Laser heating device for atomic spin magnetic field test and heating method

A technology of laser heating and atomic spin, which is applied in the preparation of test samples, etc., can solve the problems that are not suitable for the use of small instruments, increase the overall complexity of the system, and affect the accuracy of the test, so as to avoid its own system errors and improve The effect of test accuracy and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

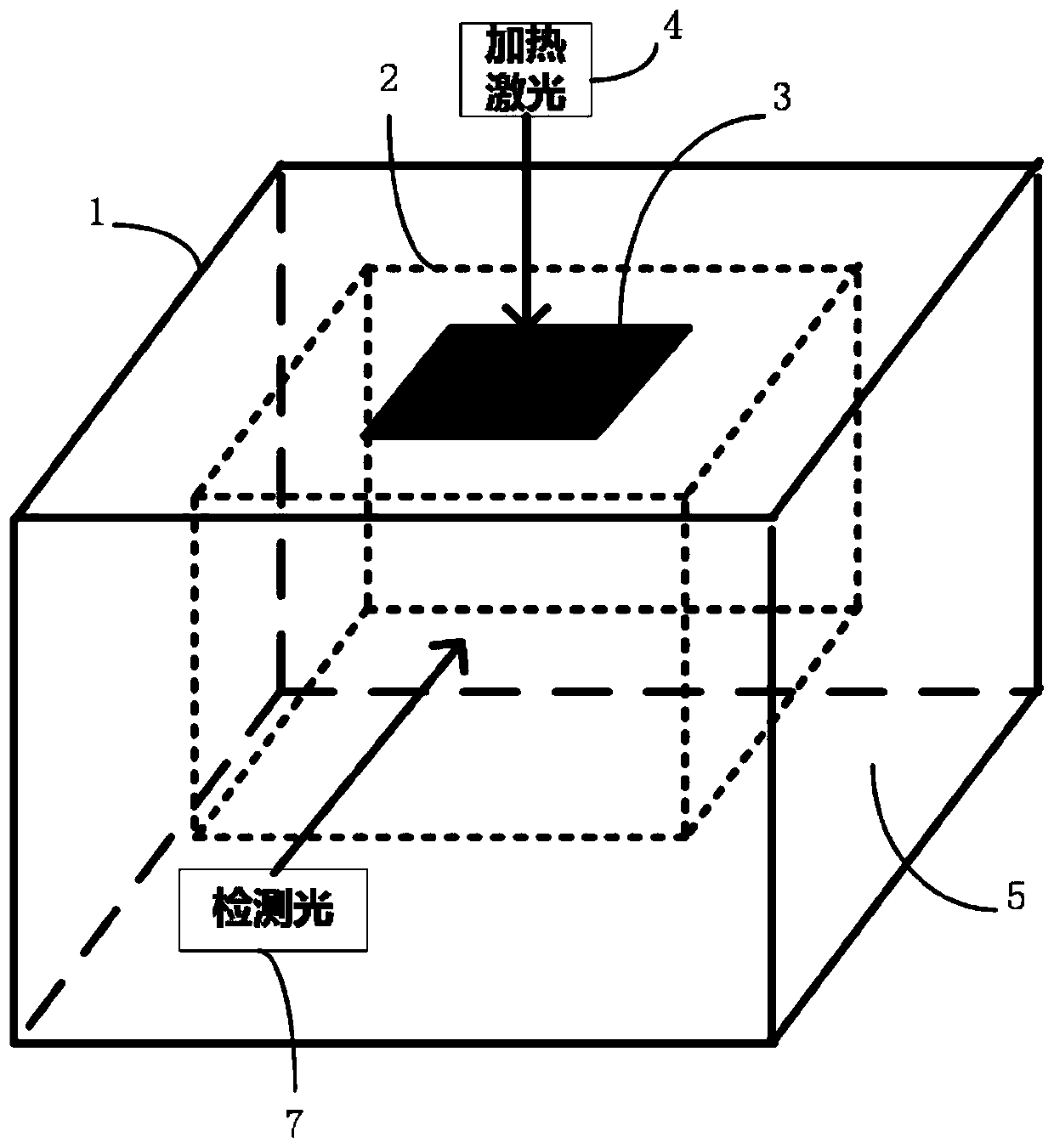

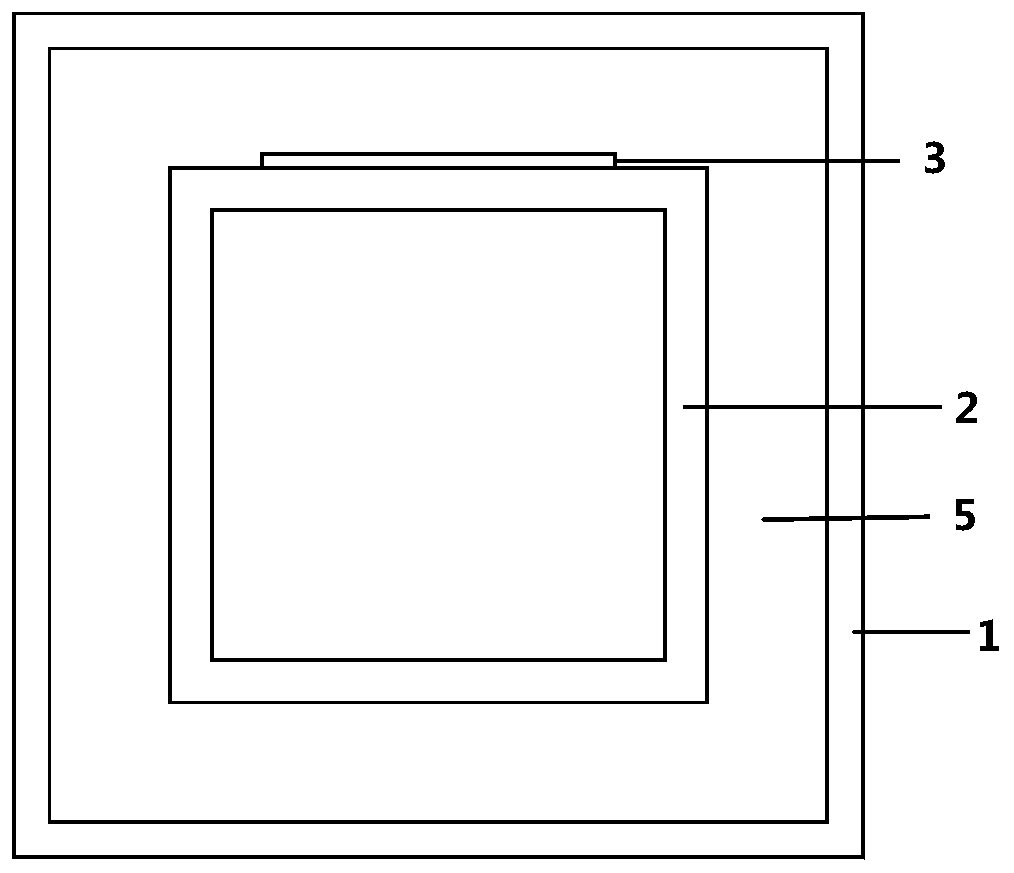

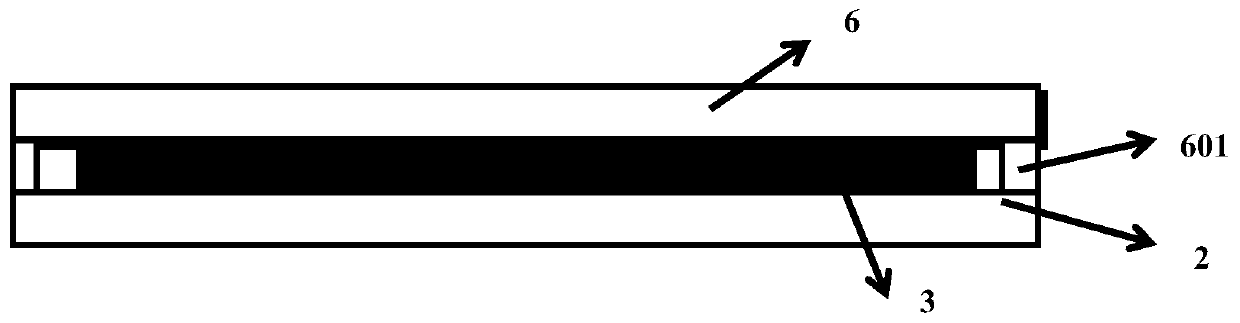

[0034] Such as figure 1 with figure 2 As shown, the laser heating device for atomic spin magnetic field testing in this embodiment includes an outer chamber 1, an inner chamber 2, a heat absorbing sheet 3 and a heating laser 4; the inner chamber 2 is used to inject the gas to be tested ( Such as alkali metal atoms rubidium, cesium, etc.); the inner chamber 2 is placed inside the outer chamber 1, a vacuum layer 5 is formed between the outer chamber 1 and the inner chamber 2, and the heat-absorbing sheet 3 is attached and installed in the inner chamber On the outer wall of the inner chamber 2, the heating laser 4 is located outside the outer chamber 1, and is used to irradiate the heat absorbing sheet 3 to convert light energy into heat energy, and heat the gas to be measured inside through the wall of the inner chamber 2. When testing, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com