Patents

Literature

68results about How to "Stable and dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

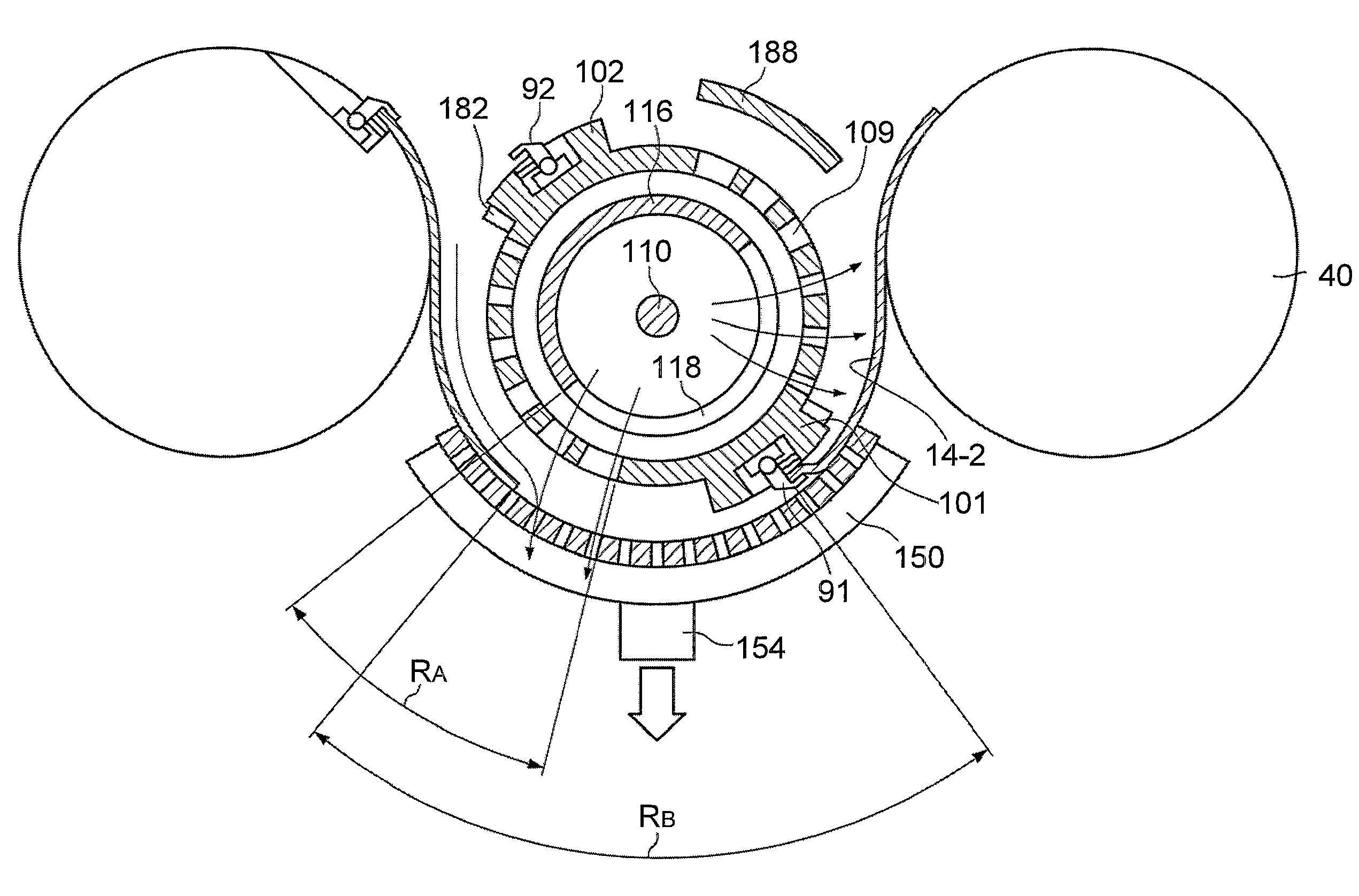

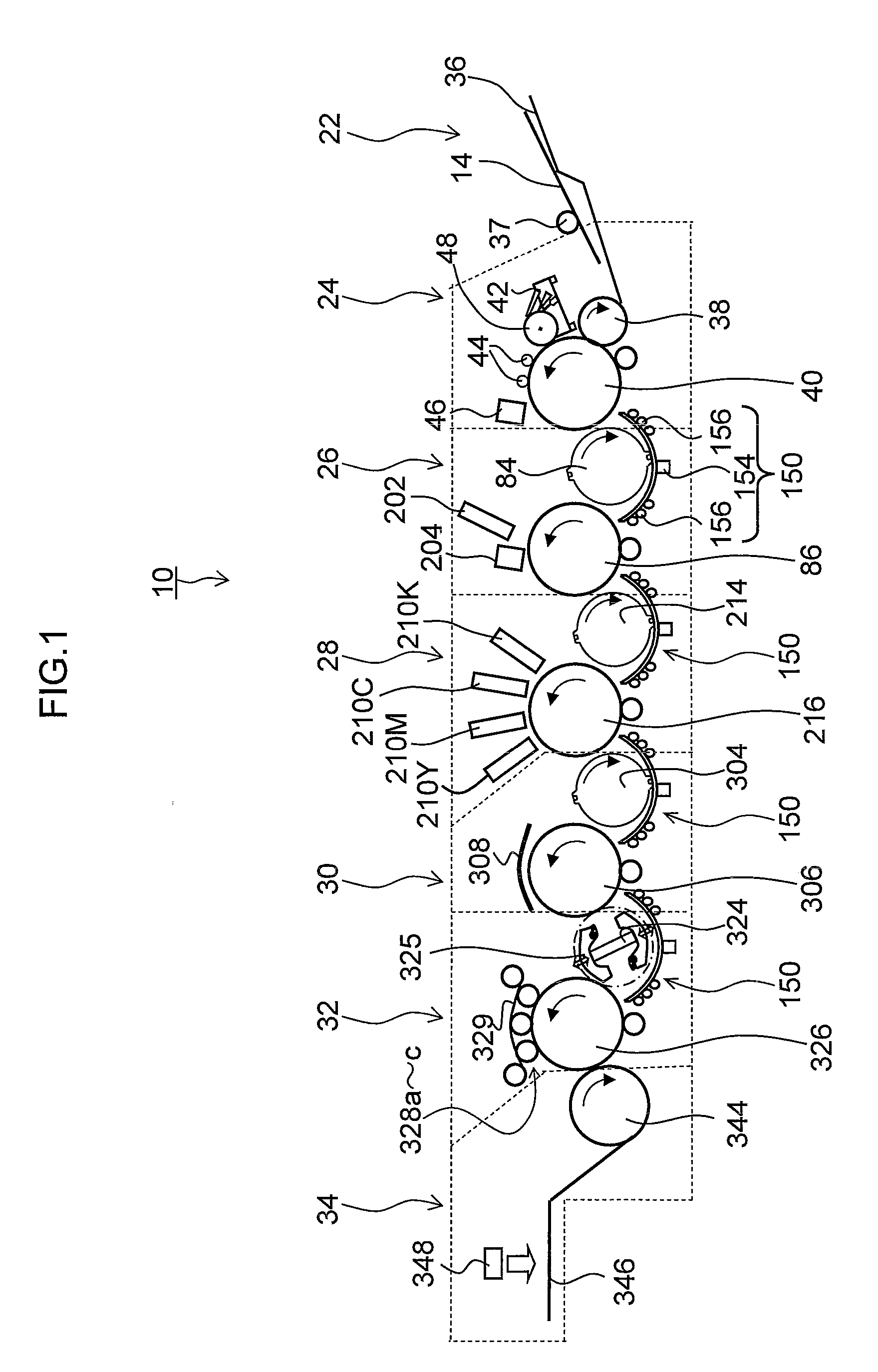

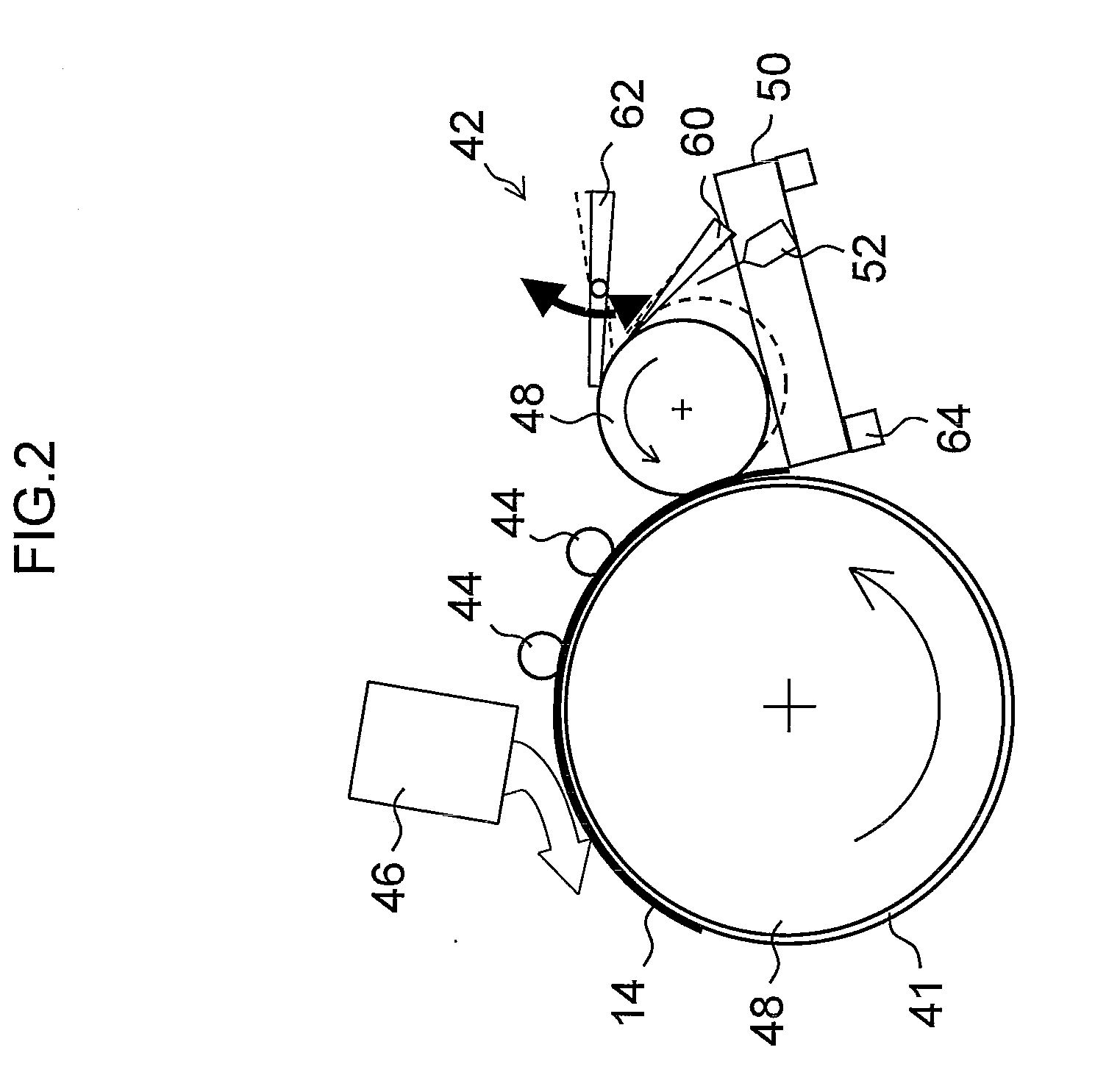

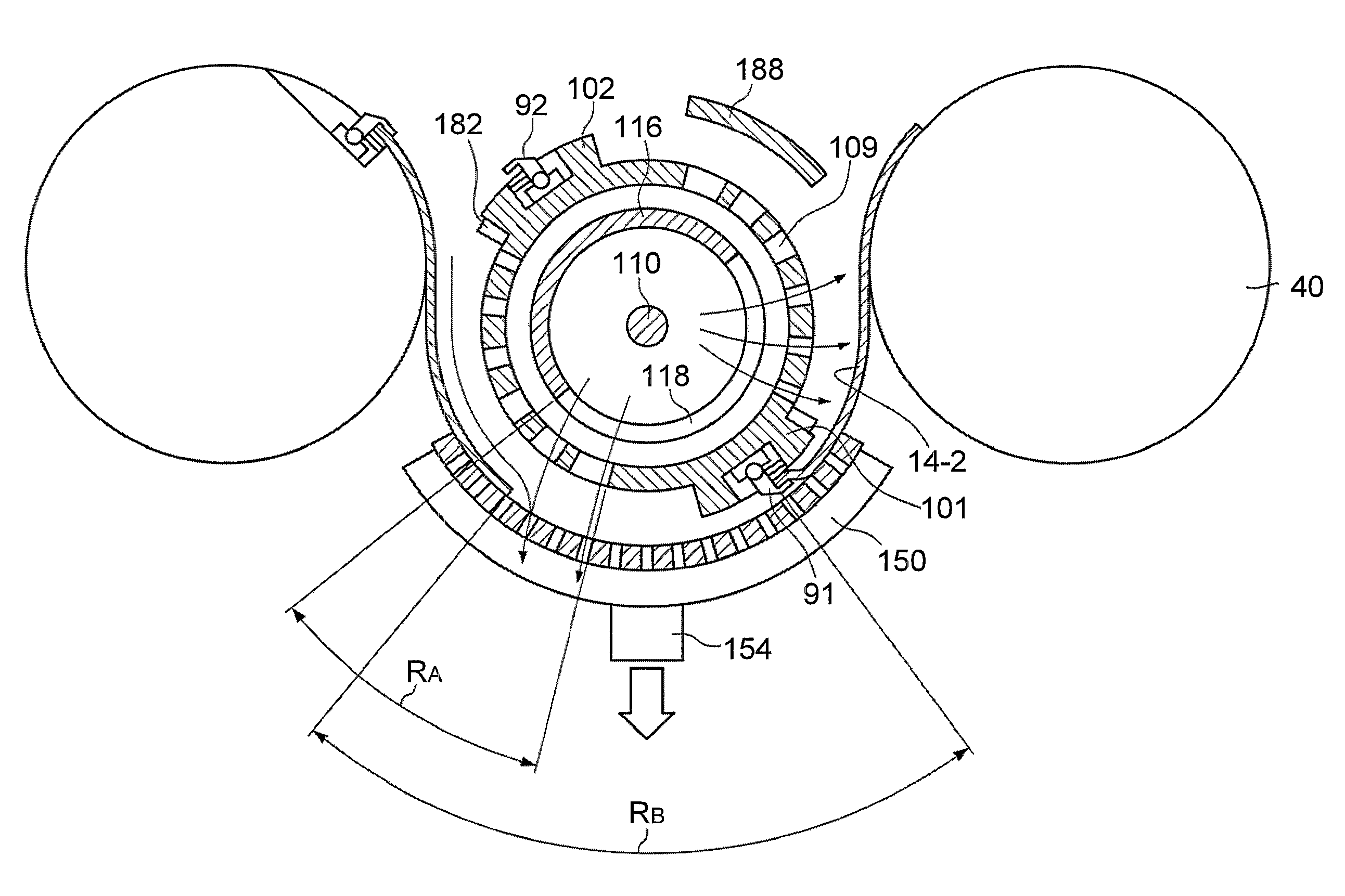

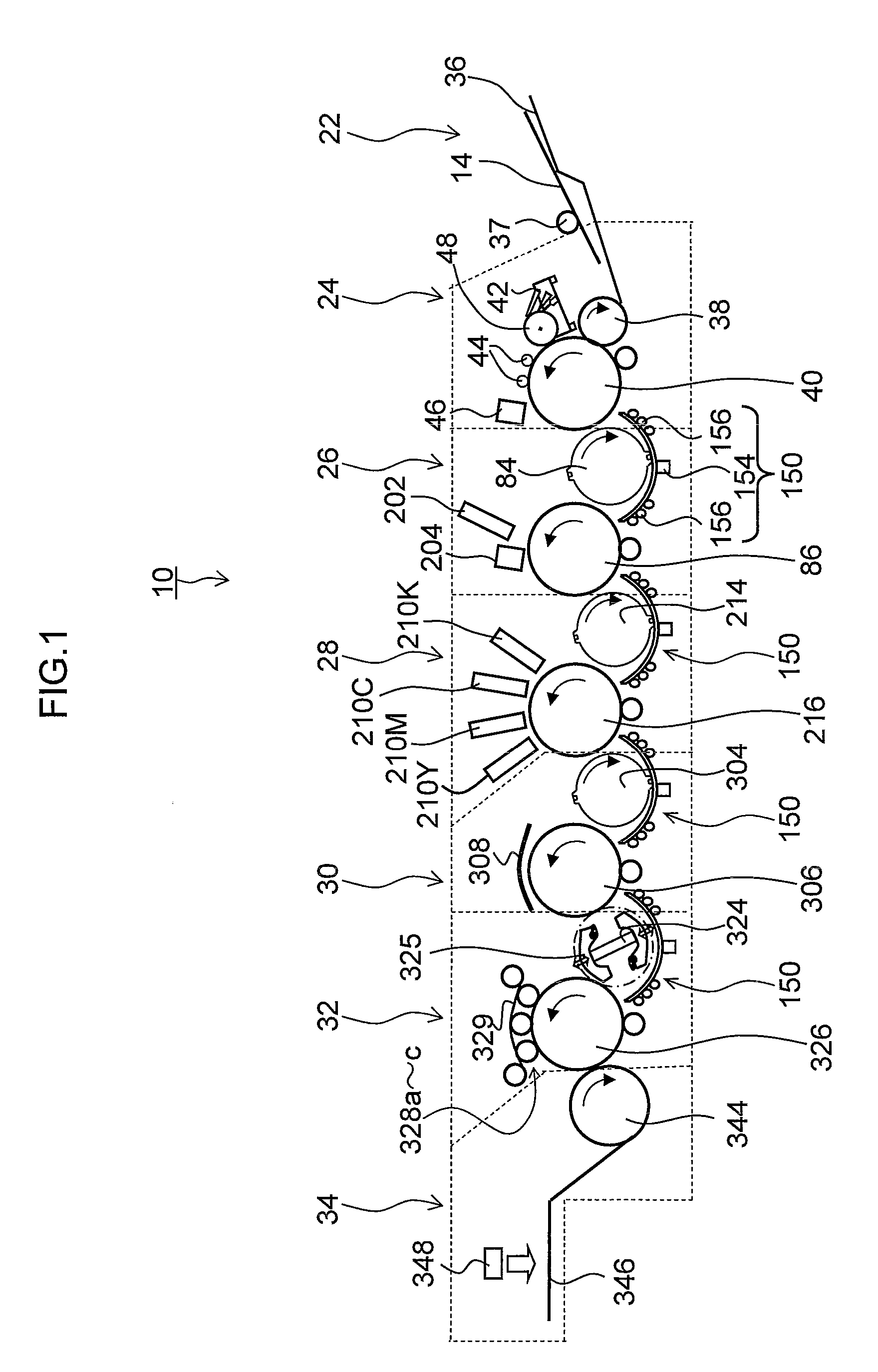

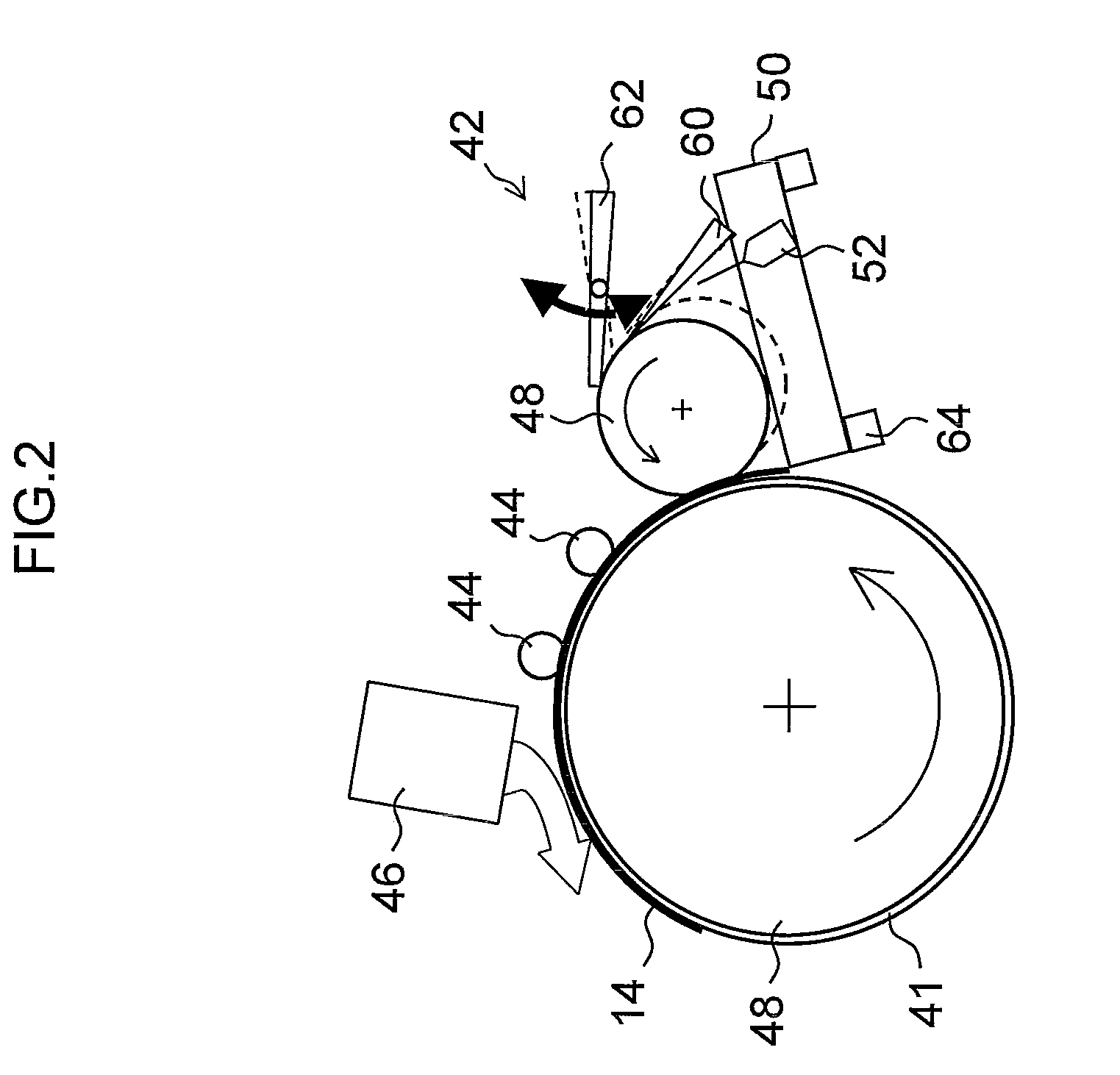

Inkjet recording apparatus and inkjet recording method

ActiveUS20090295894A1Suppress wrinkling or drying non-uniformitiesSuppress soiling of the interior of the machineInking apparatusOther printing apparatusEngineeringRecording media

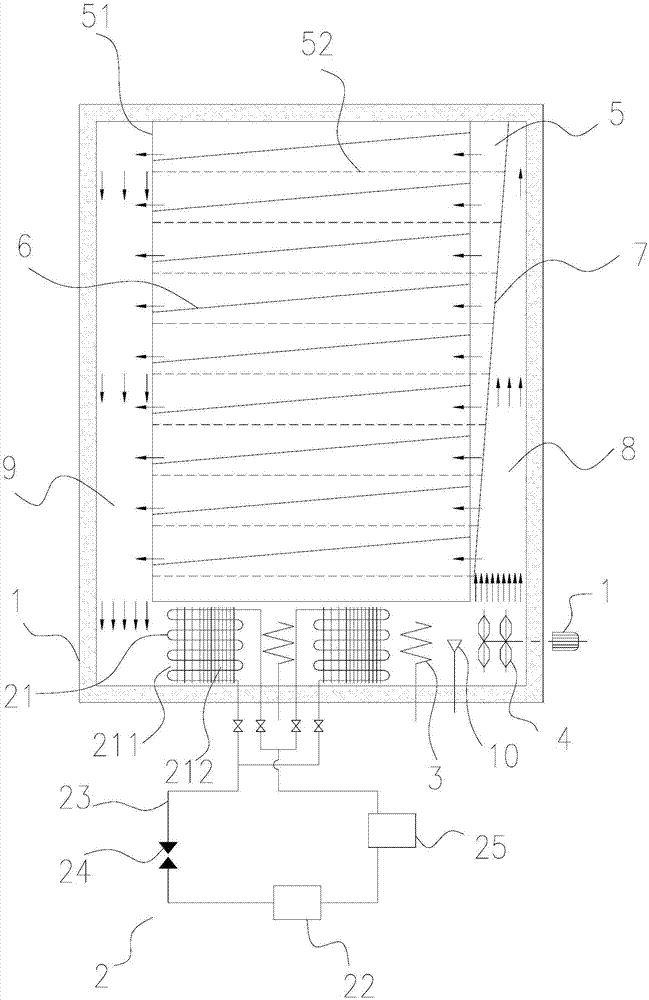

The inkjet recording apparatus includes: a conveyance device which conveys a recording medium; a drying air flow spraying device which sprays a drying air flow onto the recording medium while the recording medium is conveyed by the conveyance device; a negative pressure suctioning device which opposes the drying air flow spraying device, and suctions a rear surface of the recording medium and suctions at least a portion of the drying air flow sprayed by the drying air flow spraying device while the recording medium is conveyed by the conveyance device; and an inkjet head which ejects ink to be deposited on the recording medium.

Owner:FUJIFILM CORP

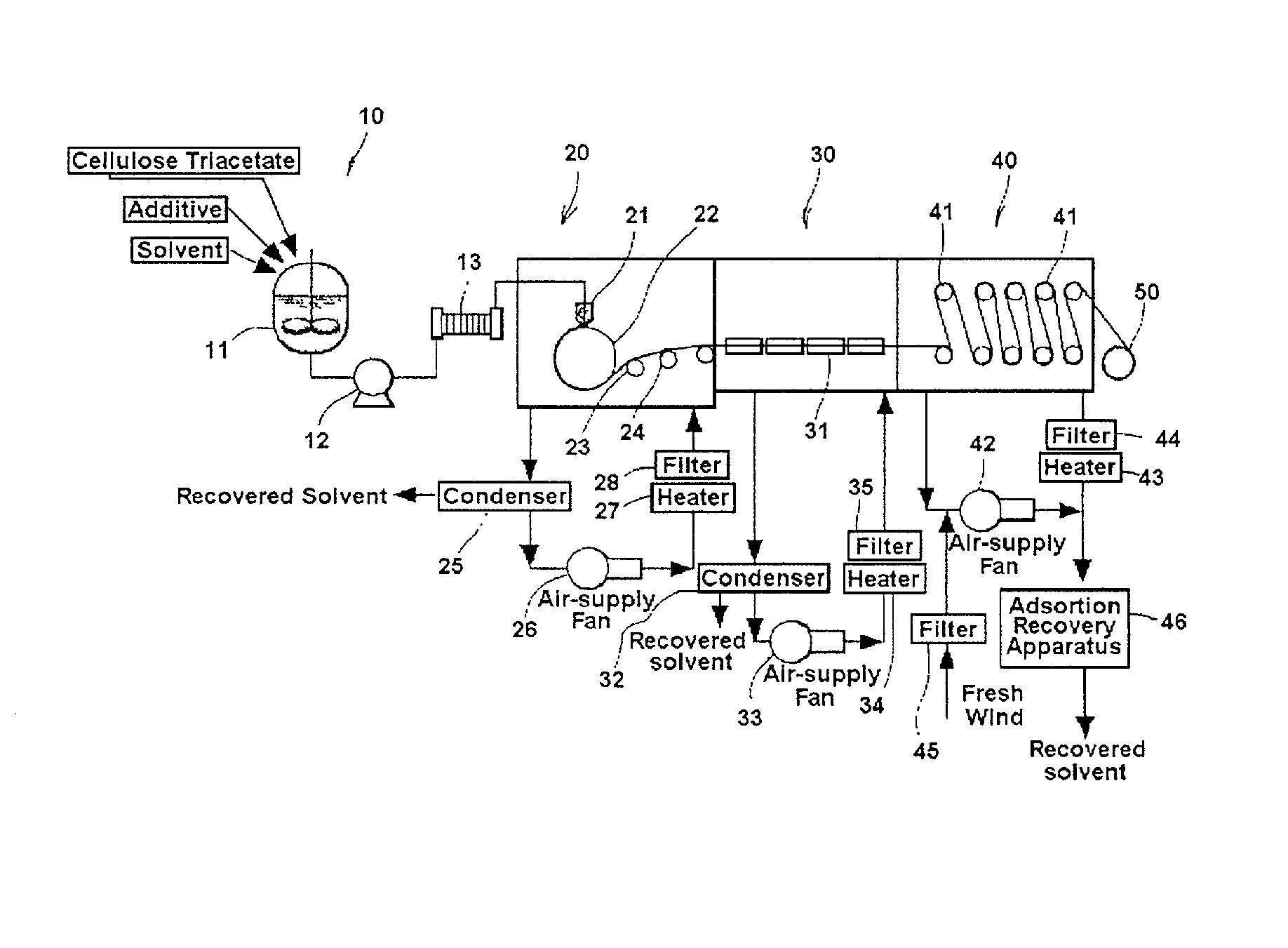

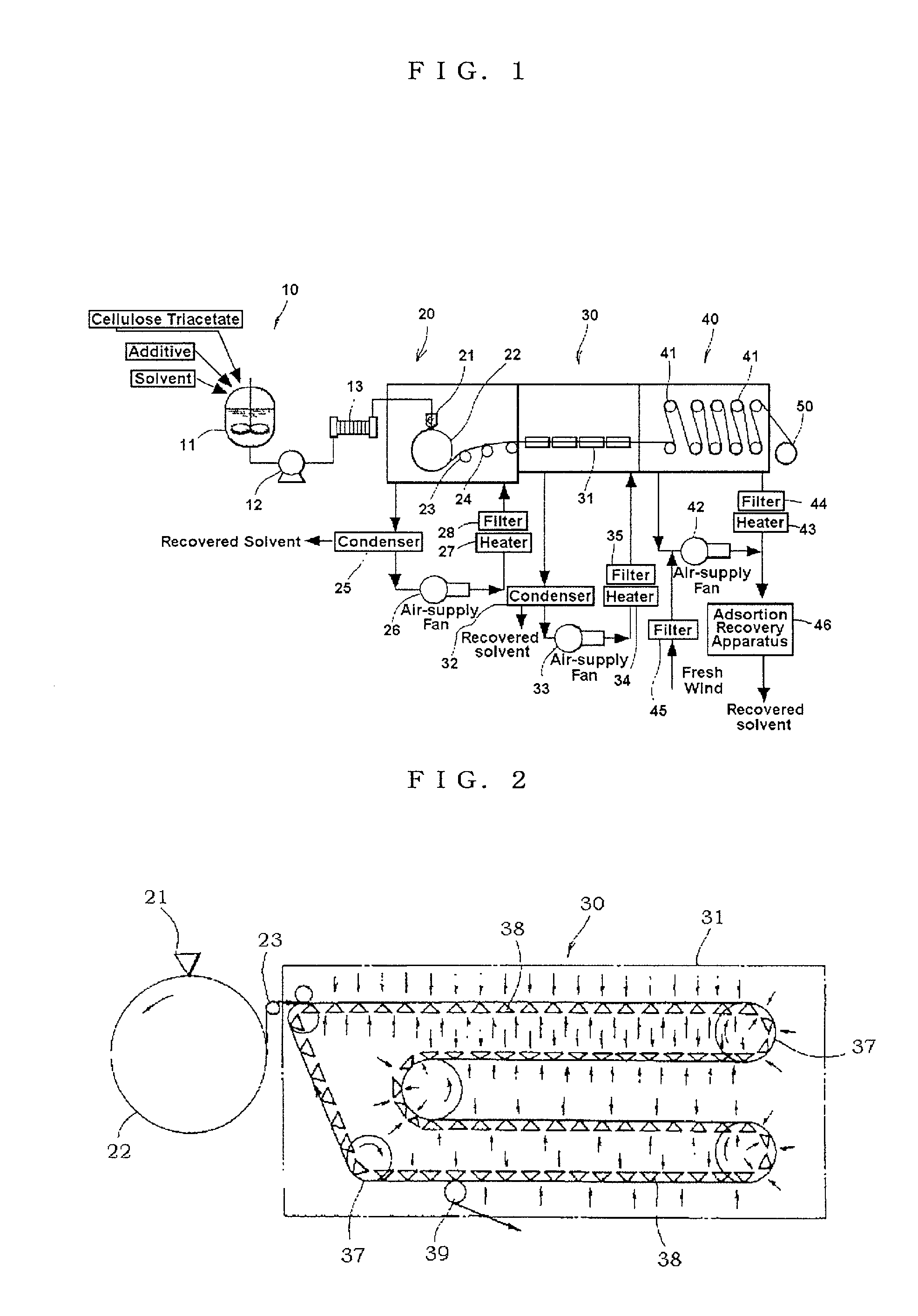

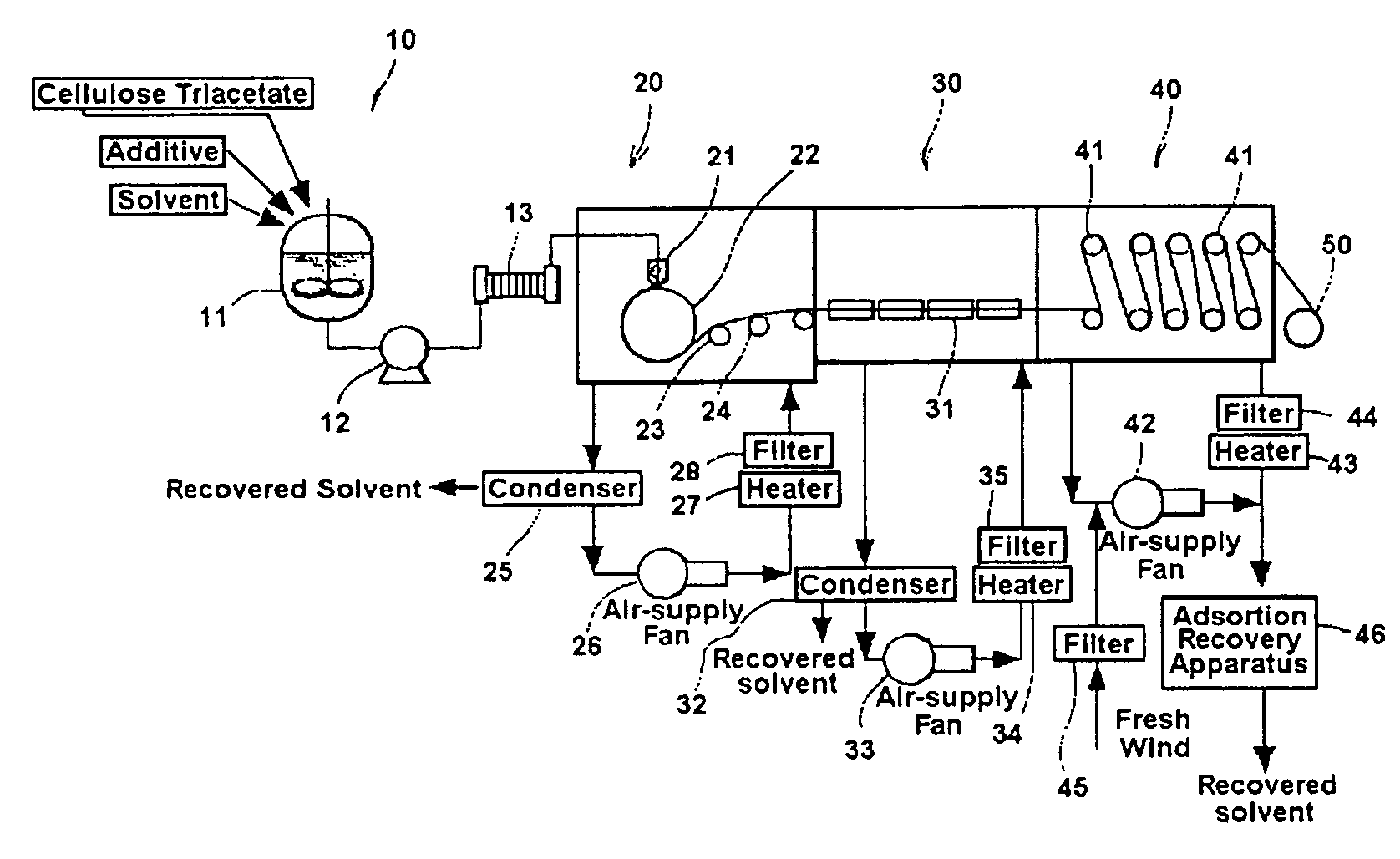

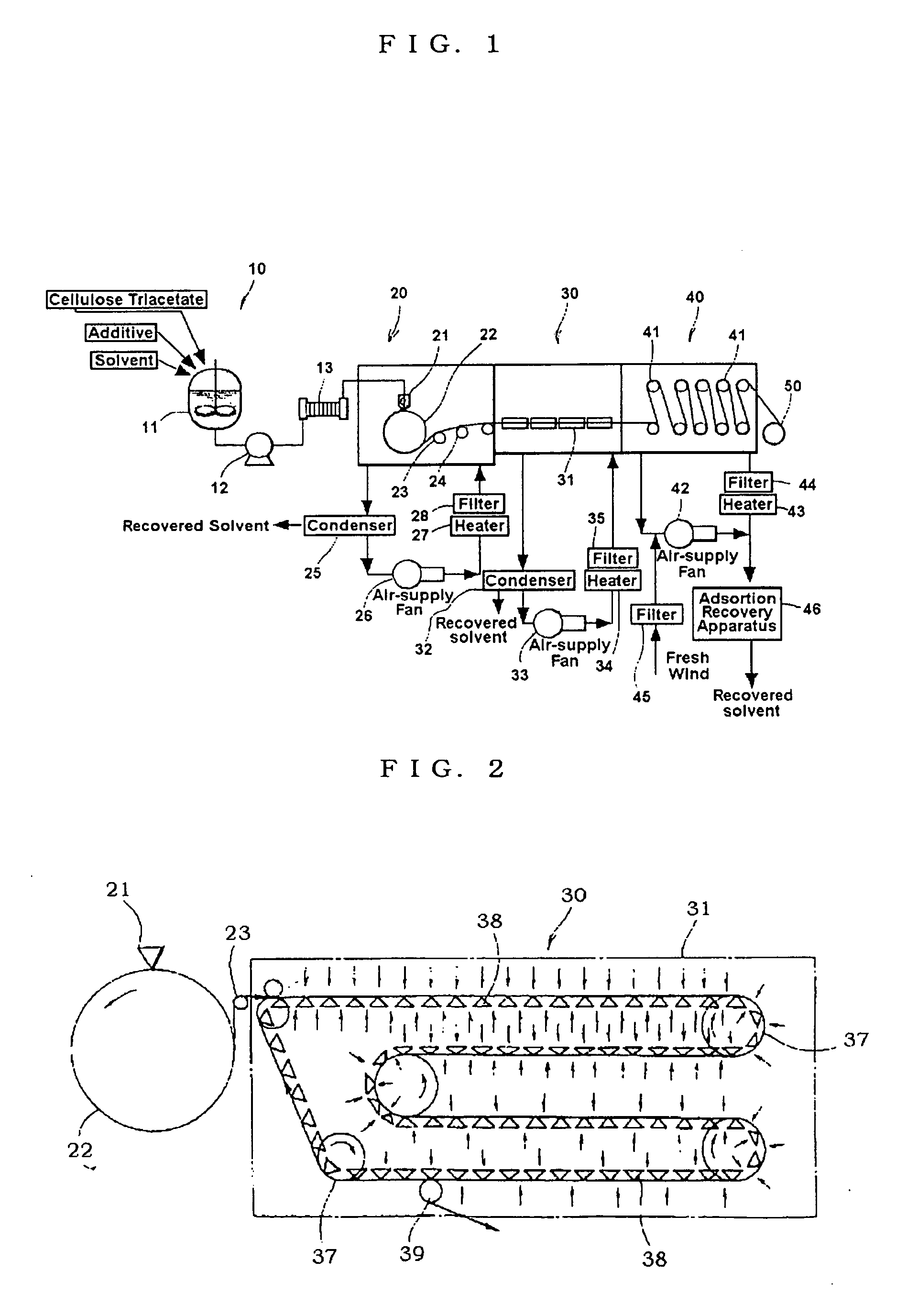

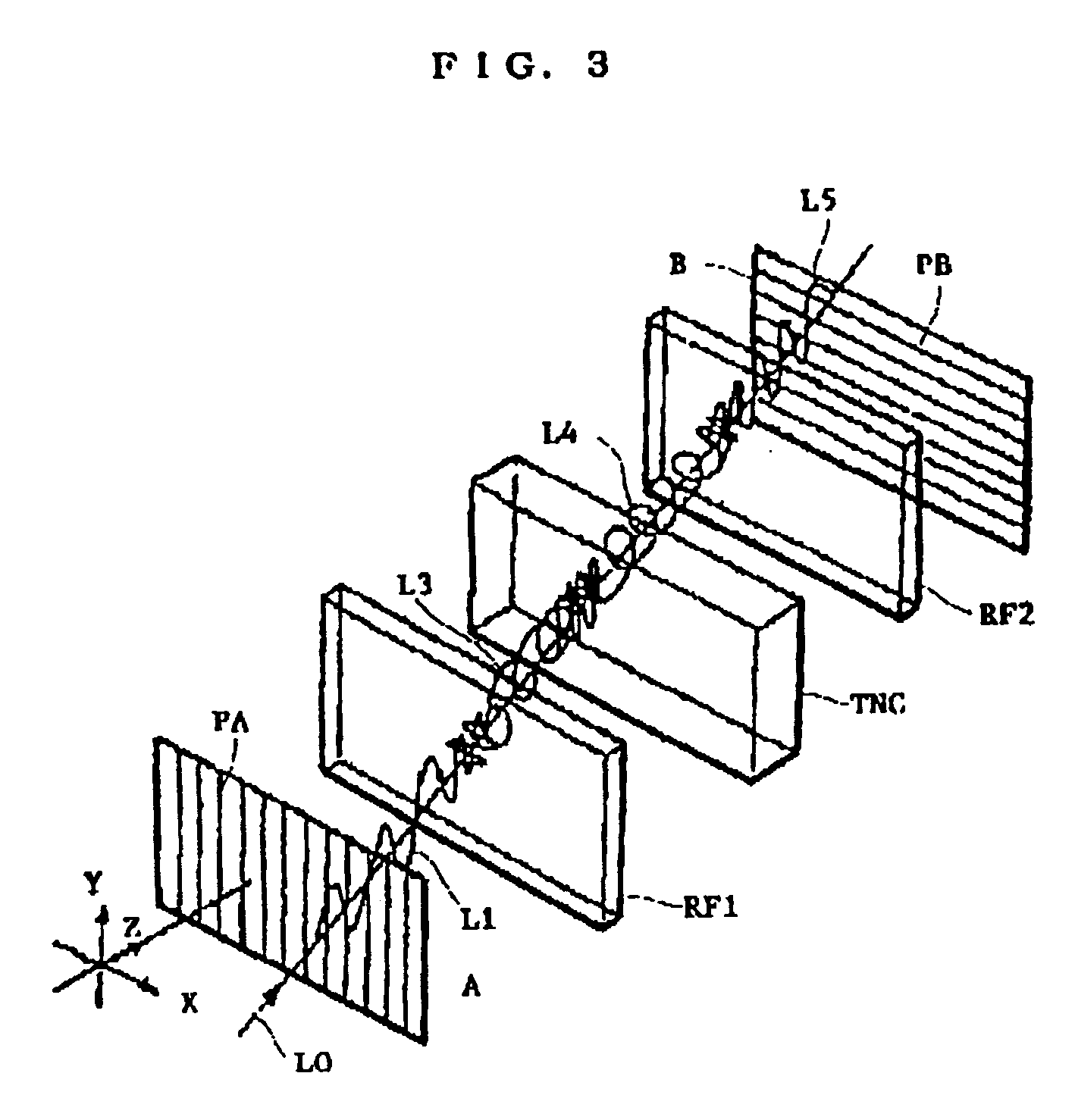

Solvent casting process, polarizing plate protective film, optically functional film and polarizing plate

InactiveUS20030057595A1Good quality and stabilityHigh productivityDead plant preservationArtificial flowers and garlandsSolventSolid matter

A process for solvent casting which comprises, casting a dope from a casting die onto a casting support, drying the cast dope on the casting support to form film, stripping off the film from the casting support, and further drying the film, wherein the dope has a solid matter content of from 17 mass % to 30 mass %, and a mean drying rate between the casting of the dope and the stripping off is more than 300 mass % / minute and not more than 1000 mass % / minute is proposed. The process for solvent casting for producing a film comprising the steps of casting a dope from a casting die to a casting support, forming the film by drying the dope to some extent, stripping off the film from the casting support and further drying the film while conveying the film with carrying it at both side edges of the film by a tenter under a specified condition is also proposed. The high-speed solution film forming methods enable to produce the film having good quality with stable conveying and with stable drying especially in the conveying of the film by the tenter machine in the drying steps after stripping off from the casting support.

Owner:FUJIFILM HLDG CORP +1

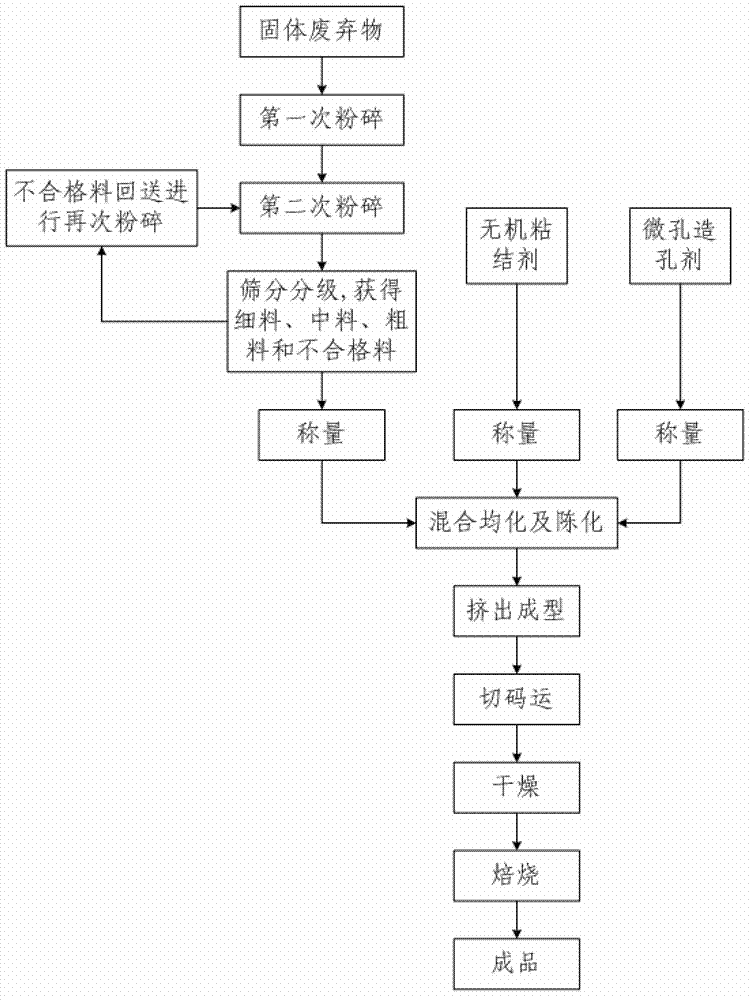

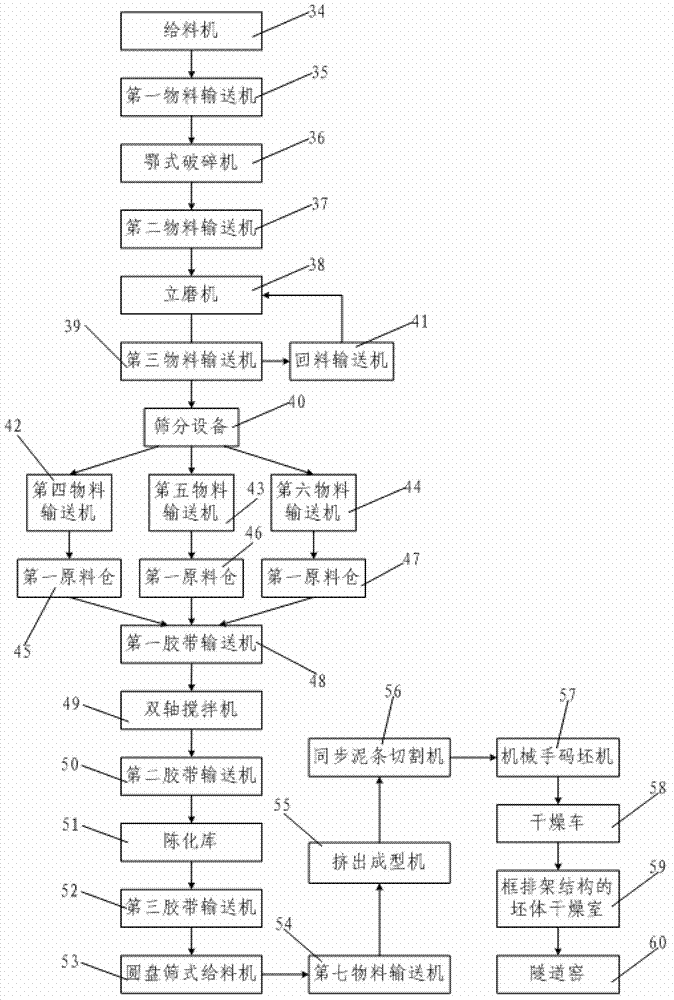

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Terylene fine-denier triangle super bright FDY filament and preparation method thereof

InactiveCN101139741AGood flexibilityFeel goodFilament/thread formingMonocomponent polyesters artificial filamentMaterials scienceFilament yarn

The invention discloses a terylene fine denier triangular super-glossy FDY filament and relevant preparation method, and belongs to the technical field of terylene fibers. During the course of filature preparation, the invented fine denier triangular super-glossy terylene filament can lower filature speed, shorten calm zone distance and milden air blow cooling conditions; meanwhile, the fiber adopts nozzle oiling mode to improve oiling position, in order to successfully prepare fine denier triangular super-glossy FDY terylene filament with denier no more than 0.7dtex, fiber corss section similar to regular triangle and super-bright glossy. The terylene filament has advantages of extremely perfect flexibleness, excellent hand feeling, and moreover, the product is characterized by fewer broken filament, fewer short ends, more uniform yarn more stable quality.

Owner:JIANGSU HENGLI CHEM FIBER

Solvent casting process, polarizing plate protective film, optically functional film and polarizing plate

InactiveUS20050110186A1Good quality and stabilityImprove productivityFlat articlesCoatingsTectorial membraneSolvent

A process for solvent casting including, casting a dope from a casting die onto a casting support, drying the cast dope on the casting support to form film, stripping off the film from the casting support, and further drying the film, wherein the dope has a solid matter content of from 17 mass % to 30 mass %, and a mean drying rate between the casting of the dope and the stripping off is more than 300 mass % / minute and not more than 1000 mass % / minute. Also, a process for solvent casting including the steps of casting a dope from a casting die to a casting support, forming the film by drying the dope to some extent, stripping off the film from the casting support and further drying the film while conveying the film with carrying it at both side edges of the film by a tenter under specified conditions.

Owner:FUJIFILM CORP

Inkjet recording apparatus and inkjet recording method

ActiveUS8292419B2Suppress wrinkling or drying non-uniformitiesSuppress soiling of the interior of the machineInking apparatusOther printing apparatusMechanical engineeringRecording media

The inkjet recording apparatus includes: a conveyance device which conveys a recording medium; a drying air flow spraying device which sprays a drying air flow onto the recording medium while the recording medium is conveyed by the conveyance device; a negative pressure suctioning device which opposes the drying air flow spraying device, and suctions a rear surface of the recording medium and suctions at least a portion of the drying air flow sprayed by the drying air flow spraying device while the recording medium is conveyed by the conveyance device; and an inkjet head which ejects ink to be deposited on the recording medium.

Owner:FUJIFILM CORP

High-performance water-based epoxy ink and preparation method thereof

The invention belongs to the field of water-based ink and production technology thereof, and in particular relates to high-performance water-based epoxy ink and a preparation method thereof. The water-based ink is prepared from a water-based epoxy resin emulsion binder, pigments, auxiliaries, water and other little alcohol substance. The preparation method comprises the following steps of: takingwater-based epoxy resin as the binder; adding a certain amount of pigments, solvent, defoaming agents, wetting agents, dispersing agents and the like; mixing and grinding the materials to prepare a component A; fully mixing a certain amount of water-based epoxy hardener and a proper amount of water to prepare a component B; and fully and uniformly mixing the component A and the component B, and filtering the mixture through a screen to prepare the ink. The prepared ink has the advantages of good solvent resistance, water resistance, gloss retention and adhesive force, stable performance, quick drying, good printing adaptability, dark ink color and bright colors. Because the solvent is water, the ink has the characteristics of no toxicity, no pungent odor, noninflammability, no pollution and the like and is favorable for protecting environment and improving construction environmental quality.

Owner:TONGJI UNIV

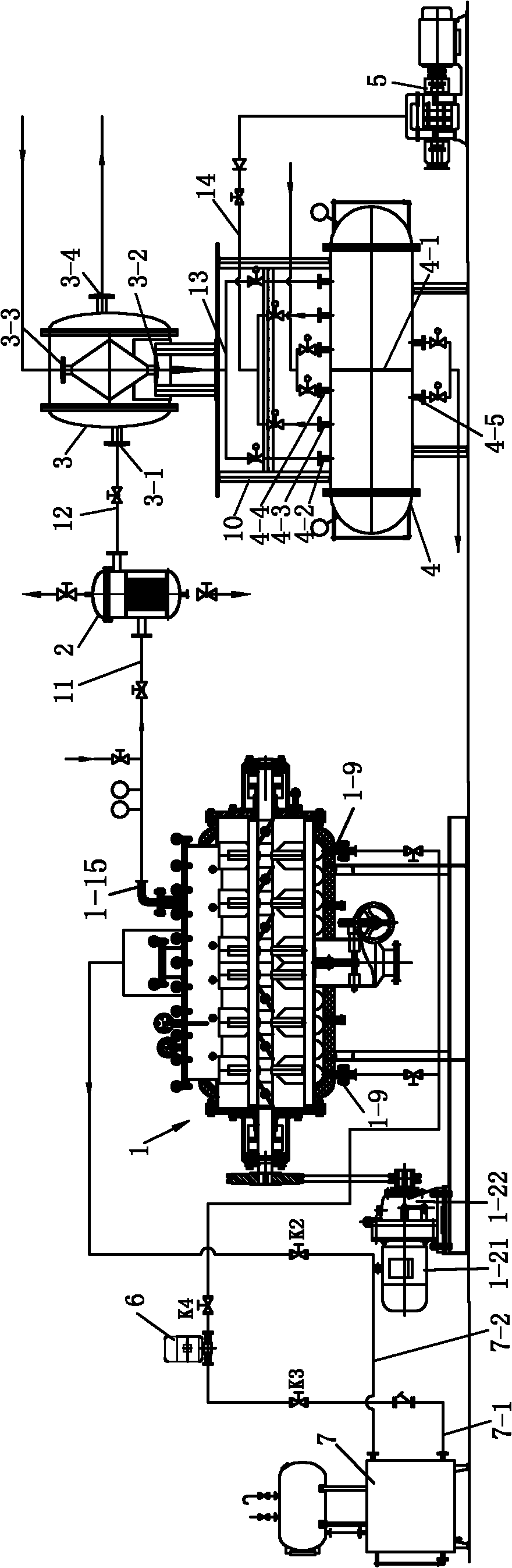

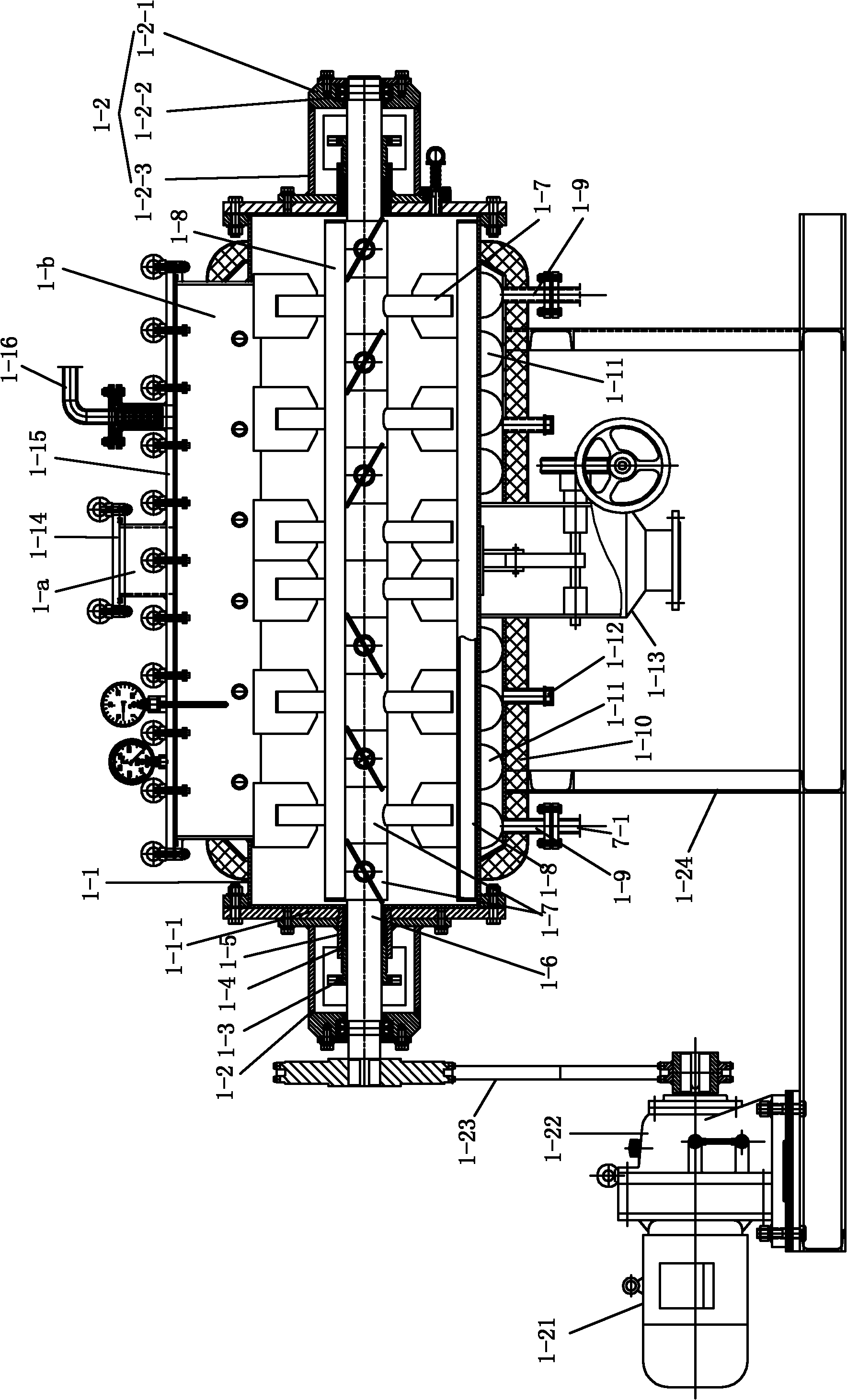

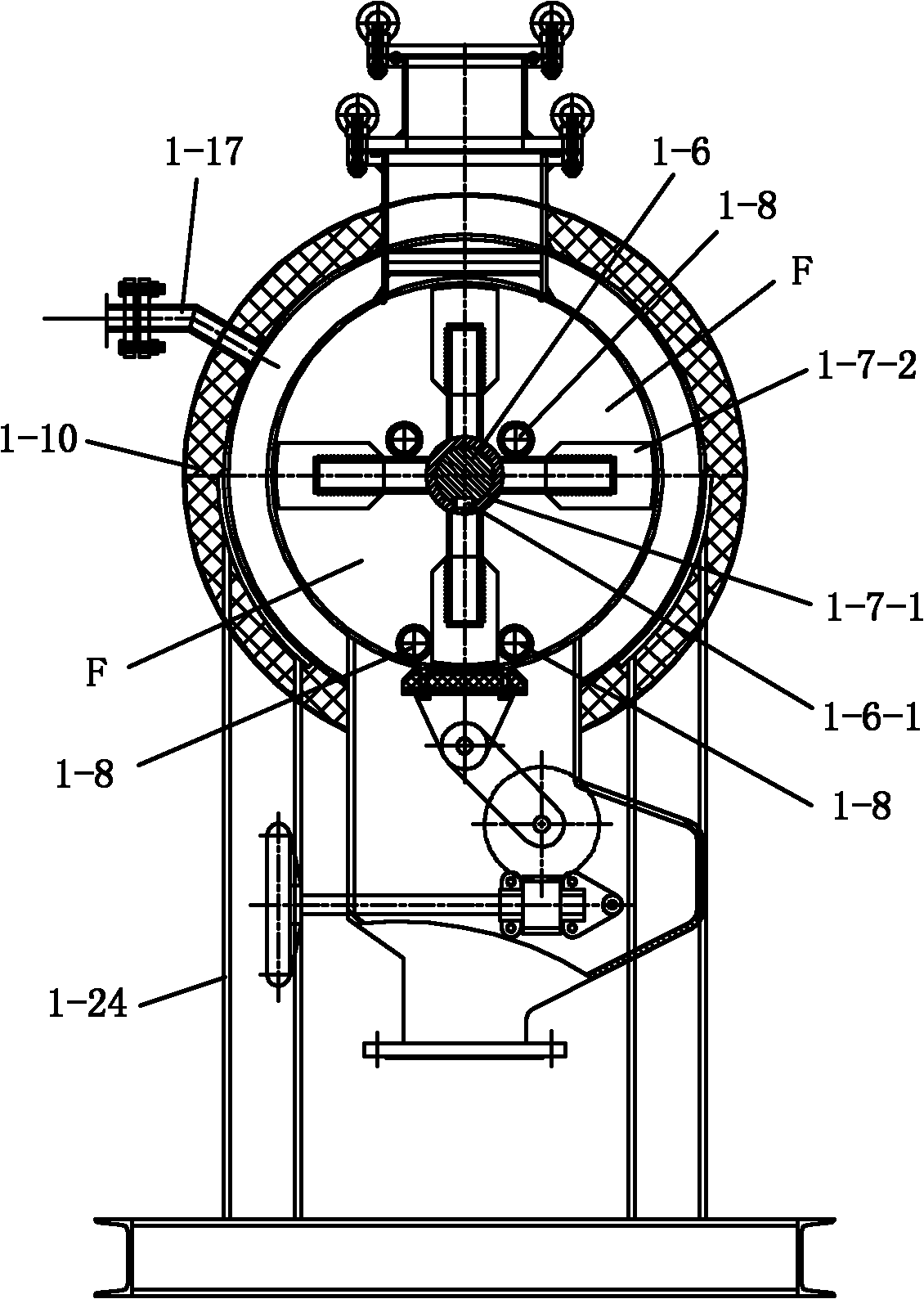

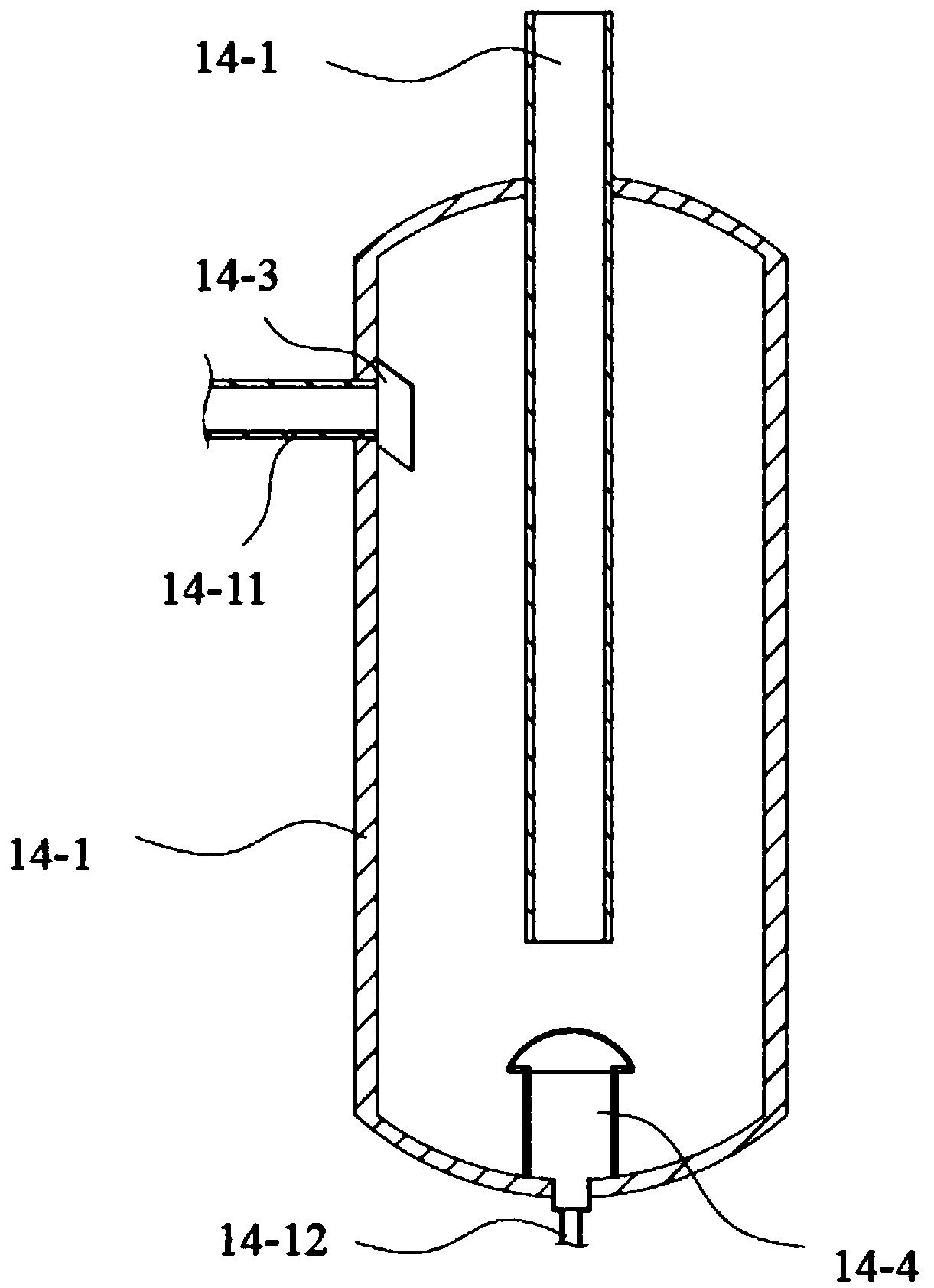

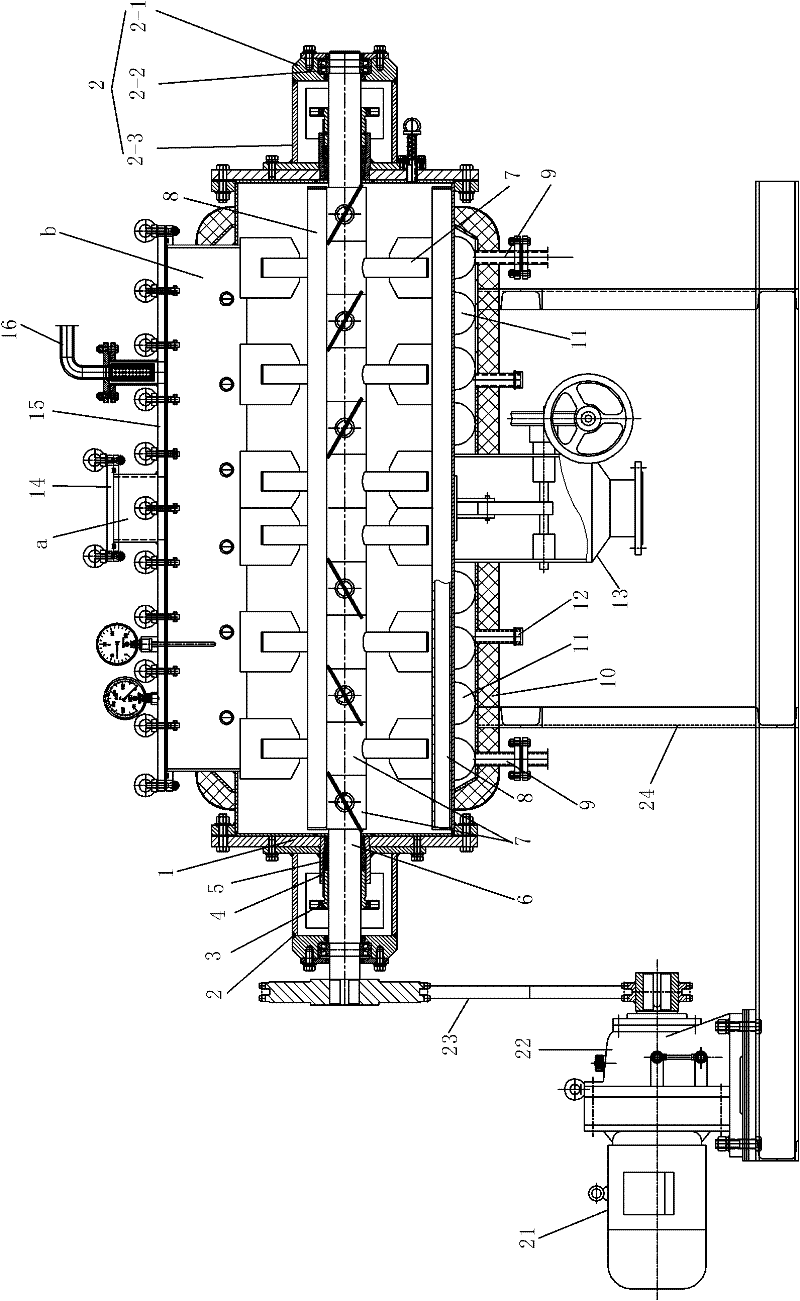

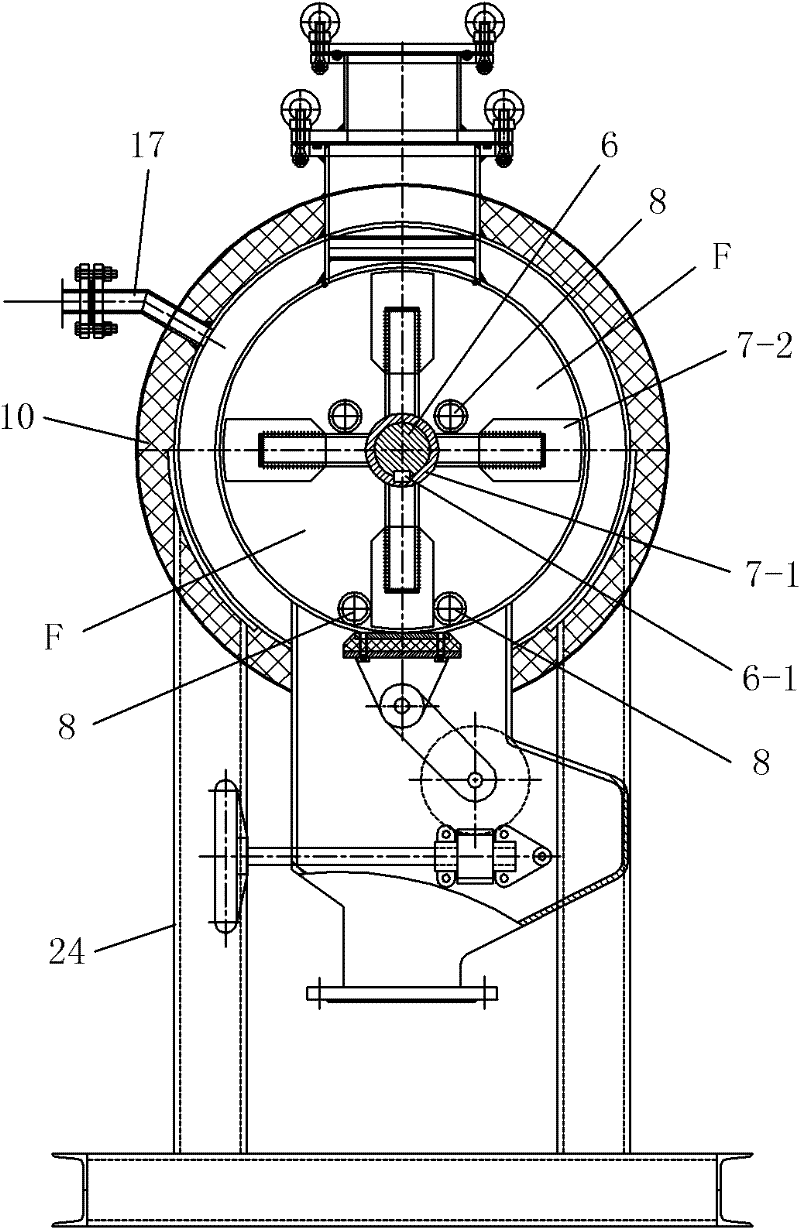

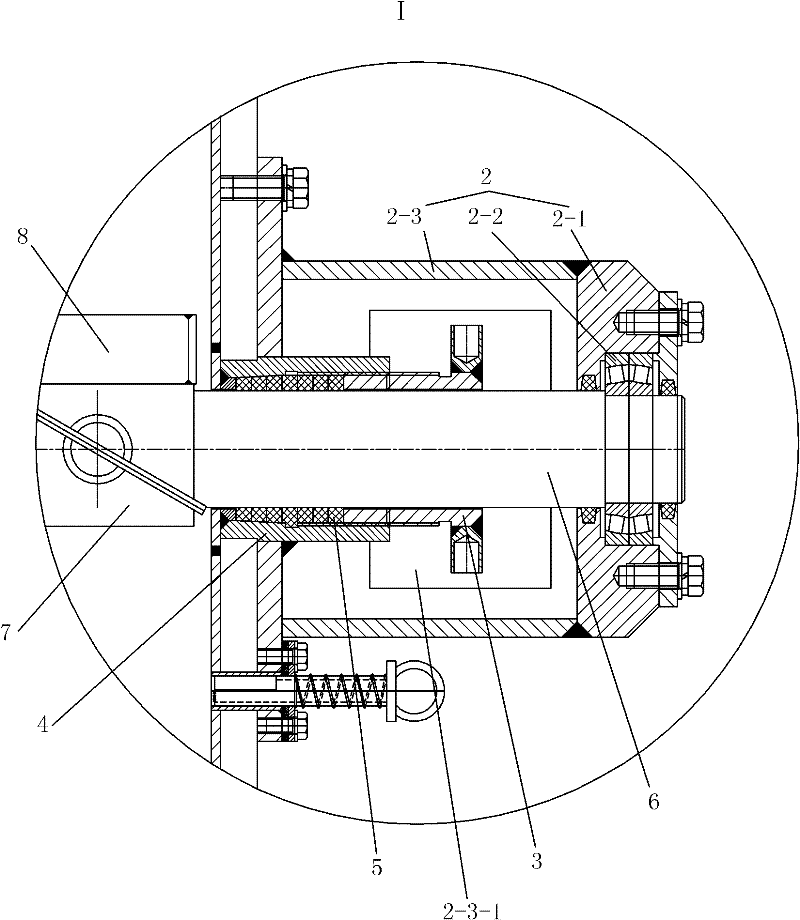

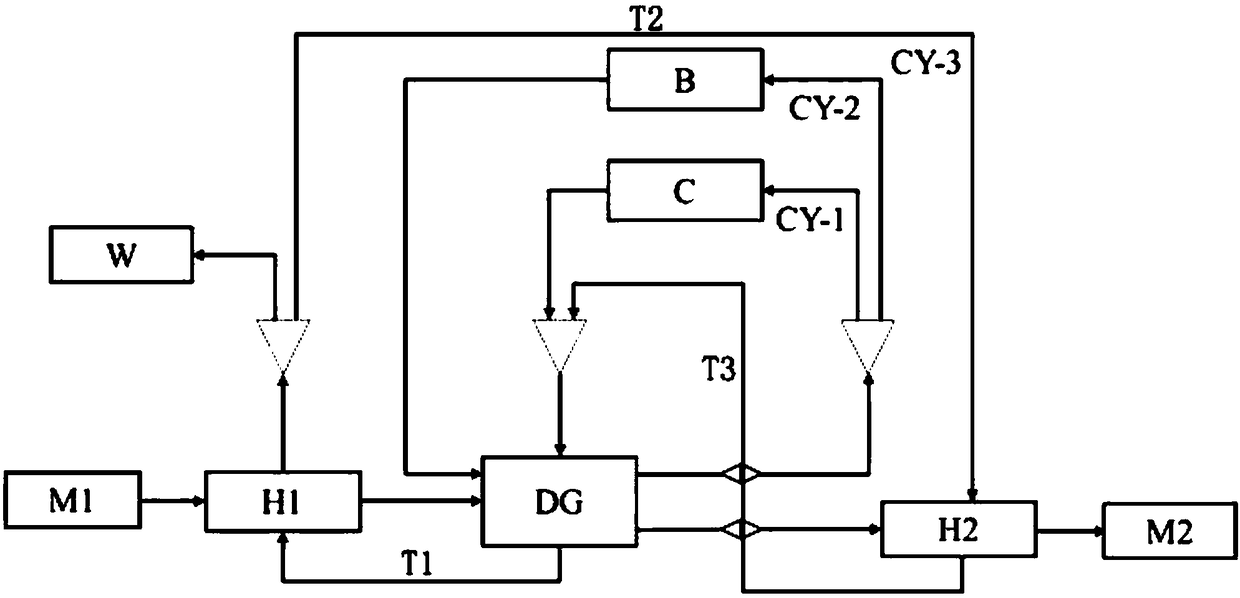

Rake type vacuum drying system

ActiveCN102183126ASpeed up crushingLarge specific surface areaDrying machines with non-progressive movementsDrying solid materialsVapor–liquid separatorLithium iron phosphate

The invention provides a rake type vacuum drying system, which comprises a rake type vacuum drying host machine, a bag type filter, a condenser, a gas-liquid separator, a vacuum pump, an oil pump and a hot oil tank, wherein a main shaft of the rake type vacuum drying host machine is a solid main shaft; a plurality of rake tooth components are arranged on the main shaft; each rake tooth component comprises a sleeve shaft and four solid rake teeth uniformly distributed on the sleeve shaft in a fixed manner, and is connected on the main shaft through a sleeve shaft key; the rake teeth of the respective rake tooth components face towards the same direction, so that four passageways are formed in a tank body; and striking rods are respectively arranged in respective passageways or in spaced passageways. In the invention, materials inside the tank body of the drying host machine are struck continuously by using the striking rods, so that the crushing of the materials is accelerated, the materials can obtain larger specific surface areas, the drying process is accelerated, and finished products have uniform fineness and low water content; thus, the rake type vacuum drying system is suitable for drying lithium iron phosphate materials, and the product quality and drying efficiency are improved; moreover, the system is used for recovering solvents through the condenser and the gas-liquid separator, and is beneficial to reduction of the cost.

Owner:JIANGSU XIANFENG DRYING ENG

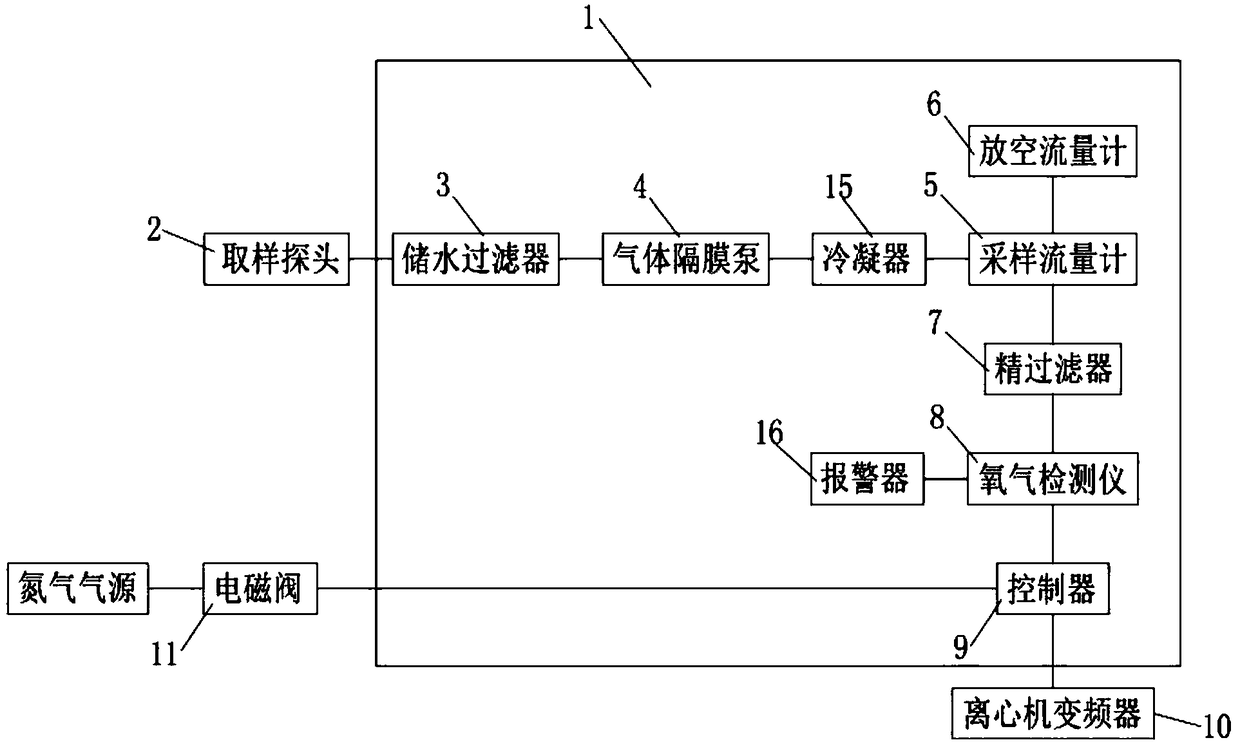

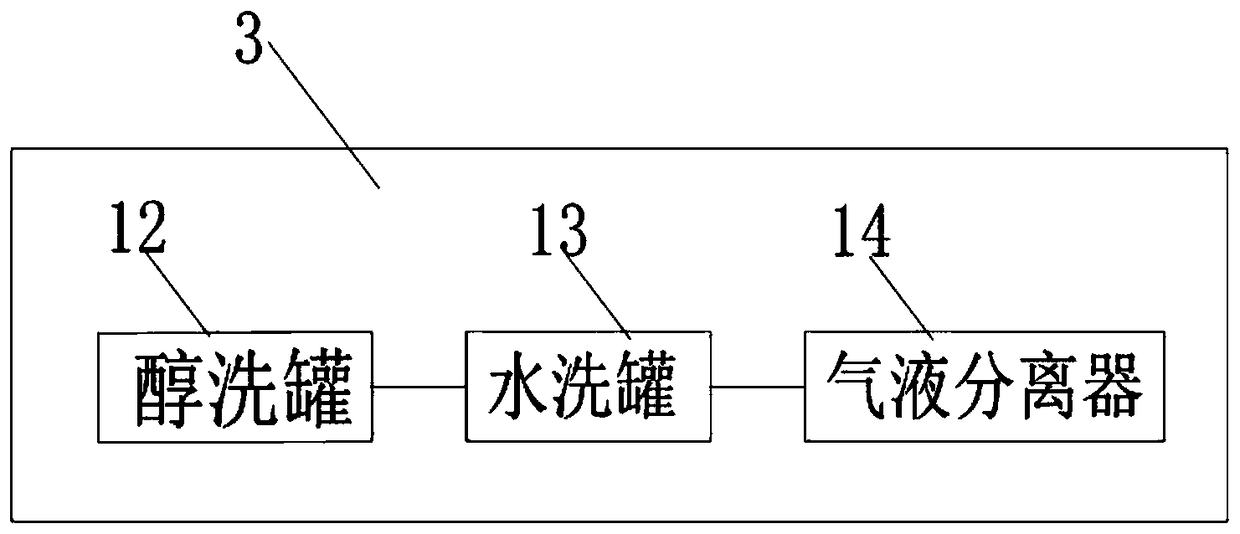

Oxygen content detector

InactiveCN109507246AStable and dryAccurate measurementWithdrawing sample devicesVolume meteringDiaphragm pumpData connection

The invention relates to the technical field of gas analysis equipment, in particular to an oxygen content detector, comprising a box body, a sampling probe, a water storage filter, a gas diaphragm pump, a condenser, a sampling flow meter, an emptying flow meter, a fine filter, an oxygen detector, a controller, a centrifuge frequency converter and an electromagnetic valve, wherein the sampling probe is arranged in a process pipeline; the water storage filter is arranged in the box body and is connected with the sampling probe; the gas diaphragm pump is arranged in the box body and is positioned on a pipeline between the sampling probe and the water storage filter; the condenser is arranged in the box body and is connected with the water storage filter; the sampling flow meter is arranged in the box body and is connected with the condenser; the emptying flow meter is connected with the sampling flow meter; the fine filter is connected with the sampling flow meter; the oxygen detector isconnected with the fine filter and is used for performing oxygen content analysis; the controller is in data connection with the oxygen detector; the centrifuge frequency converter is connected withthe controller; the electromagnetic valve is arranged at a pipe orifice of a nitrogen source and is connected with the controller. The sample gas treated by the oxygen content detector is dry, stableand accurate in measurement; the oxygen content detector can realize automatic feedback and control, thus being safe and reliable.

Owner:江苏威尔安智能科技有限公司

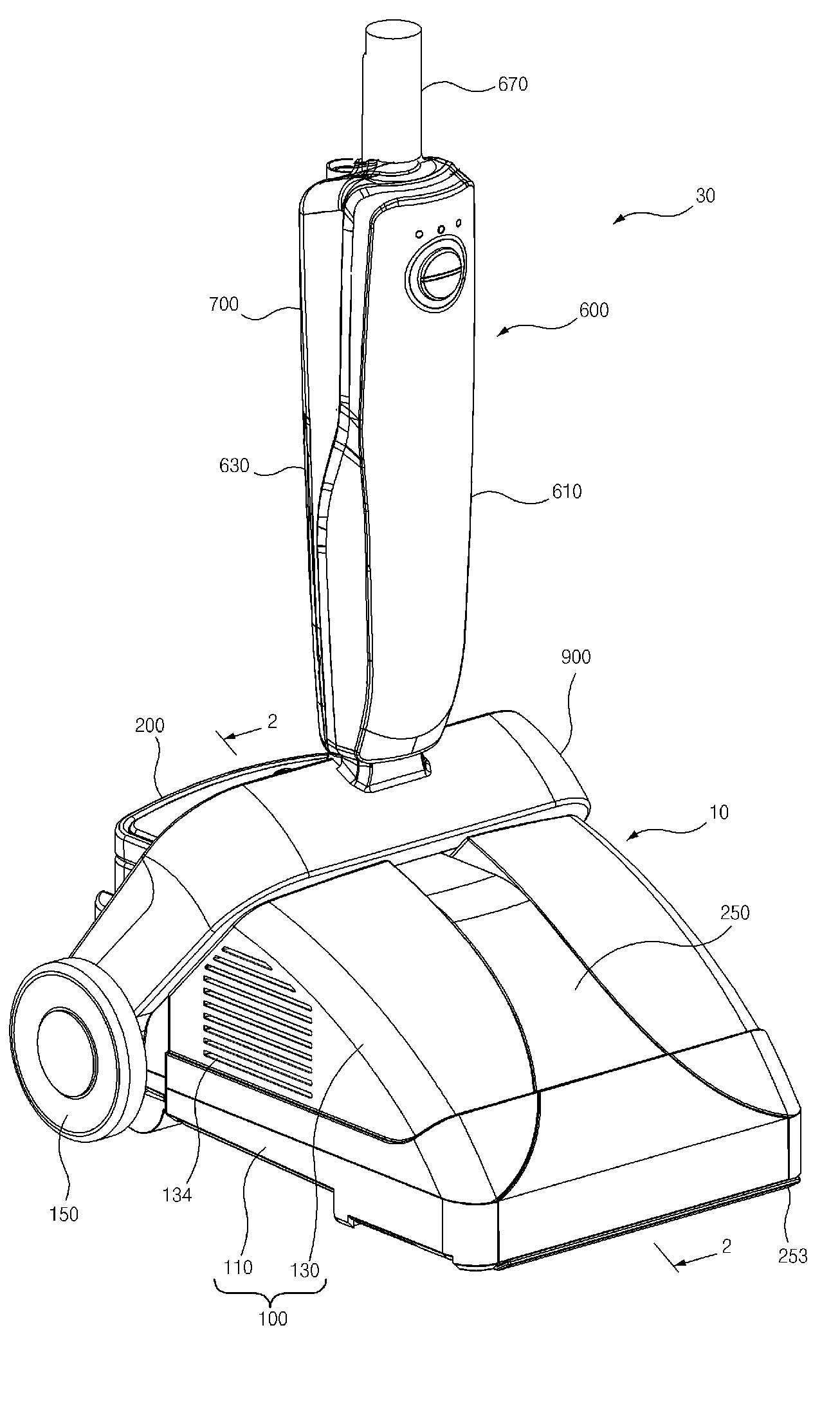

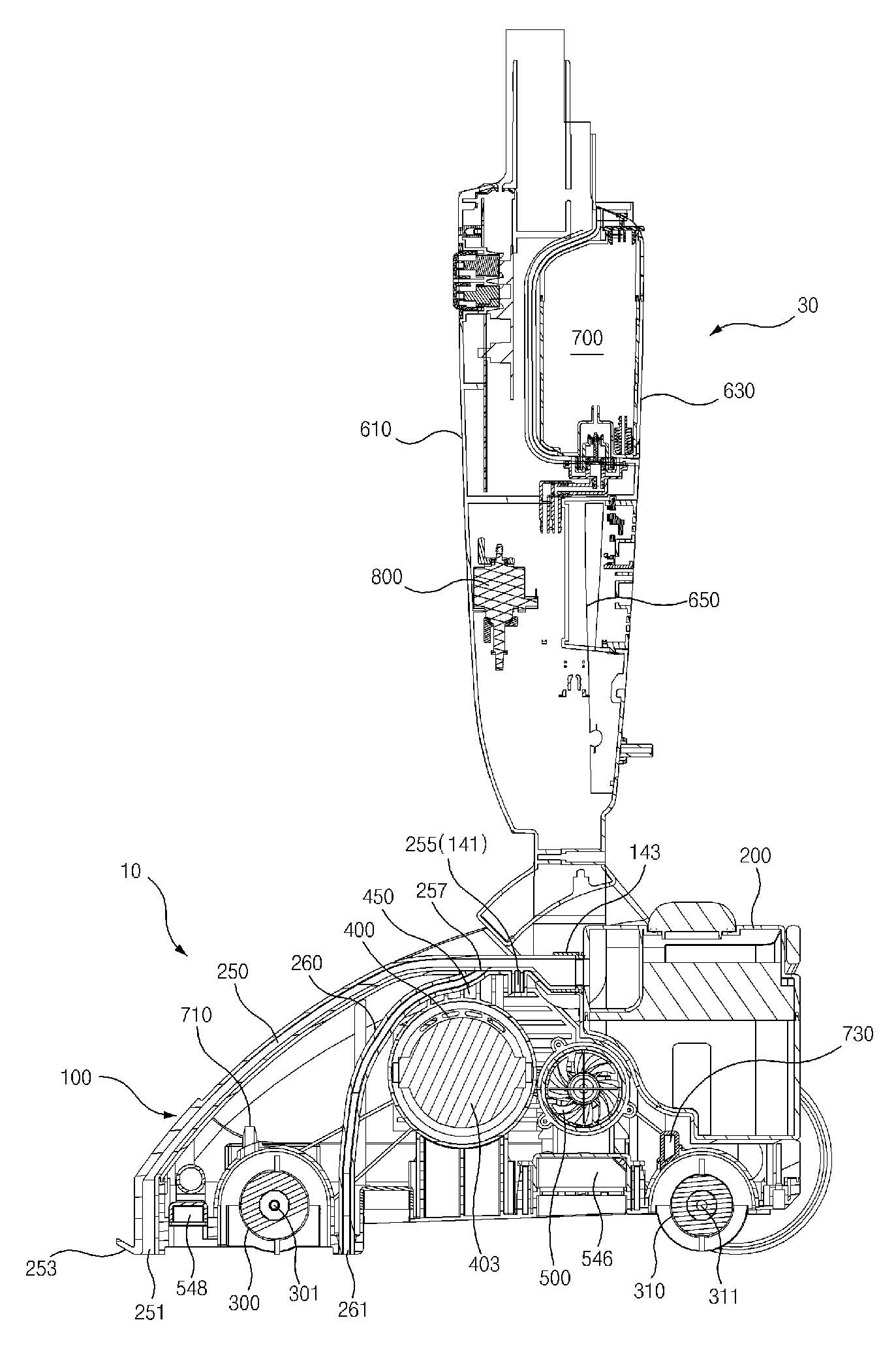

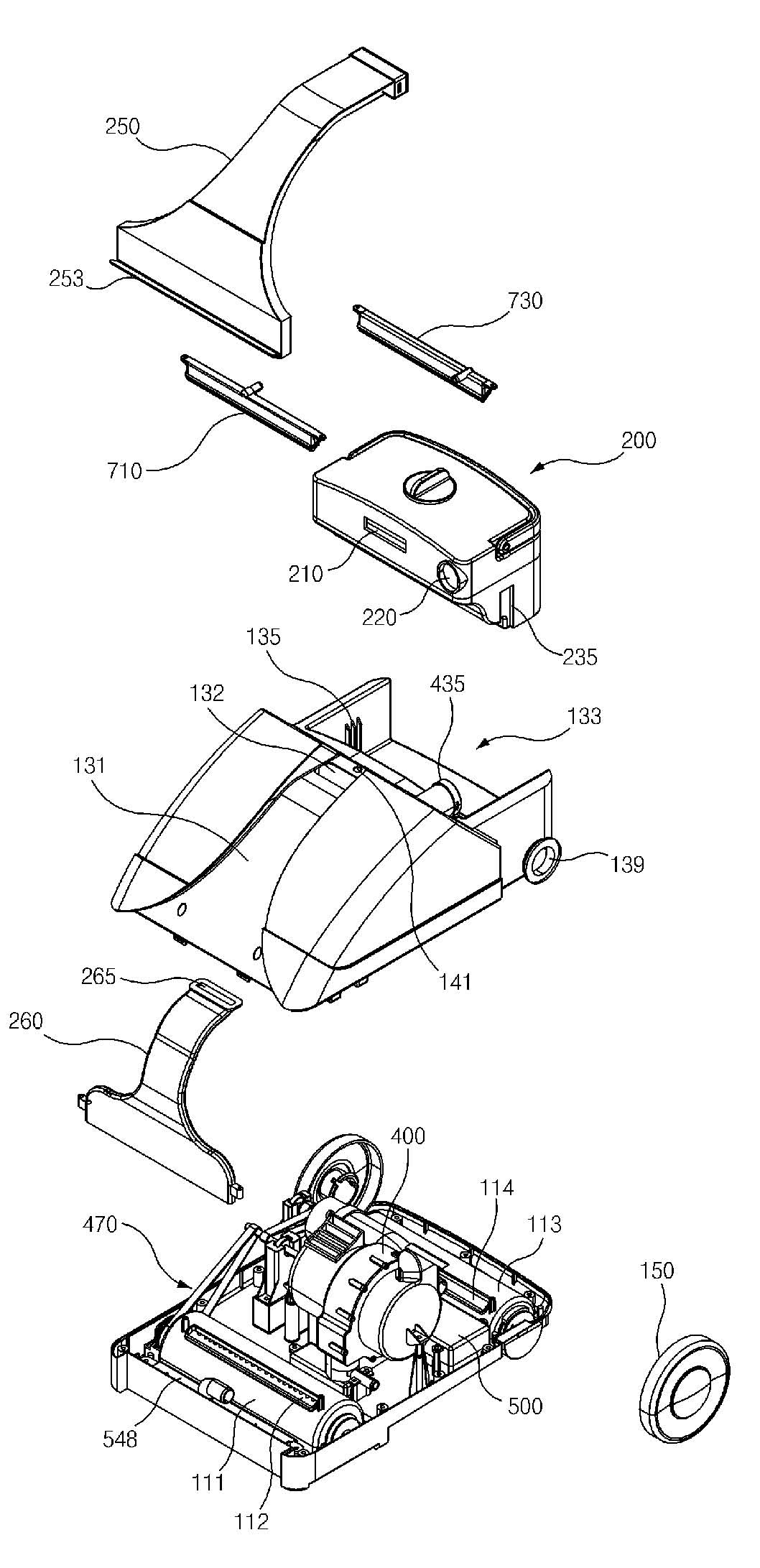

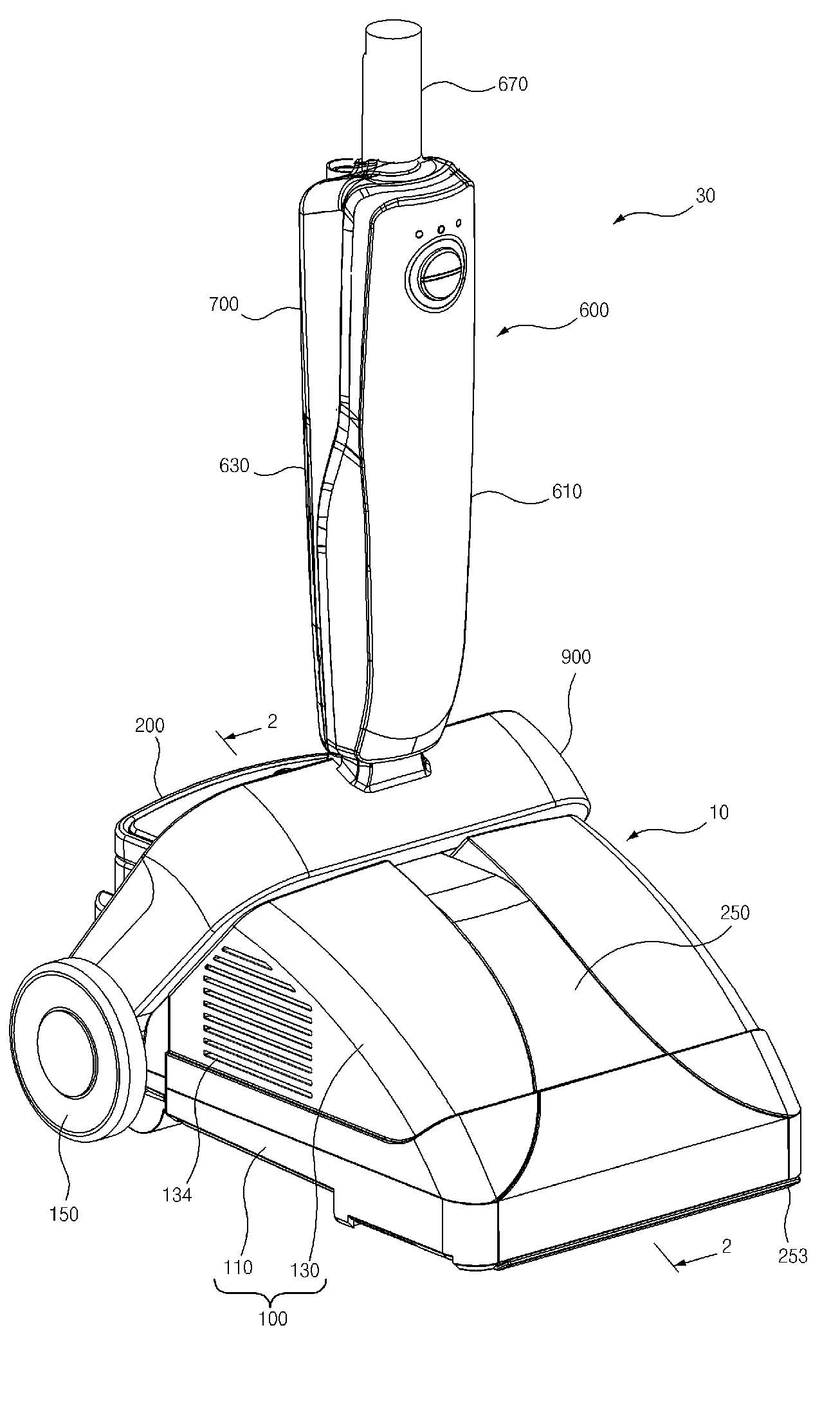

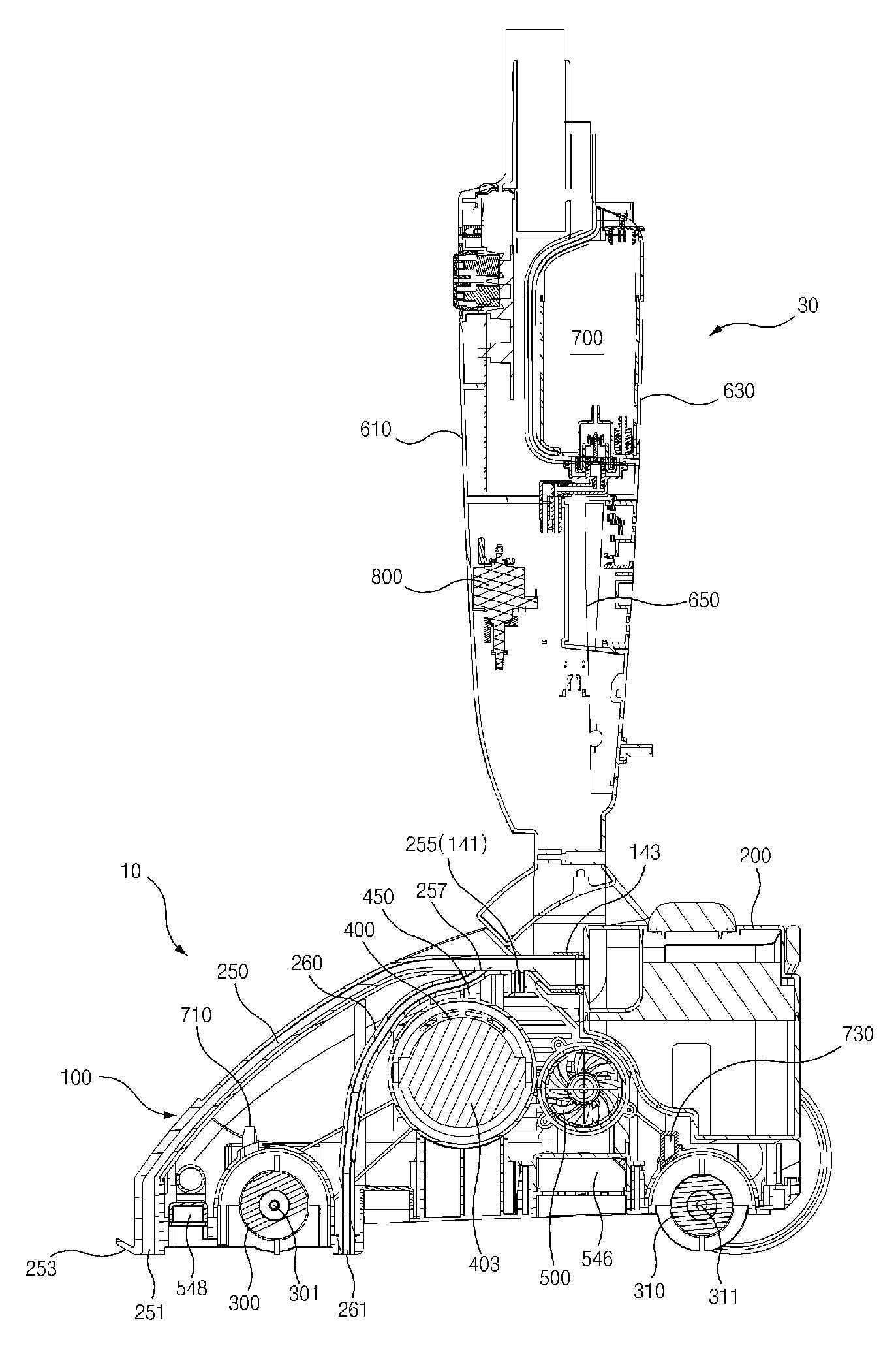

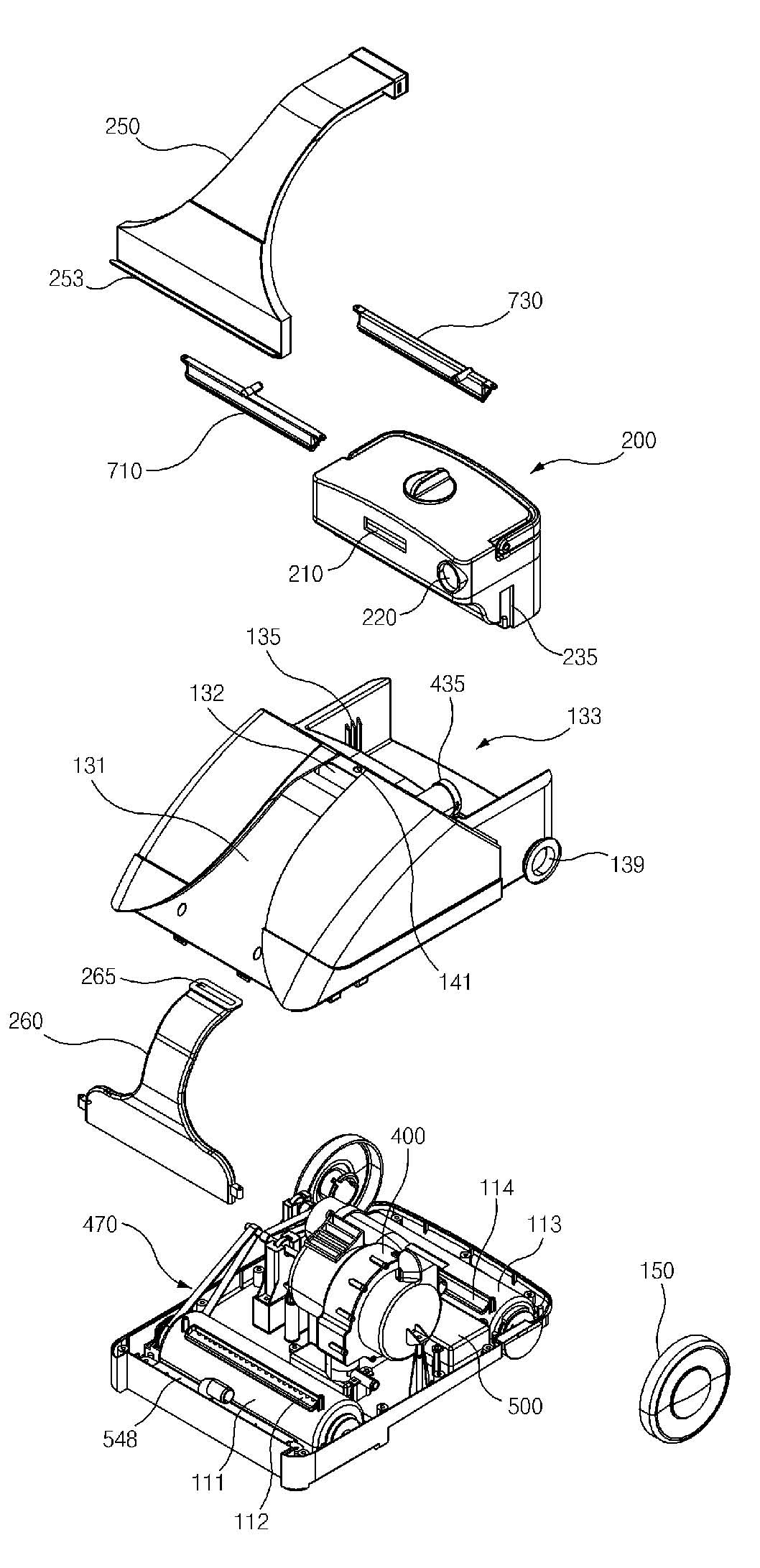

Carpet cleaner

InactiveCN102652659ALarge capacityIncrease the areaCarpet cleanersFloor cleanersLotionControl theory

The invention relates to a carpet cleaner, which is characterized in that, the cooling exhaust air stream of a sucking motor is suitable for lotion pressure injection, and therefore, the lotion can be uniformly injected in the length direction of the rotary shaft of a rotary brush.

Owner:SUZHOU HAAN TECH +1

Carpet cleaner

InactiveCN102652657AAvoid short circuitStable Carpet DryingCarpet cleanersFloor cleanersEngineeringLotion

The invention relates to a carpet cleaner, which is characterized in that, a wet carpet can be rapidly dried, and washing efficiency can be improved via sufficient dissolution of a lotion, and particularly relates to a carpet cleaner which realizes stabilization of a heater via air supply to the heater through drive force of a sucking motor.

Owner:SUZHOU HAAN TECH +1

Water-soluble environment protective paint

The invention discloses a water-soluble environment protective paint. The water-soluble environment protective paint comprises the following raw materials: water, a dispersant 5040, a wetting agent op--10, hydroxyethyl cellulose with an average molecular weight of 300000, titanium dioxide, kaolin, a light calcium carbonate powder, a heavy calcium carbonate powder, ammonia water, a silane coupling agent, a preservative, a defoamer, a film coalescing aid, propylene glycol, acrylate emulsion, and a thickener ASE60. The water-soluble environment protective paint has advantage of simple technology, convenient operation, smooth and light paint film, high durability, quick drying, firm adhering, and stable color. The silane coupling agent as the inorganic adhesive is added, so that the inorganic molecule silane is embedded into the paint film, and thus the molecular bond energy inside the paint film is greatly improved, and the ageing resistance and the water resistance of the emulsion paint are effectively promoted.

Owner:KUNMING HUIJIANG ECONOMIC TRADE

Printing ink using inorganic nanometer material and preparation method and application thereof

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing silane organic solvent, wherein the structure of the fluorine-containing silane organic solvent is shown in a formula I, namely (Rb')n'-(Rfb)n-(Rfa)m-(Ra')m'-SiR1(R2)(R3); in the formula I, Rfa and Rfb are independently selected from partially or totally fluorated alkyl and aryl; Rb' is independently selected from H (hydrogen), aliphatic group with C1 to C30, aromatic group, F (fluorine), Cl (chloride), Br (bromine), I (iodine), sulphonate, sulfonyl ester, and methoxyl; Ra' is selected from aliphatic group with C1 to C30, aromatic group, sulphonate, sulfonyl ester, and methoxyl; R1, R2 and R3 are independently selected from H, hydroxyl or substituted hydroxyl, and aryl or substituted aryl; the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1, and m and n are not simultaneously 0; m' and n' are respectively 0 or 1.

Owner:SHENZHEN TCL IND RES INST

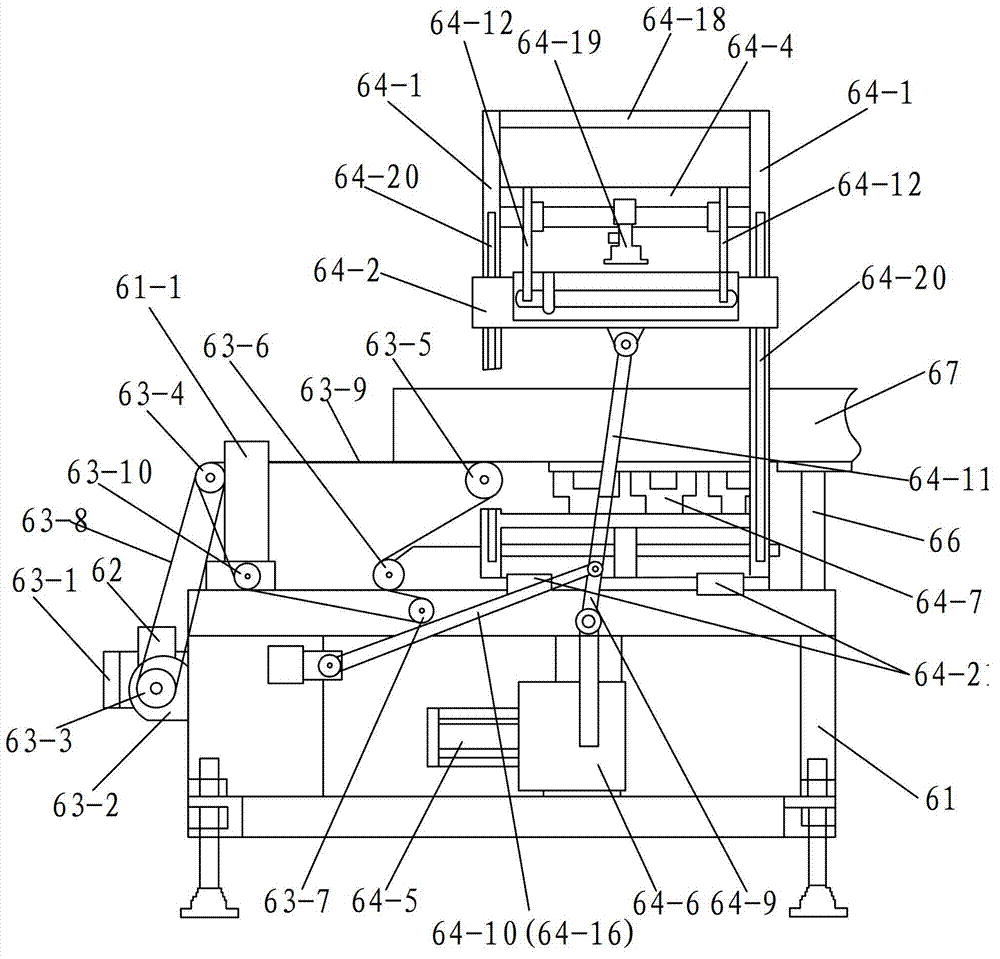

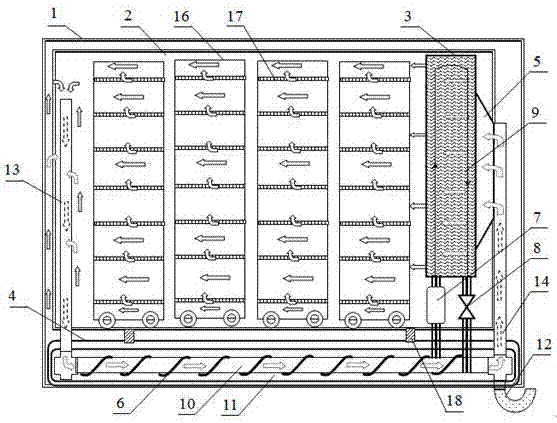

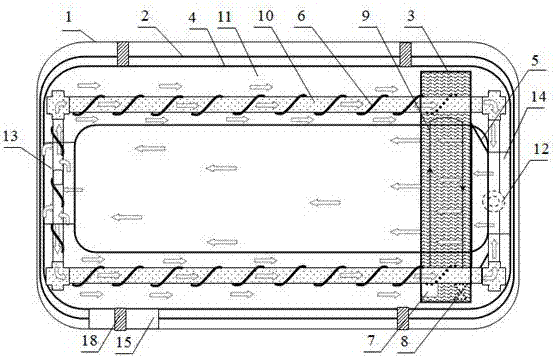

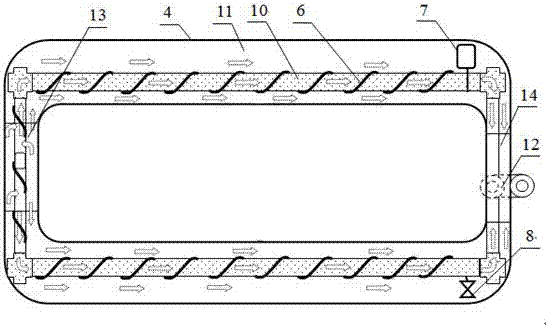

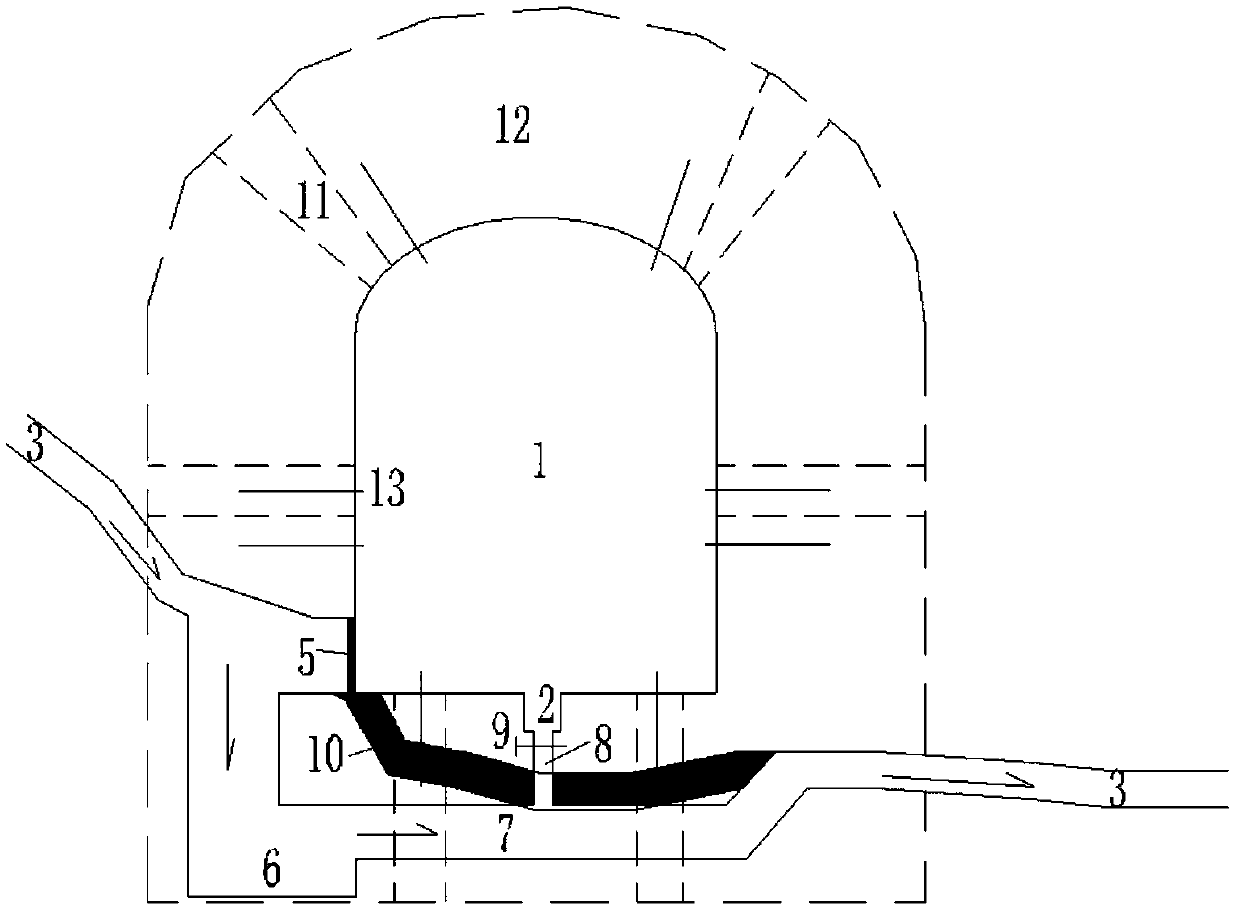

Medium and energy internal recycle drying method and drying machine

PendingCN106949716ANo overheatingGentle drying processMechanical apparatusDrying gas arrangementsCold airProcess systems

The invention relates to the field of drying equipment, in particular to a medium and energy internal recycle drying machine. The medium and energy internal recycle drying machine is characterized by comprising a drying machine body (1), a drying room (2) and a circle system; and the circle system comprises a draught fan (5), an evaporator (6), a compressor (7), an expansion valve (8), a condenser (9), a hot air internal flow passage (10), a hot air external flow passage (11), a water outlet pipe (12), a vertical hot air passage (13) and a cold air passage (14). According to the provided drying machine, in the drying process, a drying medium and heat energy of a process system recycle in the drying machine and are not discharged outside, the heat loss of exhausted gas does not exist, the material overheating phenomenon cannot occur, the drying process is gentle and stable, the drying quality is good, and the drying energy consumption is greatly saved; and meanwhile, the heat exchanging efficiency of a condensation room is greatly improved, the dehumidifying effect is intensified, and the ventilation power consumption is lowered.

Owner:SOUTH CHINA AGRI UNIV

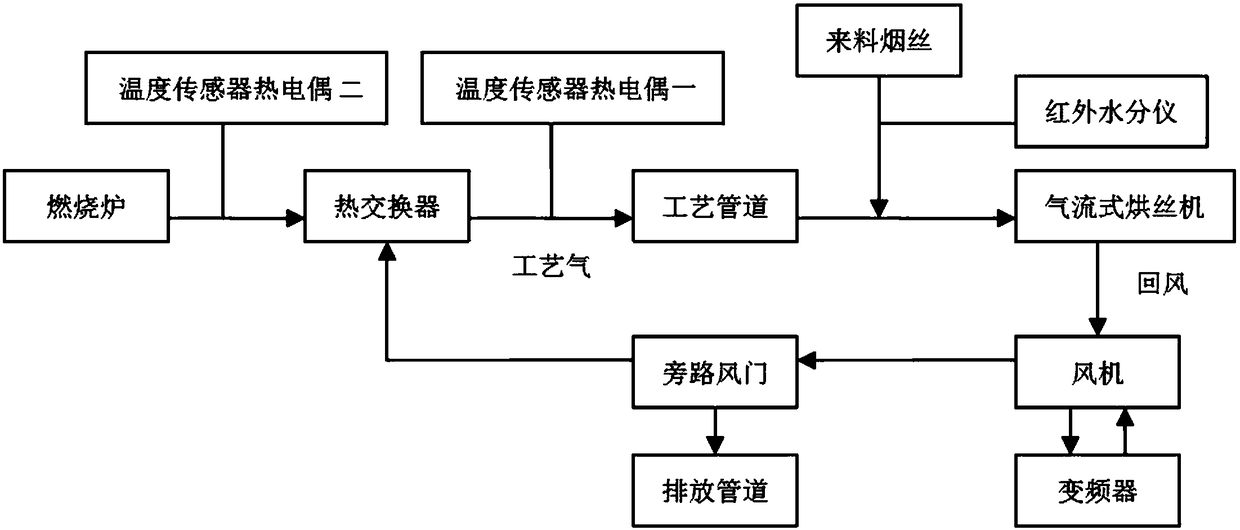

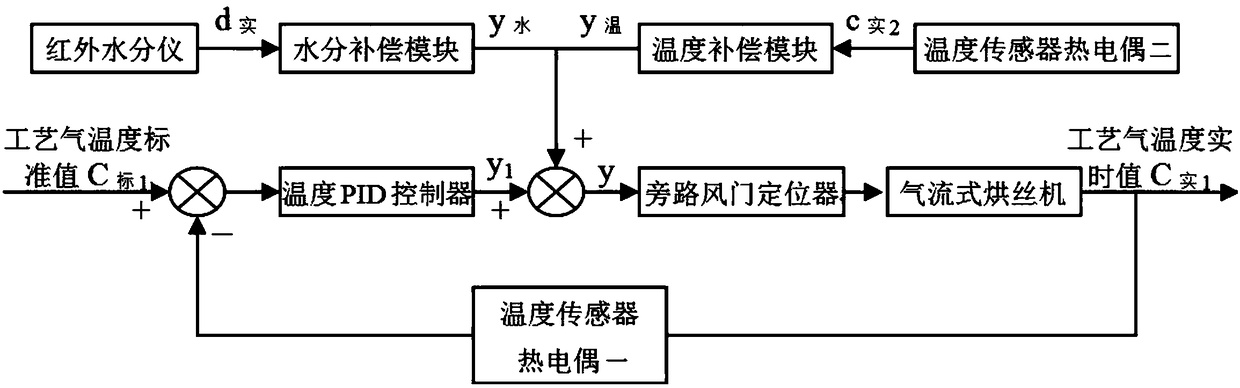

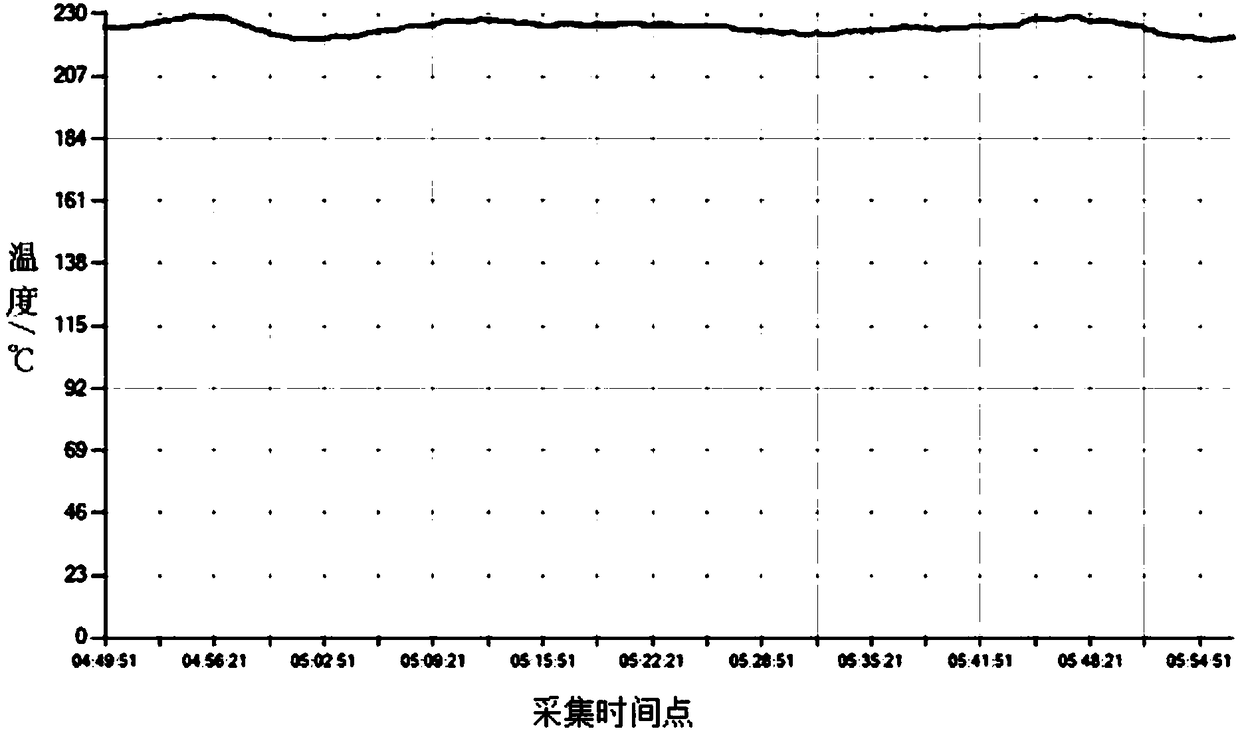

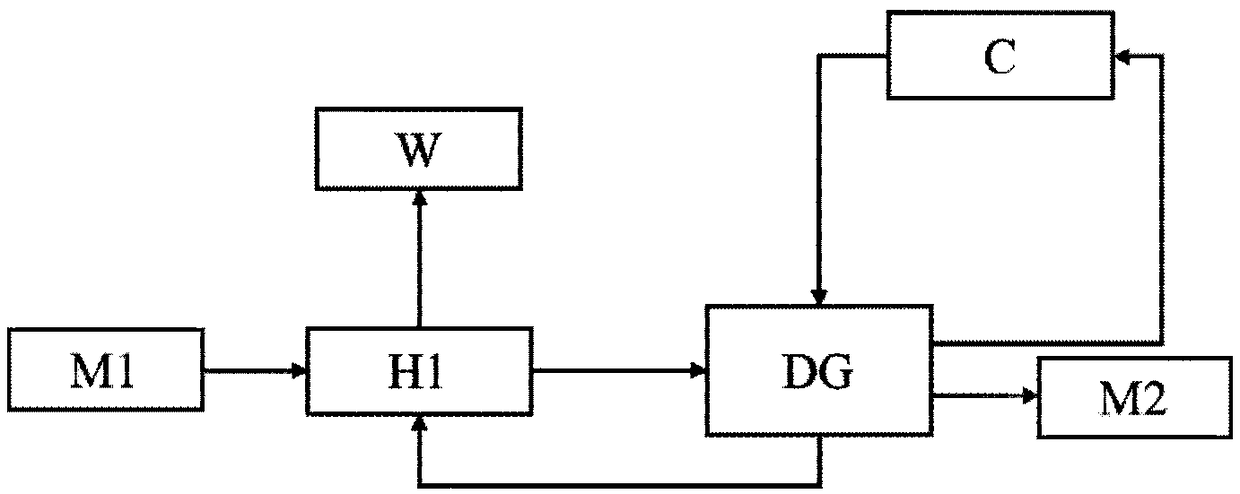

Process gas temperature control method for superheated steam drier

ActiveCN108208902AImprove closed-loop control accuracyStable and dryTobacco preparationProcess engineeringTobacco water

The invention discloses a process gas temperature control method for a superheated steam drier. The process gas temperature control method comprises the following steps: setting standard values of incoming tobacco water, process gas temperature and combustion furnace temperature as d<standard>, c<standard1> and c<standard2> respectively, and detecting real-time values of the incoming tobacco water, process gas temperature and combustion furnace temperature as d<real>, c<real 1> and c<real 2> respectively; respectively performing real-time comparison on the c<real 1> and c<standard1>, d<real> and d<standard> and c<real 2> and c<standard2>, and outputting the bypass air damper opening degree y1, ywater and ytemperature by virtue of a temperature PID (Proportion Integration Differentiation) controller, a water compensation module and a temperature compensation module in real time; and calculating a bypass air damper opening set value y according to a formula of y=y1+ywater+ytemperature, outputting the set value to a bypass air damper locator to be used for controlling the real-time opening of the bypass air damper. According to the method, the incoming tobacco water and the combustionfurnace temperature can be pre-judged, the set value of the bypass air damper opening can be corrected in advance, and the process gas temperature is rapidly and accurately adjusted.

Owner:CHINA TOBACCO JIANGSU INDAL

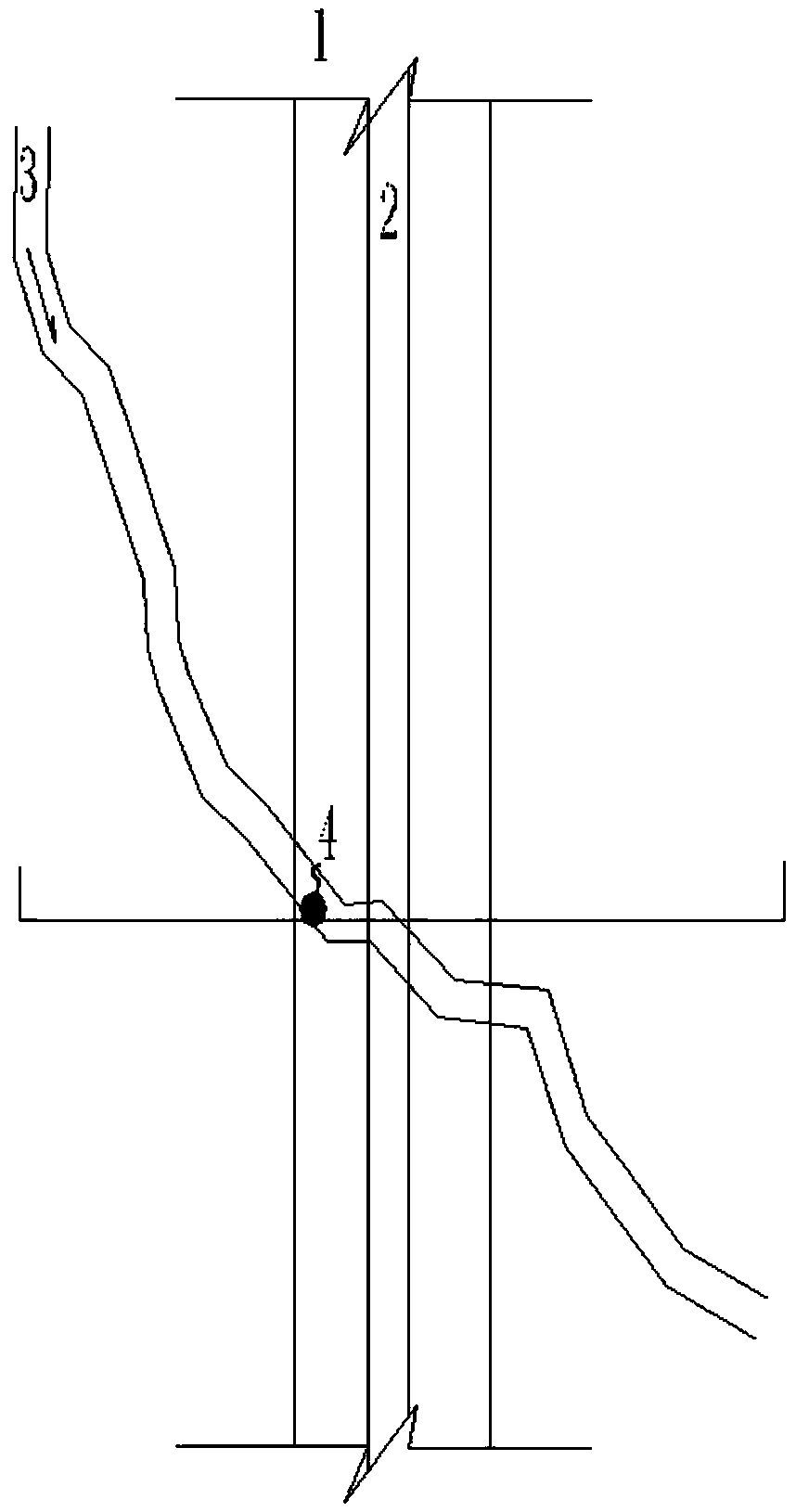

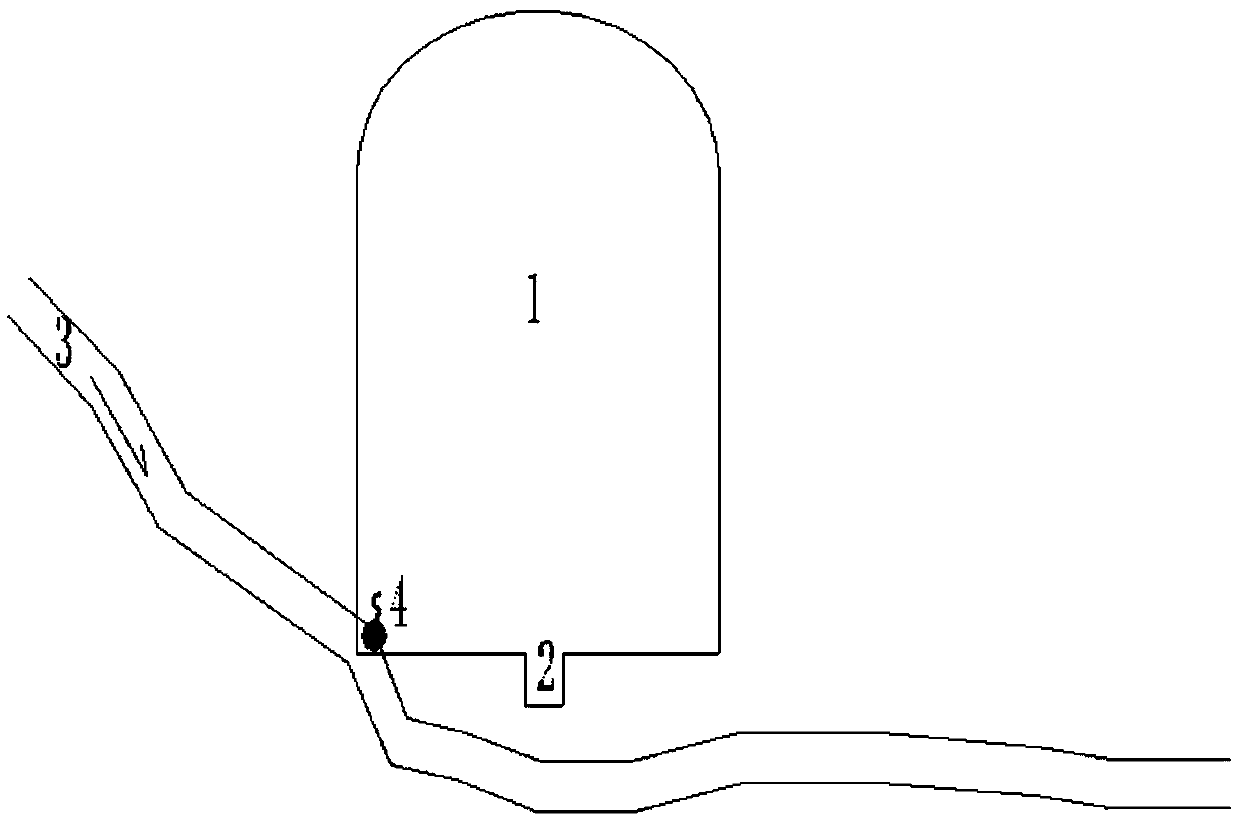

Replacement processing structure and method for water burst channel of underground cavern

PendingCN109538293AReduce external water pressureStable and dryUnderground chambersDrainageKarstEngineering

The invention discloses a replacement processing structure and method for a water burst channel of an underground cavern. The processing structure comprises a grit chamber formed in a rock mass in thewater coming direction of a karst pipeline through expanding excavation, an artificial culvert is arranged behind the grit chamber, and the artificial culvert is communicated with a pipeline in the drainage direction; the karst pipeline is communicated with a drainage ditch in a underground cavern space, and a controllable common drainage system is formed; a connecting channel is formed between the artificial culvert and the drainage ditch, and a bidirectional water quantity control valve is arranged at a channel opening of the connecting channel. After a high-pressure large-flow water burstof the underground cavern is treated through the technical scheme, an original channel is locally changed by the water burst, and the water burst is discharged out of the culvert through the artificial culvert; an anti-seepage consolidation ring around a water burst point bears external water pressure generated by increase of the underground water level and achieves an anti-seepage function; a radial drainage hole is used for pressure relief and drainage guide, and the dryness and stability of the cavern can be guaranteed. The problem of high-pressure large-flow water burst of the undergroundcavern is solved in a short construction period and at low investment.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD +1

Blasting bead drying box

InactiveCN107449226AStable and dryFast dryingDrying gas arrangementsDrying machines with local agitationControl systemEngineering

The invention relates to a blasting bead drying box comprising a box body, a refrigerating device, a heating device, a draught fan and a control system. The box body is internally provided with an air channel and a containing space communicating with the air channel, and a baking disc for storing blasting beads is arranged in the containing space. The refrigerating device is provided with an evaporator and a condenser, the evaporator is arranged in the box body, and the condenser is arranged outside the box body. The heating device is arranged at the downstream of the evaporator in the direction of an air flow in the box body and used for heating air in the box body. The draught fan is configured to drive the air in the box body to flow along the air channel. The control system is used for controlling operation of the refrigerating device, the heating device and the draught fan. According to the blasting bead drying box, the constant-temperature and constant-humidity temperature can be provided, large wind power is provided to conduct air drying on the blasting beads, and the production efficiency and quality of the blasting beads are improved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Inorganic nanometer material printing ink, preparation method and applications thereof

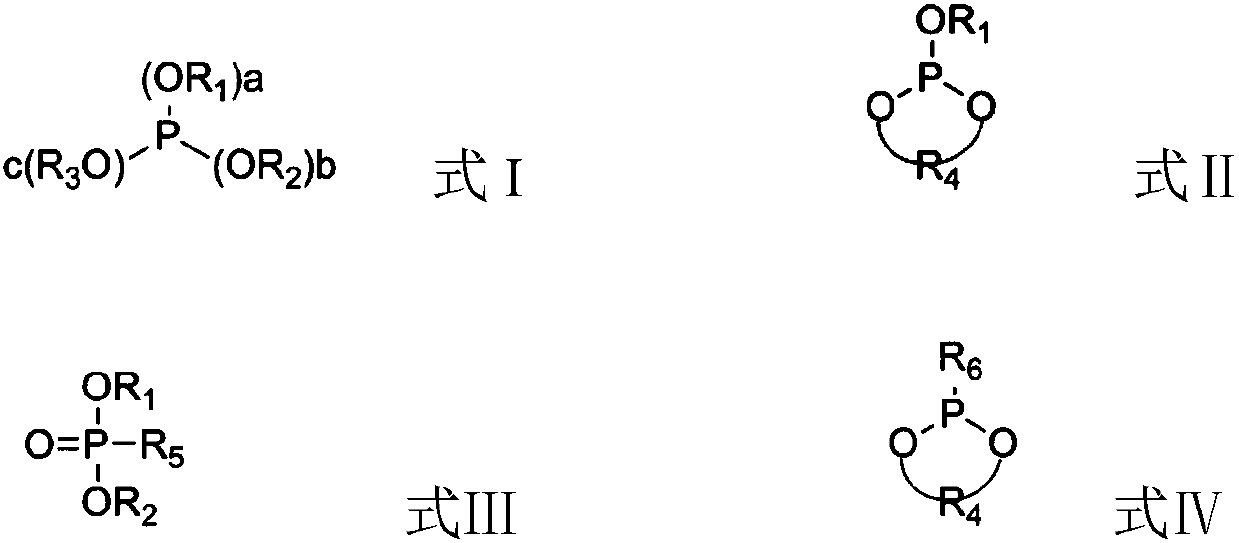

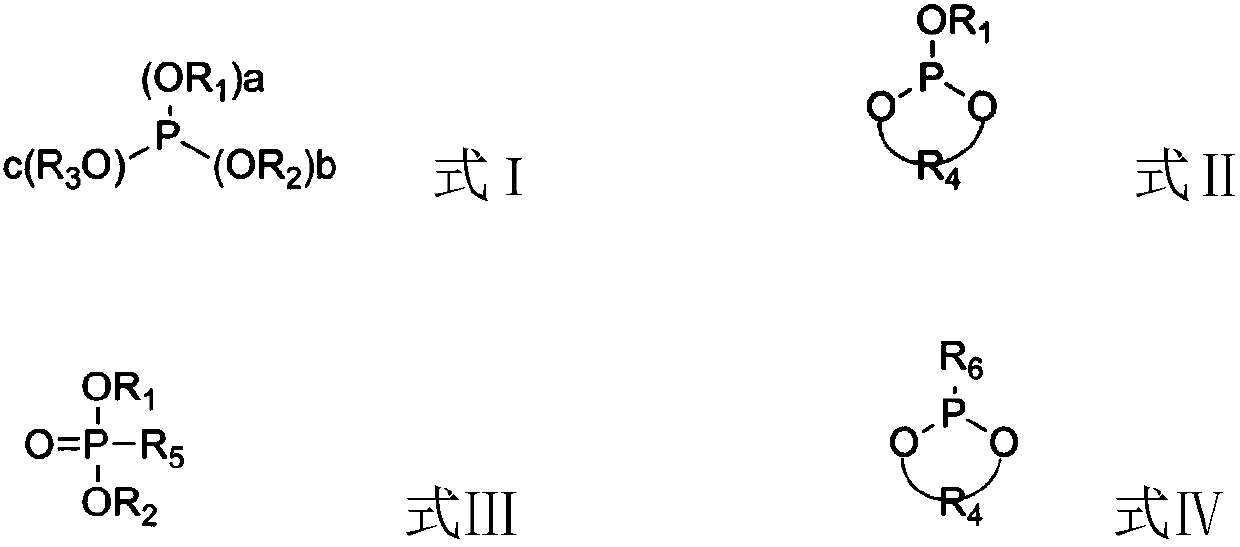

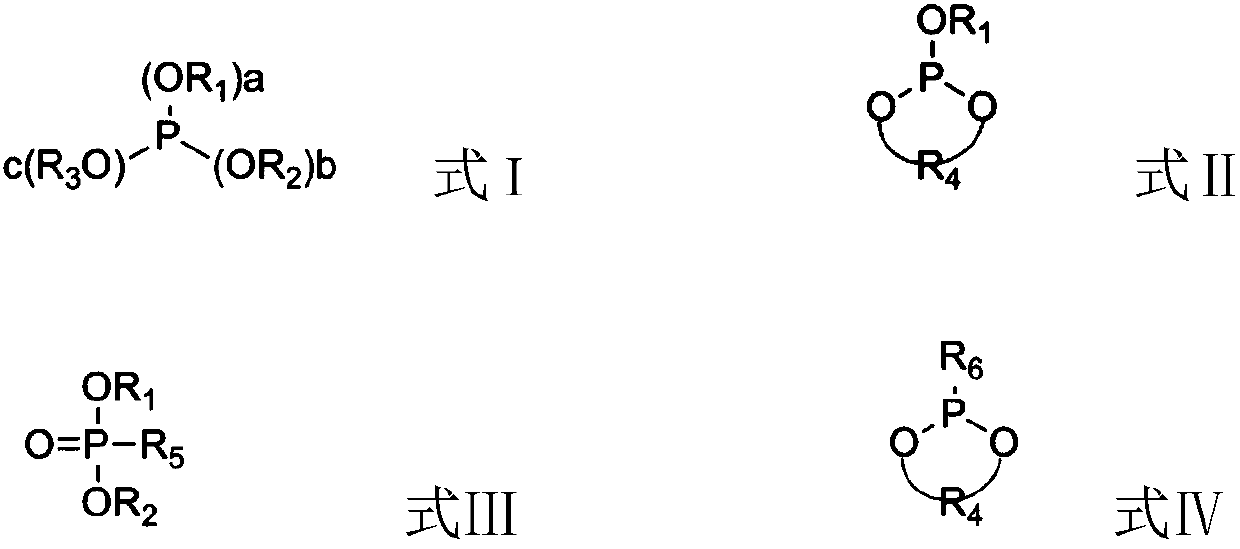

The invention provides an inorganic nanometer material printing ink, wherein the solvent in the inorganic nanometer material printing ink is an organic solvent, the inorganic nanometer material printing ink comprises at least an inorganic nanometer material and at least a phosphite-based organic solvent, the phosphite-based organic solvent has a structure represented by any one of structure formulas I, II, III and IV, and in the formulas I, II, III and IV, R1, R2 and R3 are independently selected from H and C1-30 aliphatic groups or aromatic groups, at most one of R1, R2 and R3 is H, R4 is selected from a C1-30 aliphatic group or aromatic group, R5 is selected from H, hydrocarbonyl and a hydrocarbonyl derivative, R6 is selected from H, hydrocarbonyl and a hydrocarbyl derivative, a, b and care individually selected from an integer of 0-3, and the sum of a, b and c is 3.

Owner:TCL CORPORATION

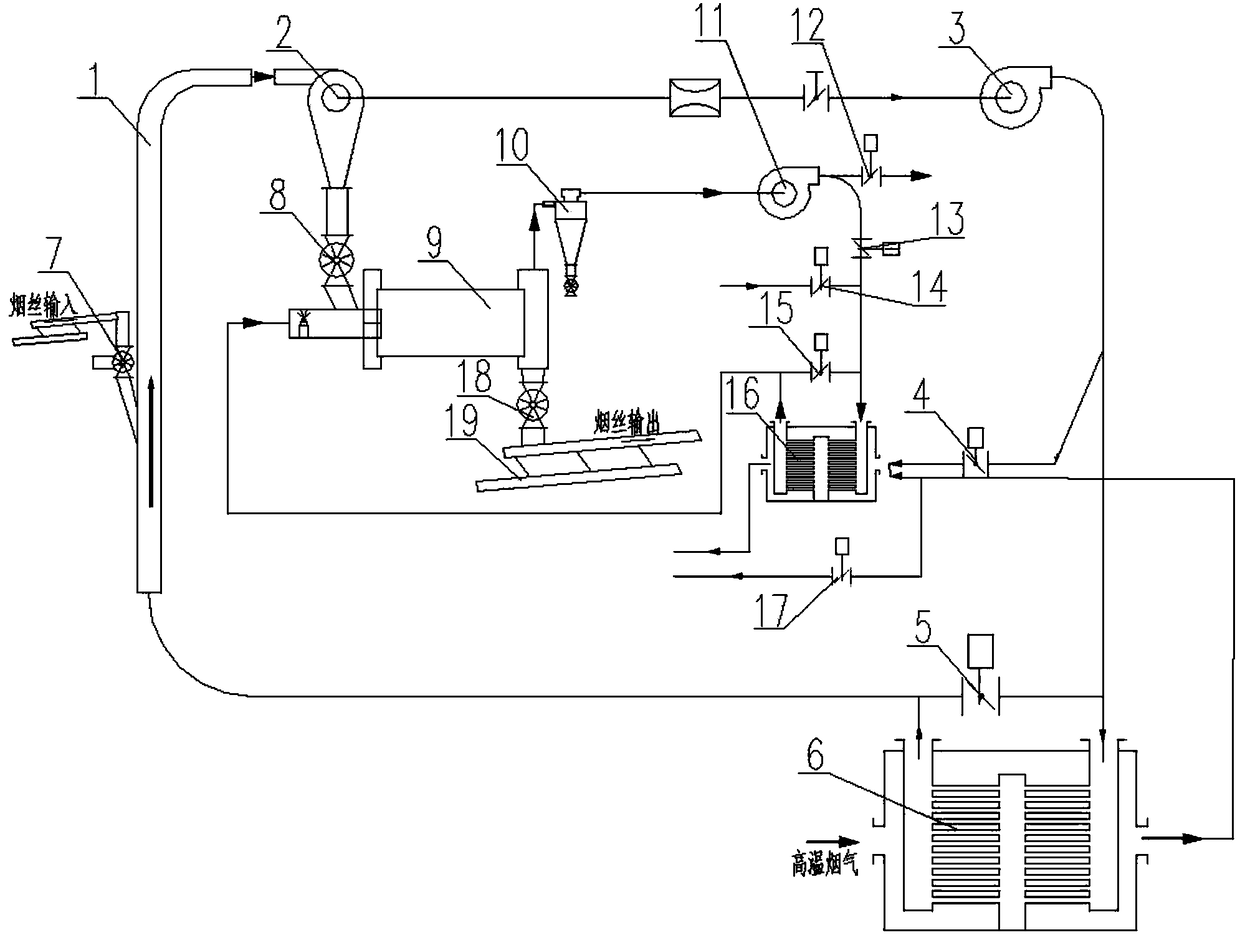

Combined tobacco material drying equipment

PendingCN108283326AHigh expansion rateStable and dryTobacco preparationEngineeringProcess requirements

The invention discloses combined tobacco material drying equipment. The equipment includes an airflow-type tobacco shred baking device and a roller-type tobacco shred baking device, and a dischargingend of the airflow-type tobacco shred baking device is communicated with a feeding end of the roller-type tobacco shred baking device to conduct drying treatment on tobacco materials in sequence. Through series combination of the airflow-type tobacco shred baking device and roller-type tobacco shred baking device, drying is conducted on the tobacco materials, and the tobacco materials can be effectively dried and meet a process requirement. The combined tobacco material drying equipment has the advantages of the airflow-type tobacco shred baking device and roller-type tobacco shred baking device, defects of a single drying mode are made up by the two tobacco shred baking devices, and therefore the dried materials are more flexible, stable and uniform. Moreover, by using recovered tail gasenergy of the airflow-type tobacco shred baking device for supplying heat to the roller-type tobacco shred baking device, the purpose of saving energy can be thus achieved.

Owner:QINHUANGDAO TOBACCO MACHINERY

Evaporative pattern casting process of high-chrome wear-resistant castings

InactiveCN107088644AMade preciselyIncrease usageFoundry mouldsMould handling/dressing devicesDry sandWire cutting

The invention discloses an evaporative pattern casting process of high-chrome wear-resistant castings. The evaporative pattern casting process is less in air pollution, high in casting quality and lower in cost. The evaporative pattern casting process of the high-chrome wear-resistant castings comprises the following steps that model making is carried out, a foam plastic plate is cut and glued to manufacture a foam plastic model, the foam plastic model is placed into a cavity of a standard mold to be subject to comparison, and the foam plastic model is machined and corrected through an electric heating wire cutting device; the model is combined into a cluster; the model cluster is baked, is placed into a drying chamber to be dried, and is taken out from the drying chamber to be cooled, air exchange in the drying chamber is achieved, and baking is repeatedly executed three times; coating applying is carried out, the surface of the model cluster obtained after baking is coated with a fireproof coating, then the model cluster is placed into a baking room to be dried and is taken out from the baking room to be cooled, air exchange in the baking room is carried, and coating applying is repeatedly carried out three times; box embedding modeling is carried out, a sand box opening is covered with asbestos cloth, the asbestos cloth is covered with a plastic film for sealing, and dry sand in a sand box is vacuumized; casting replacement is carried out; and shakeout piece taking is carried out.

Owner:湖南山瑞重工科技有限公司

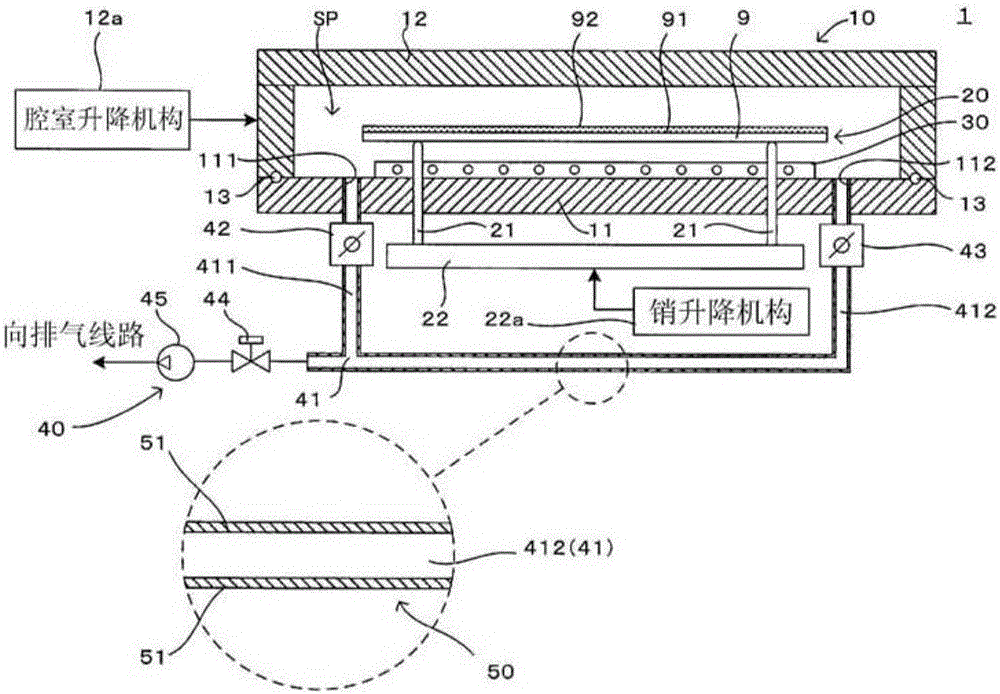

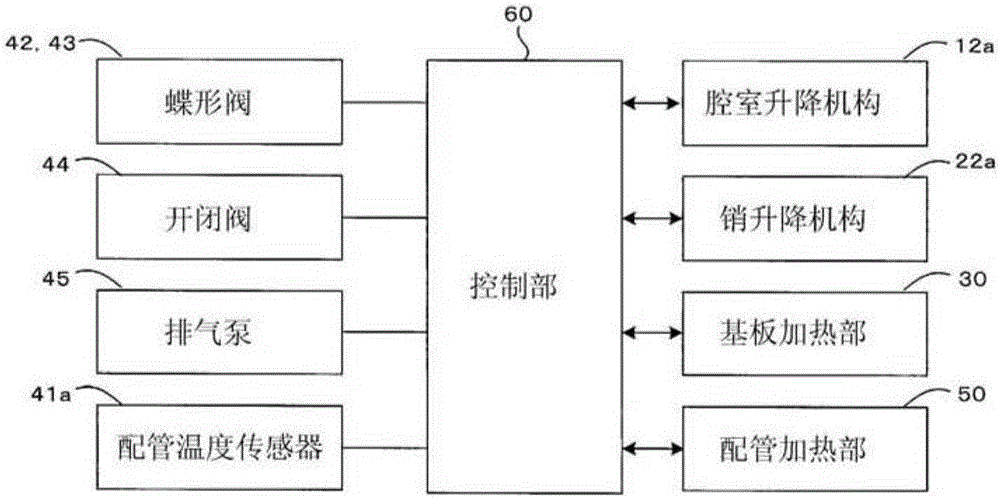

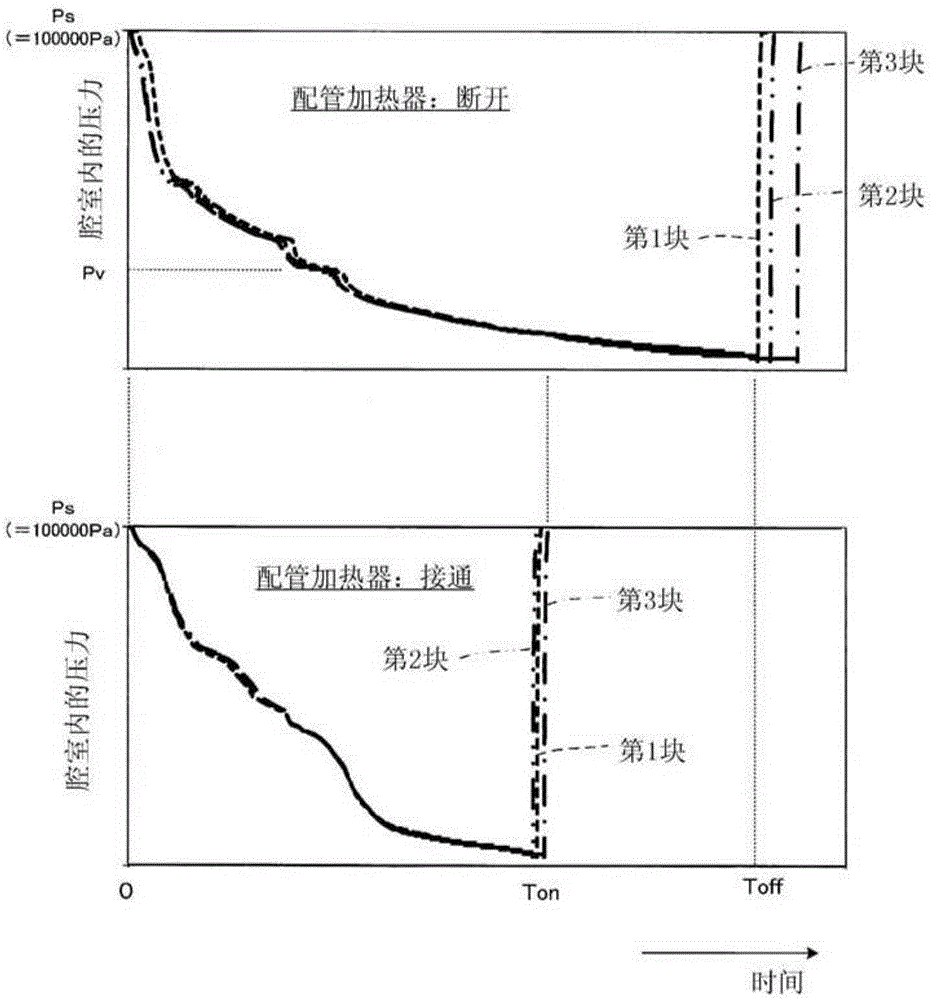

Reduced pressure drying device and reduced pressure drying method

The invention provides a reduced pressure drying device and reduced pressure drying method. The reduced pressure drying device receives a substrate in the inner space in a chamber, and exhausts ambient gas of the inner space through an exhausting pipe connected with the chamber to reduce the pressure of the inner space and heat the inner space. In this way, the solvent content contained in a coating film of the substrate can be gasified and the coating film is dried. The reduced pressure drying device comprises an auxiliary pipe heating portion which heats an auxiliary pipe. The reduced pressure drying device can stably reduce pressure and heat simultaneously.

Owner:DAINIPPON SCREEN MTG CO LTD

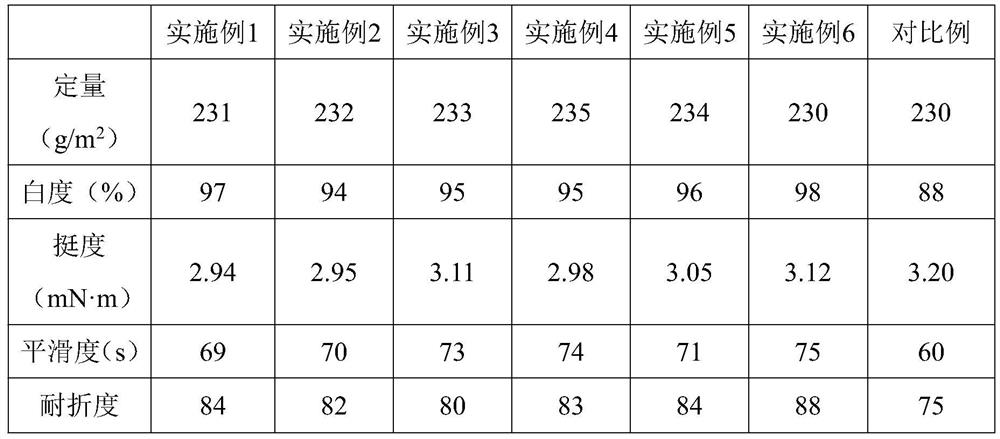

High-whiteness coated ivory board and preparation method thereof

PendingCN113668281AAvoid yellowingGood printability of paperCoatings with pigmentsSpecial paperPolymer scienceWhitening Agents

The invention relates to the field of papermaking, and discloses a high-whiteness coated ivory board and a preparation method thereof. The high-whiteness coated ivory board comprises raw paper and a coating layer covering the surface of the raw paper, wherein the raw paper comprises a surface paper layer, a core paper layer and a bottom paper layer, the coating layer comprises a pre-coating layer, a surface coating layer and a back coating layer, the paper pulp of the raw paper comprises 80-90 parts of hardwood pulp and 10-20 parts of softwood pulp, the paper pulp is formed by bleaching treatment through a biological enzyme method, the coating materials of the pre-coating layer, each of the surface coating layer and the back coating layer comprises a pigment, a coating adhesive and a coating additive, the pigment comprises 85-95 parts of ground calcium carbonate and 5-15 parts of kaolin, and the coating additive comprises a fluorescent whitening agent accounting for 0.05-0.10% of the total weight of the coating materials. The preparation method comprises the steps of paper pulp preparation, net loading, squeezing and water removal, preliminary drying, on-line coating in a machine, drying and subsequent calendaring, reeling, cutting and packaging. The invention provides a method for preparing the high-whiteness coated ivory board by using a biological enzyme method for bleaching and using a small amount of a whitening agent, and the whiteness of the prepared coated ivory board is 94% or above.

Owner:湖北骏马纸业有限公司

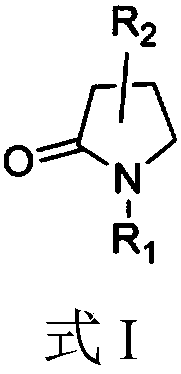

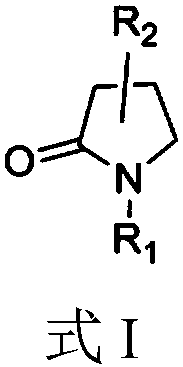

Inorganic nanometer material printing ink, preparation method and applications thereof

InactiveCN109929327AImprove stabilityGood dispersionInksSemiconductor devicesOrganic solventPrinting ink

The invention provides an inorganic nanometer material printing ink, wherein the solvent in the inorganic nanometer material printing ink is an organic solvent, the inorganic nanometer material printing ink comprises at least an inorganic nanometer material and at least a pyrrolidone-based organic solvent, the pyrrolidone-based organic solvent has a structure represented by a structure general formula I, and in the formula I, R1 and R2 are independently selected from C1-C20 aliphatic groups and C1-20 aromatic groups.

Owner:TCL CORPORATION

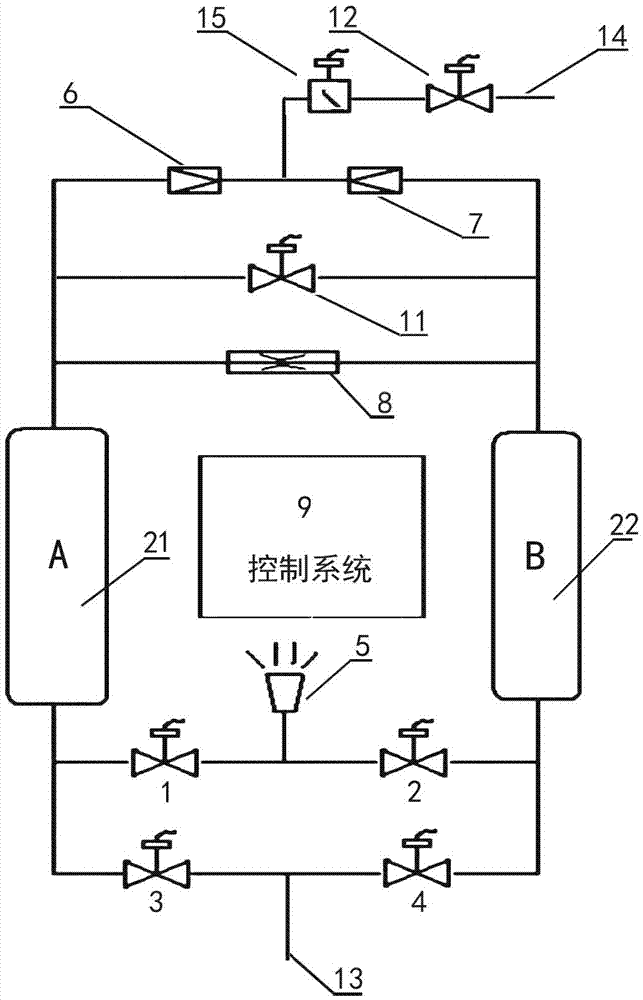

Compressed air dryer

ActiveCN107224843ASimple structureNo consumable partsGas treatmentDispersed particle separationAutomatic controlSorbent

The invention relates to a compressed air dryer in the field of air dehumidifying technological equipment. The compressed air dryer comprises an adsorption tank A and an adsorption tank B which are arranged in parallel and are filled with adsorbents; the lower parts of the adsorption tank A and the adsorption tank B are connected in parallel via two air inlet valves and two humidity discharging valves; an air inlet is formed between the two air inlet valves; a silencer is arranged between the two humidity discharging valves; the upper parts of the adsorption tank A and the adsorption tank B are connected via a throttle valve, a pilot valve and two check valves; the output ends of the two check valves are opposite to each other; a moisture detection instrument and an air outlet valve are connected between the check valves. The compressed air dryer realizes two functions of drying and dehydration regeneration, realizes water closed ring automatic control, and is simple and reliable in structure; a control system adopts a PLC (programmable logic controller) and realizes accurate control, the adsorbents are active aluminum oxide particles, the adsorption force is strong, the adsorbents are in a fluid state in the adsorption tank A and the adsorption tank B, water exchange and heat exchange are conducted, the exchange efficiency is doubled, and the compressed air dryer is worthy of wide popularization and application.

Owner:刘友葵

Printing ink using inorganic nanometer material and preparation method and application thereof

The invention provides a printing ink using an inorganic nanometer material. The printing ink using the inorganic nanometer material adopts an organic solvent, and comprises at least one type of inorganic nanometer material and at least one type of fluorine-containing ester organic solvent, wherein the structure of the fluorine-containing ester organic solvent is shown in a formula II, namely (Rb')n'-(Rfb)n-COO-(Rfa)m-(Ra')m'; in the formula II, Rfa and Rfb are independently selected from partially or totally fluorated alkyl and aryl; Ra' and Rb' are independently selected from H (hydrogen), aliphatic group with C1 to C30, aromatic group, F (fluorine), Cl (chloride), Br (bromine) and I (iodine); the value ranges of m, n, m', and n' meet the requirements that m and n are respectively 0 or 1, and m and n are not simultaneously 0; m' and n' are respectively 0 or 1.

Owner:TCL CORPORATION

Production technology of superfine, velvet and fluffy fiber

The invention discloses a production technology of a superfine, velvet and fluffy fiber. The production technology comprises the following steps: polyester melt preparation, pipeline transportation, processing using a booster pump, processing using a melt cooler, processing using a static mixer, processing using a melt distributing valve, processing using a spinning box, processing using meteringpump, processing using a spinning assembly, processing using a spinneret, ring blowing air duct cooling, oil nozzle oiling, processing using a channel, processing using a pre-network, processing usinga GR1GR2 guide plate, winding forming, and doffing and packaging. The invention has the advantages of effectiveness in prevention of low temperature of the surface of the spinneret, uniformity in filament bundling oiling, and stability in the yarn levelness and strength of the product.

Owner:TONGKUN GRP ZHEJIANG HENGTENG DIFFERENTIATION FIBER

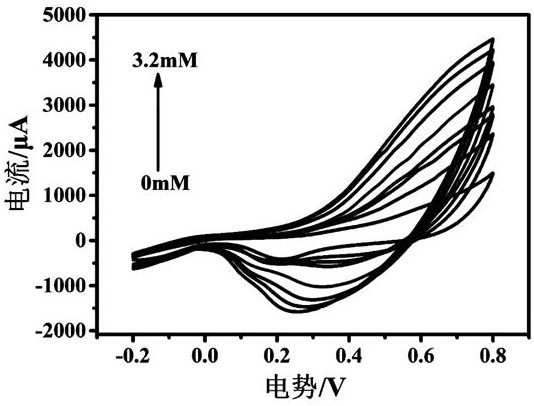

Preparation method of flexible biosensor electrode

PendingCN113933371AClosely arrangedSlightly scratchedMaterial electrochemical variablesGlucose detectionSurface modification

The invetion relates to a preparation method of a flexible biosensor electrode and relates to the technical field of electrochemical sensors, and the methid comprises the following steps: by taking a PDMS film as a substrate, carrying out surface modification on the substrate, and then preparing a patterned three-electrode by using a chemical gold deposition method; and constructing a flexible biosensor for glucose detection by fixing a Ni / Co-MOF nano material with electrocatalytic activity on a working electrode. Complex equipment is not needed, the price is low, and the constructed sensor can be applied to real-time monitoring of human body disease signals.

Owner:YANGZHOU UNIV

Rake vacuum drying main machine

ActiveCN102168911BSpeed up crushingLarge specific surface areaDrying machines with non-progressive movementsDrying solid materialsLithium iron phosphatePulp and paper industry

The invention relates to a rake vacuum drying main machine, which comprises a tank body, wherein a main shaft of the main machine is solid, and a plurality of rake tooth components are arranged on the main shaft; each rake tooth component consists of a sleeve shaft and four solid rake teeth which are distributed and fixed on the sleeve shaft uniformly and is connected on the main shaft by a sleeve shaft key; the orientations of the rake teeth of all rake tooth components are the same, so that four channels are formed in the tank body; and a knocking rod is arranged in each channel or the spaced channel. In the rake vacuum drying main machine, materials are knocked continuously inside the tank body of the drying main machine by utilizing the knocking rods to accelerate the crushing of the materials, so that the materials have the large specific surface area, the drying process is accelerated, finished products are uniform in fineness and low in moisture; and the rake vacuum drying mainmachine is suitable for drying lithium iron phosphate materials, and improves the quality and drying efficiency of the products.

Owner:JIANGSU XIANFENG DRYING ENG

MVR band drying system and drying method thereof

PendingCN109282615AReduce consumptionImprove heat utilizationDrying gas arrangementsDrying machines with progressive movementsProcess engineeringHeat transfer process

The invention discloses an MVR band drying system and a drying method thereof. The system comprises a band dryer and further comprises a feeding and discharging unit, an MVR circulating unit, a steamrecycling unit and a waste heat recycling circulating unit which are connected with the band dryer. The MVR band drying system and the drying method thereof can improve the heat transfer process of the drying process so as to enhance stability and safety of the drying process.

Owner:常州博睿杰能环境技术有限公司

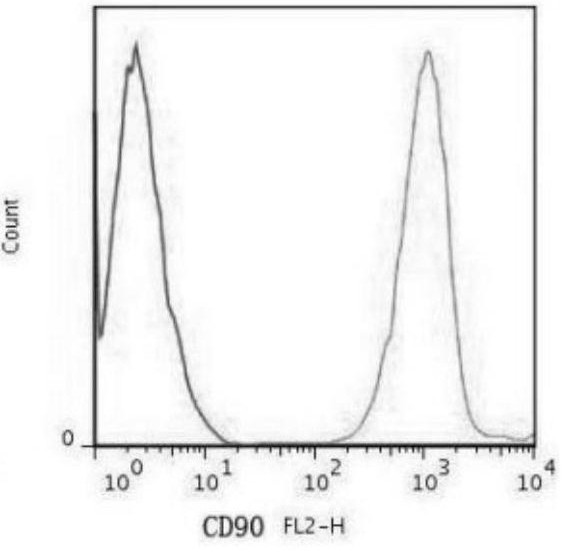

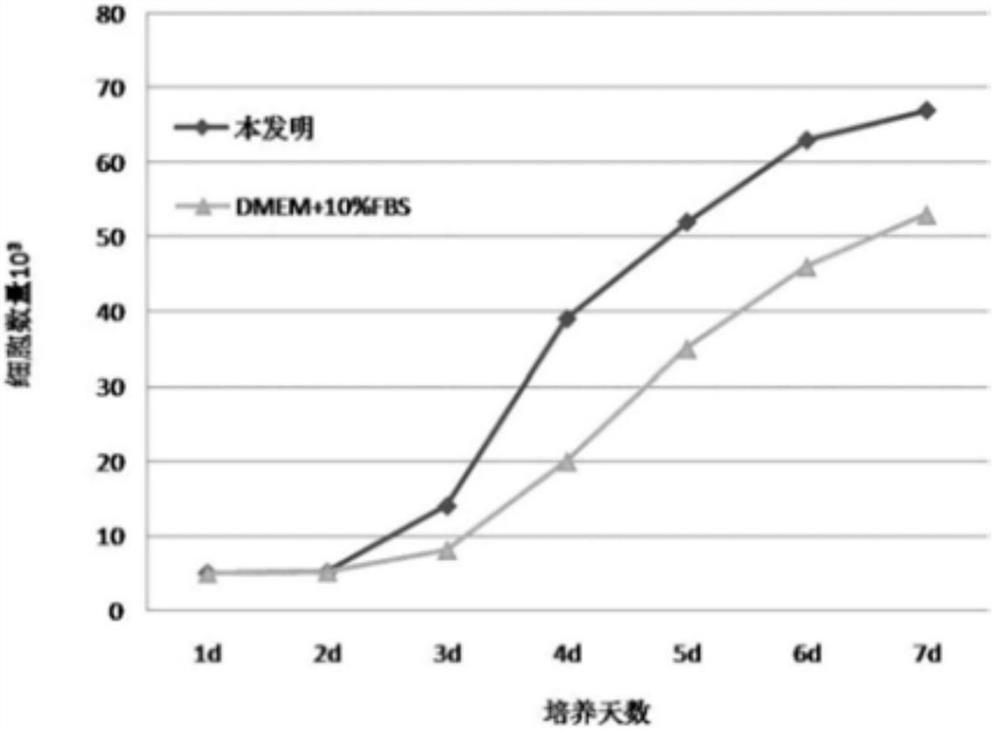

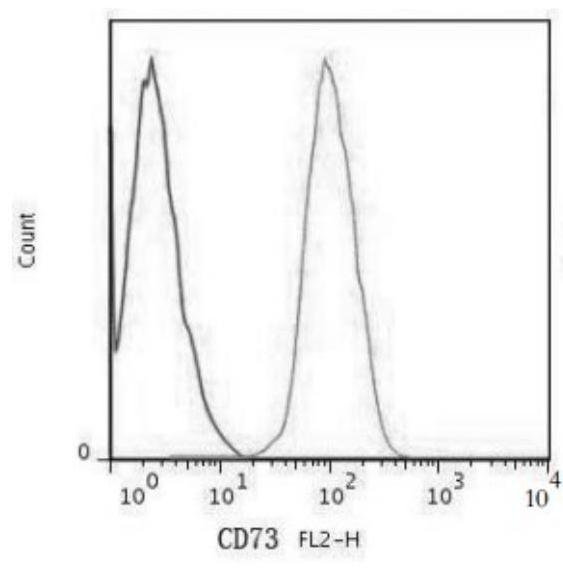

Mesenchymal stem cell subculture method

PendingCN112626011APromote division and proliferationStable and dryCulture processSkeletal/connective tissue cellsDigestionTrypsin

The invention discloses a mesenchymal stem cell subculture method. The method is characterized by comprising the following steps of 1) preparing a serum-free subculture medium which comprises the following components of an alpha-MEM medium, a platelet-derived factor, a fibroblast growth factor and ascorbic acid, wherein the concentration of the platelet-derived factor is 10-15 ng / mL, and the concentration of the fibroblast growth factor is 10-15 ng / mL; and 2) adding primary mesenchymal stem cells into a T-75 porous culture bottle, adding the serum-free subculture medium, performing culture in a 5% CO2 incubator at 37 DEG C, performing digesting by using a trypsin-EDTA solution when the cell fusion degree reaches 80%-90%, and carrying out subculture according to a ratio of 1:(4-5) after the digestion is finished. According to the culture method, the human umbilical cord mesenchymal stem cells with high purity, strong differentiation capacity, stable stemness and strong multiplication capacity can be obtained in a short time.

Owner:广东佰鸿干细胞再生医学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com