Process gas temperature control method for superheated steam drier

A temperature control method and technology for process gas, which are applied in the field of process gas temperature control of an air-flow filament drying machine and tobacco silk production process control, and can solve unresolved temperature fluctuations, inability to correct bypass damper setting values in advance, and temperature adjustment. Lag and other problems, to achieve the effect of stable tobacco drying process, easy design and implementation, and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

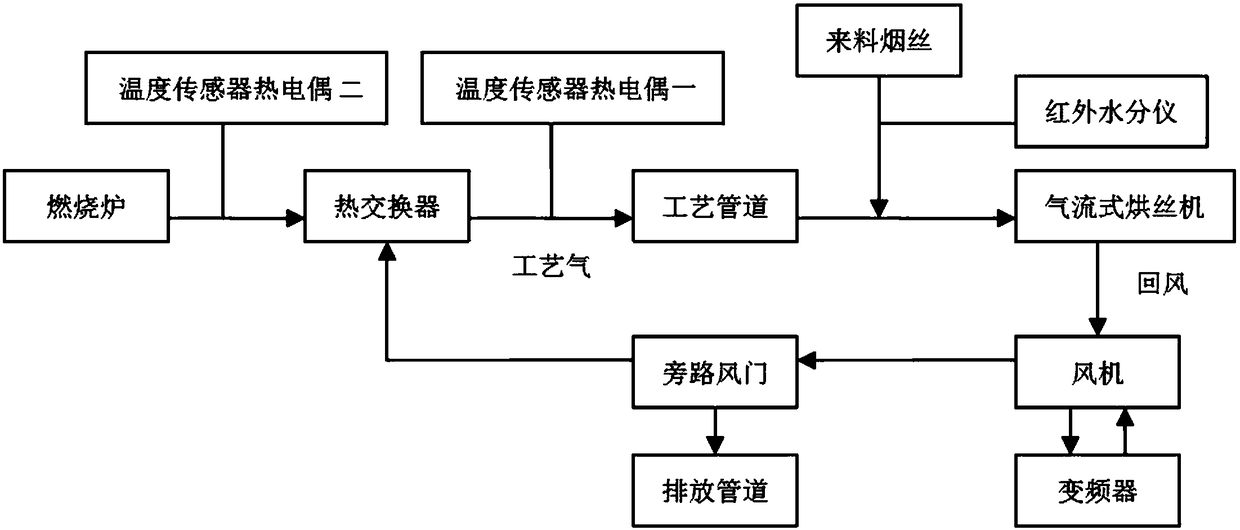

[0025] The equipment selected in this example is the airflow drying machine HXD produced by Dickinson Legge Company in the United Kingdom. Moisture is 13.2%.

[0026] The concrete steps of embodiment are as follows:

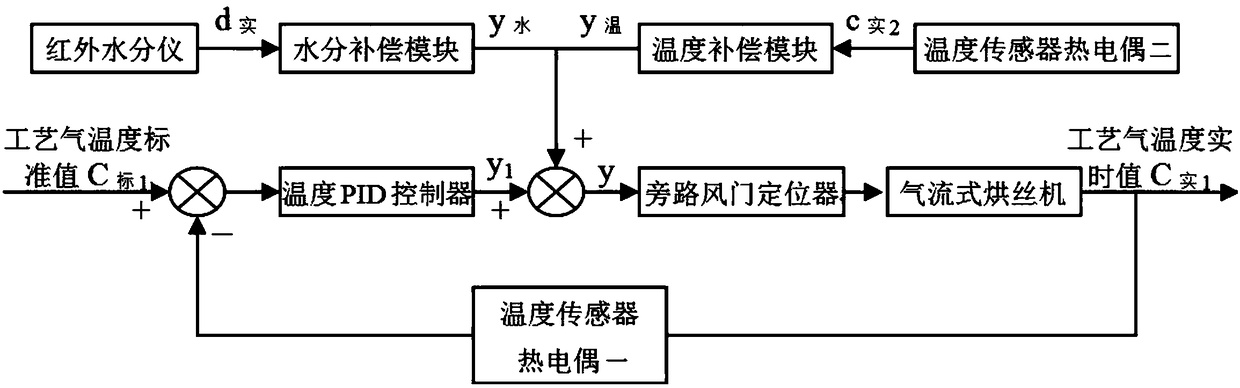

[0027] A: Set basic parameters: set the standard value of incoming tobacco moisture d 标 is 22.5%, the standard value of process gas temperature c 标1 is 250°C, the standard value of the furnace temperature c 标2 is 580°C;

[0028] B: Collect real-time data: detect the real-time value of the moisture content of the incoming cut tobacco through the infrared moisture meter d 实 , the real-time value c of the process gas temperature is detected by the temperature sensor thermocouple 实1 , the real-time value c of the combustion furnace temperature is detected by the temperature sensor thermocouple 2 实2 ;

[0029] C: The real-time value c of the process gas temperature 实1 with standard value c 标1 (250°C) for real-time comparison, and the temperature PID controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com