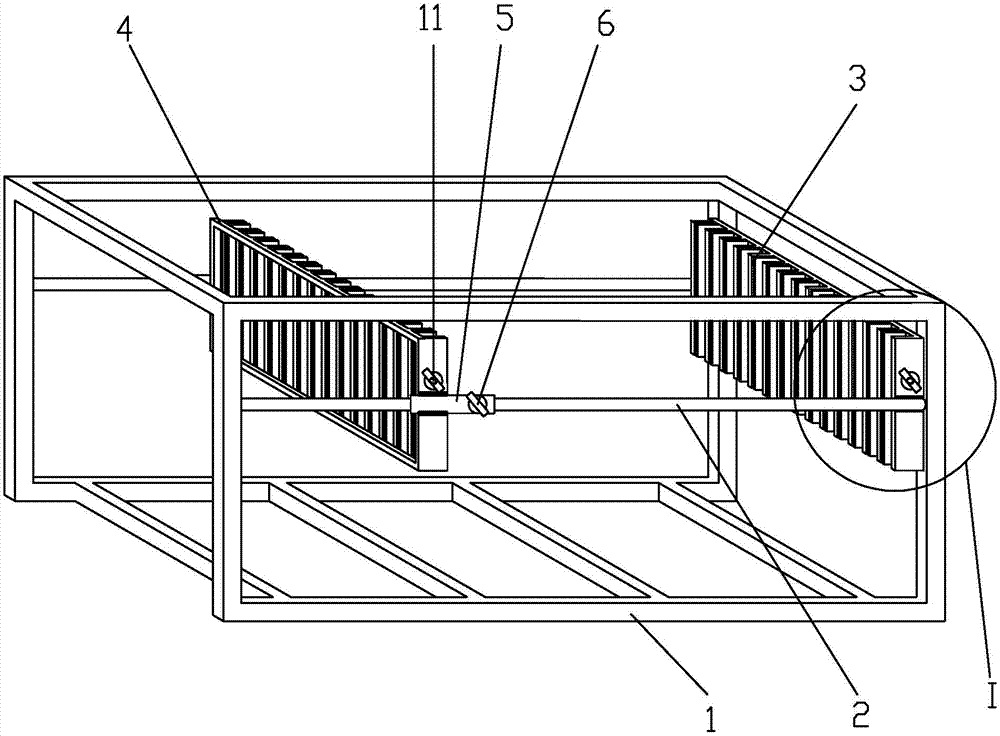

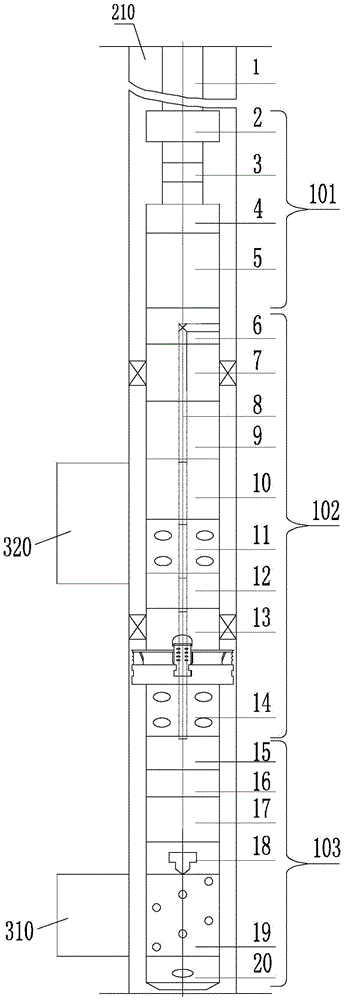

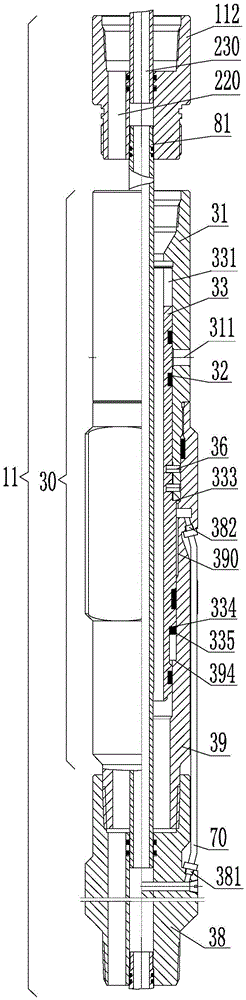

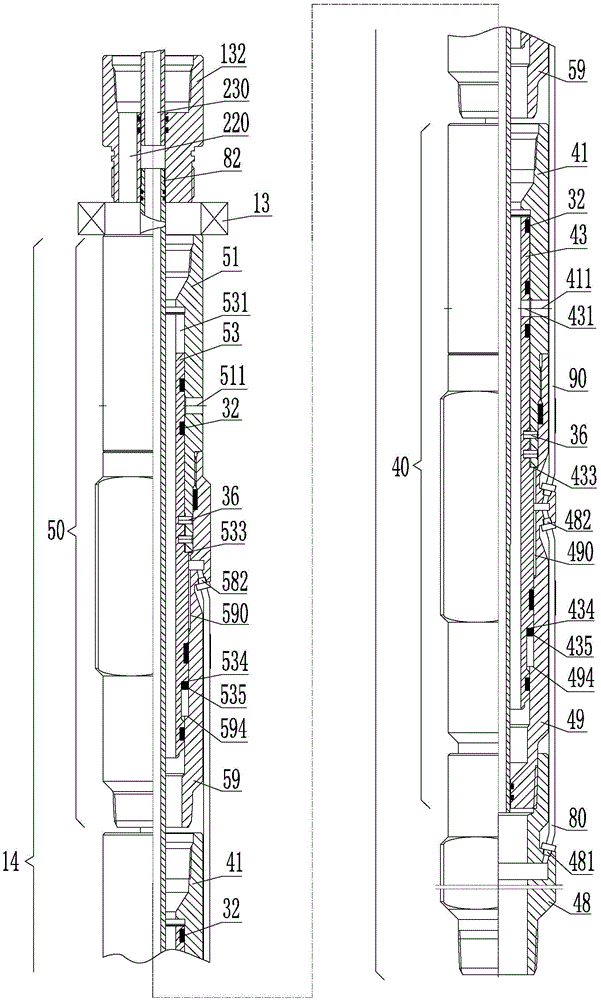

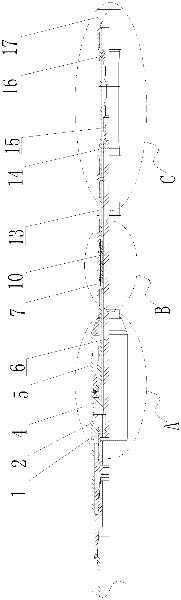

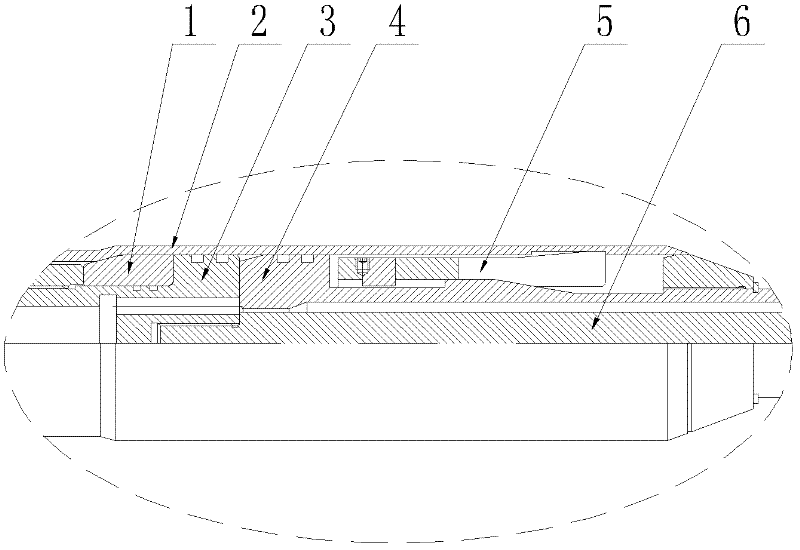

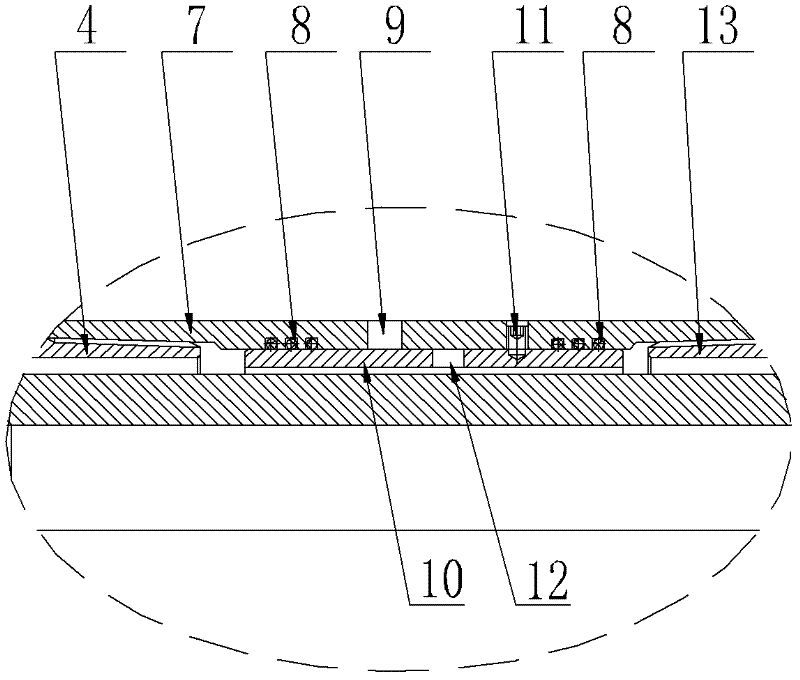

Layering continuous well testing system and use method thereof

InactiveCN105545282AAvoid embedding cardsSave cycleSurveyFluid removalMaterial PerforationMechanical engineering

The invention provides a layering continuous well testing system and a use method thereof. The layering continuous well testing systems which are placed in a casing at interval comprise drainage test assemblies, straddle assemblies, and perforation assemblies connected from top to bottom. The cut-through cavity of the drainage test assemblies is communicated with the cut-through cavity of the straddle assemblies, to form a production channel. The straddle assemblies comprise a pressure transmitting joint, an upper packer, an upper pilot-controlled sieve tube, a lower packer, and a lower pilot-controlled sieve tube. In the production channel, pressure transmitting pipes which extend from the pressure transmitting joint and are communicated with an ignition head are arranged at interval. The pressure transmitting hole on the pressure transmitting joint is communicated with the upper port of the pressure transmitting pipe, to form a pressurization channel. The upper pilot-controlled sieve tube is provided with a first diversion channel which is separated from the production channel. The pressurization channel is injected with fluid, so the first diversion channel is communicated with the production channel. The lower pilot-controlled sieve tube is provided with a second diversion channel which can be connected with the production channel. Fluid is injected to make the second diversion channel separated from the production channel. The system can perform well testing on an upper layer and a lower layer.

Owner:PETROCHINA CO LTD

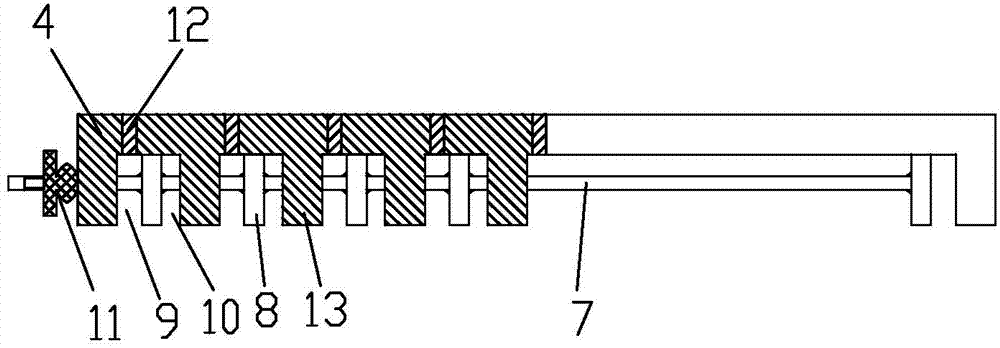

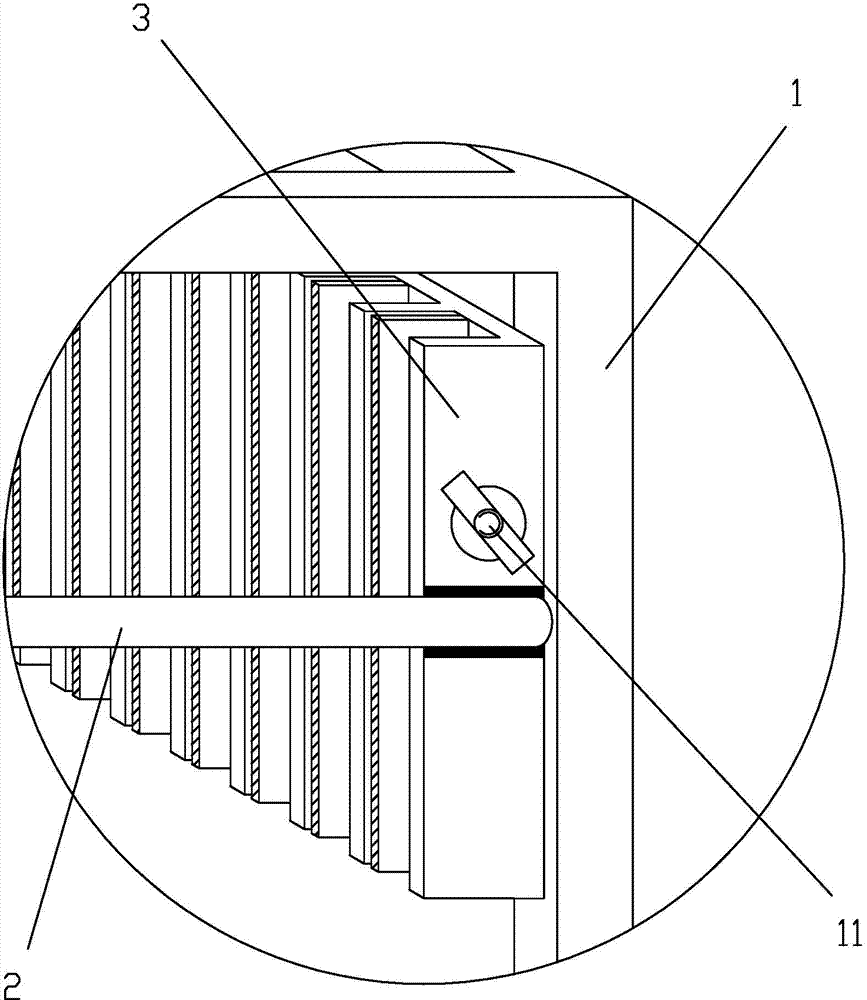

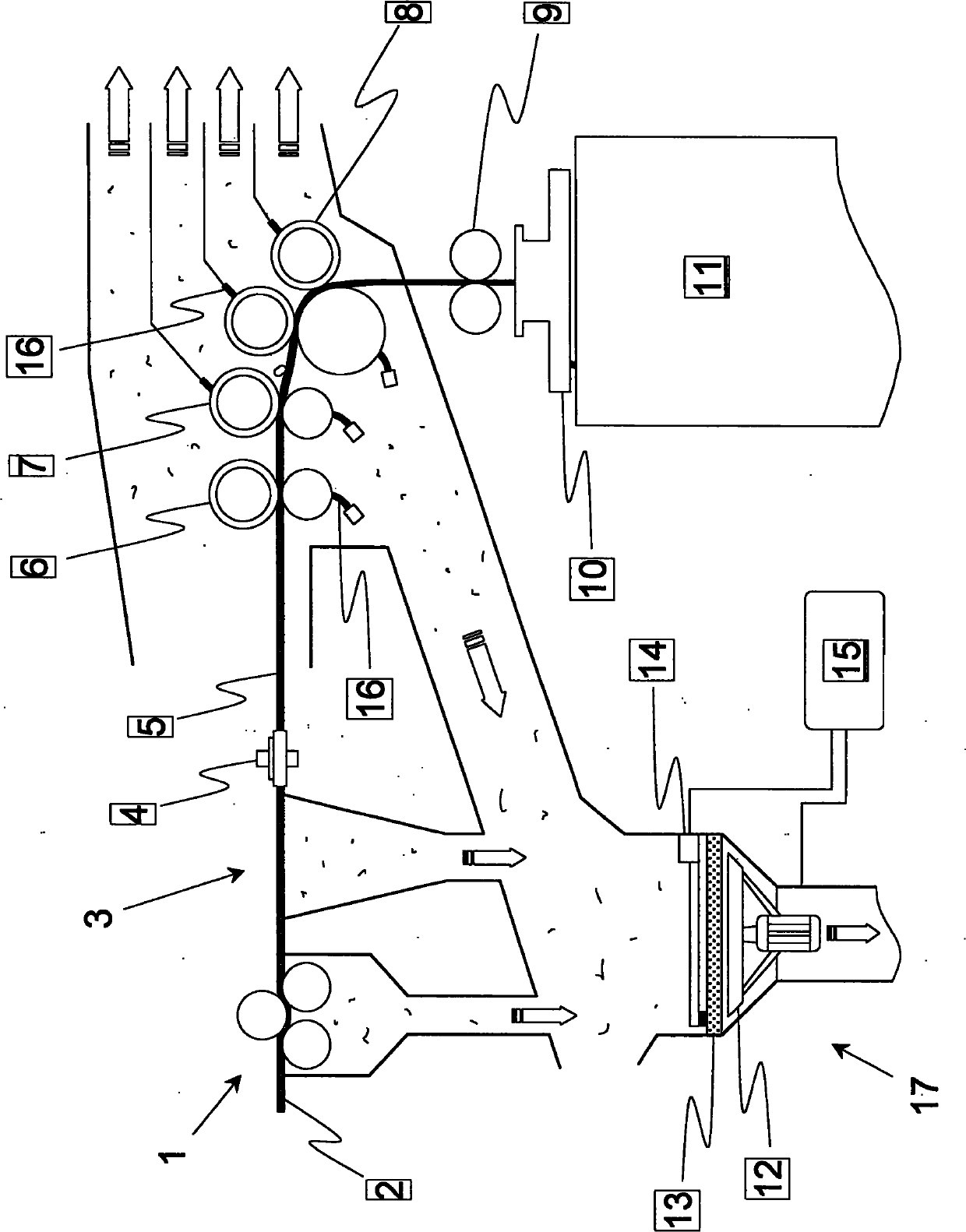

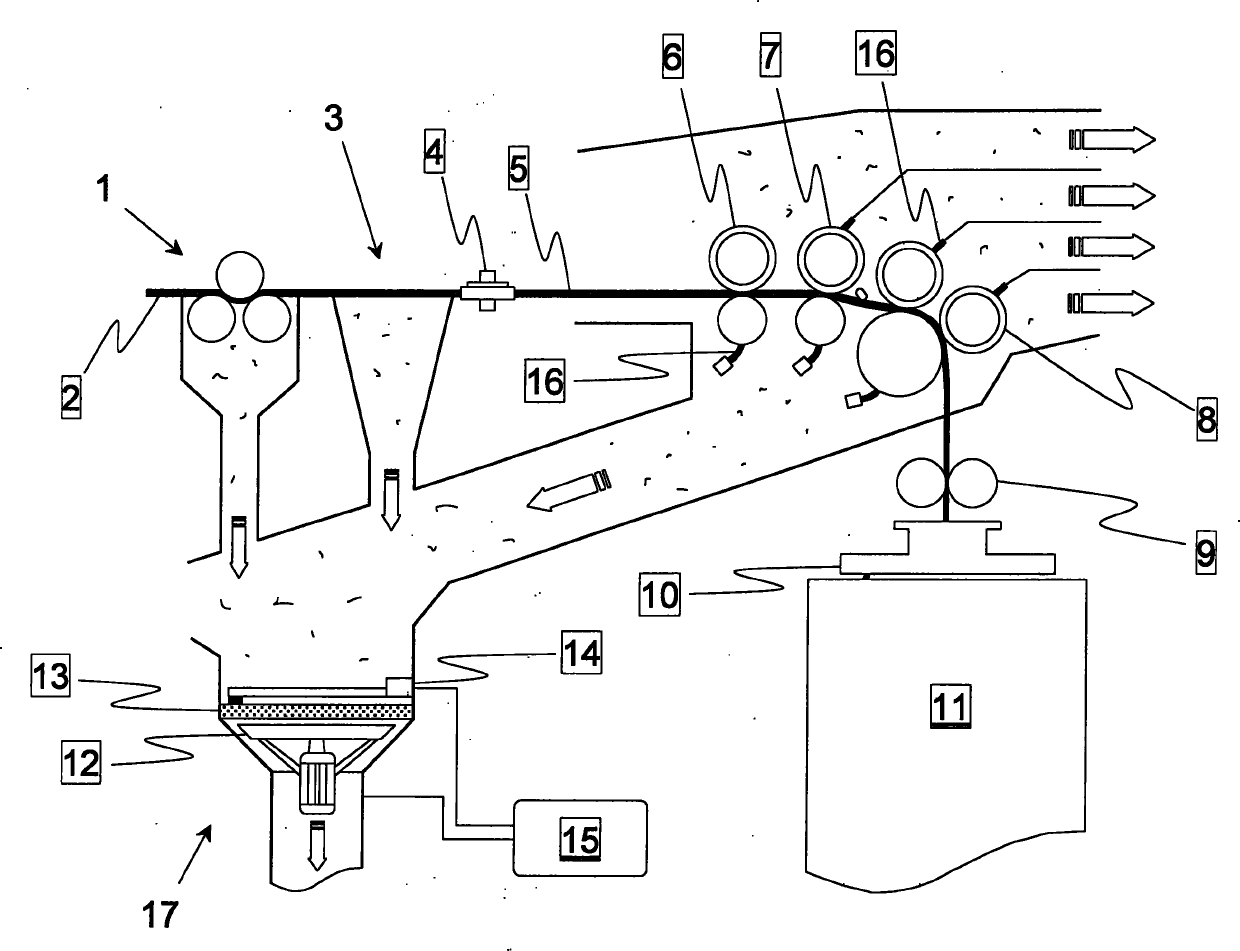

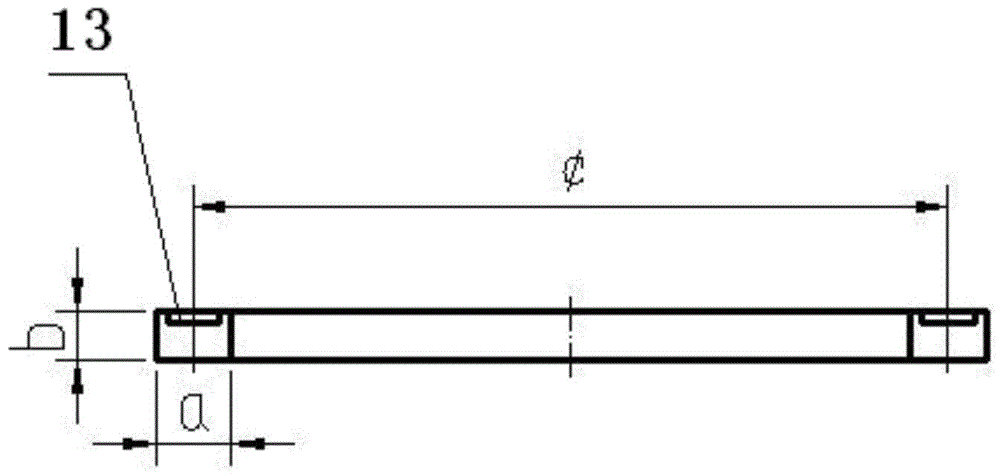

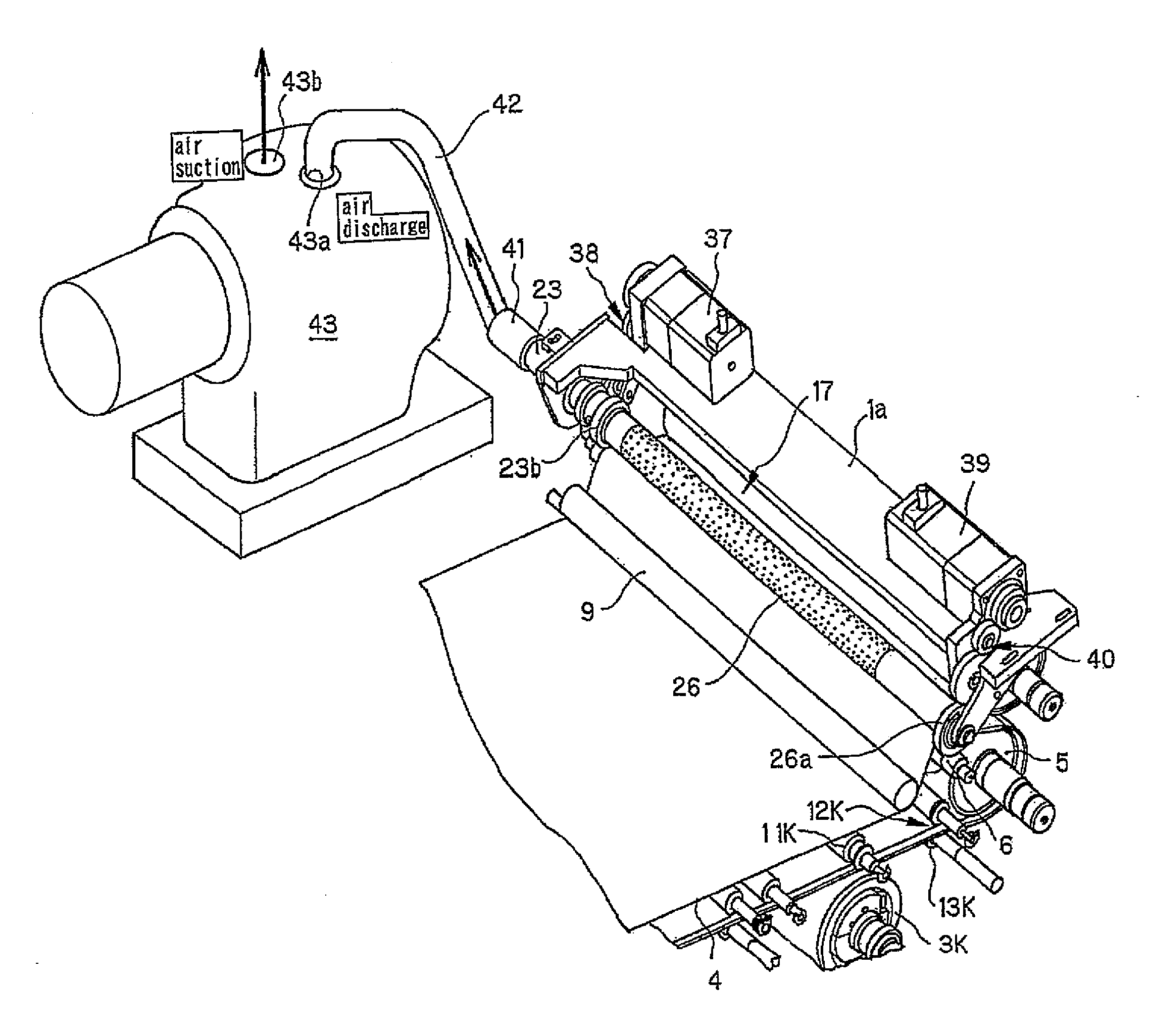

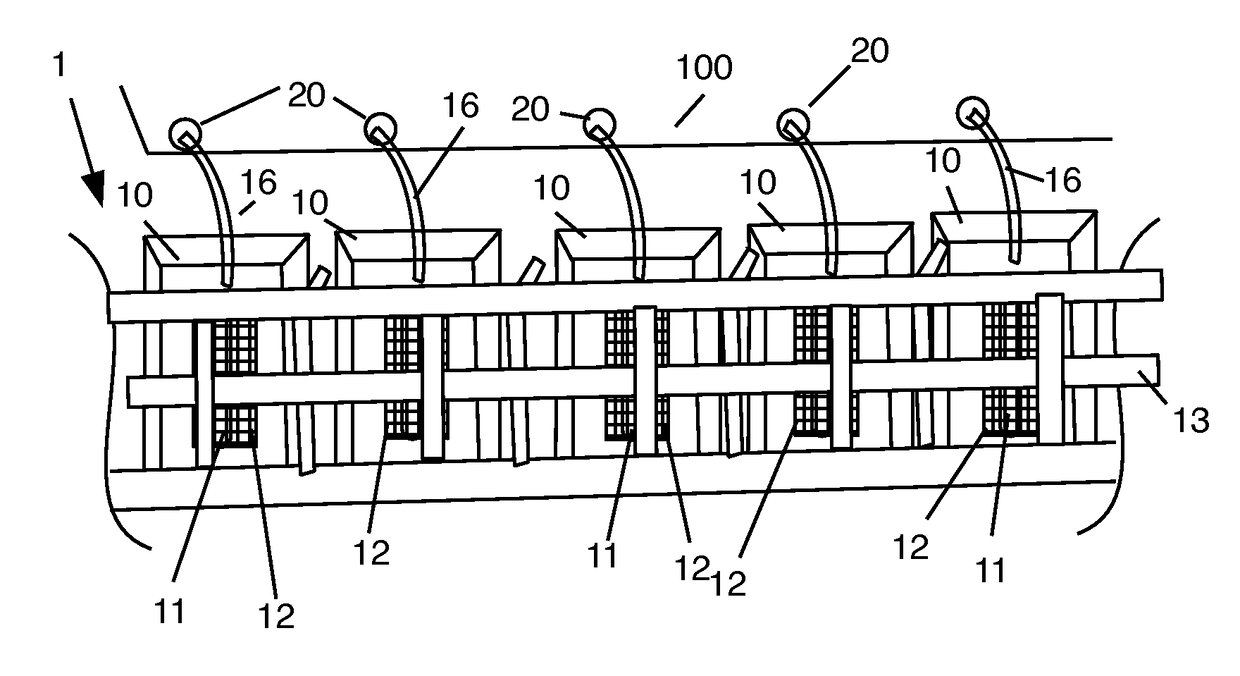

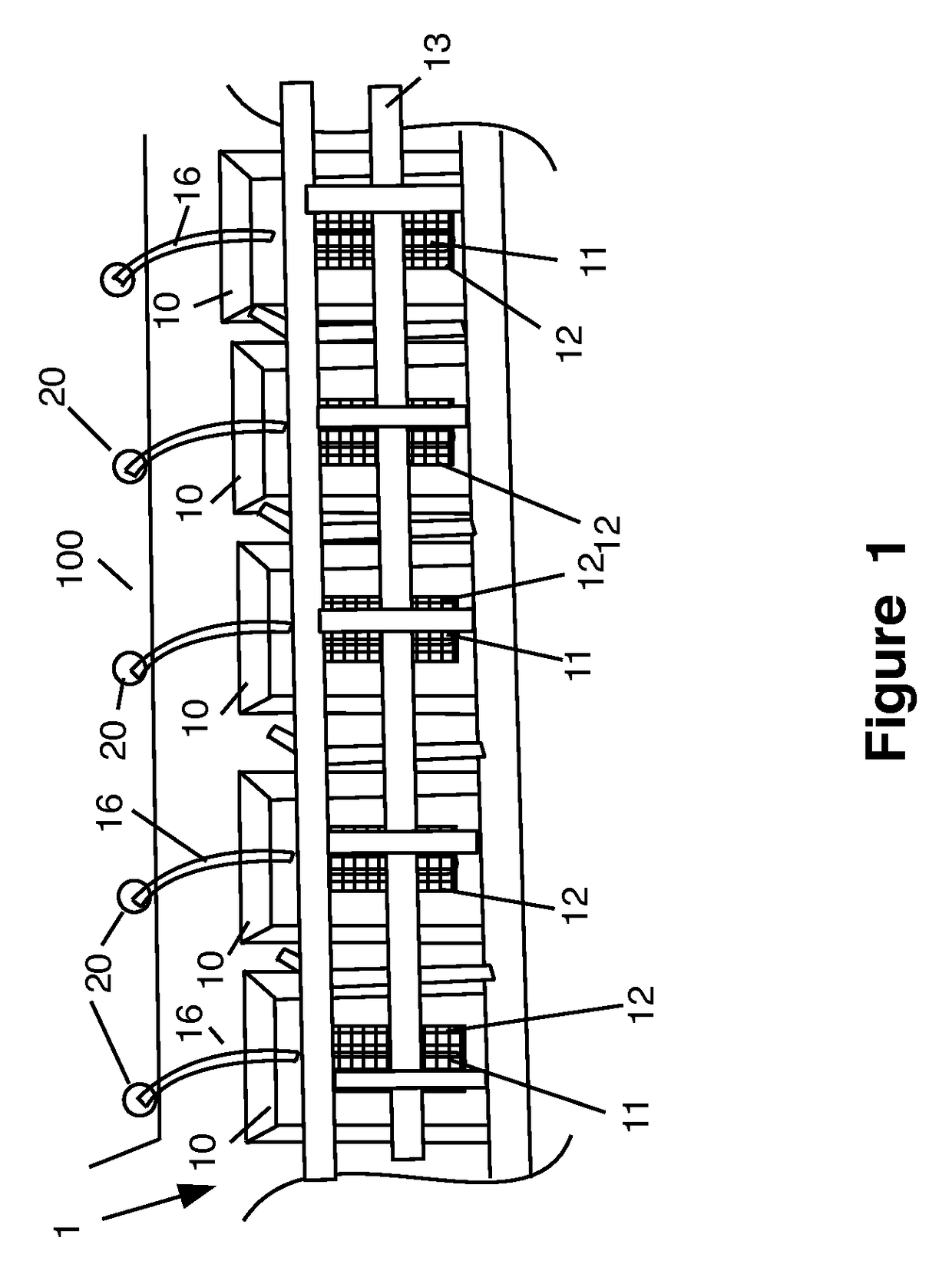

Spinning machine with suction apparatus and method for controlling suction apparatus of spinning machine

ActiveCN101994179AReduce speedGuaranteed volume flowFilament handlingDrafting machinesEngineeringRubbing

The present invention relates to a method for controlling a suction apparatus of a spinning machine, particularly a spinning or spinning preparing machine, e.g. a rubbing mill, a napping machine or a combing machine, wherein the suction apparatus (17) includes a ventilator (12) for generating air flow, a filter element (13) for filtering the air flow and a cleaning device for cleaning the filter element (13). According to the invention, rotational speed of the ventilator and an operating status of the cleaning device are coordinated by a controller (15). Furthermore, the invention describes a corresponding spinning machine having the suction apparatus (17), wherein the suction apparatus includes a ventilator (12) for generating air flow, a filter element (13) for filtering the air flow and a cleaning device for cleaning the filter element (13). The spinning machine is characterized in that the ventilator (12) and the cleaning device (14) is connected with the controller (15) of the spinning machine, such that the rotational speed of the ventilator and the operating status of the cleaning device are coordinated.

Owner:RIETER INGOLSTADT GMBH

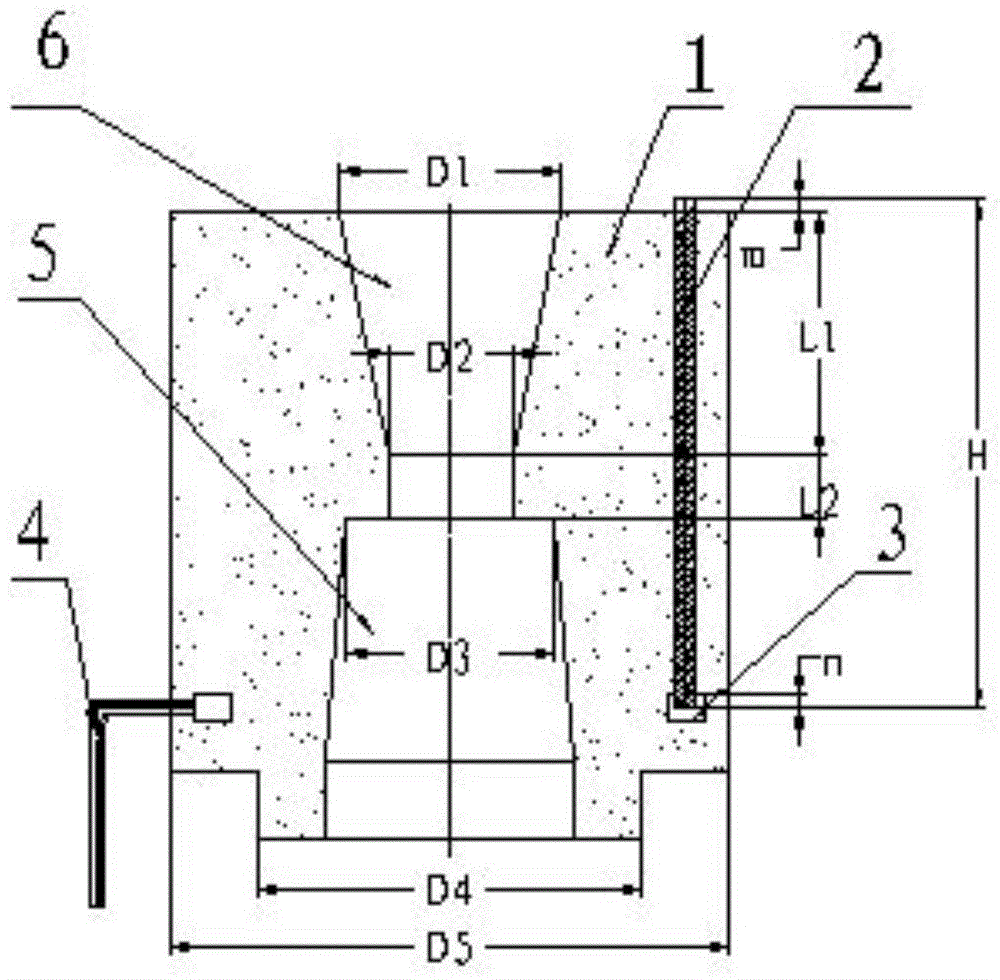

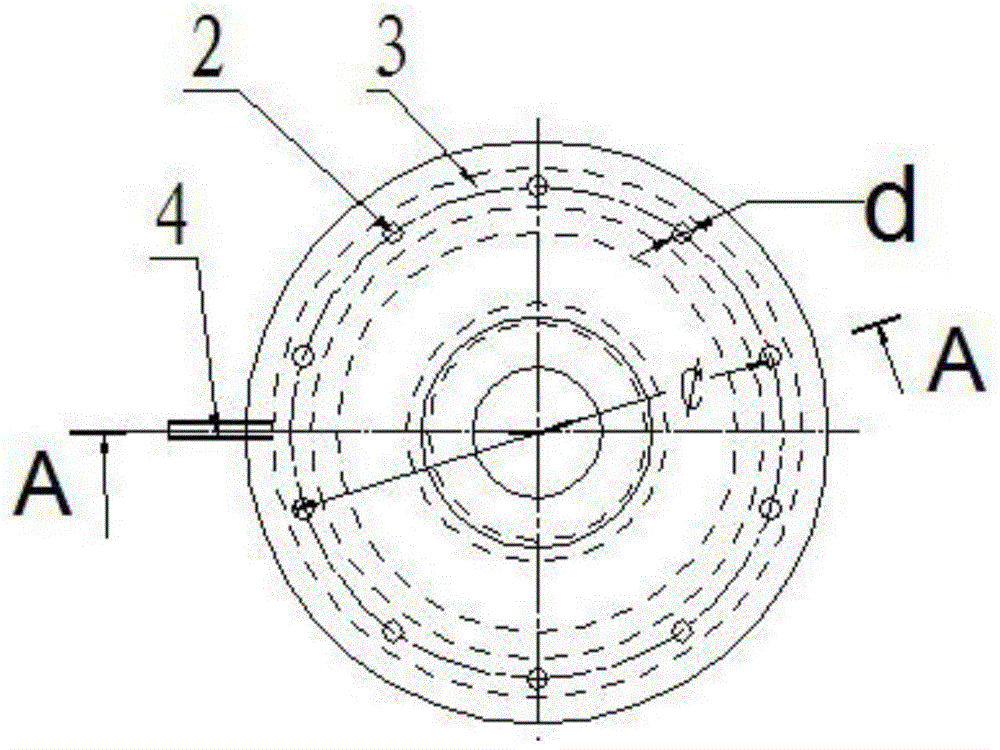

Ladle breathable upper nozzle seat brick and method for controlling nozzle slag entrainment

The invention relates to a ladle ventilating upper nozzle seat brick and a method for controlling nozzle slag volume, which comprises a ladle upper nozzle seat brick body, a ventilating ceramic rod and an air chamber box, the air chamber box is located at the bottom of the ventilating ceramic rod and connected with the ventilating ceramic rod Connected, there are a plurality of breathable ceramic rods, which are evenly arranged in the body of the upper nozzle block in a ring around the flow steel hole. The top of each breathable ceramic rod protrudes from the upper surface of the upper nozzle block body. A plurality of slots for fixing the air-permeable ceramic rods are provided, and the bottom end of each air-permeable ceramic rod extends into the slot of the air intake chamber box. When the molten steel in the ladle is at a low level, argon gas is blown in from the inlet pipe to form a ring-shaped air curtain barrier around the upper nozzle of the ladle to wash the molten steel that is about to enter the upper nozzle. The problem of eddy current slag entrainment at the nozzle not only improves the cleanliness of molten steel, but also reduces the amount of molten steel in the ladle injection surplus, a year-on-year decrease of more than 30%.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

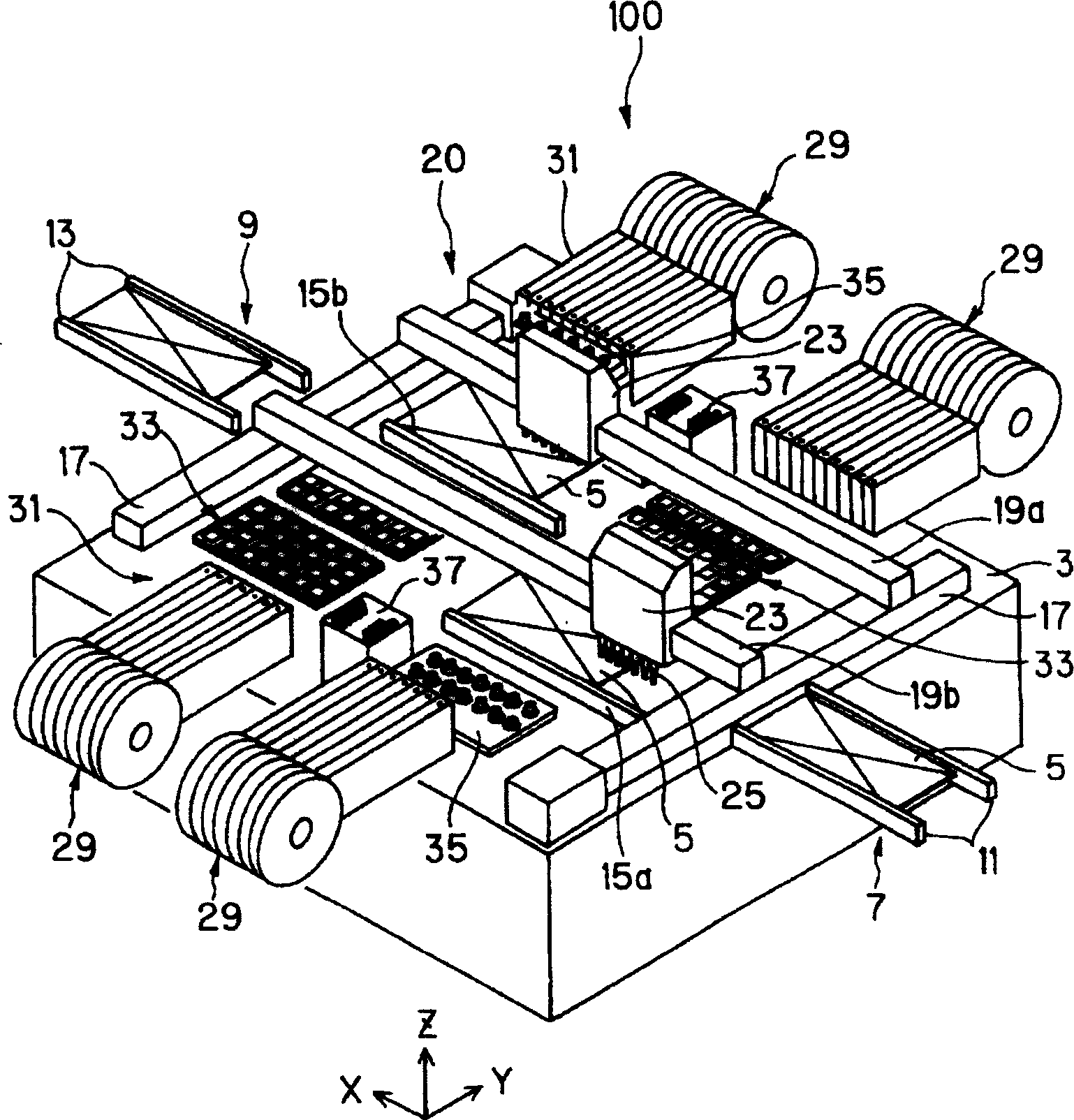

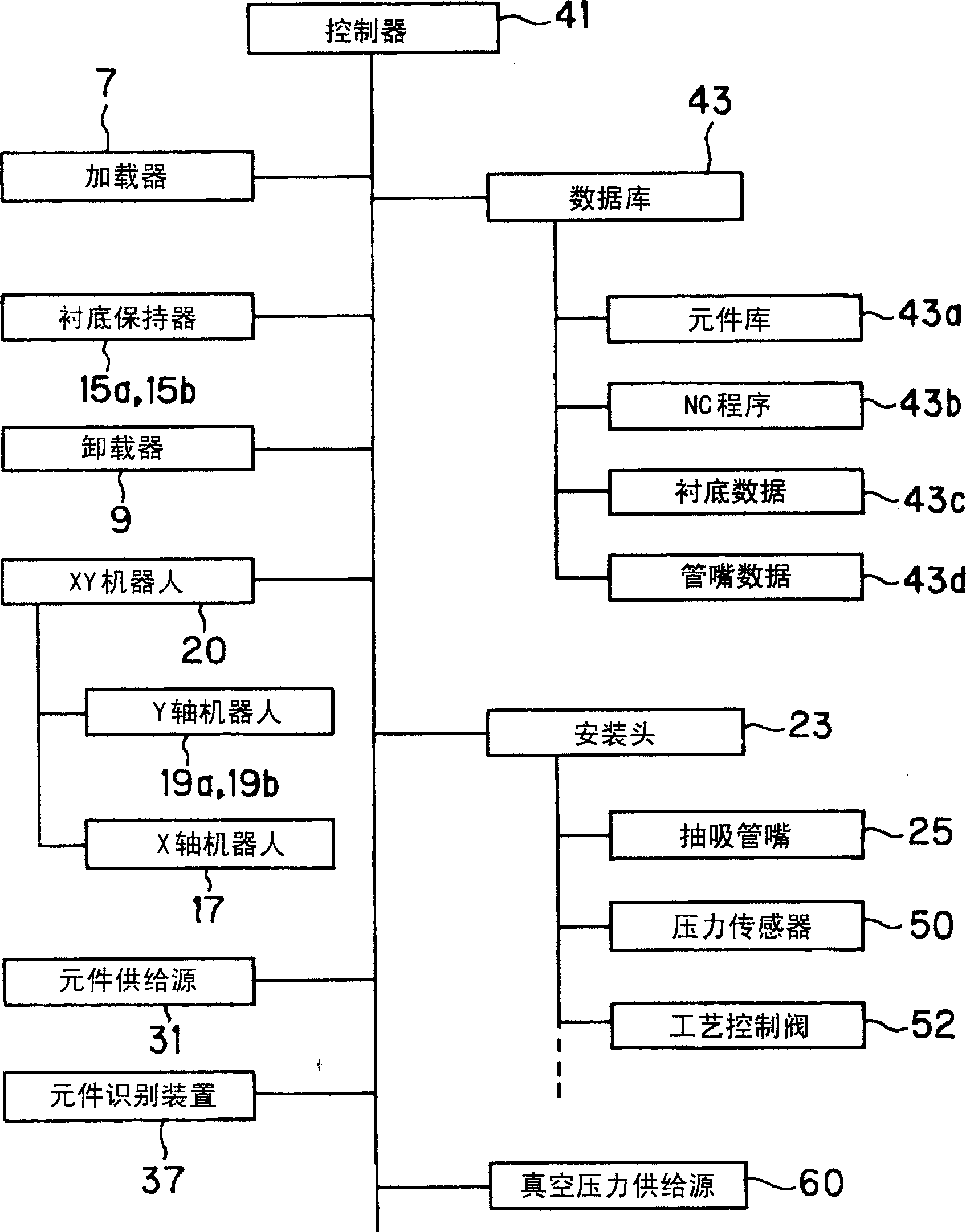

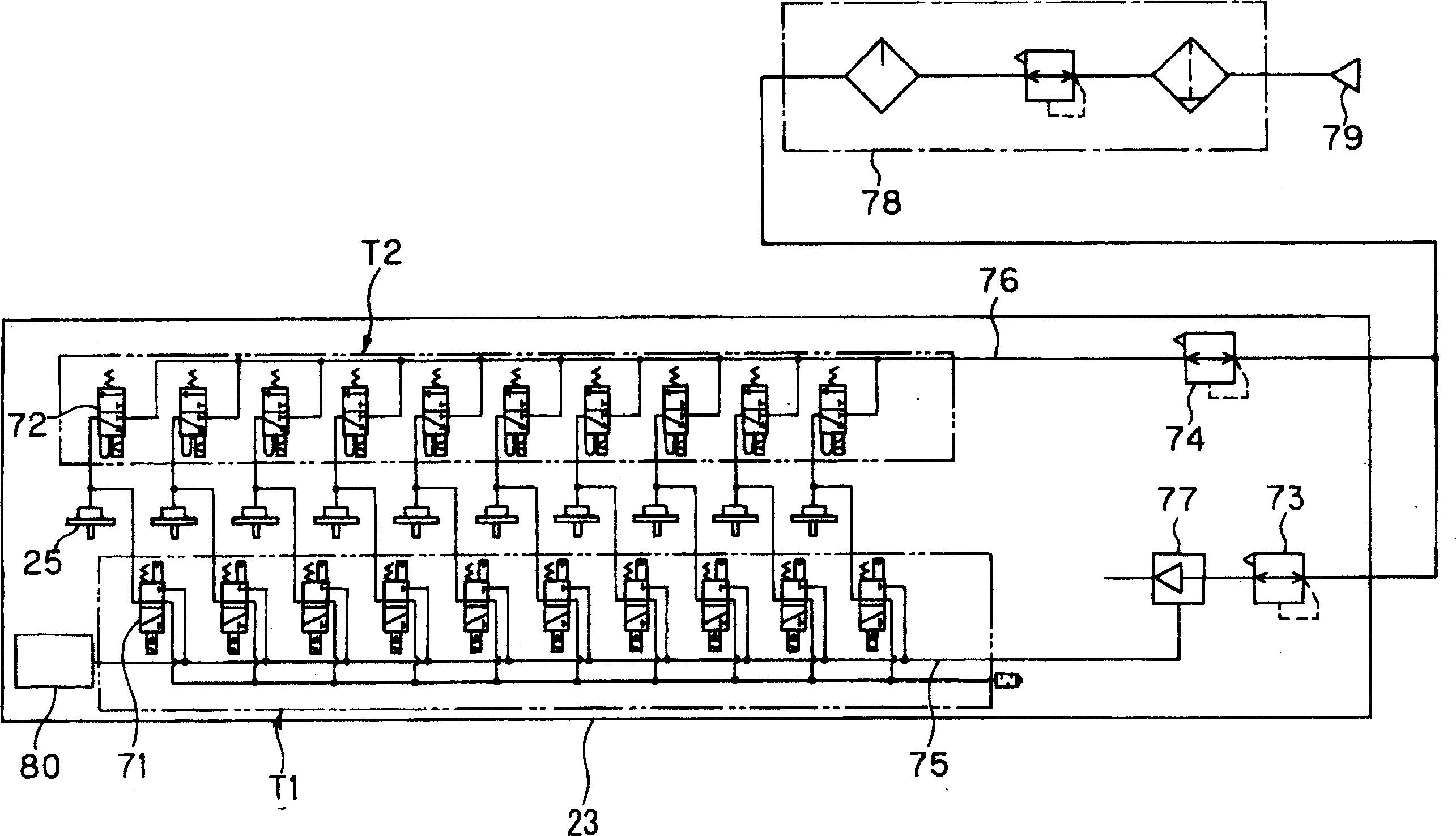

Method and equipment for mounting part

InactiveCN1669378ASufficient suction powerLow costElectrical componentsVacuum pressureIdentification device

The present invention is to provide a method and an apparatus for mounting components having a feature of detecting with high accuracy component pick up failure by the nozzle at component pick up stage, and / or component carrying back by the nozzle at component mounting stage. Achieved vacuum pressure is initialized to zero after completion of component pick up by the nozzle 25 , and vacuum pressure decrease of the nozzle 25 is detected from the initialized zero point. If the detected value is bigger than the predetermined threshold, it may be judged that at least one of the nozzles failed to pick up a component. The failed nozzle may be identified by using a component recognition device 37 . Blowing air blow volume flowing through the nozzle 25 is measured upon completion of component mounting. If the blowing air flow is smaller that the predetermined threshold, it is judged that the nozzle 25 carries back a component 30 . Two thresholds may be used, and it may be judged that the component has been properly mounted if the measurement value is bigger than both thresholds, filter 22 is clogged if the measurement value is in between the two thresholds, and the nozzle 25 carries back the component if the measurement value is smaller than both thresholds.

Owner:PANASONIC CORP

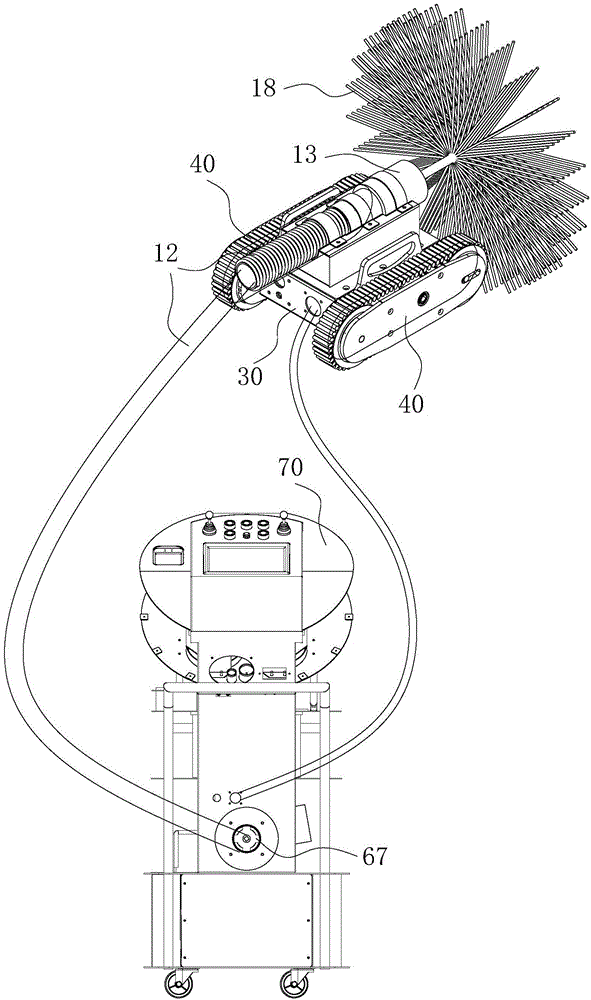

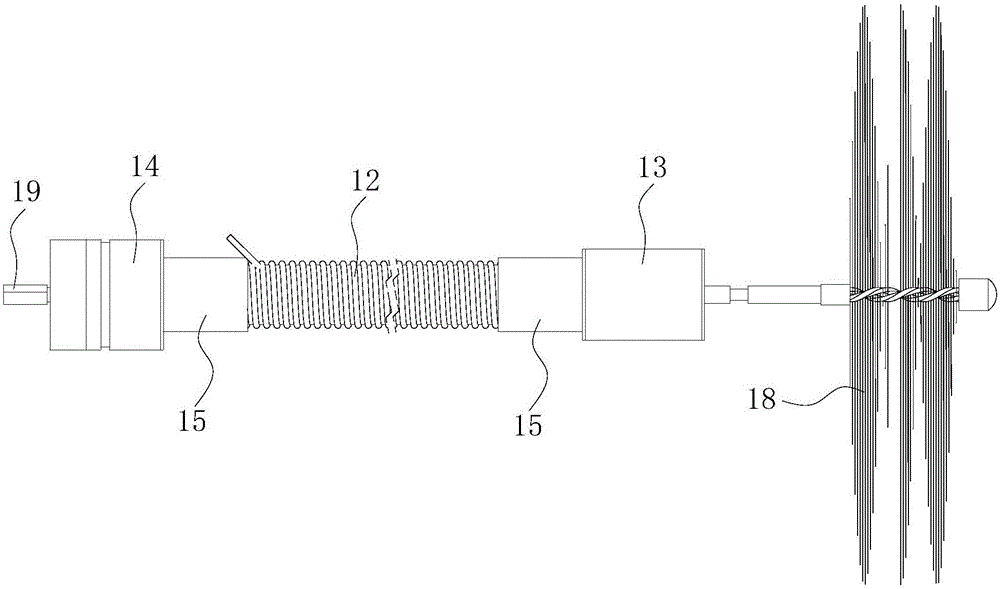

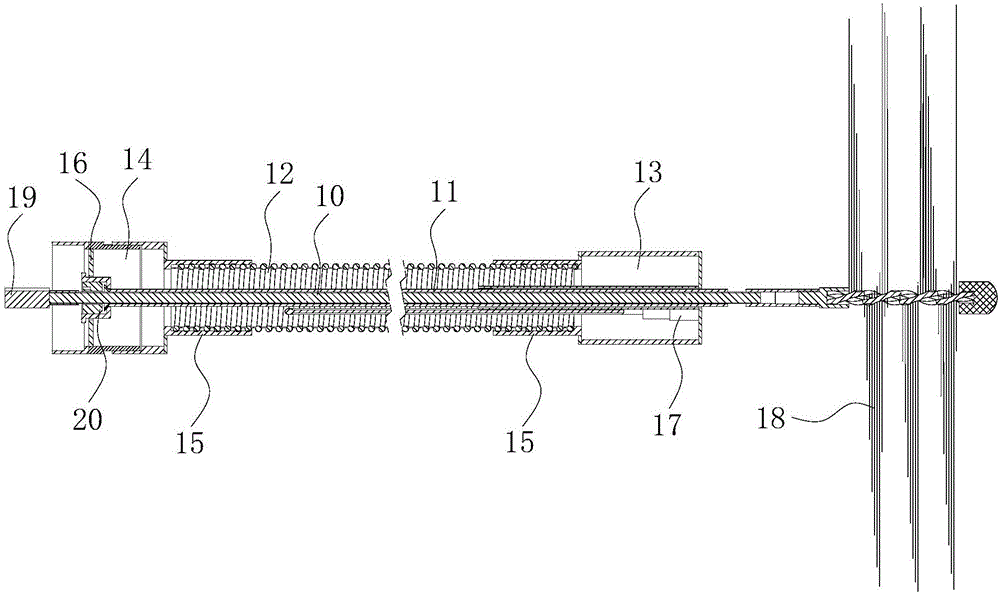

Cleaning flexible shaft and pipeline cleaning system and method

ActiveCN106493131AImprove cleaning efficiencyObserve the cleaning situationHollow article cleaningDirt cleaningEngineeringMechanical engineering

The invention discloses a cleaning flexible shaft and a pipeline cleaning system and method. The cleaning flexible shaft comprises a flexible shaft core, a shaft core sleeve, a ventilating pipe, a dust collection end piece and a connecting piece. The shaft core sleeve is arranged on the flexible shaft core in a sleeving mode. The ventilating pipe is arranged on the shaft core sleeve in a sleeving mode, and the ventilating pipe and the shaft core sleeve form a ventilating channel. The two ends of the ventilating pipe are connected with the dust collection end piece and the connecting piece correspondingly. The dust collection end piece is provided with a first ventilating hole. A second ventilating hole is formed in a supporting plate which is arranged between the connecting piece and the shaft core sleeve. The first ventilating hole, the ventilating channel and the second ventilating hole communicate with one another. The pipeline cleaning system comprises a base body, walking mechanisms, a control terminal and the cleaning flexible shaft. The walking mechanisms are arranged on the two sides of the base body. The cleaning flexible shaft is arranged on the base body. The control terminal is provided with a flexible shaft connecting part. The back end of the cleaning flexible shaft is connected with the flexible shaft connecting part. The cleaning flexible shaft and the pipeline cleaning system can be used for pipeline cleaning and also can collect dust during pipeline cleaning, using is convenient, and the pipeline cleaning efficiency can be improved.

Owner:广东齐创科技投资集团有限公司

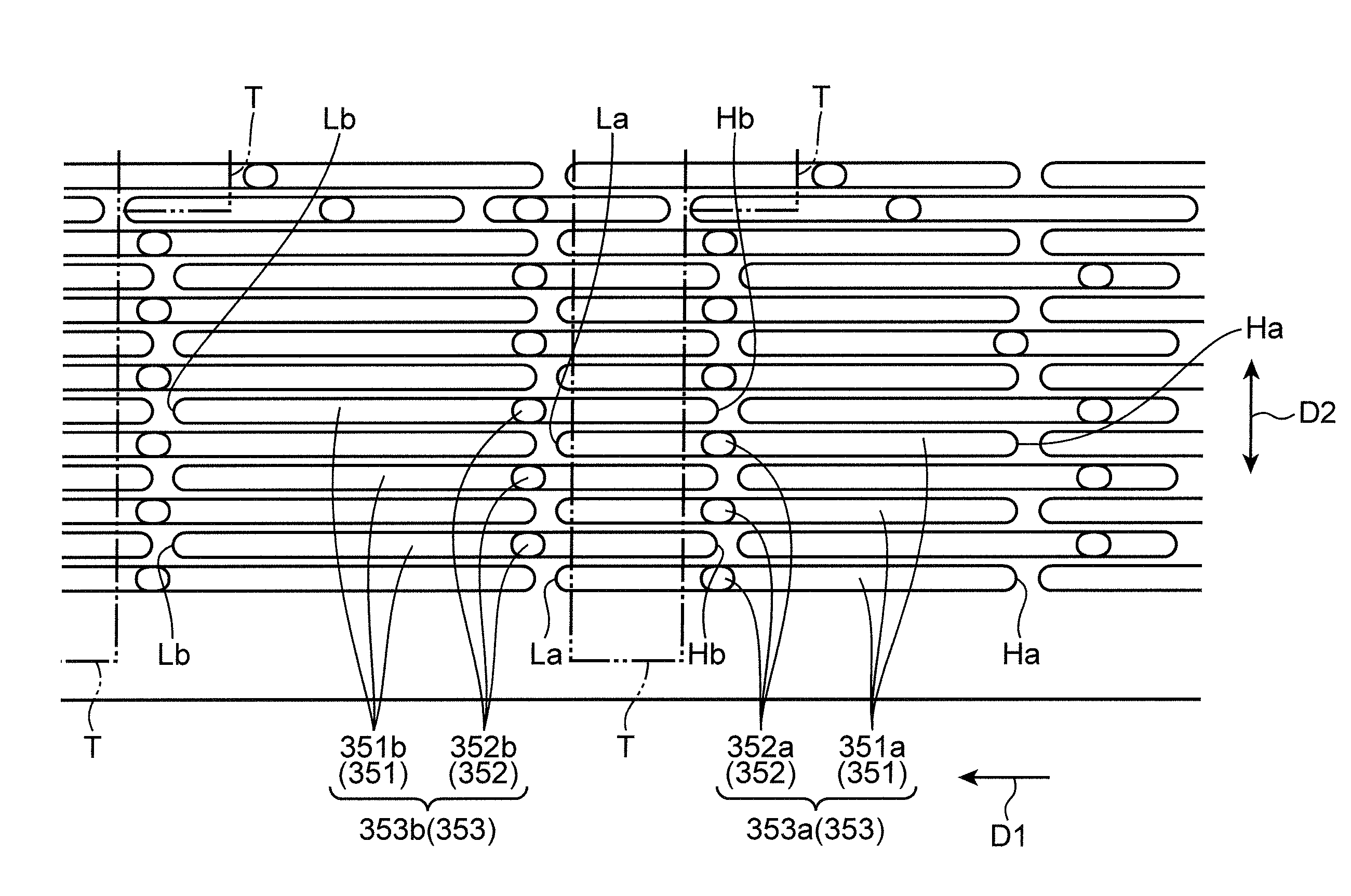

Inkjet recording apparatus

ActiveUS8382276B2Prevent suctionPreventing the recording mediumOther printing apparatusNozzleEngineering

A conveying platen is provided with a plurality of air circulation parts, each of which includes a long groove opened toward the conveying belt and formed in a longitudinal direction following a conveying direction, and a hole that penetrates in a thickness direction from a part of a bottom surface of the long groove. These air circulation parts are arrayed in the conveying direction and a width direction perpendicular to the conveying direction. The conveying platen has an opposed region which faces a nozzle surface. The long groove is provided in the opposed region. The hole is provided in a region other than the opposed region.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

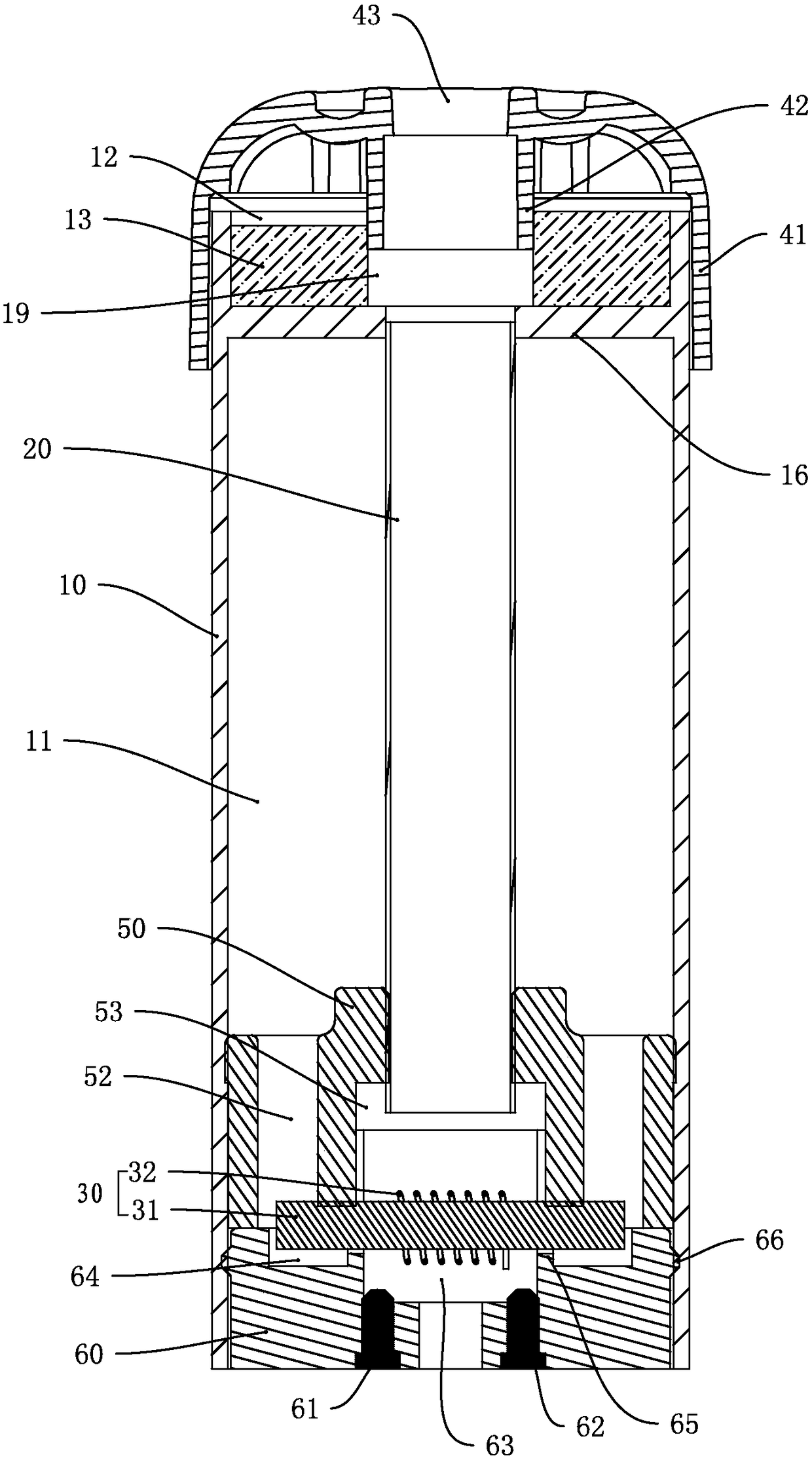

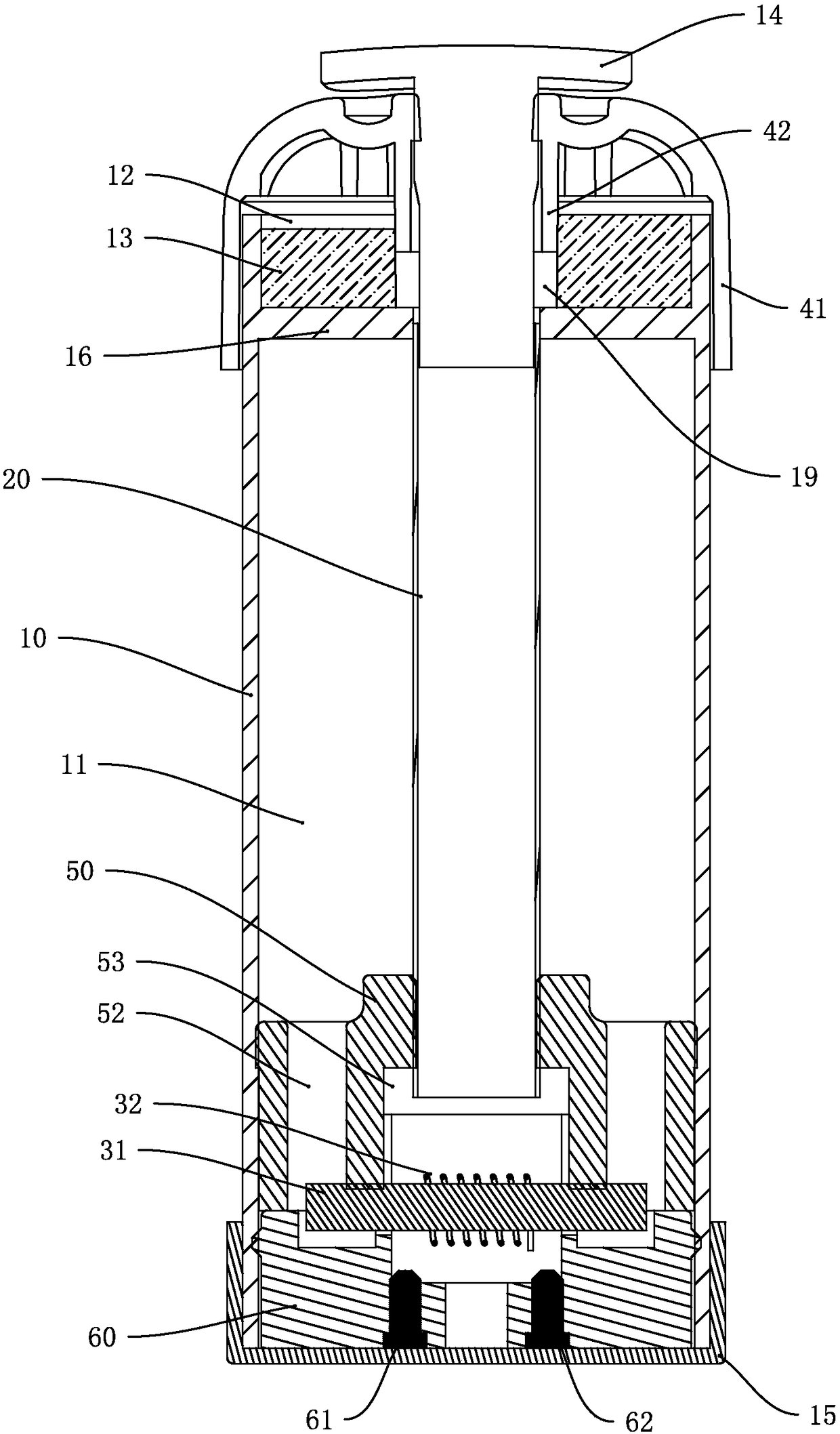

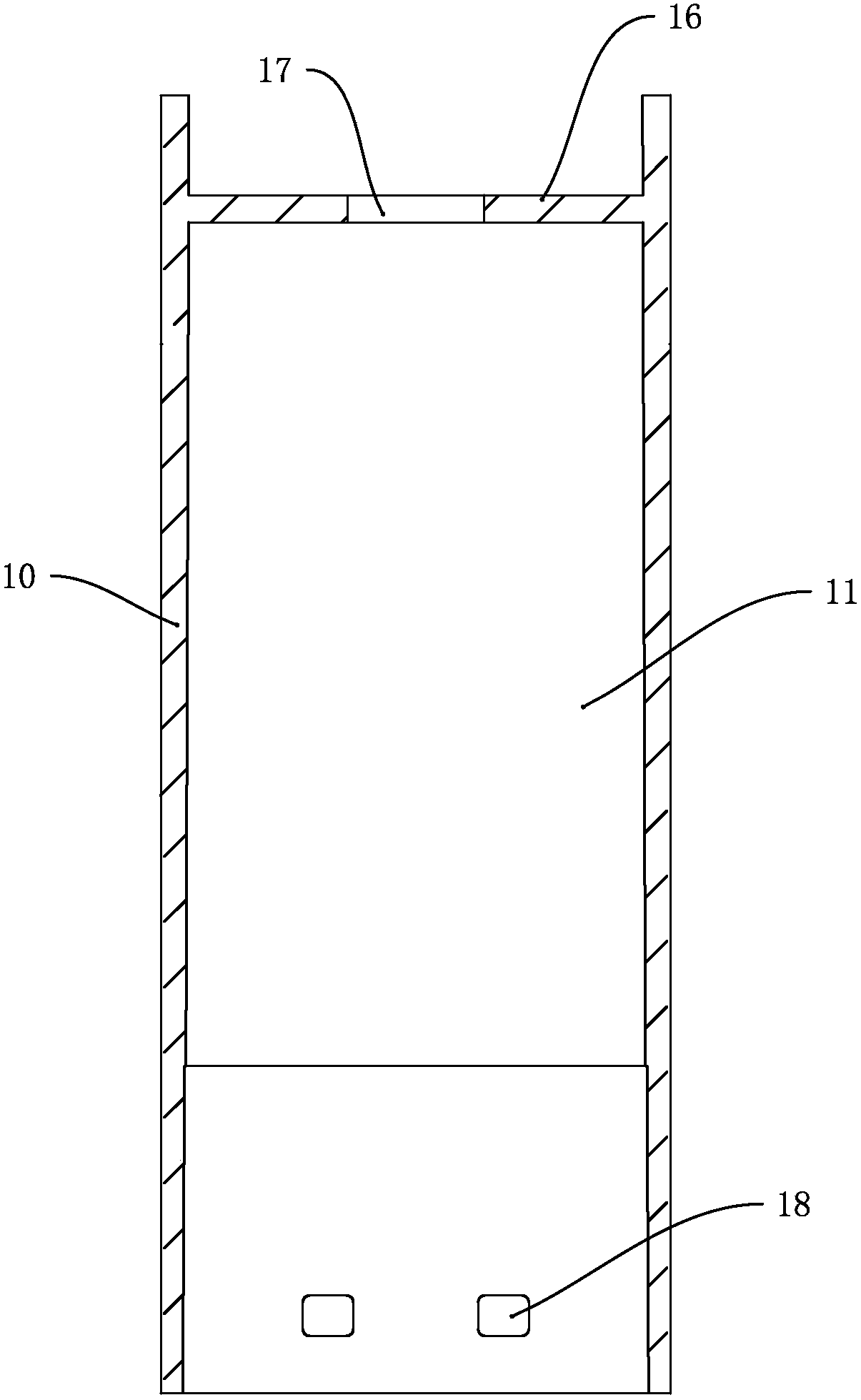

Electronic atomization cigarette cartridge

The invention discloses an electronic atomization cigarette cartridge. The electronic atomization cigarette cartridge comprises a sleeve pipe, an air pipe, a heating component, a suction nozzle, a sealing sleeve and a heating bracket, wherein the upper end of the sleeve pipe is in sealed connection with the suction nozzle; the lower end of the sleeve pipe is in sealed connection with the heating bracket; an air outlet hole and tar inlet holes are formed in the sealing sleeve and longitudinally pass through the sealing sleeve; the tar inlet holes are arranged around the air outlet hole; the sealing sleeve is arranged on the upper surface of the heating bracket and is used for forming a receiving groove with the upper surface of the heating bracket; the heating component is arranged in the receiving groove; a ratio of the sectional area of the heating component to the sectional area of the receiving groove is 30%-50%; the air pipe is arranged in the sleeve pipe; a cigarette tar cavity isformed between the air pipe and the sleeve pipe; the upper end of the air pipe is connected with the suction nozzle; the lower end of the air pipe is communicated with the air outlet hole; the cigarette tar in the cigarette tar cavity enters the heating component through the tar inlet holes. The electronic atomization cigarette cartridge has the advantages that the cigarette tar in a tar storagebin can penetrate into the heating component, the situation that the excess cigarette tar in the tar storage bin enters the receiving groove can also be avoided, and the electronic atomization cigarette cartridge is capable of effectively preventing the cigarette tar from being leaked externally and sucked into the mouth.

Owner:SHENZHEN HANGSEN STAR TECH

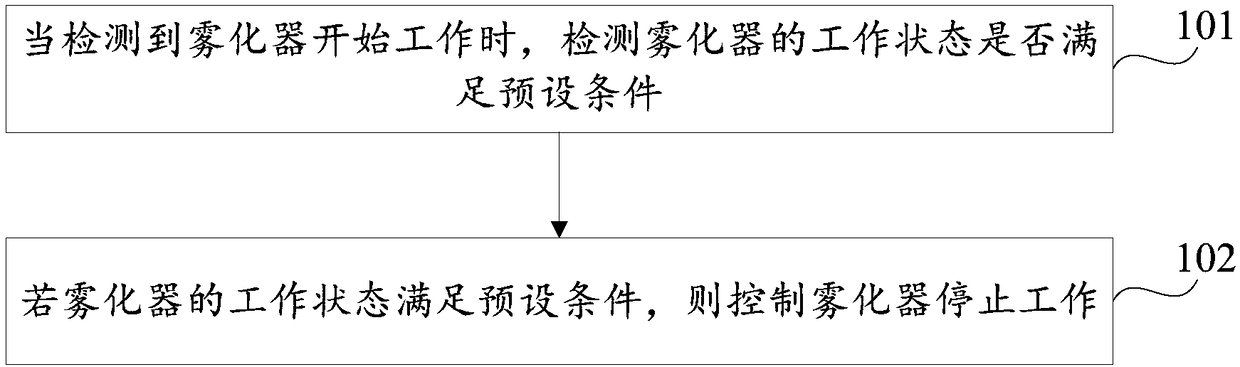

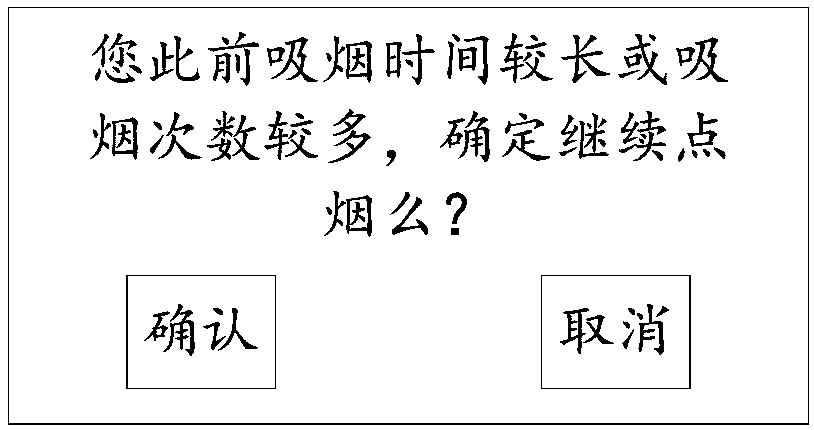

Electronic cigarette and control method and device thereof

ActiveCN109426210ARealize automatic controlImprove control efficiencyTobaccoProgramme control in sequence/logic controllersTarAutomatic control

The invention discloses an electronic cigarette and a control method and device thereof, and belongs to the field of electronic technologies. The control method applied to the electronic cigarette comprises that, when it is detected that an atomizer starts working, whether a working state of the atomizer satisfies preset conditions is detected, the atomizer is used to atomize tobacco tar in the electronic cigarette, and the preset conditions include that the work time length of the atomizer in this time reaches a first preset time length, or the working frequency of the atomizer in a preset period is greater than or equivalent to the preset frequency; and if the working state of the atomizer satisfies preset conditions, and atomizer is stopped from working. Thus, a user is avoided from smoking the electronic cigarette any more, the electronic smoke is controlled automatically, the control efficiency is improved, and the electronic smoke can help the user quitting smoking.

Owner:JOYETECH EURO HLDG

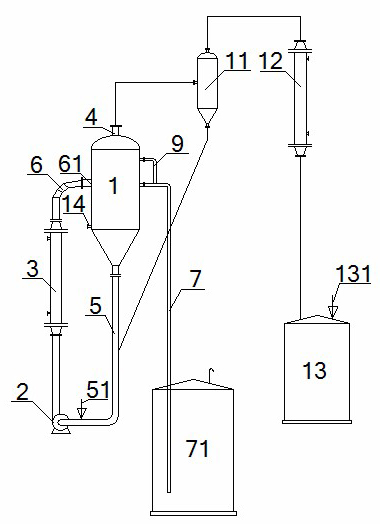

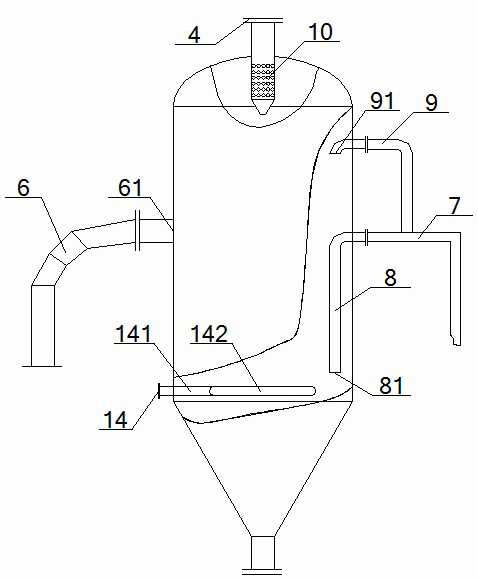

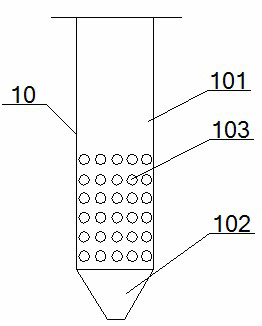

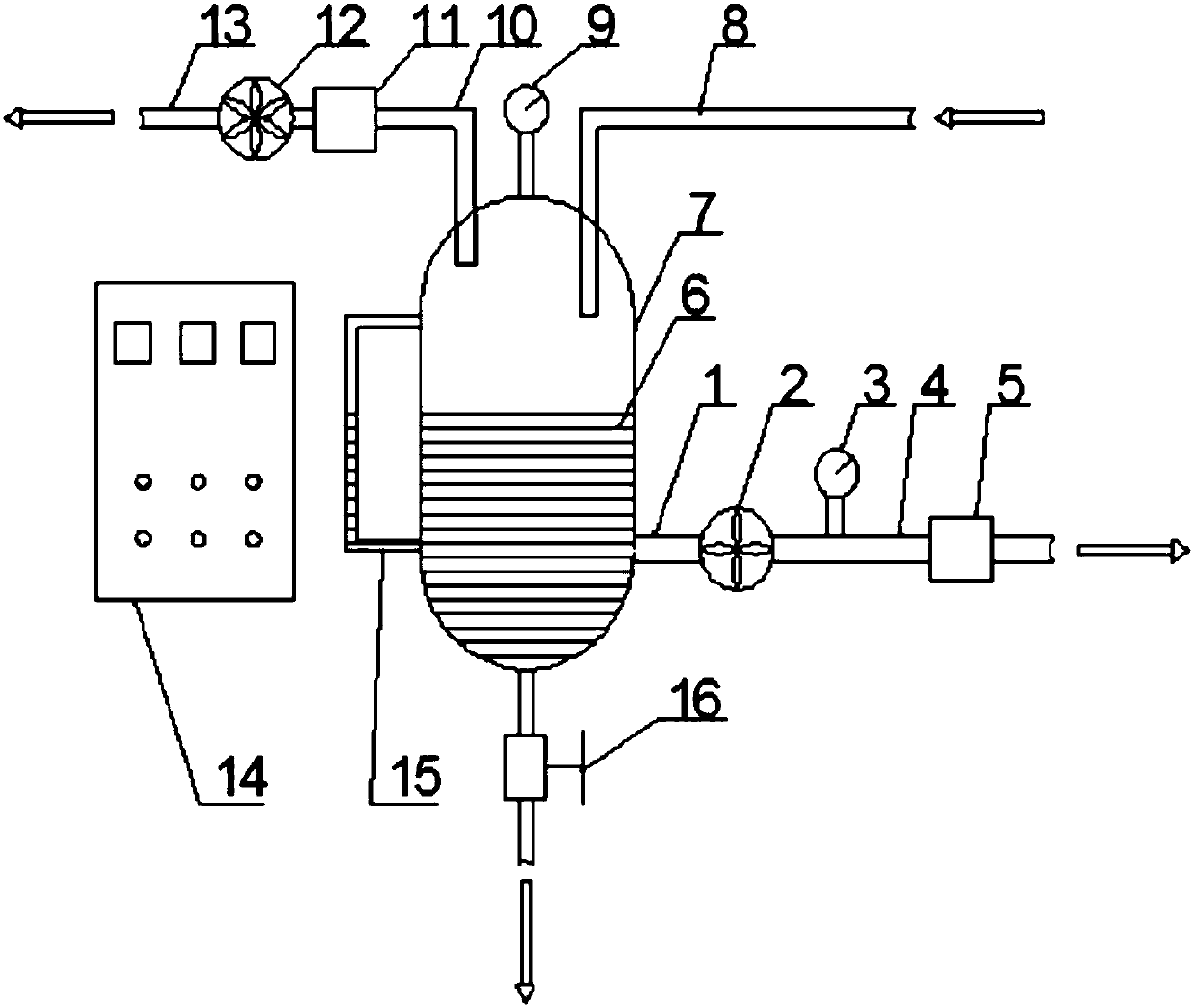

Concentration apparatus for wet method phosphoric acid refinement

ActiveCN102424373AImprove evaporation effectAchieving a flash effectPhosphorus compoundsSiphonPhosphoric acid

The invention relates to a concentration apparatus for wet method phosphoric acid refinement. The concentration apparatus comprises a flash evaporation chamber, a forced circulation pump, a heater, a concentration material liquid outlet pipe, a concentration material fluid inner pipe, a foam removing pipe, a cyclone separator and a steam pipe. A secondary steam outlet and a lower circulation pipeare respectively arranged on the upper end and the lower end of the flash evaporation chamber. An upper circulation pipe and the concentration material liquid outlet pipe are respectively arranged onthe left side and the right side of the flash evaporation chamber. The height of the inner pipe opening on the concentration material fluid inner pipe is less than the height of the pipe opening of the upper circulation pipe. One end of an atmospheric pressure synchronization pipe is communicated with the concentration material liquid outlet pipe, and the other end of the atmospheric pressure synchronization pipe is communicated with the flash evaporation chamber or atmosphere. The foam removing pipe is connected with the secondary steam outlet. The other end of the secondary steam outlet is connected with the cyclone separator. The other end of the cyclone separator is connected with a condensate groove by a condenser. The steam pipe is arranged on a position close to the bottom of the flash evaporation chamber. With the design of the present invention, the flash evaporation effect is achieved, the siphon is prevented, it is ensured that the tiny droplet of the material liquid does not easily escape along with the secondary steam, such that the requirement of steam stripping defluoridation or steam stripping extractant recovery can be met so as to form a continuous production.

Owner:吴杰

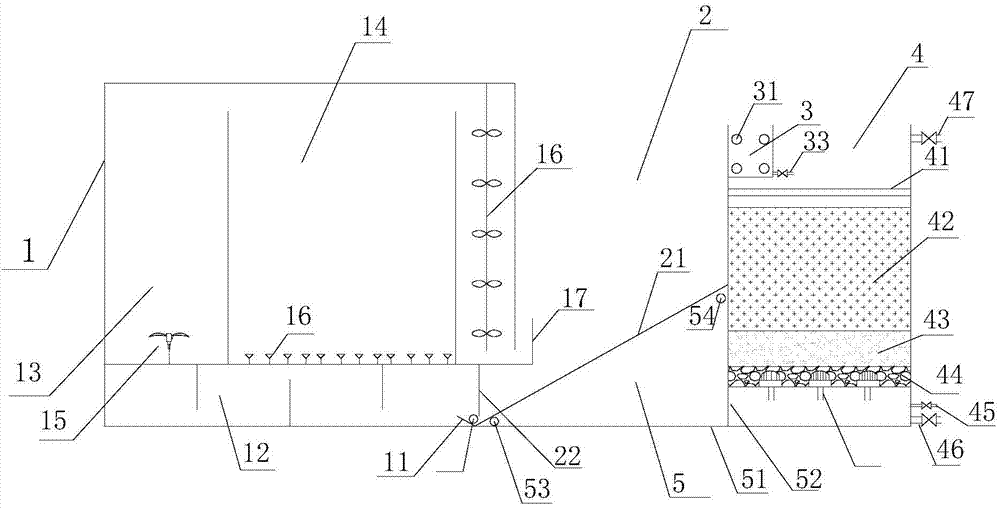

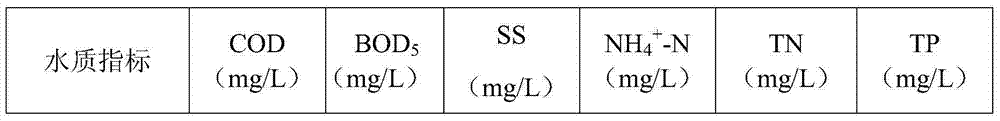

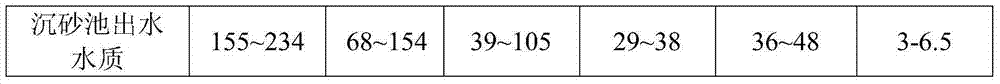

Medium- and small-sized sewage treatment integrated device

ActiveCN104773917ACompact structureSmall footprintMultistage water/sewage treatmentWater qualitySmall footprint

The invention provides a medium- and small-sized sewage treatment integrated device which comprises a biotreatment unit, a precipitate and sludge return unit, an optical catalytic oxidization unit, a deep treatment unit and a disinfection unit sequentially connected, wherein the precipitate and sludge return unit is respectively connected with the water inlet of the optical catalytic oxidization unit and the water inlet and water outlet of the deep treatment unit; the biotreatment unit comprises a water inlet region, an anaerobic treatment region, an anaerobic treatment region and an aerobic treatment region which are sequentially connected; the deep treatment region comprises a water distributing tank, a particle active carbon filter material layer, a quartz sand filter layer and a cobblestone supporting layer which are sequentially connected from top to bottom. The device has the characteristics of being compact in structure, small in occupied area, convenient to use, flexible to operate, low in treatment cost, high in effluent quality, strong in adaptability and the like and has relatively good popularization and application prospects.

Owner:HOHAI UNIV

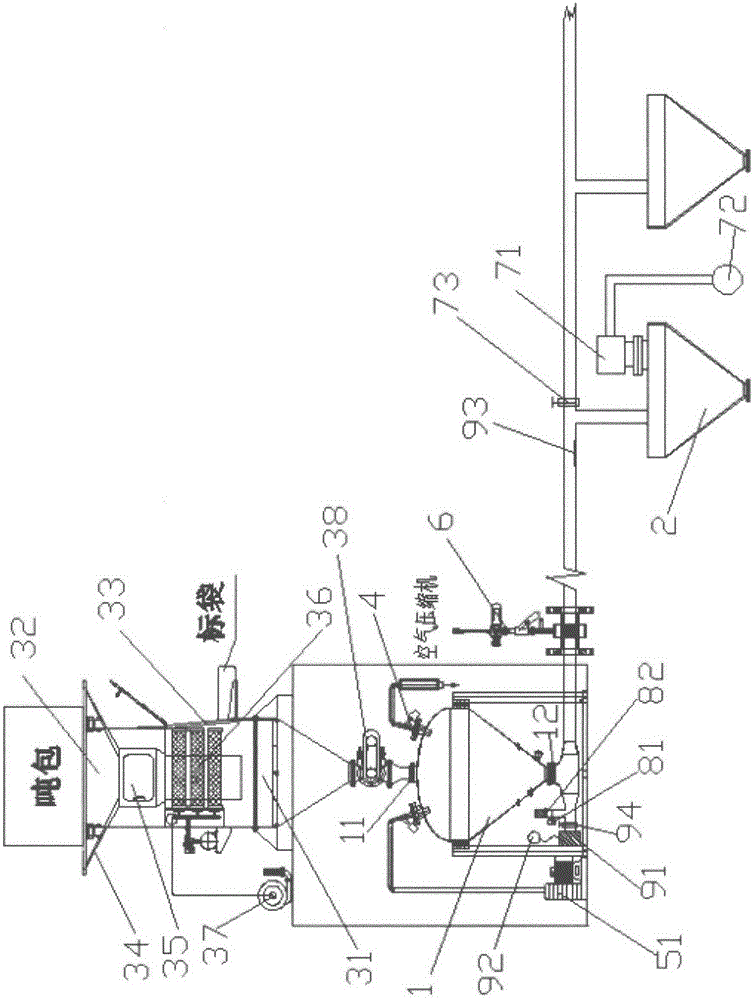

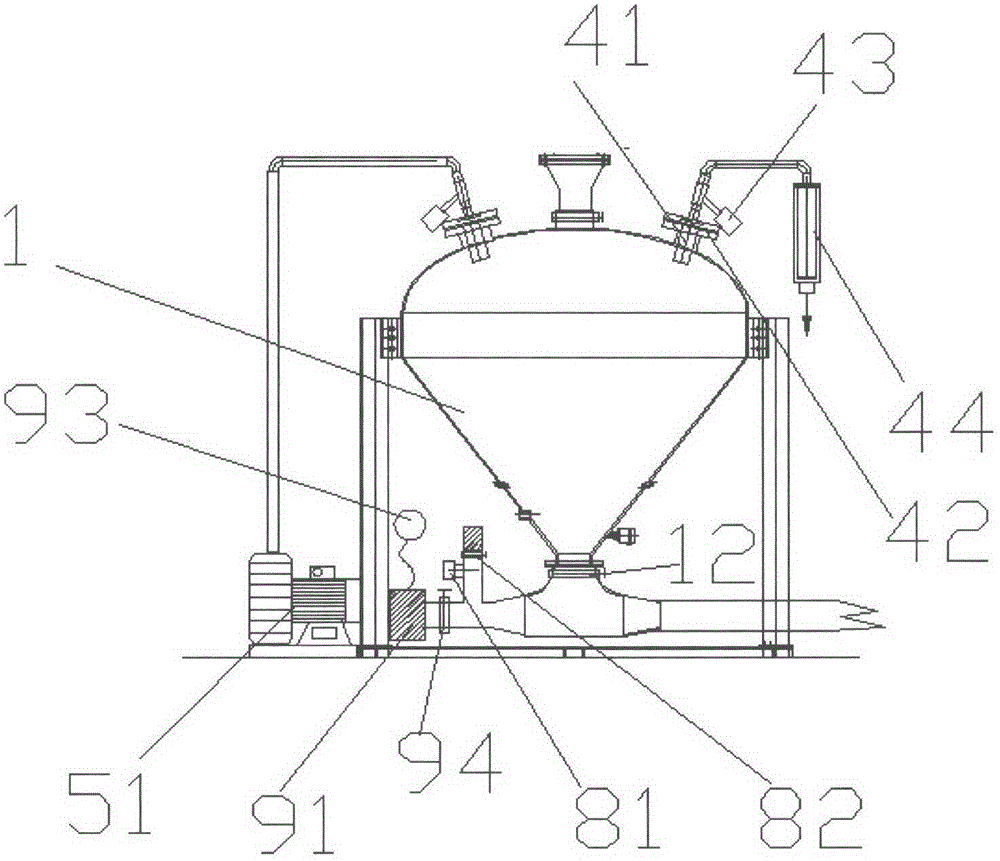

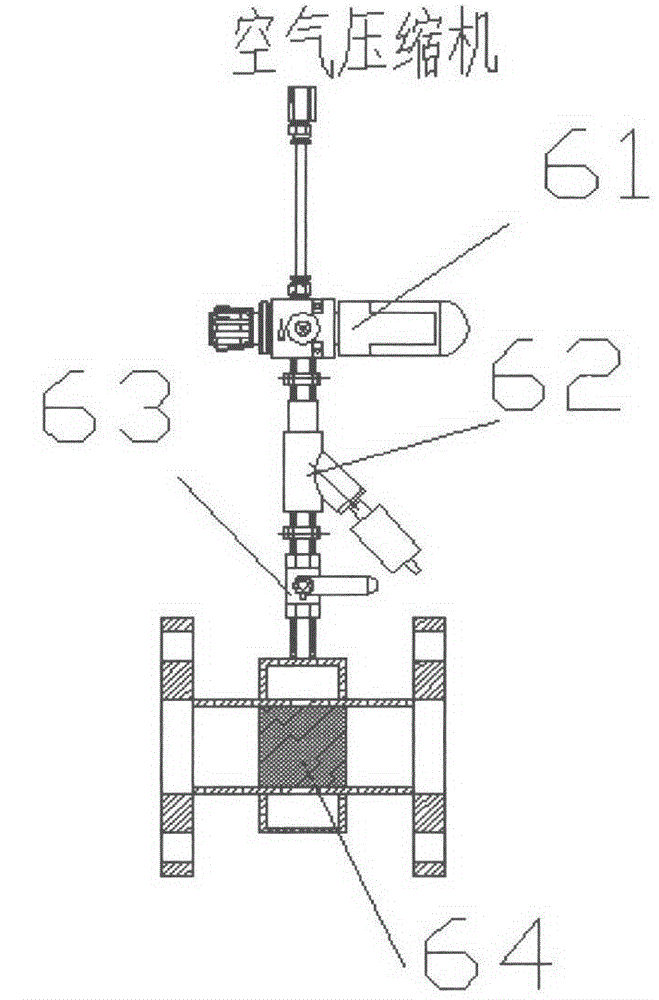

Positive-pressure conveying system device

The invention discloses a positive-pressure conveying system device which comprises a sending tank and a storehouse. The sending tank and the storehouse are connected through a pipeline. Butterfly valves are arranged at the position of a feeding port of the sending tank and the connecting position of the bottom of the sending tank and a discharging pipe. The positive-pressure conveying system device further comprises a tonnage and standard dual-purpose unpacking and material collecting device, an exhaust noise-reduction device, a negative-pressure accelerated feeding device, a material plug forming device, a pipeline cleaning device, a pipeline blocking removing device, and a mixing device with the ratio of fed materials and inlet gas capable of being adjusted. By means of the positive-pressure conveying system device, material conveying can be completed with high efficiency, pollution is reduced, energy consumption is reduced, time and labor are saved, and the production cost is reduced.

Owner:CHANGZHOU CHANGHENG DEYU POWDER INTEGRATIVE SYST

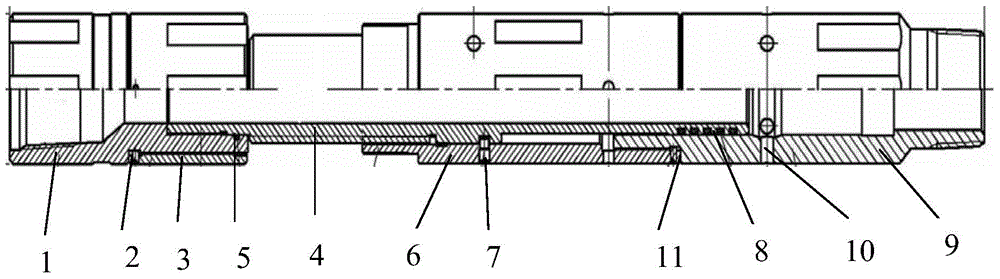

Automatic balance pressure expansion and fishing integrated expansion pipe tool and its use method

ActiveCN102296939AImprove safety and reliabilityReduce construction riskWell/borehole valve arrangementsSealing/packingEngineeringTube tool

The invention discloses an automatic pressure-balancing expansion-catch integrated expandable tube tool and a use method thereof. The automatic pressure-balancing expansion-catch integrated expandable tube tool comprises an expandable tube and a bottom plug arranged on the bottom of the expandable tube, a slidable pull rod which runs through the expandable tube and the bottom plug is arranged in the expandable tube, the lower end of the bottom plug is connected with an oil drain device which comprises an oil drain device shell sleeved on the outside of the pull rod, the gap between the oil drain device shell and the pull rod is formed into an annular space, a sliding sleeve which can slide in the annular space is arranged in the annular space, a back nut which is radially raised outwards is fixed on the bottom of the pull rod, the oil drain device shell is radially provided with an oil drain outlet, the sliding sleeve is radially provided with an aligning slotted hole, and the back nut can abut against and drive the sliding sleeve to slide in the annular space, so that the aligning slotted hole can be aligned and communicate with the oil drain outlet. The invention has the advantages that: the occurrence of the pumping phenomenon in the process of catch is prevented, the difficulty of bottom plug catch is decreased, and the safety and reliability of on-site operation in oil fields are enhanced.

Owner:PETROCHINA CO LTD

Anti-leakage lubricating oil supply system of power device

The invention discloses an anti-leakage lubricating oil supply system of a power device, and belongs to the technical field of mechanical and power equipment lubrication supply. The lubricating oil supply system comprises an oil supply pump oil inlet pipe, an oil supply pump, an oil supply pressure meter, an oil supply pump oil outlet pipe, an oil supply filter, lubricating oil, an oil storage tank, an equipment oil return pipe, an oil storage tank pressure meter, a vacuum pump air inlet pipe, a vacuum pump air inlet filter, a vacuum pump and a vacuum pump exhaust pipe. According to the system, the lubricating system conducts lubrication in the running manner of the negative pressure lower than the environment pressure, an inlet and an outlet of a lubricating oil pump are in negative pressure; during work, the lubricating oil pump conveys the lubricating oil to the lubricating part; through control the pressure of the vacuum pump and the oil pump, it is guaranteed that the pressure atthe lubricating part is lower than the outer pressure of the lubricating system, a small amount of gas flows into a sealing cavity from the exterior of the lubricating system, the lubricating oil is driven to flow in the equipment oil return pipe direction, and accordingly the purpose that lubricating oil is prevented from leaking outwards from a gap is achieved. The system is applicable to gas turbines or other high-speed rotation power machines.

Owner:HARBIN ENG UNIV

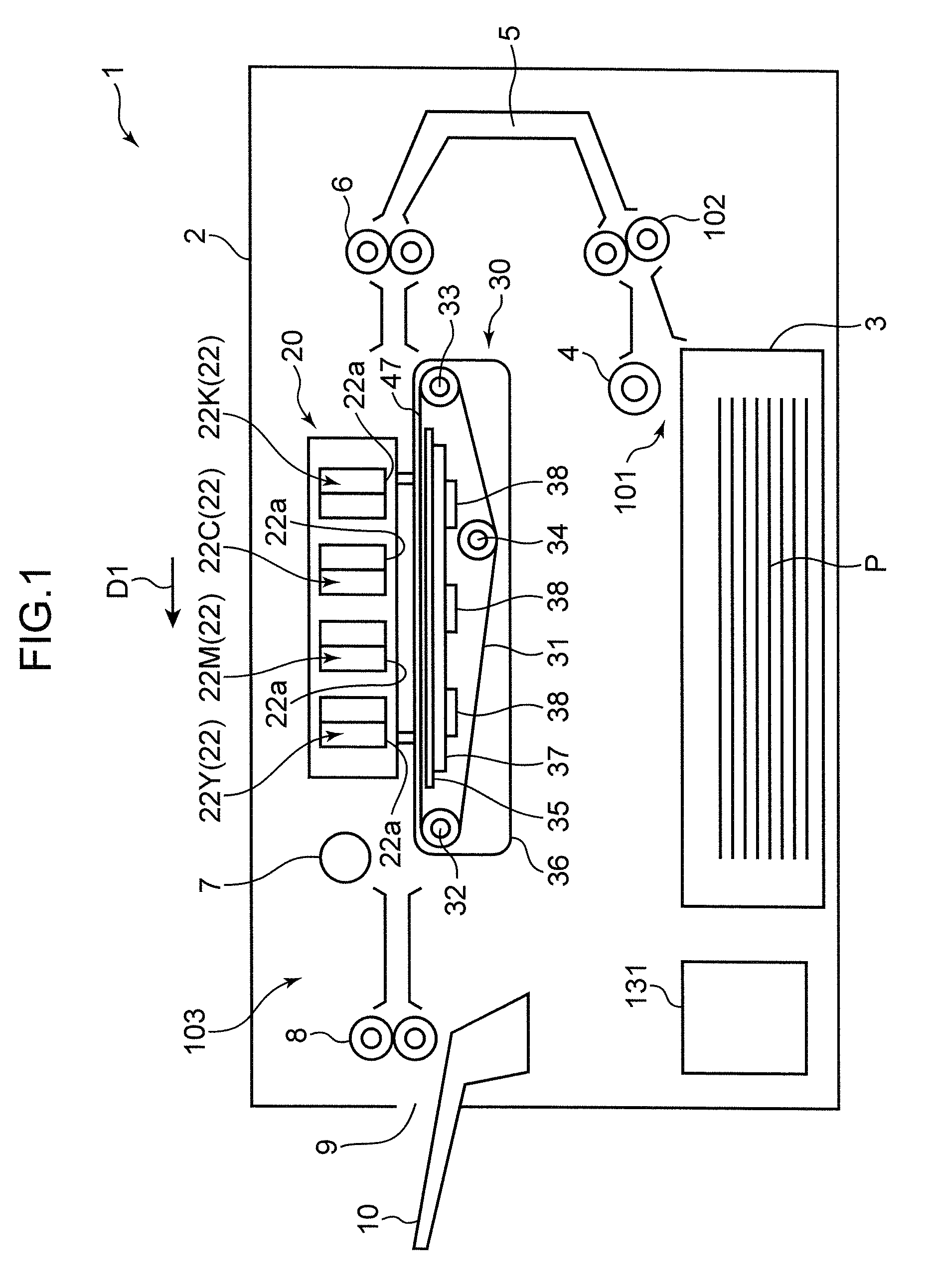

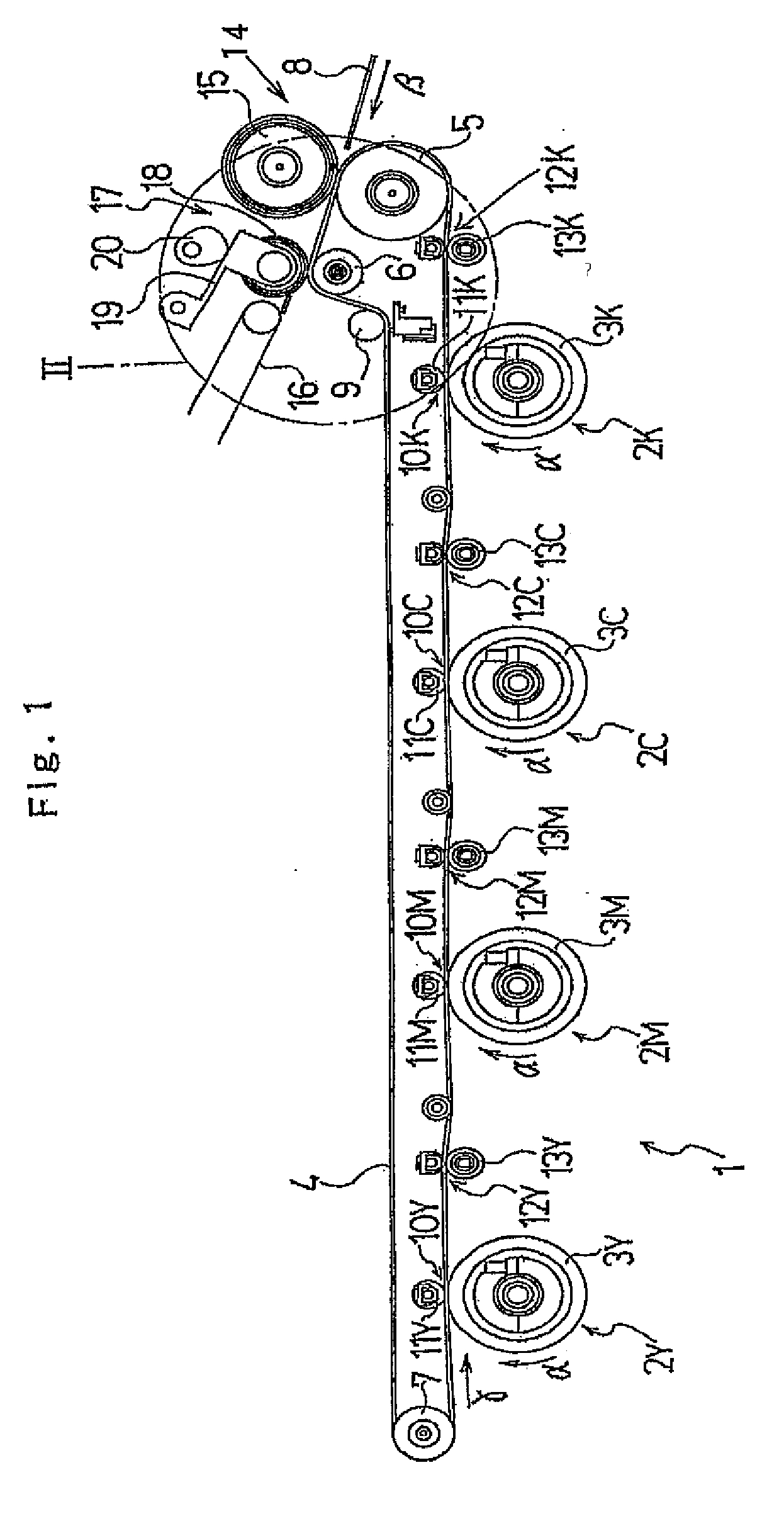

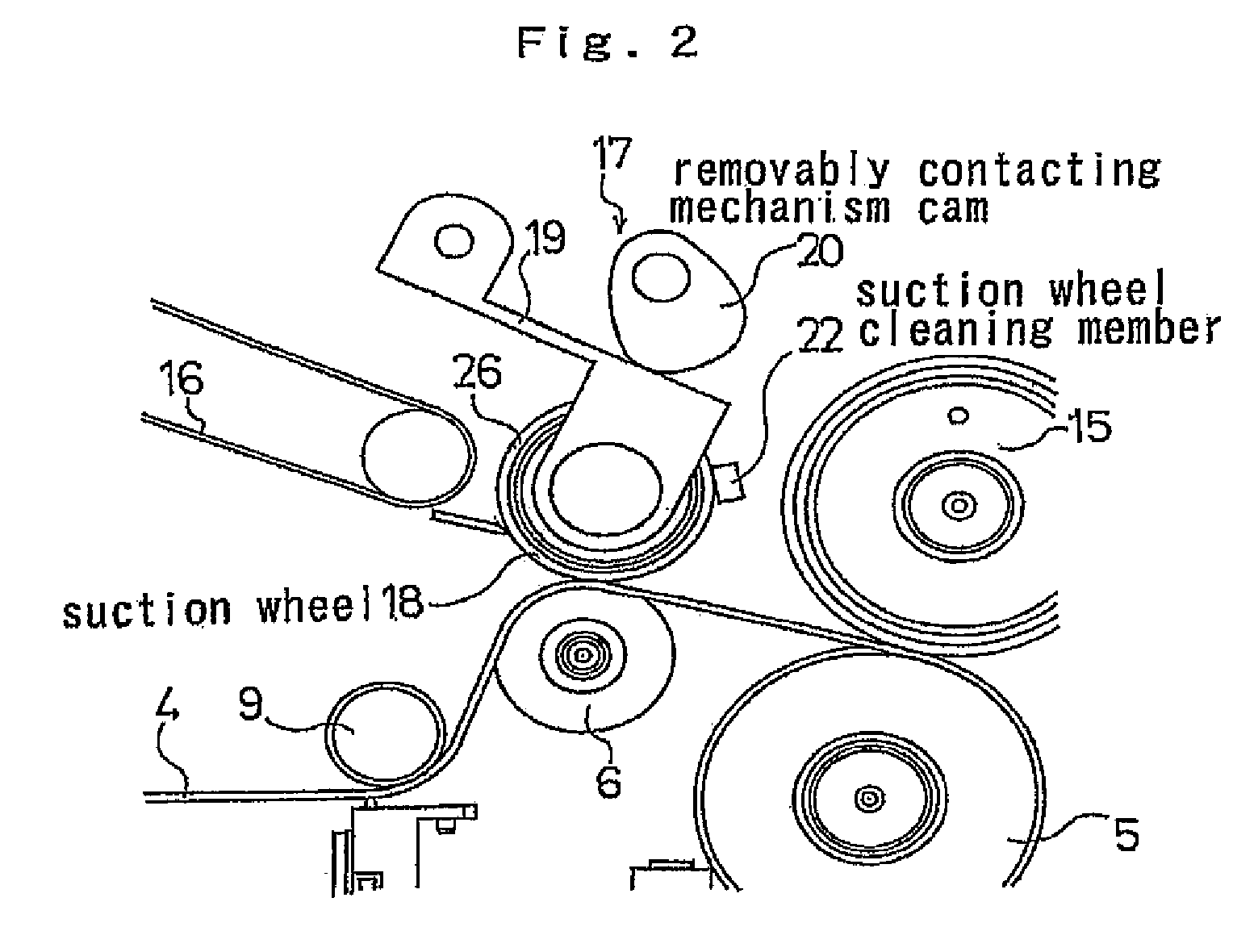

Transfer Material Separating Device, Transfer Device and Image Forming Apparatus

InactiveUS20090190979A1Reliable separationPrevent suctionElectrographic process apparatusArticle separationMaterial SeparationCam

A transfer material separating device includes a transfer material moving member (intermediate transfer belt) adapted to move with a transfer material held in contact with and pressed against it so as to have a liquid developer image transferred onto the transfer material and a transfer material separation / suction section (a suction wheel, a suction wheel support lever, a cam and a spring) for sucking the transfer material moving with the transfer material moving member at the surface opposite to the image transfer surface thereof and separating the transfer material from the transfer material moving member.

Owner:SEIKO EPSON CORP

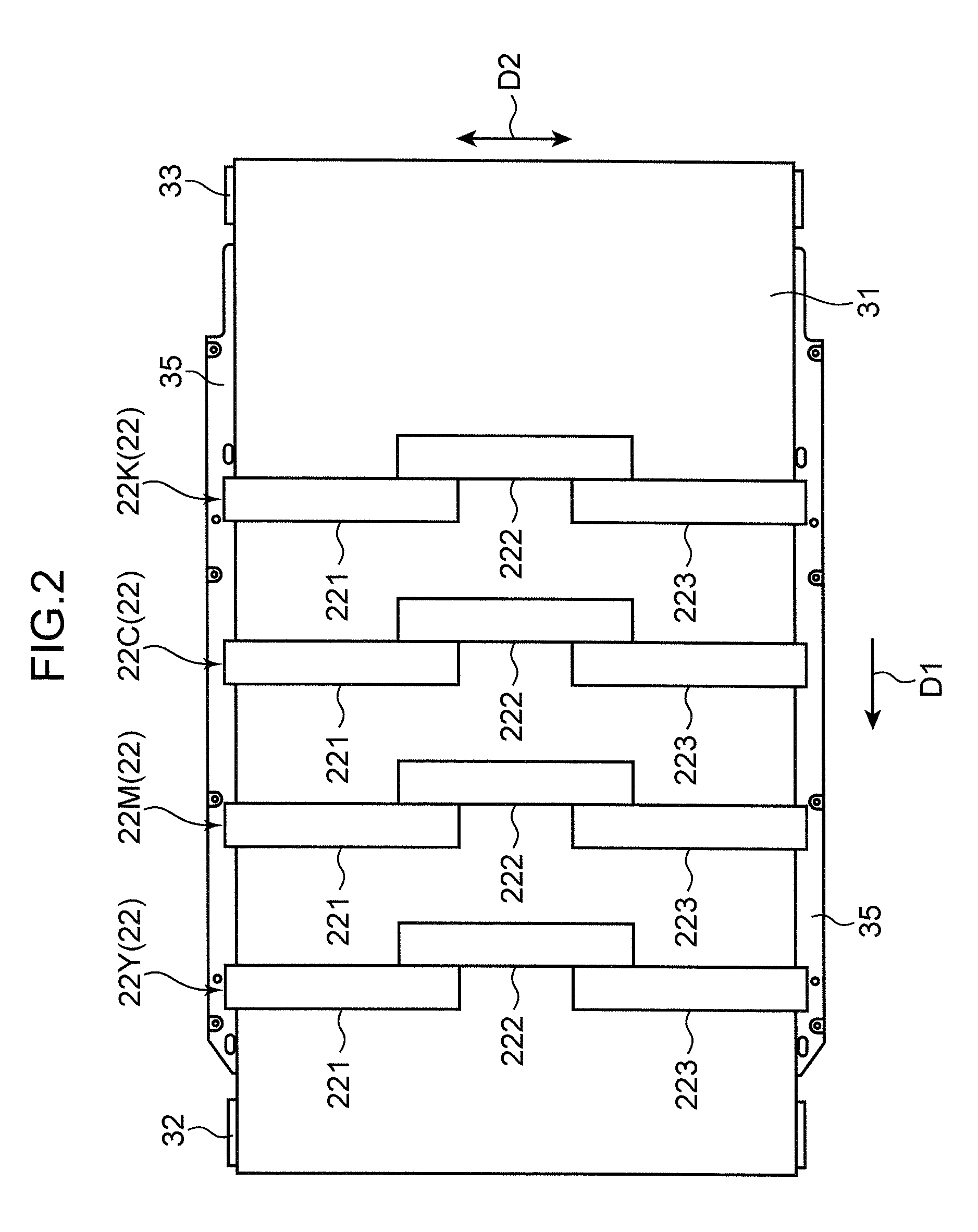

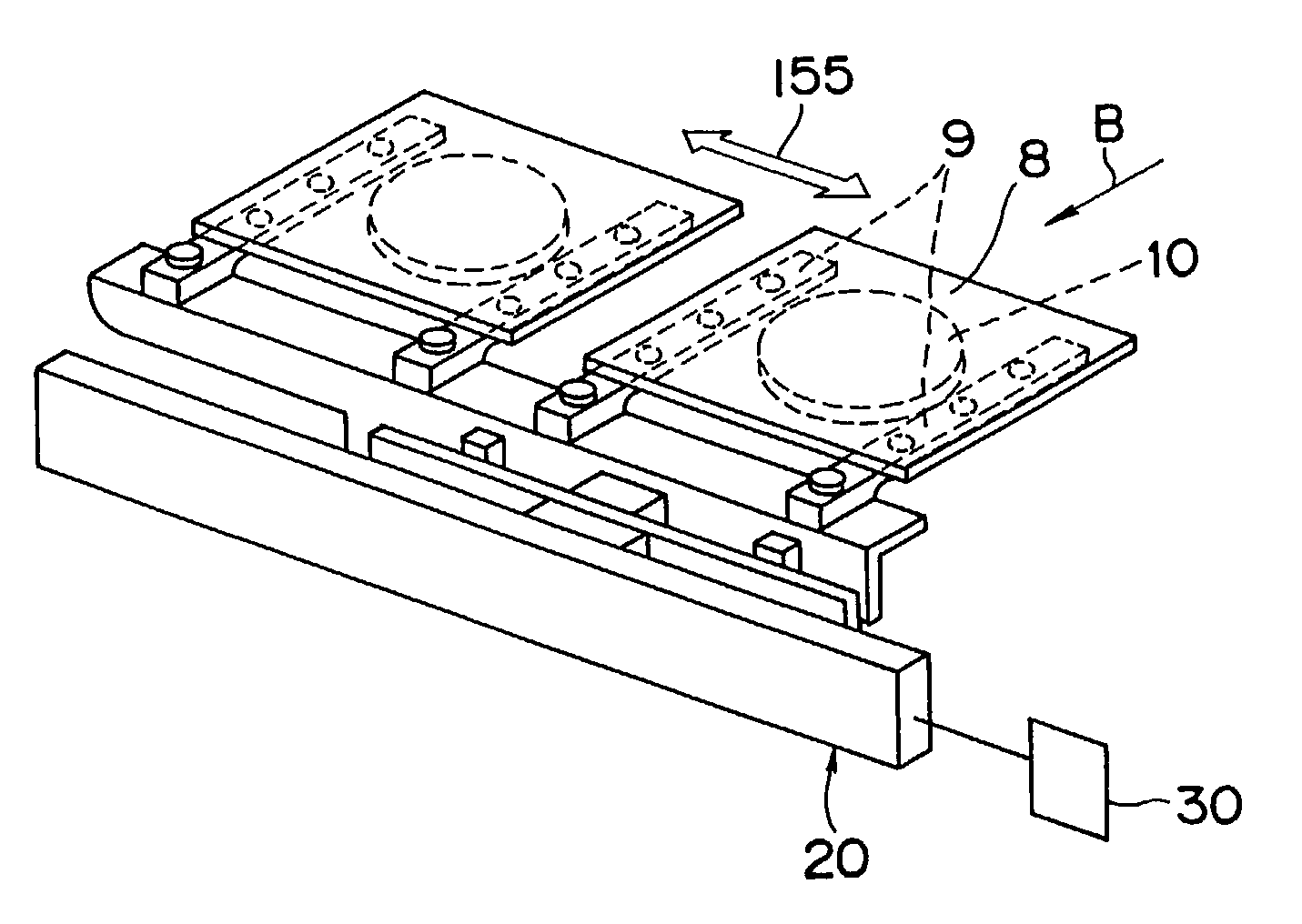

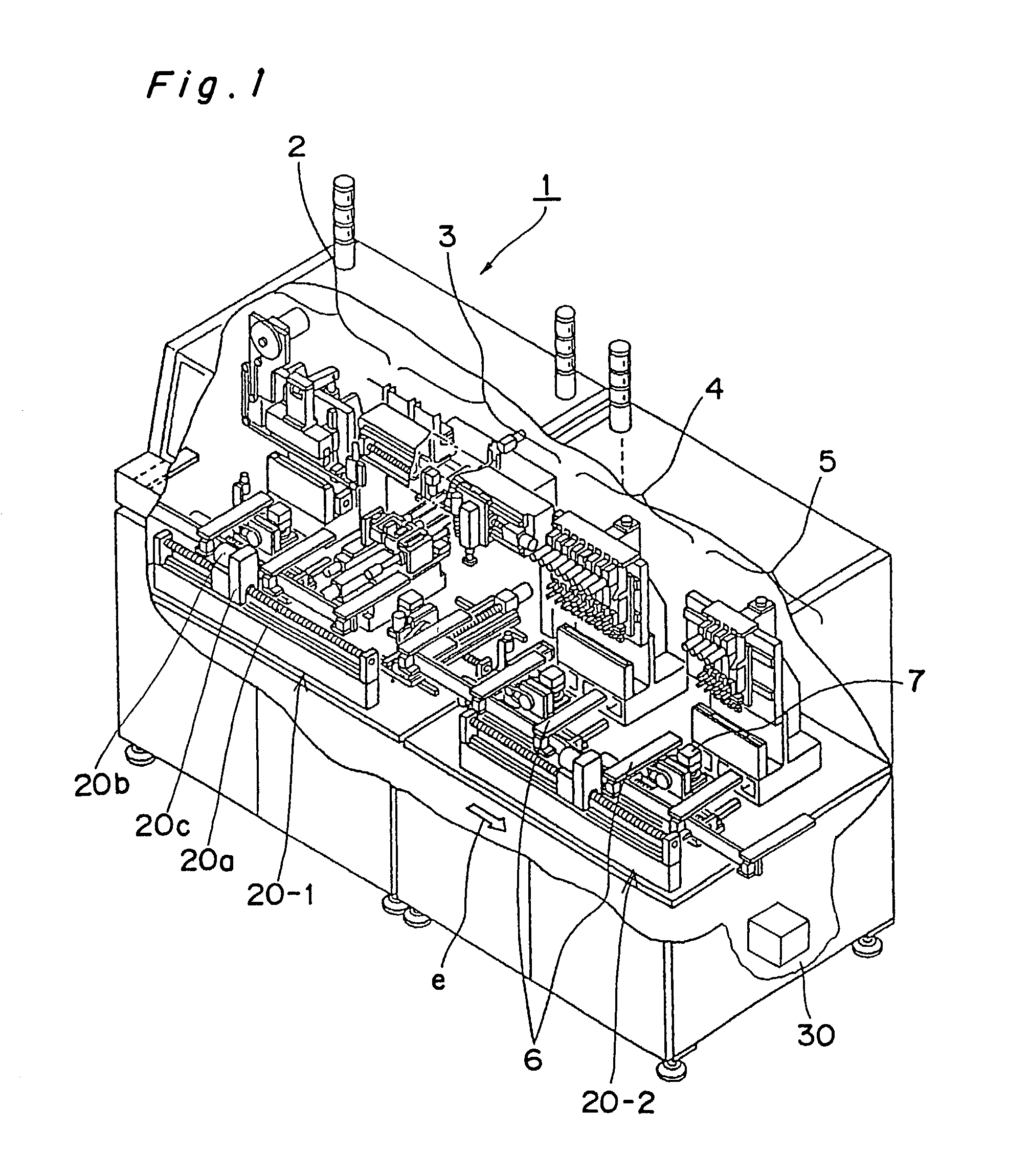

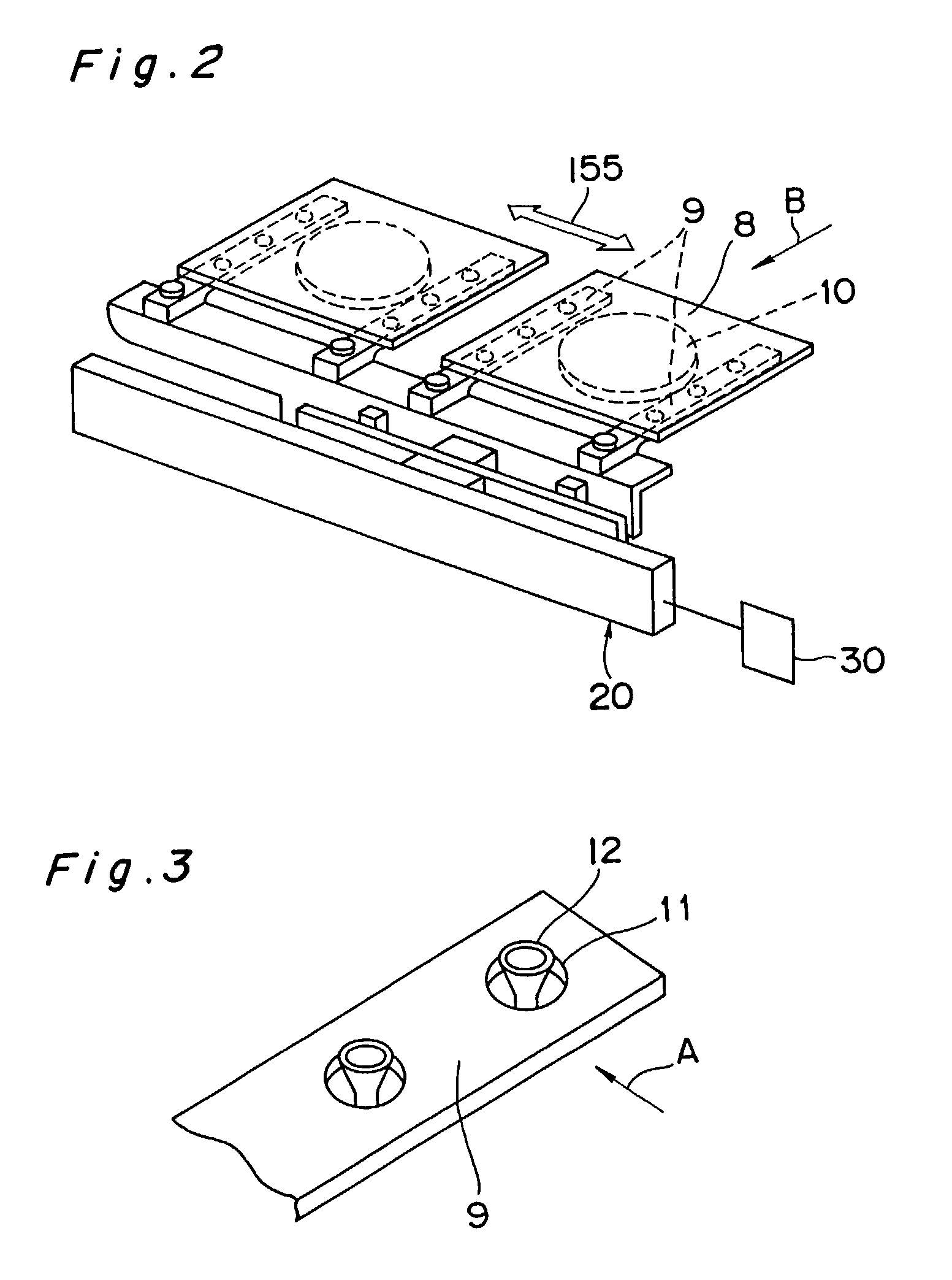

Component mounting apparatus and component mounting method, and recognition apparatus for a component mount panel, component mounting apparatus for a liquid crystal panel, and component mounting method for a liquid crystal panel

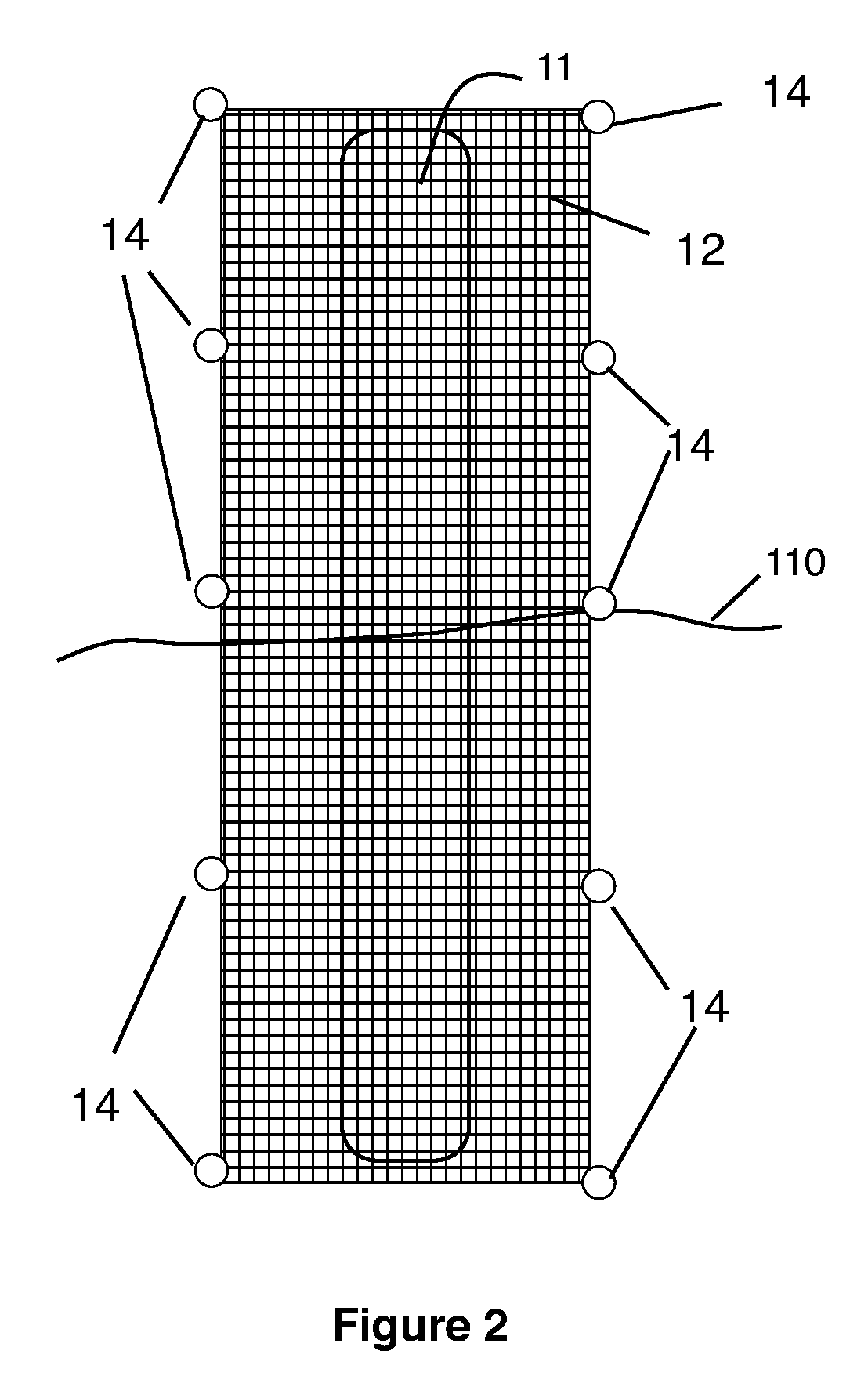

InactiveUS7089073B2High accuracyNegate deflection amountComputer controlSimulator controlLiquid-crystal displayLiquid crystal

Transfer of liquid crystal panels to subsequent processes is performed with the panels placed on transfer arms and held by suction pads. A small suction force can be sufficient, and a suction irregularity is prevented. The transfer arms are arranged at a lower side of the liquid crystal panels, thus not obstructing the liquid crystal panels. In arranging the liquid crystal panels at an image pickup device, a panel holding device is controlled to be driven so as to position panel marks to a bonding height position while negating a deflection amount of the liquid crystal panels, and furthermore a component holding device is controlled to be driven so as to position component marks to the bonding height position and to mount electronic components to the liquid crystal panels at the bonding height position.

Owner:PANASONIC CORP

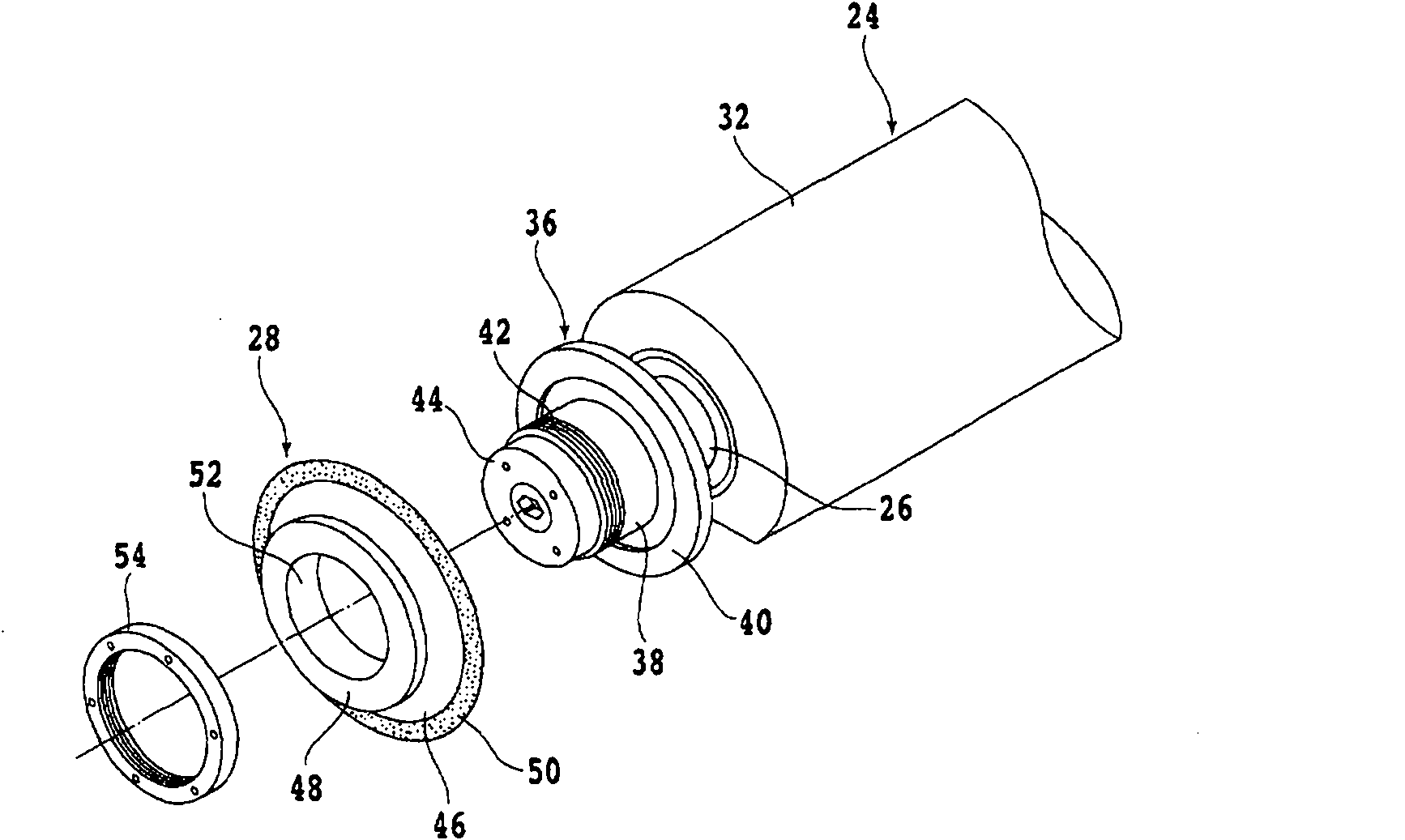

Cutting device

ActiveCN102097373APrevent suctionGreat suctionSemiconductor/solid-state device manufacturingFine working devicesEngineeringMechanical engineering

The invention provides a cutting device, which enables a stable suction of cutting liquid and applies no damage to an object to be processed. The cutting device comprises a sucking mouth disposed at flying side of the cutting liquid along with the rotation of the cutting tool, an inflow channel connected to the sucking mouth, a fluid separating mechanism body which comprises a first opening, a second opening and a third opening, wherein the third opening is disposed at the same height as the first opening or at the position lower than the first opening for discharging the cutting liquid, a suction source connected to the second opening, and a discharge channel with one end being connected to the third opening and the other end being provided with a discharging outlet whose height is equal to or lower than that of the first opening. The discharge channel discharges the liquid in the fluid separating mechanism body and is provided with a liquid accumulation part which enables the discharging outlet to be full of liquid all the time and prevent external gas from flowing in.

Owner:DISCO CORP

Carpet cleaner

InactiveCN102652659ALarge capacityIncrease the areaCarpet cleanersFloor cleanersLotionControl theory

The invention relates to a carpet cleaner, which is characterized in that, the cooling exhaust air stream of a sucking motor is suitable for lotion pressure injection, and therefore, the lotion can be uniformly injected in the length direction of the rotary shaft of a rotary brush.

Owner:SUZHOU HAAN TECH +1

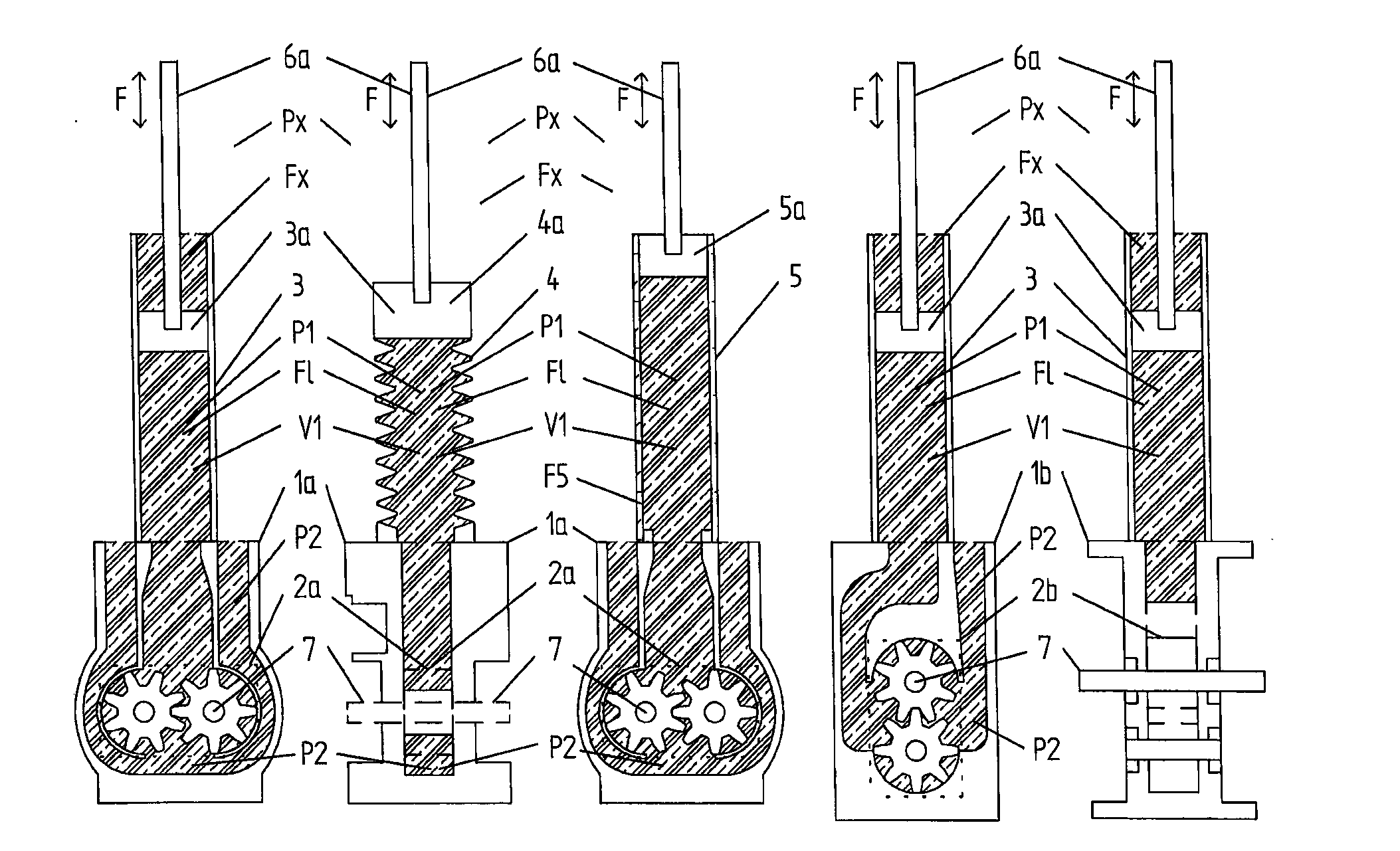

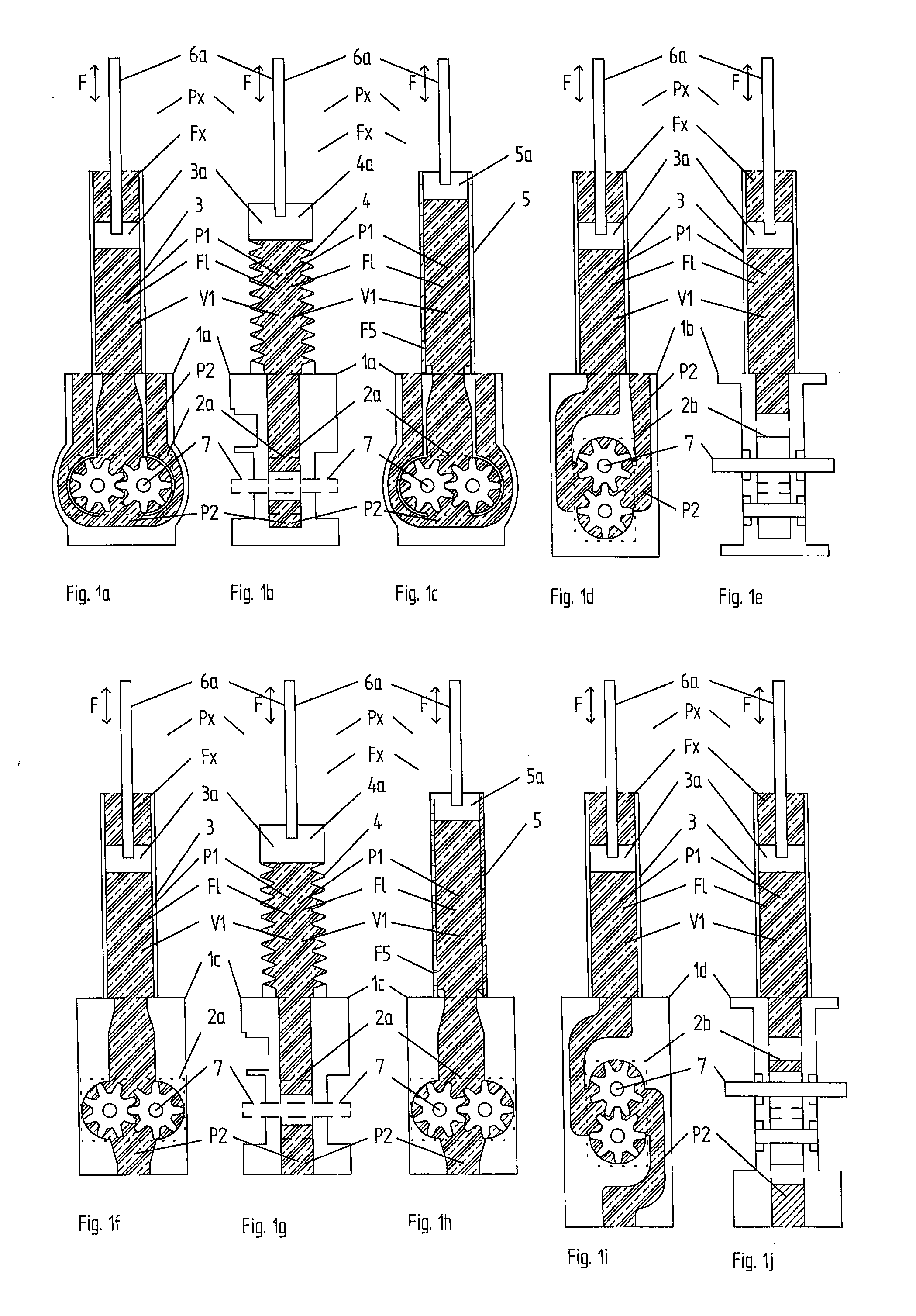

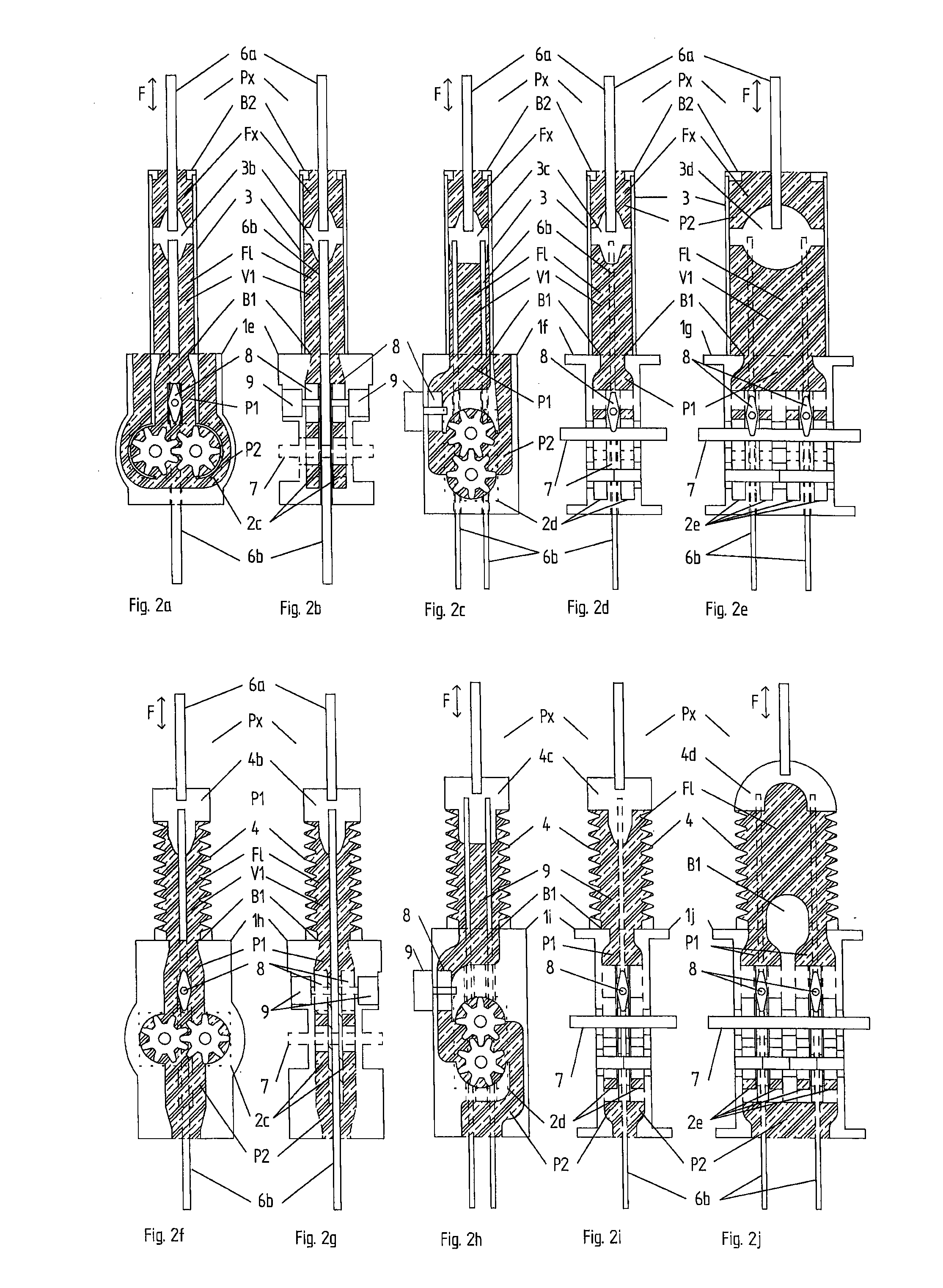

Energy Transforming Unit and Energy Transforming System Comprising Such a Unit

ActiveUS20130236347A1Avoid cavitationPressure in to fallOscillating piston enginesEngine fuctionsComputer moduleEngineering

The present invention relates to an energy transforming unit adapted to convert reciprocating forces (Fl) into rotating axle movements on at least one force transmitting axle and / or into electrical power. The unit comprises at least one restriction device (3, 4, 5) which is directly connected to the force and which is arranged to forward the incoming reciprocating forces (Fl) into a movement over at least one conversion module (2a-d, 56, 64, 73, 80, 81, 87, Cm). The energy transforming unit is characterized in that the at least one restriction device (3, 4, 5) is delimiting one, by the energy transforming unit enclosed reciprocating volume which entirely or partly passes through the at least one conversion module (2a-d, 56, 64, 73, 80, 81, 87, Cm). The reciprocating volume can comprise a non-compressible fluid arranged to forward the incoming forces into a reciprocating fluid movement over the at least one conversion module (2a-d, 56, 64, 73, 80, 81, 87, Cm) and / or the reciprocating volume can comprise at least one mechanical force transmitting arrangement adapted to the at least one conversion module. The unit further comprises a compact central unit (1a-q) which at least partly encloses the at least one conversion module.

Owner:CORPOWER OCEAN

Shear pin type bypass valve

ActiveCN104989322AEasy to enterEasy to take outWell/borehole valve arrangementsSealing/packingEngineeringScrew thread

The invention discloses a shear pin type bypass valve which comprises an upper connector, a spline mandrel and a lower connector. The upper end of the spline mandrel is sleeved with the upper connector through a screw. The outer side of the spline mandrel is provided with a segment of spline mandrel outer cylinder. A certain distance exists between the upper end of the spline mandrel outer cylinder and the bottom end of the upper connector. The lower end of the spline mandrel outer cylinder is screwed on the outer side of the lower connector through a screw. The spline mandrel outer cylinder is provided with a threaded hole. The outer wall of the corresponding spline mandrel is provided with a mounting groove. The spline mandrel outer cylinder is fixed to the spline mandrel by screwing in shear pins. The side wall, located below the bottom end of the spline mandrel, of the lower connector is provided with bypass holes, so that an inner flow channel of the spline mandrel is communicated with outer bypass annular holes. The outer side of the lower portion of the upper connector is sleeved with a pressing fixing sleeve through screw threads. The outer side of the upper portion of the spline mandrel outer cylinder is provided with an outer screw thread matched with an inner screw thread of the pressing fixing sleeve. The shear pin type bypass valve is simple in structure, the ground pressure test is implemented easily, and the shear pins replace other bypass valves to press downwards and close the bypass valves in a delayed mode.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

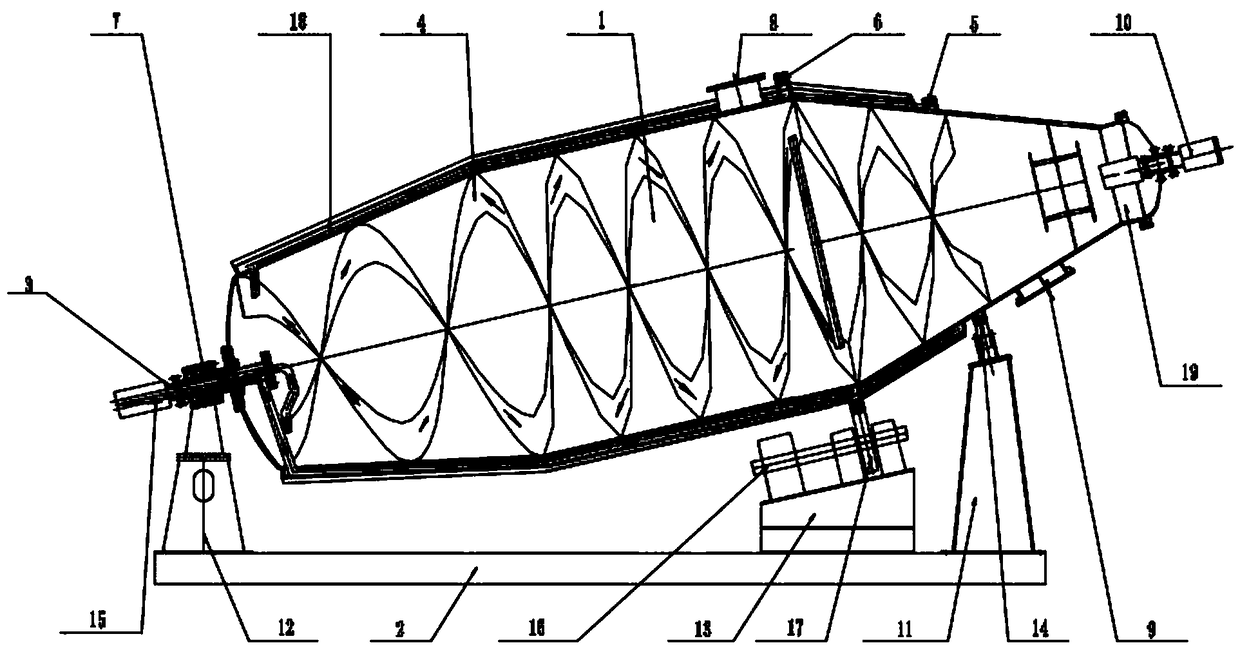

Oblique-drum vacuum solid fermentation tank internally provided with heat-exchange helical blade

ActiveCN109055193AAchieving stirringRealize dual heating/coolingBioreactor/fermenter combinationsBio-organic fraction processingHelical bladeBiochemical engineering

The invention discloses an oblique-drum vacuum solid fermentation tank internally provided with a heat-exchange helical blade. The oblique-drum vacuum solid fermentation tank internally provided withthe heat-exchange helical blade comprises a tank body and a base, wherein a hollow stirrer used for stirring and mixing is arranged on the inner wall of the tank body, and a bearing rail and a drivengear which surrounds the tank body are arranged at the front end of the tank body; a hollow radical shaft is arranged at the bottom end of the tank body, and a bearing is arranged outside the hollow radical shaft; a vacuumizing rotating connector is arranged at the top end of the tank body, and the vacuumizing rotating connector is communicated with a vacuum pump; a first supporting base, a secondsupporting base and a motor installation base are arranged on the base, a bearing wheel matched with the bearing rail is arranged on the first supporting base, the second supporting base is movably connected with the bearing, a heat-exchange medium rotating connector is arranged at the tail end of the bearing, a driving motor is arranged on the motor installation base, and a driving gear matchedwith the driven gear is arranged on the driving motor. The oblique-drum vacuum solid fermentation tank internally provided with the heat-exchange helical blade has internal and external double heating / cooling, double stirring and back mixing functions, capable of completing vacuum drying at the same time, and is suitable for multi-purpose non-in-place sterile solid fermentation production.

Owner:沈阳升顺机械设备有限公司

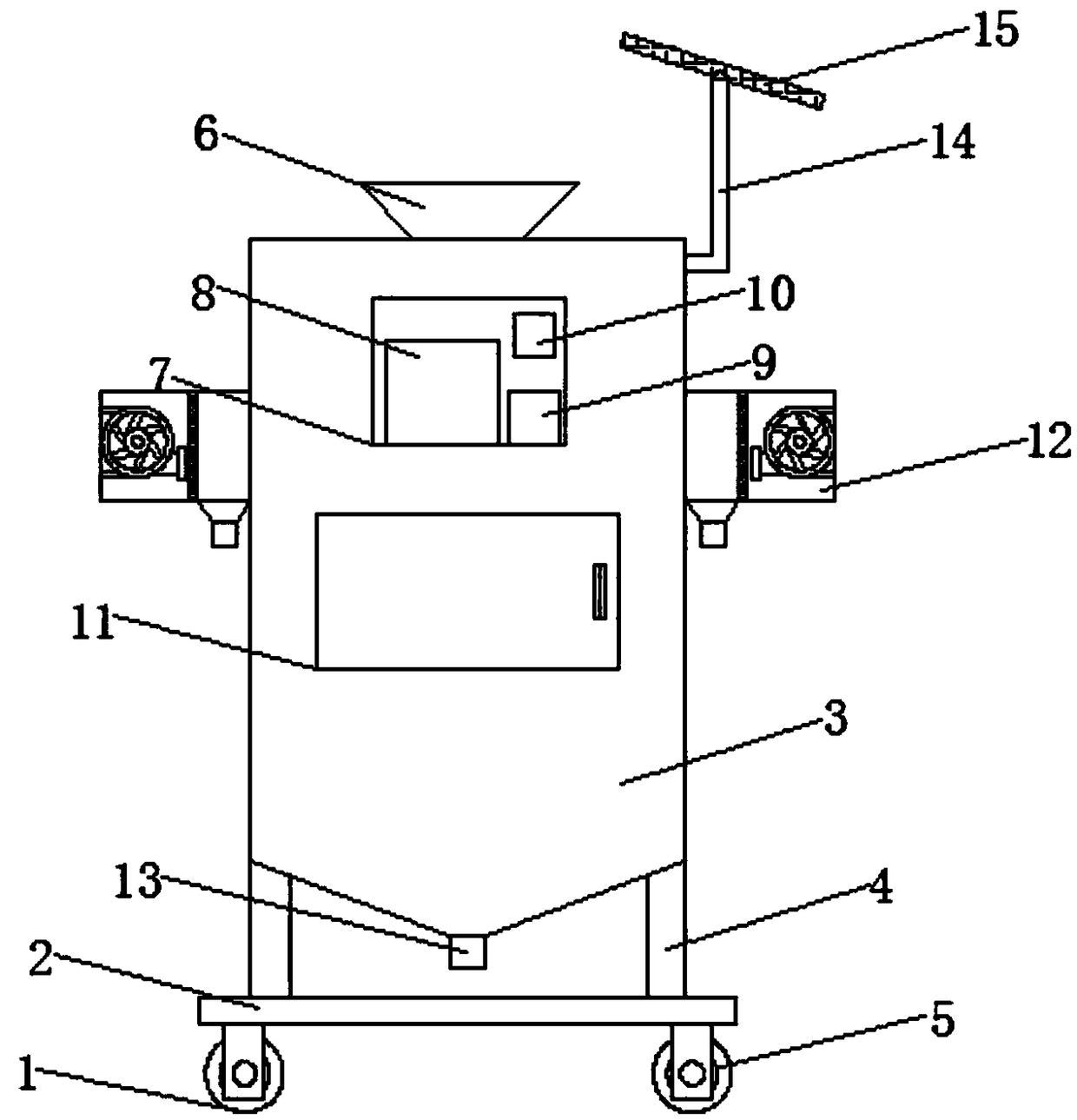

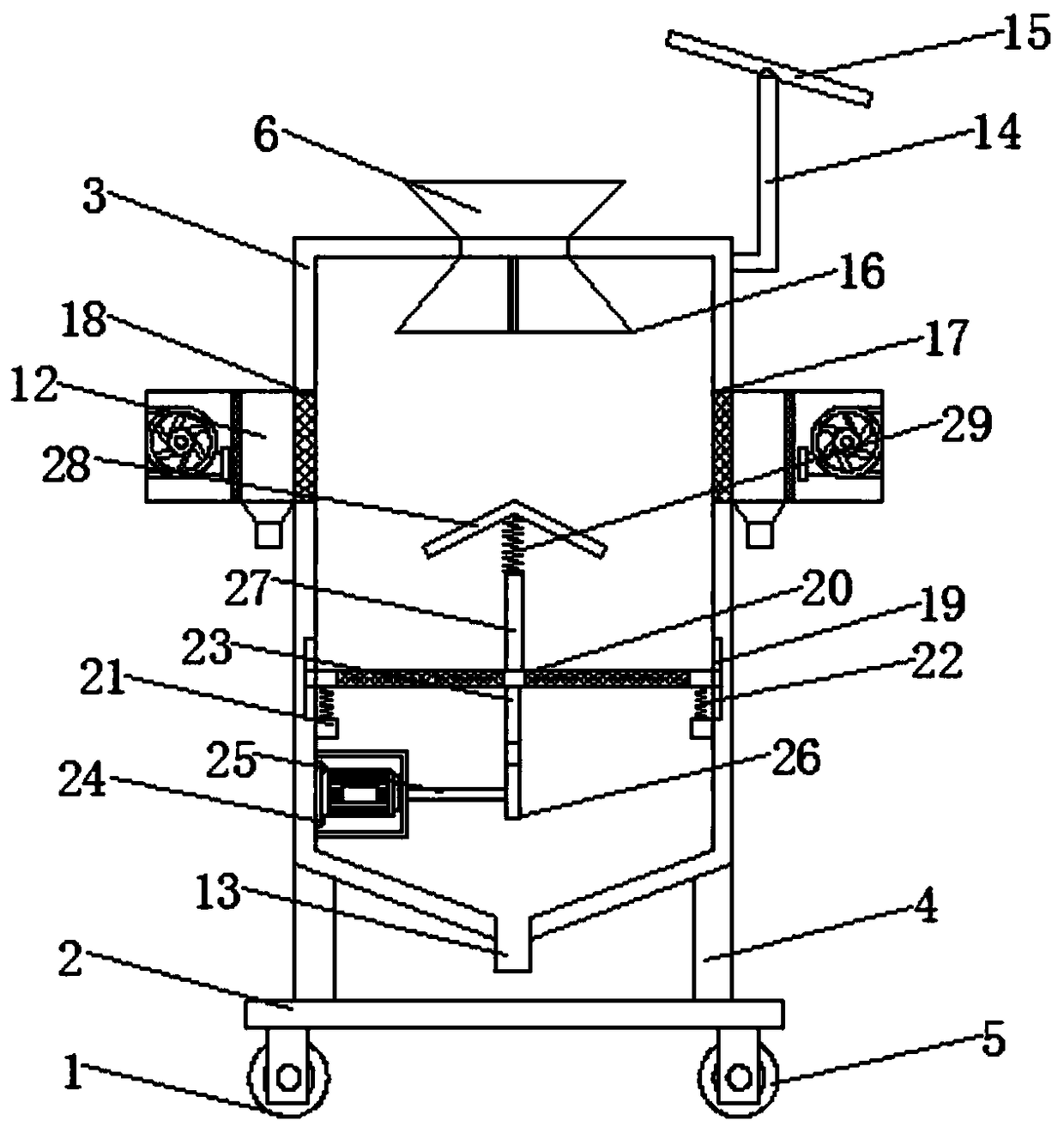

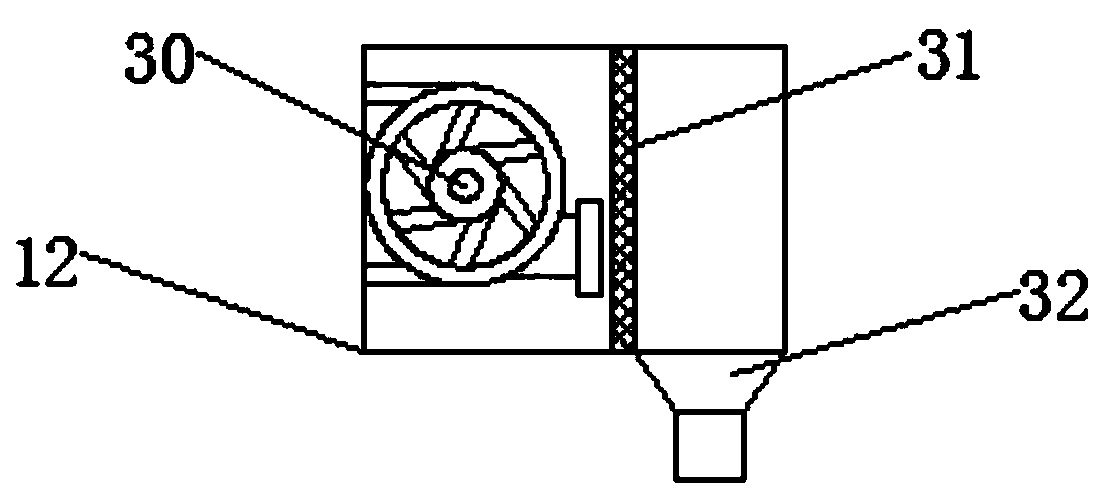

New energy paddy screening device

ActiveCN108722873AEasy to take outGood removal effectSievingBatteries circuit arrangementsNew energyHusk

The invention discloses a new energy paddy screening device. A base is arranged at the bottom of a device body; a screening box is mounted at the top of the base; a feed port is mounted at the top ofthe screening box; dust removing ports are formed in two sides of the top end in the screening box; dust removing boxes are mounted on the outer sides of the dust removing ports; chutes are formed intwo sides of the bottom end in the screening box; screening plates are mounted in the chutes; support rods are mounted at the tops of the screening plates; second springs are mounted at the top ends of the support rods; guide plates are mounted at the top ends of the second springs; a bracket is mounted at the right upper angle of the screening box; a solar panel is mounted at the top end of the bracket; support legs are mounted at the bottom of the screening box; trundles are mounted at the bottom of the base; the support rods and the guide plates are elastically connected through the secondsprings; and the guide plates can be repeatedly lifted under the effect of the second springs to realize oscillation and dispersion of paddies, so that internal empty husks and dust can be totally risen up, and are extracted by an exhaust fan to achieve the dust removing effect.

Owner:衡阳县仕杰农产品加工有限公司

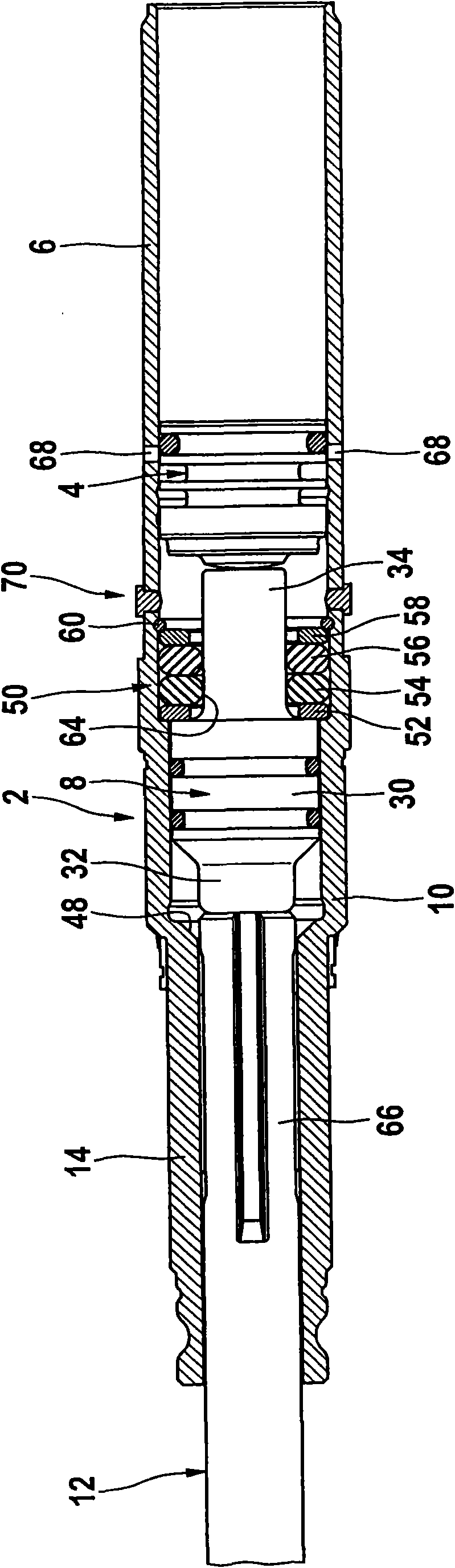

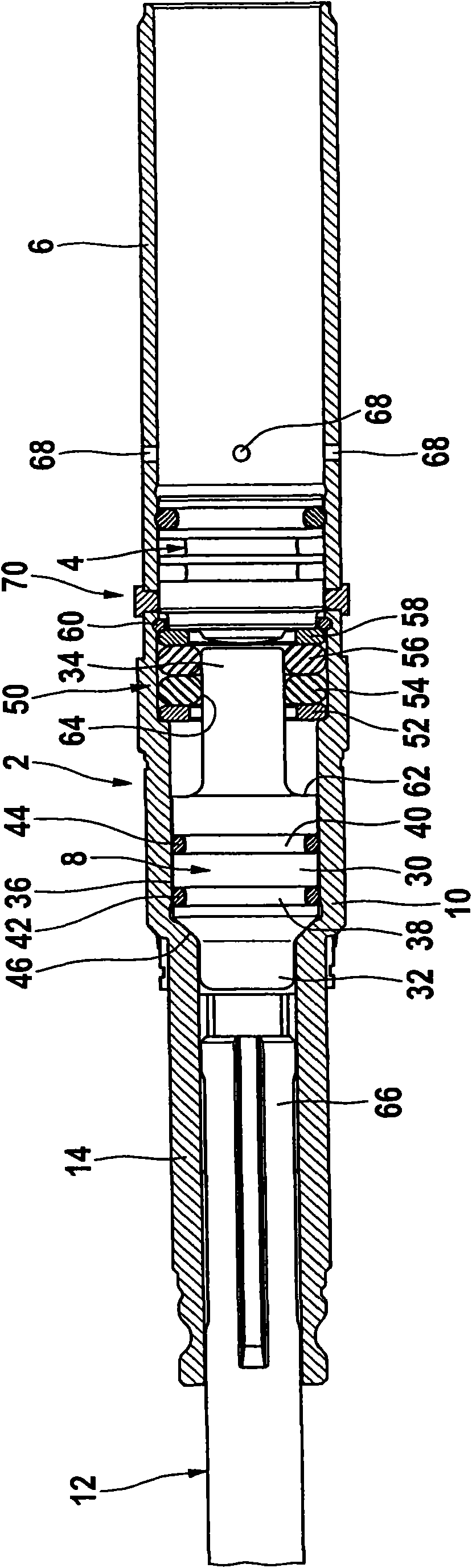

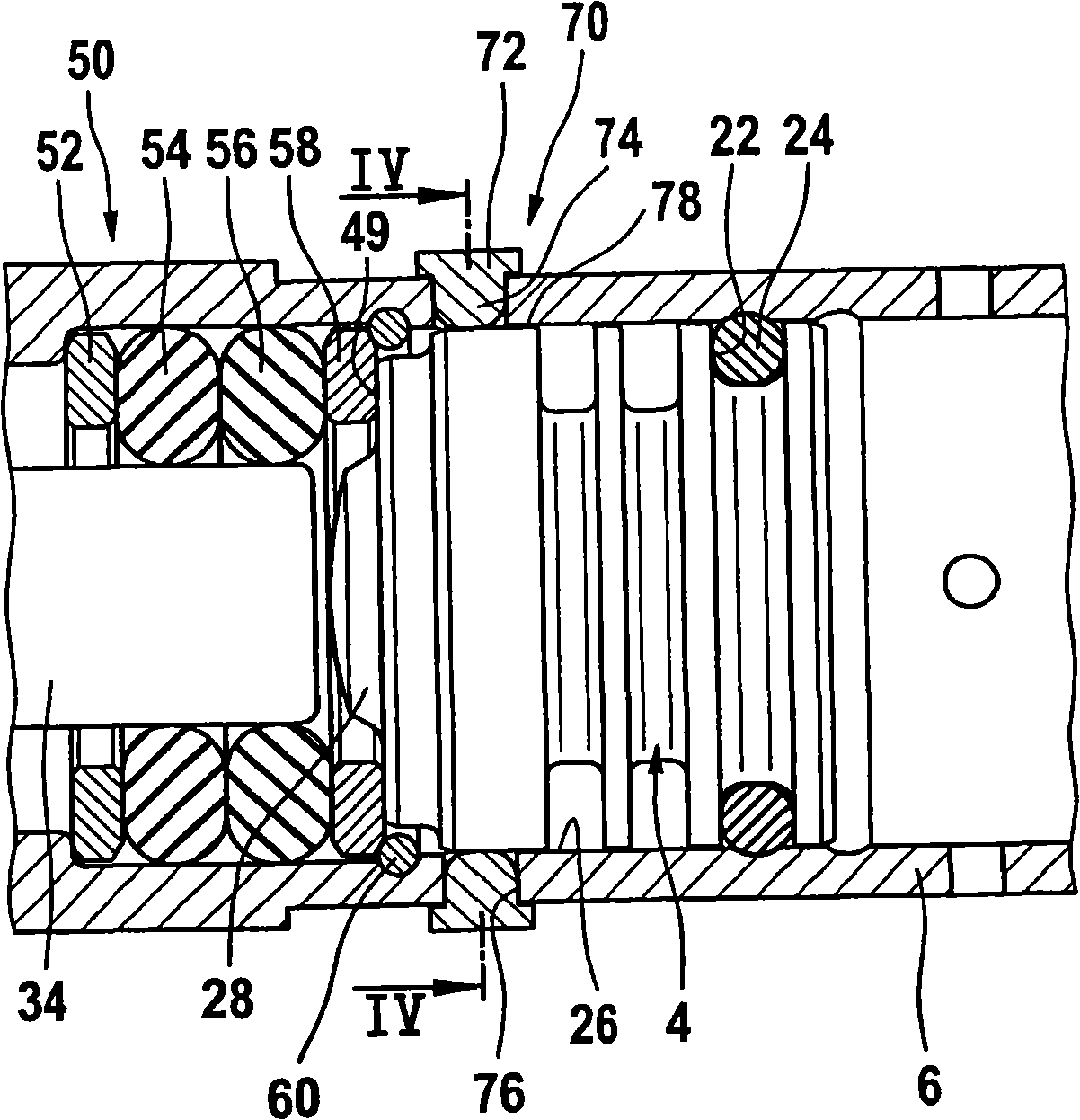

Portable machine tool with striker capture device and/or striker damping device

InactiveCN101537511ASimple installation and removalGuaranteed starting characteristicsPortable percussive toolsPortable drilling machinesAir springEngineering

A portable machine tool, such as a rotary and / or percussion hammer, comprises a percussion mechanism that has an axially movable striker 4 driven via an air spring, and an axially movable percussion pin 8. The percussion pin is arranged between the striker 4 and a tool 12 to transmit percussive impulses of the striker 4 to the tool when the tool is pressed against an abutment, and has a device (68, 70) for positioning and holding the striker (4) in a defined idling position when the machine tool is idling. The device (68, 70) for positioning and holding the striker comprises means (70) for frictionally and / or positively fixing the striker (4) in the idling position; and / or for braking the movement of the striker (4) before the idling position is reached.

Owner:ROBERT BOSCH GMBH

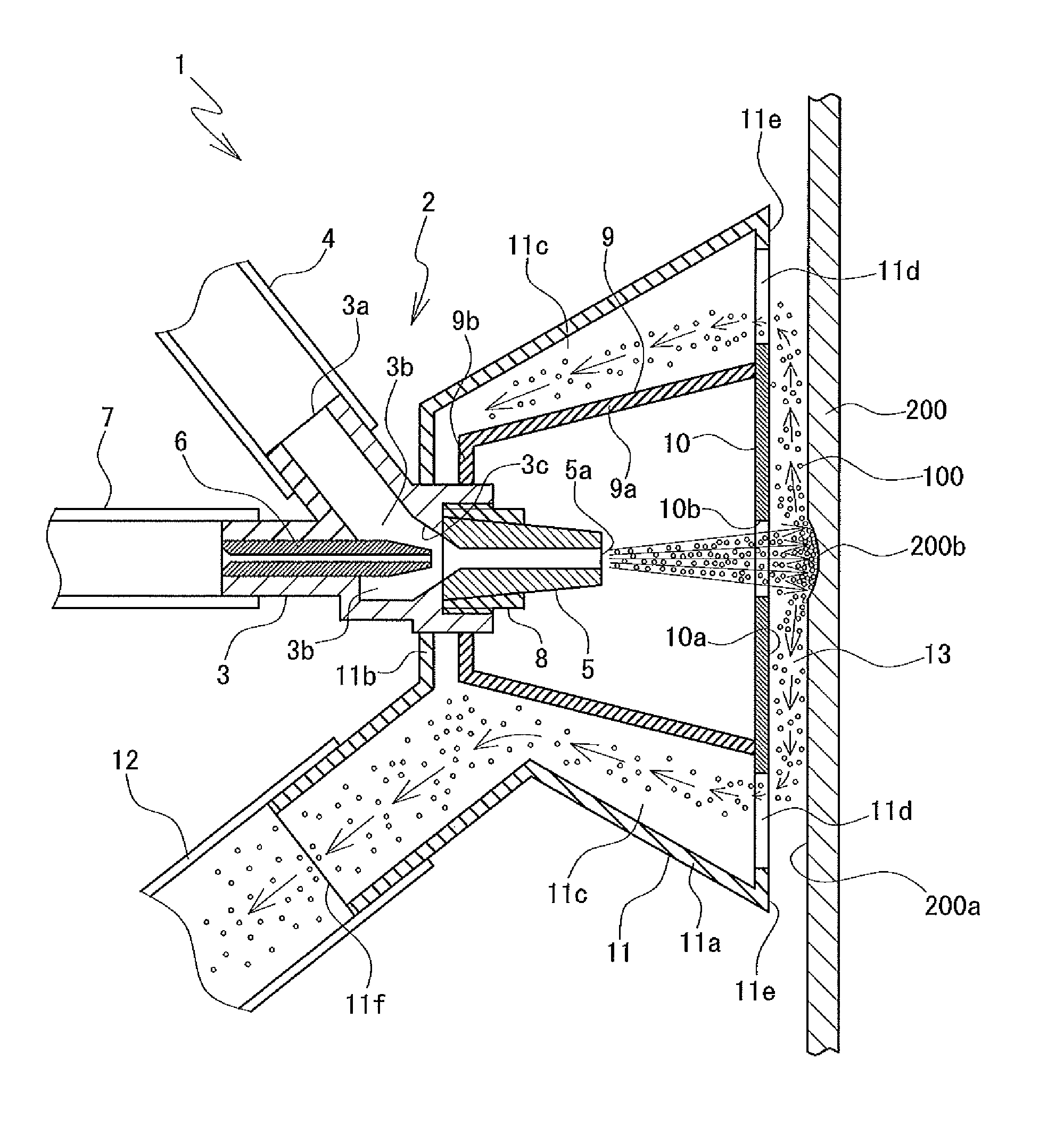

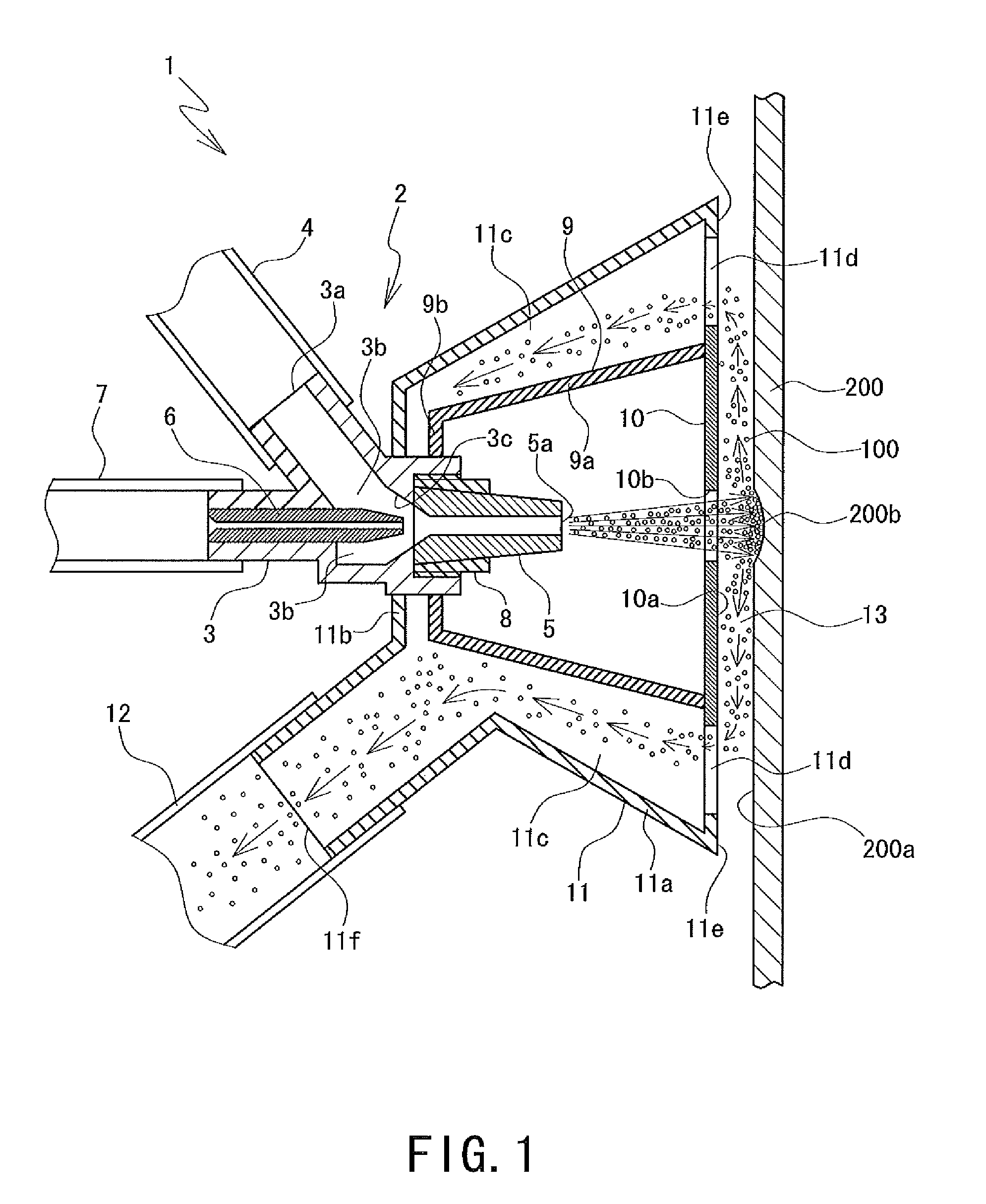

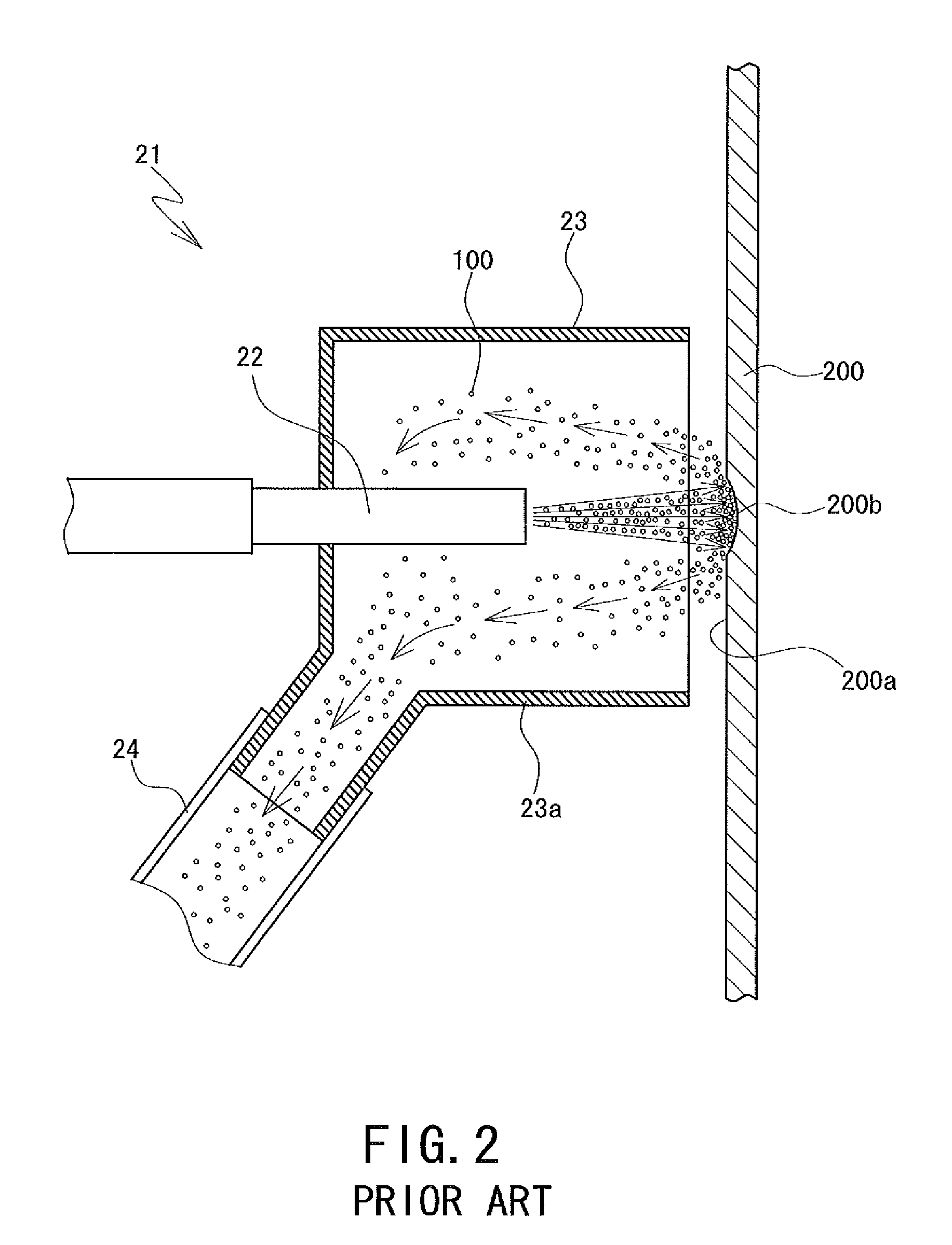

Blasting apparatus and method for blast processing

InactiveUS8801499B2Prevent suctionMaintain machining accuracyBlast gunsAbrasive machine appurtenancesSuction stressSand blasting

Owner:SHARP KK

Method and apparatus for mechanical recovery of hydrocarbons in broken ocean ice conditions

InactiveUS9644335B1Prevent suctionAvoid cloggingWater cleaningFatty/oily/floating substances removal devicesSea iceCistern

A system for collecting oil from mixed ice and water conditions. The system uses suction pods that are welded along the hull of a vessel. These pods are elongated vertically and have a vertical slit opening that allow oiled water to enter into the suction box during wave action. Each vertical opening is covered with stainless steel mesh layers to inhibit smaller ice from entering the suction box. Inside each of the suction boxes is a horizontal floating suction bar that is connected to a flexible suction hose. The suction bar is free floating within the suction box so that collection always occurs at the water's surface. The collection line from the suction box leads to a collection and separation area. The suction boxes are protected by heavy-duty metallic “bumper that are welded to the hull to protect the suction box arrays.

Owner:LUM DANIEL J

Multi-layer water seal device and method

ActiveCN104060656AImprove job stabilityPrevent suctionWater closetsSewerage structuresDraining tubeEngineering

The invention discloses a multi-layer water seal device. The multi-layer water seal device comprises two or more water seals which are sequentially arranged from top to bottom, wherein the upper water seal is of a floating bell jar type structure comprising a water seal box and a floating jar bell arranged in the water seal box; the lower water seal is arranged in a drain pipe below the floating bell jar; one side of the water seal box extends or is connected with a communication cavity chamber deviated from the drain pipe, the floating bell jar also correspondingly extends or is connected with the floating component, and the floating component is deviated from the drain pipe and floats in the communication cavity room. When sewage in the water seal box rapidly flows away through the drain pipe, floating force on the floating component from the communication cavity chamber is greater than that on the floating bell jar from the water seal box, and the larger the distance between the water seal box and the drain pipe is, the larger floating force larger. Thus, the floating bell jar is inclined towards the outer side of the water seal box because of unbalance of the floating force, it is avoided that the floating bell jar is adsorbed to the bottom wall of the water seal box under the action of the negative pressure of the drain pipe, and work stability of the water seal device is improved. The invention further discloses a multi-layer water seal method.

Owner:BEIJING KANGZHIWEI SCI & TECH

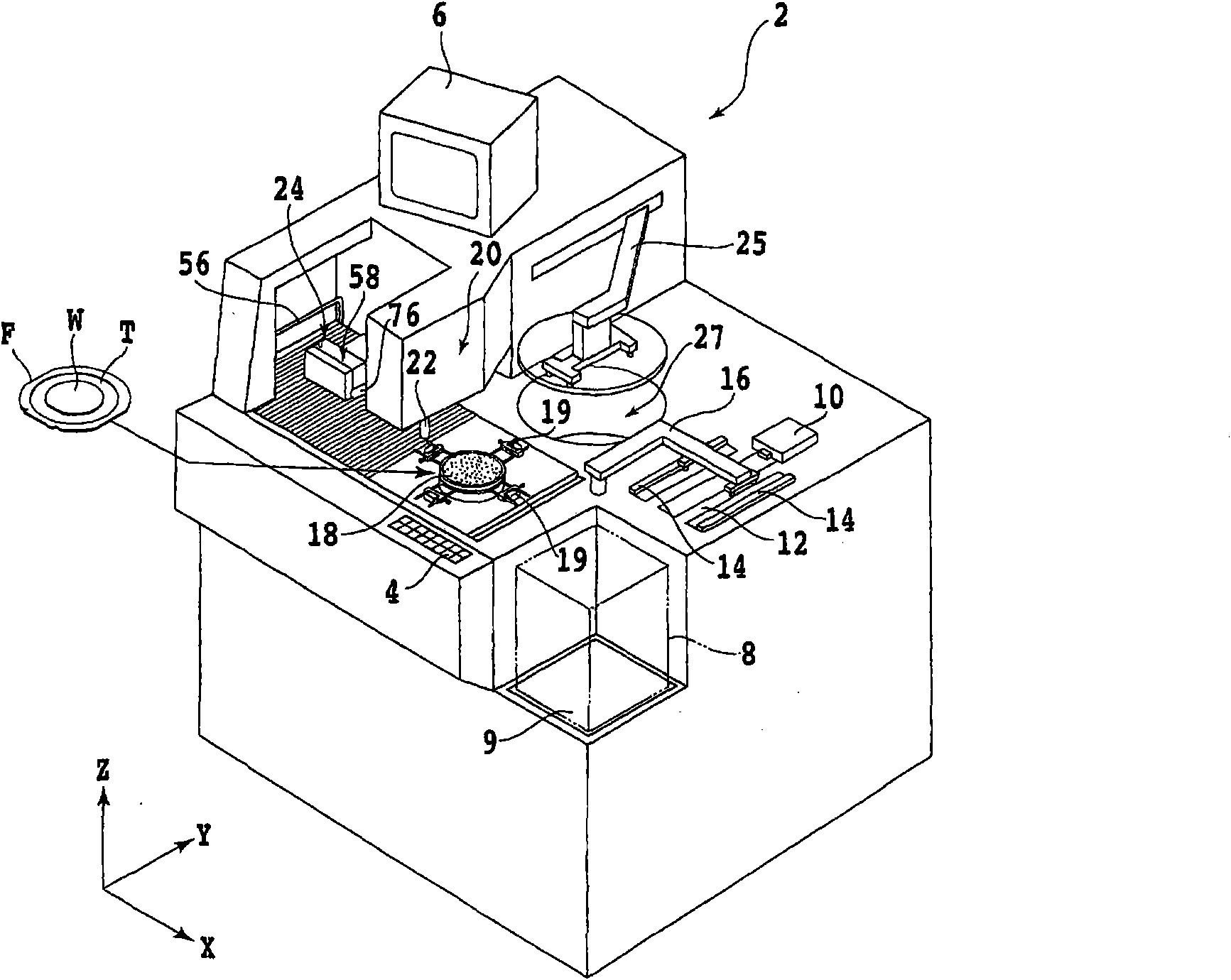

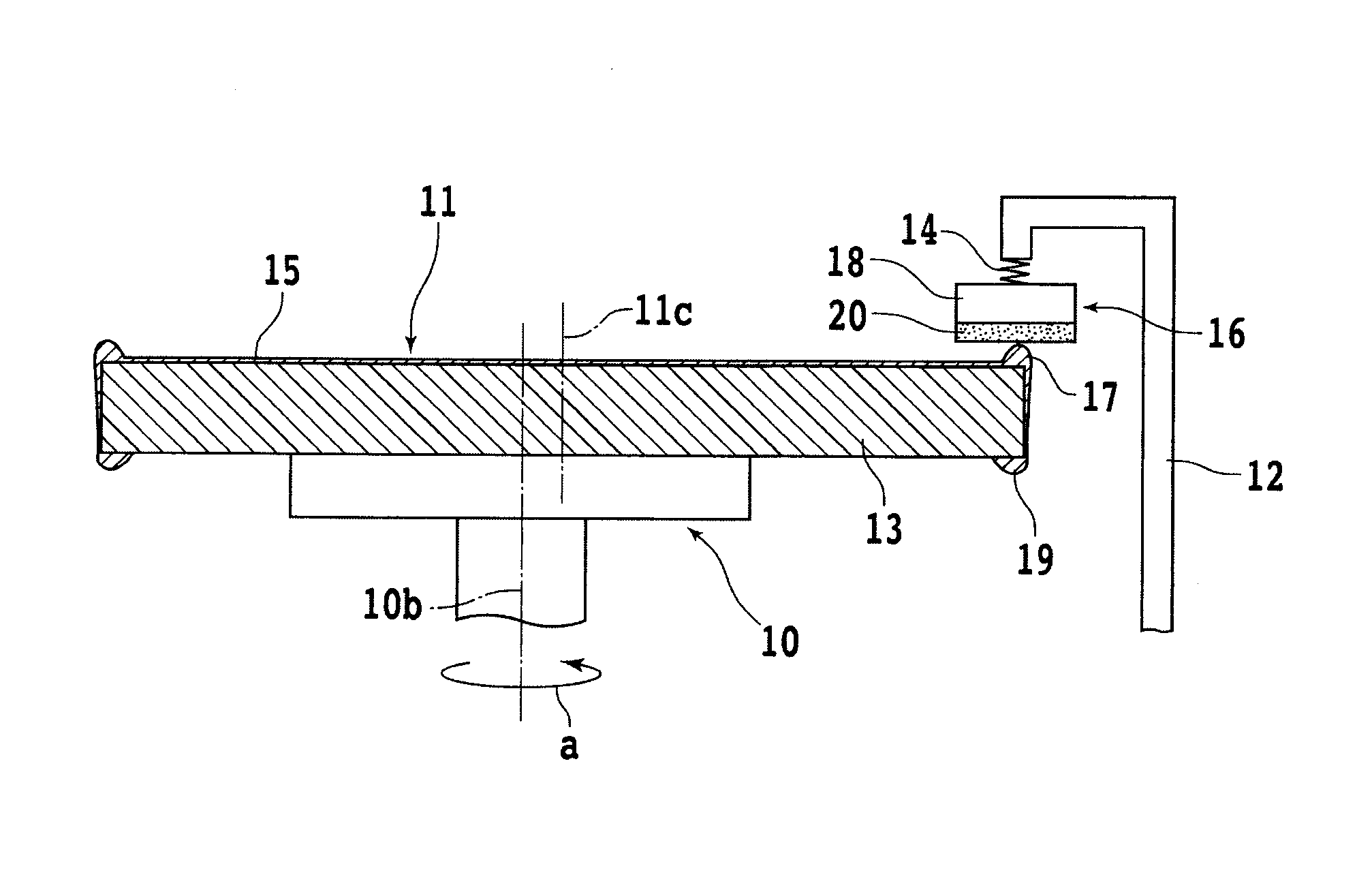

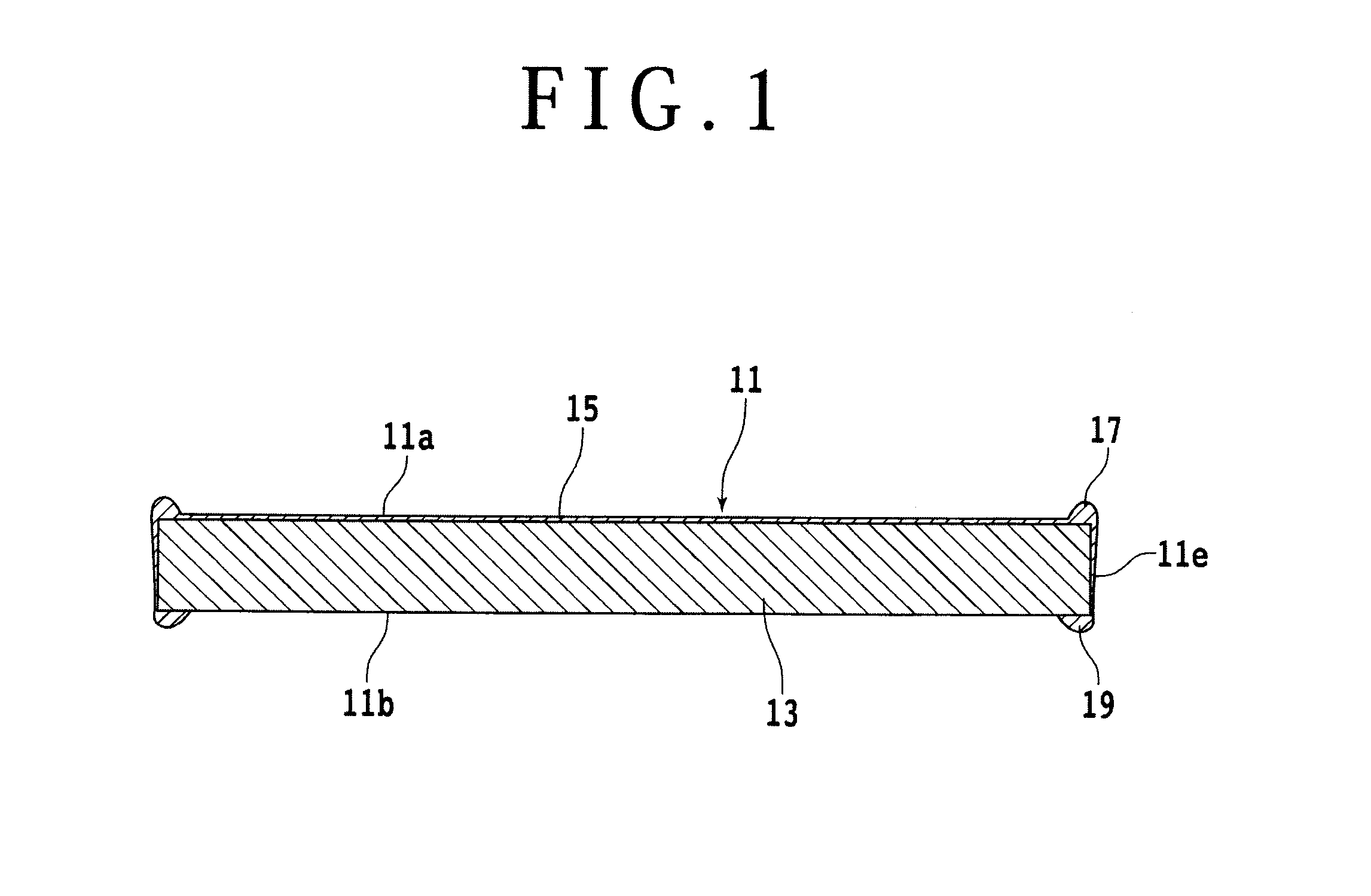

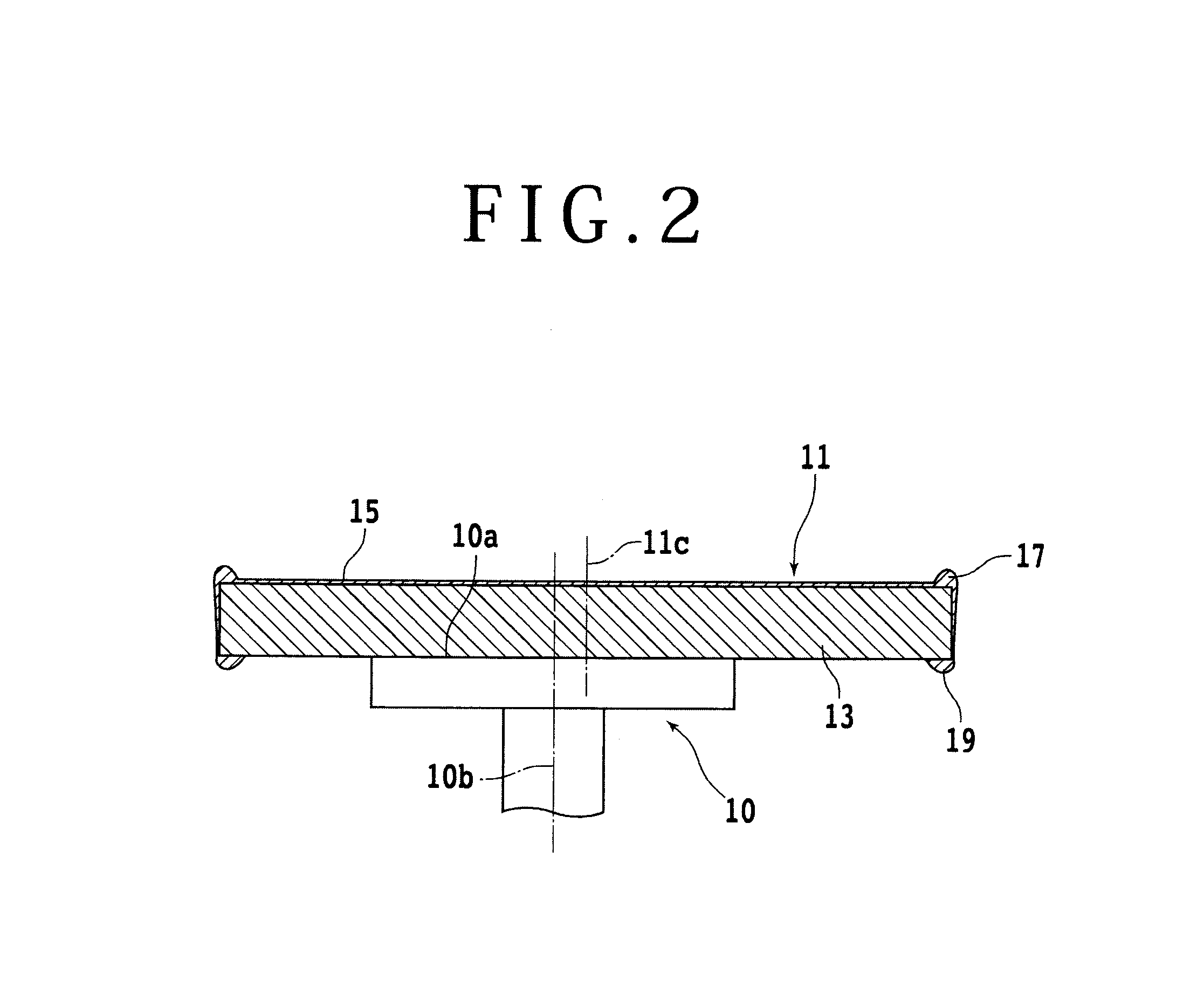

Wafer processing method

InactiveUS20130344775A1Avoid damagePrevent suctionEdge grinding machinesSemiconductor/solid-state device manufacturingRotational axisEngineering

A wafer processing method of processing a wafer having an epitaxial film formed on the front side. The wafer processing method includes a holding step of holding the wafer on a holding table having a holding surface for holding the wafer and a rotational axis extending perpendicularly to the holding surface and passing through the center of the holding surface, and a removing step of pressing a grinding member on a ridge portion formed along the peripheral edge of the wafer held on the holding table and rotating the holding table about the rotational axis, thereby removing the ridge portion.

Owner:SEKIYA KAZUMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com