Replacement processing structure and method for water burst channel of underground cavern

A technology for underground caverns and water gushing, which is applied in the field of underground engineering technology and geology to achieve the effect of low investment, short construction period, and ensuring drying and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

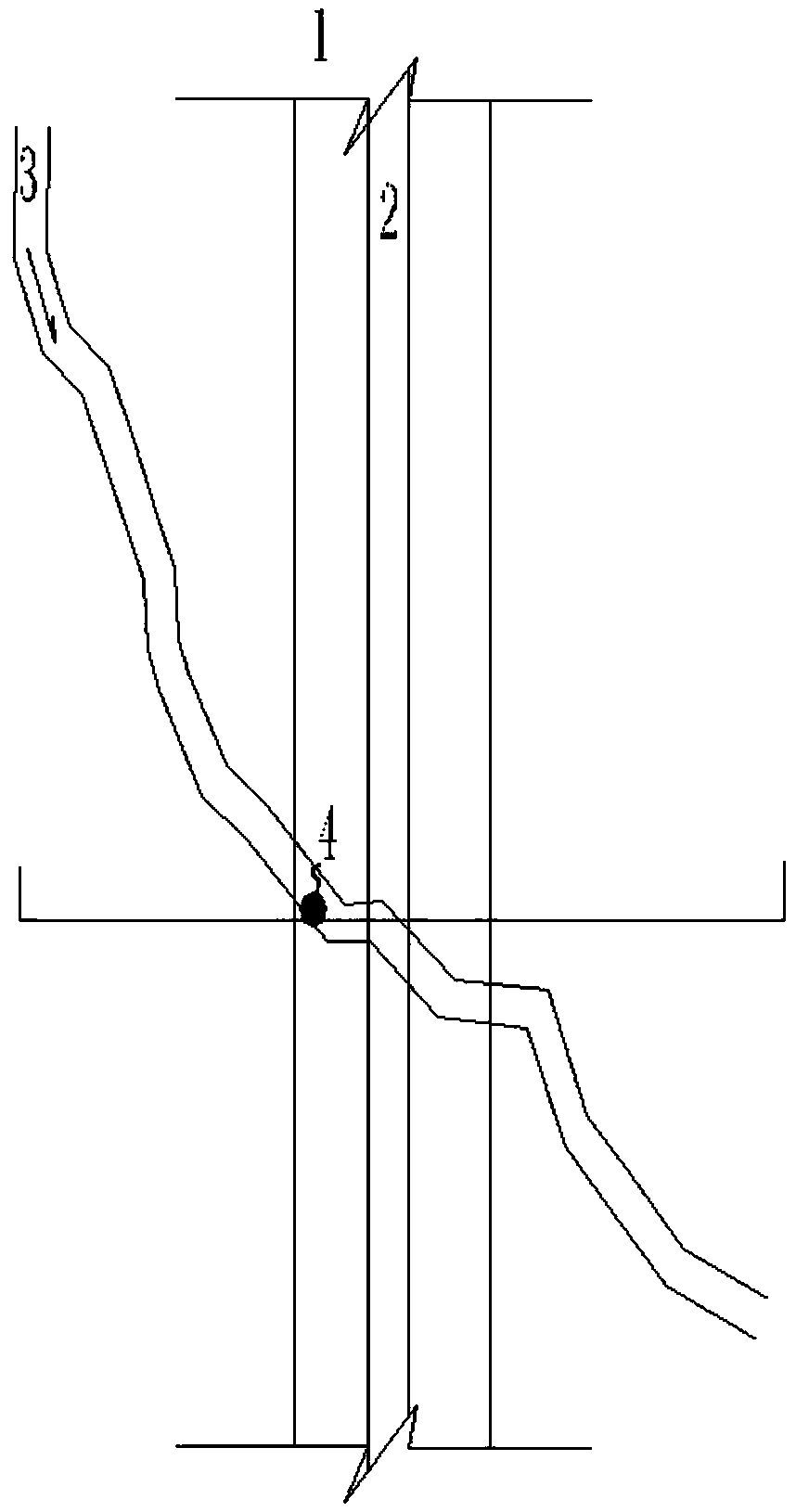

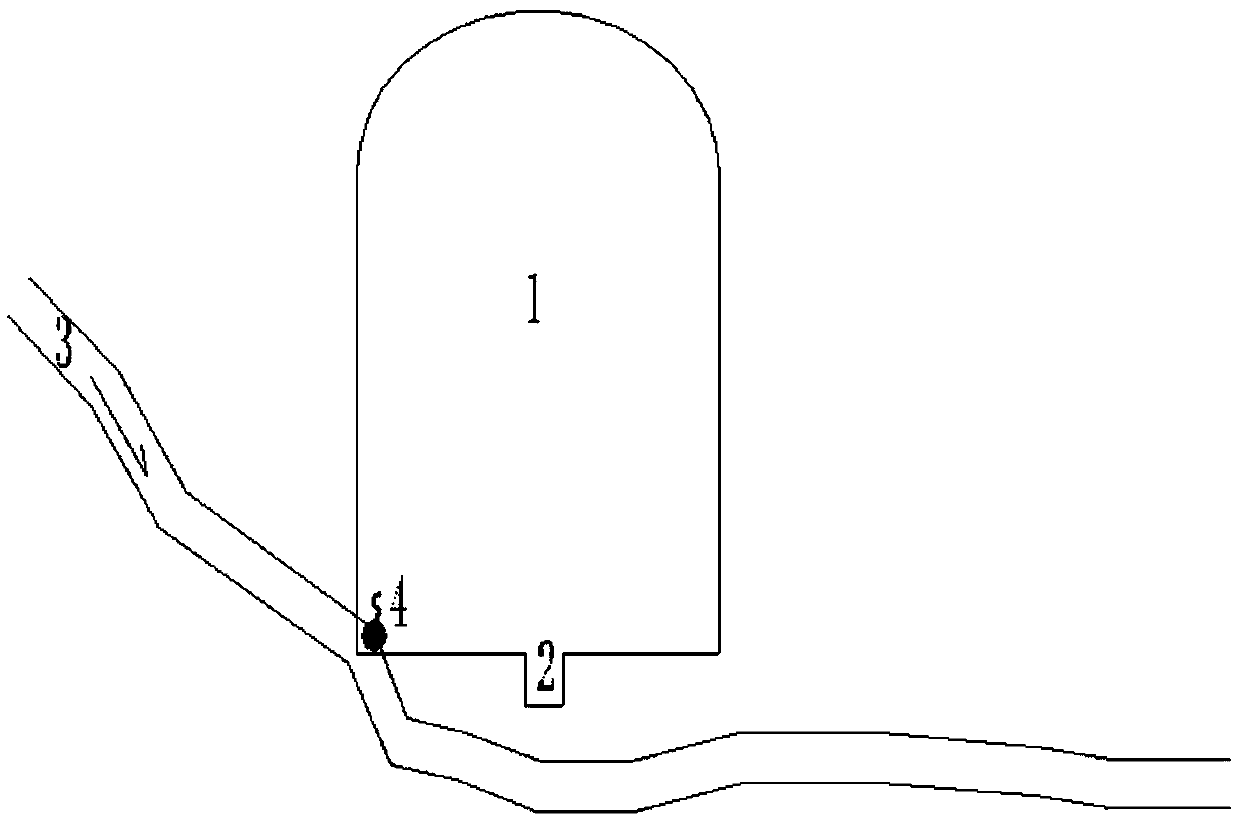

[0032] look first figure 1 and figure 2 , figure 1 and figure 2 It shows the state of water gushing in the underground cavern, where the concentrated water gushing 4 occurs at the position where the karst pipeline 3 passes through the underground cavern space 1, and the underground cavern space 1 is equipped with a drainage ditch 2, but the water flowing out of the concentrated gushing water 4 cannot be directly discharged into the drainage ditch 2.

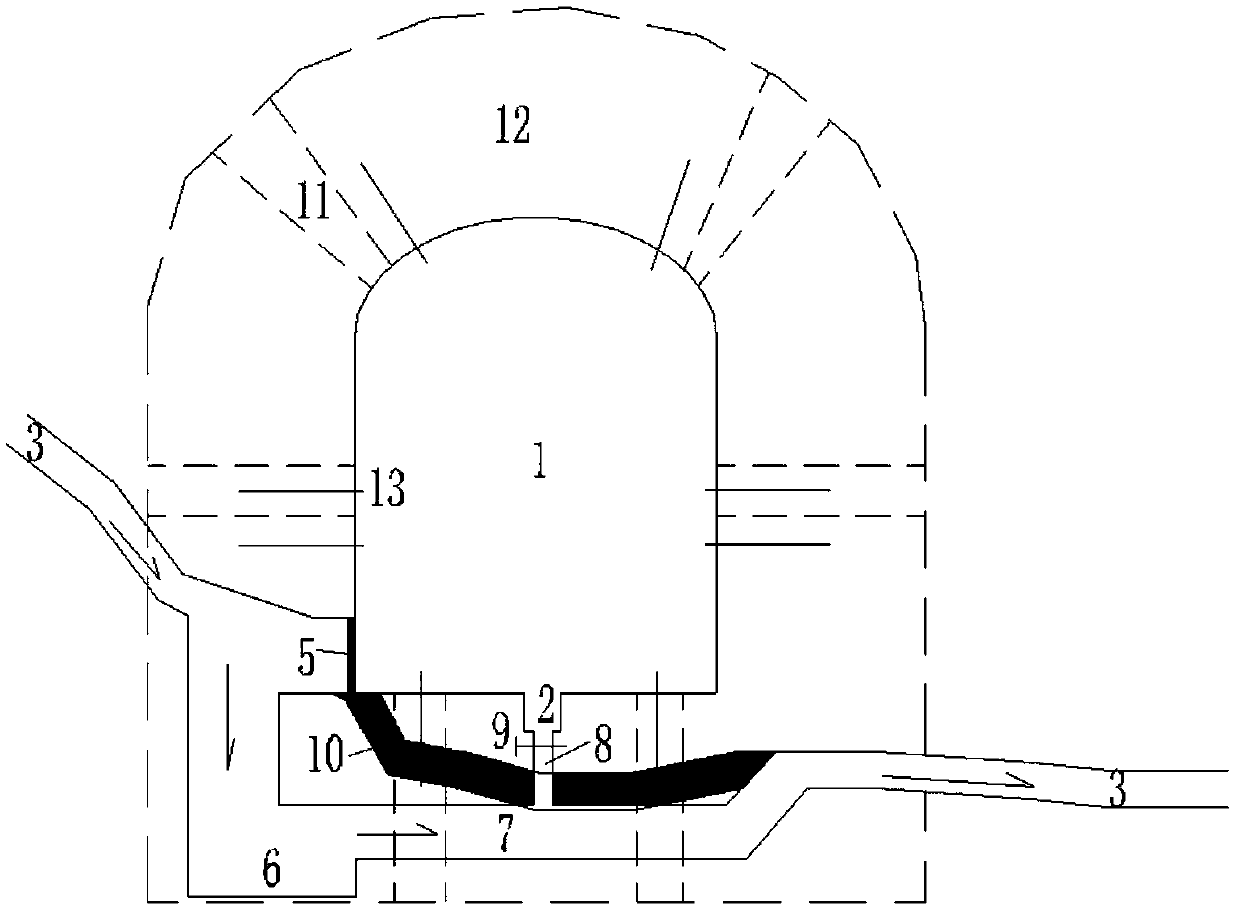

[0033] Look image 3 , image 3 It is the structure processed by the technical scheme of the present invention. It can be seen that the processing structure includes a grit chamber 6 formed by expanding and digging in the rock mass in the direction of water flow of the karst pipeline 3, and the grit chamber 6 is located at figure 2 Below the concentrated water gushing 4, there is an artificial culvert 7 behind the grit chamber 6, so that the artificial culvert 7 at the bottom of the underground cavern space 1 replaces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com