Carpet cleaner

A technology for cleaners and carpets, which is applied to carpet sweepers, carpet sweepers, and cleaning equipment. It can solve problems such as inability to fully absorb dust or water, decline in cleaning efficiency, and increase in occupied space, so as to prevent suction and increase Large area, the effect of preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

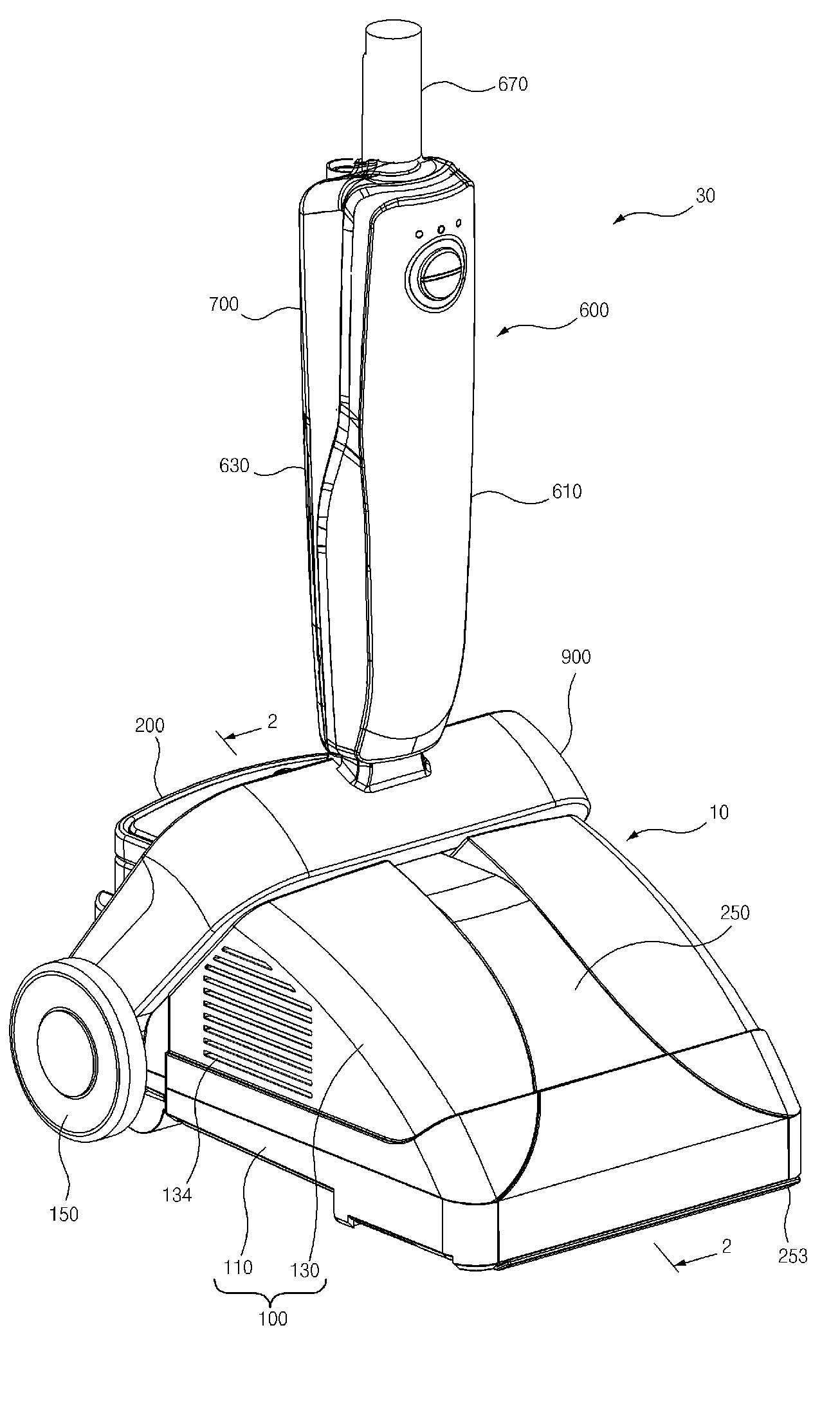

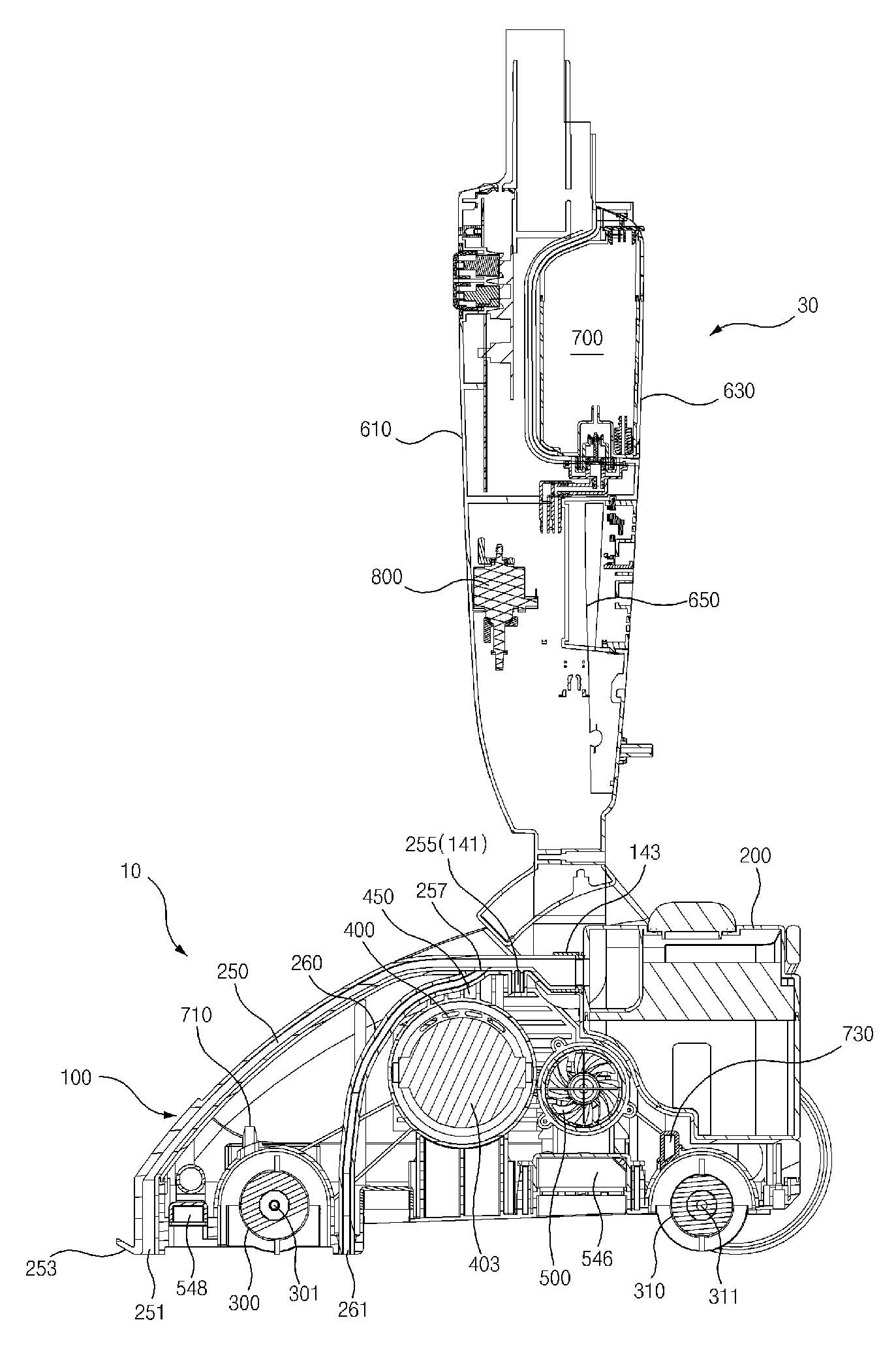

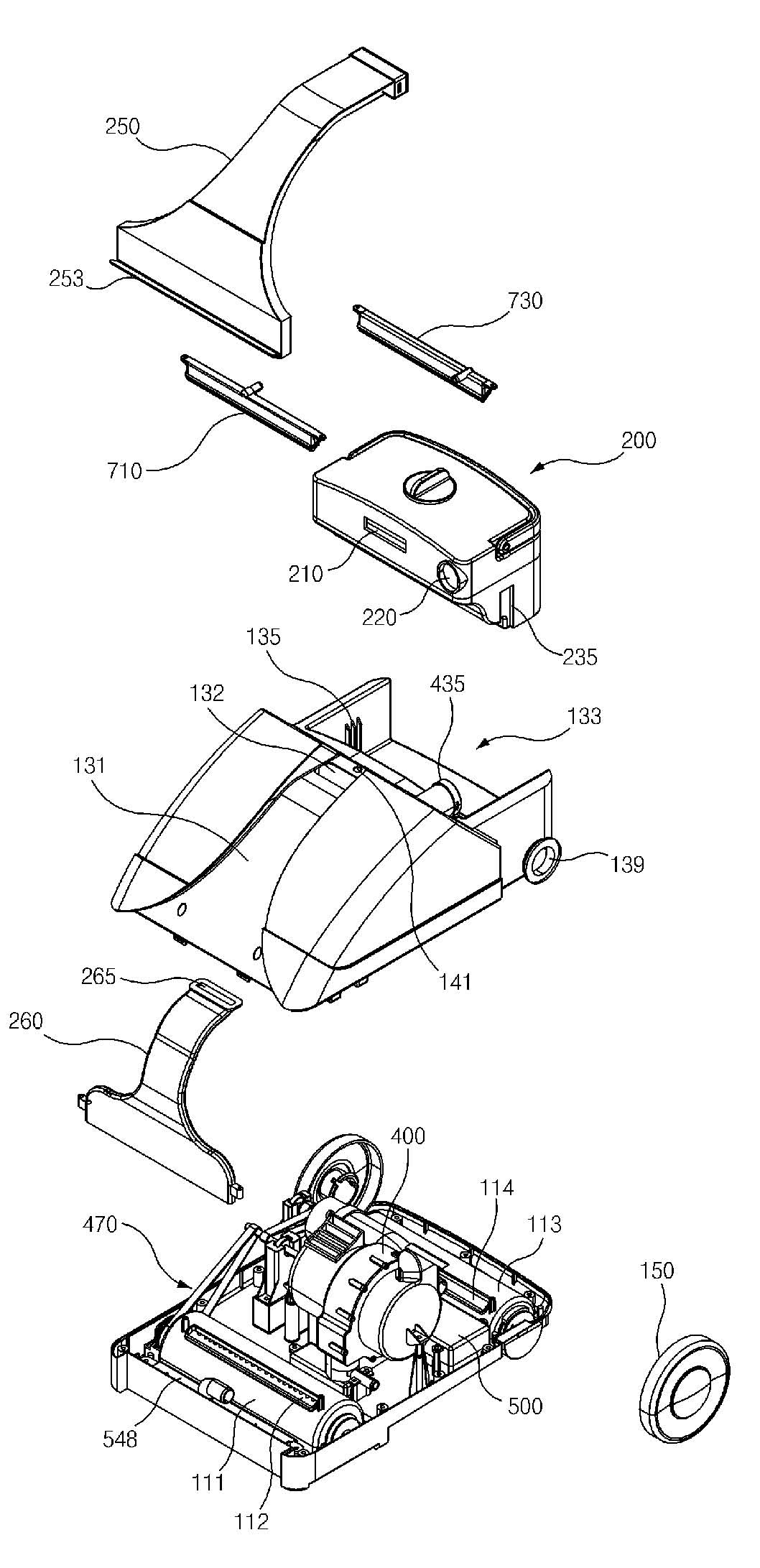

[0085] figure 1 It is a perspective view of the appearance of the carpet cleaner involved in the preferred embodiment of the present invention, figure 2 for along figure 1 The sectional view seen after the 2-2 line is cut, image 3 and Figure 4 for figure 1 Combination and separation perspective view of the base components, Figure 5 and Figure 6 to remove image 3 Left and right perspective view of the state after the upper case, Figure 7 for from Figure 5 A perspective view of the state after removing the suction duct, Figure 8 for Figure 6 bottom perspective view of Figure 9 to remove Figure 8 A perspective view of the state behind the base, Figure 10 A three-dimensional view of the dryer, Figure 11 for along Figure 10 The sectional view seen after the 11-11 line is cut, Figure 12 is a side view of the shape of the suction mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com