Floating ball type one-way drainage valve on slope or retaining wall

A technology of retaining wall and floating ball, applied in the direction of control valves, valve devices, artificial waterways, etc., can solve the problems of inflexible use, drainage failure, water loss, etc., achieve low cost, reduce external water pressure, prevent The effect of strong permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

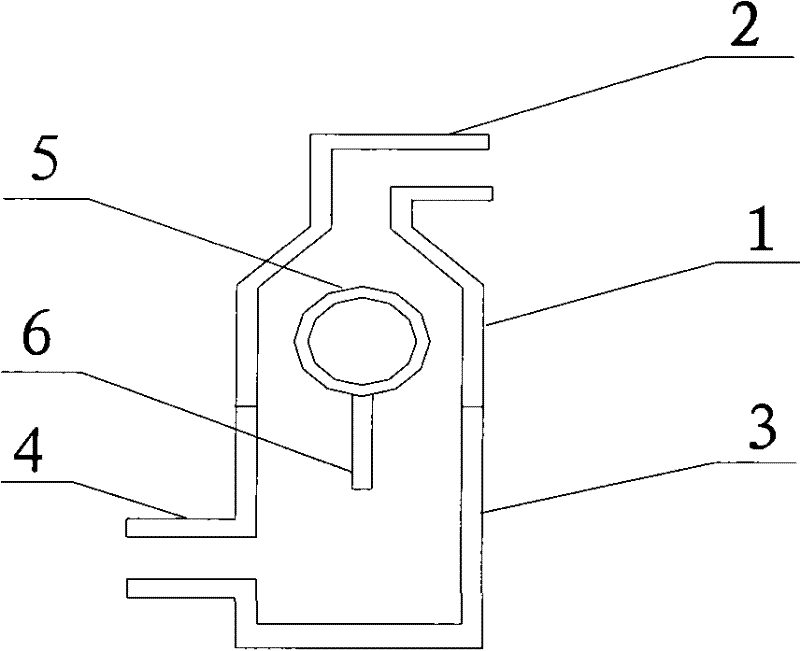

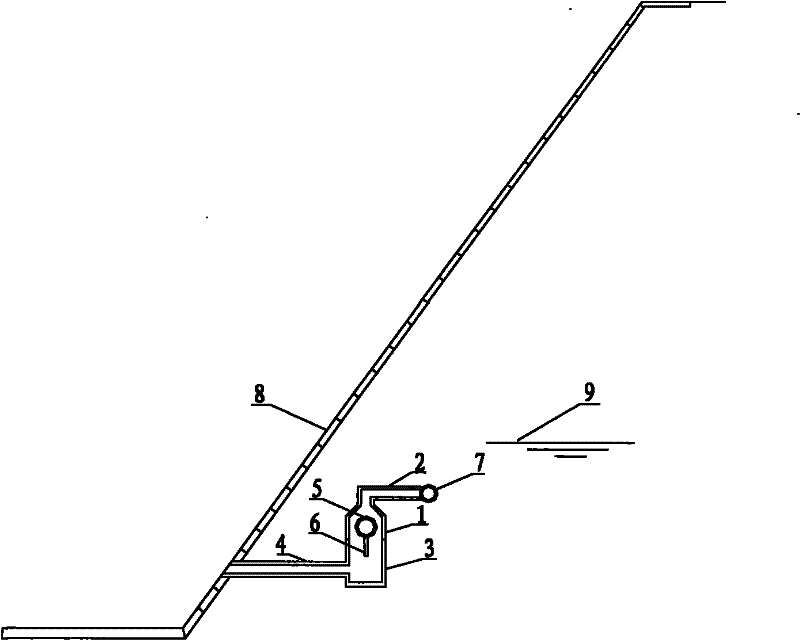

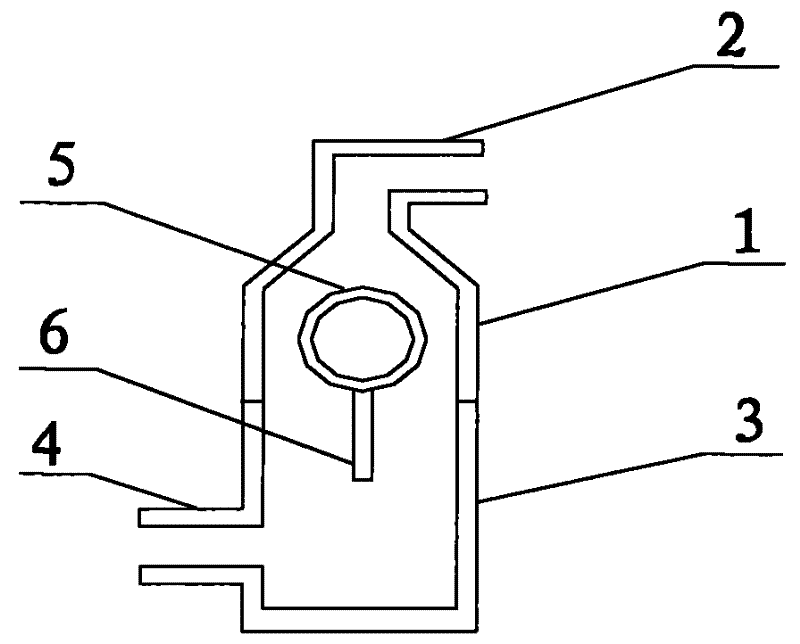

[0011] Such as figure 1 As shown, the present invention is a floating ball type one-way drain valve on a slope and retaining wall, which includes an upper valve body 1 and an outlet pipe 2 connected to the valve body 1, a lower valve body 3 and a valve body 3 The connected outlet pipe 4, the floating ball 5 and the straight rod 6 connected with the floating ball 5, the above structures are all made of hard polyvinyl chloride material. The upper valve body 1 is funnel-shaped, the neck of the upper valve body 1 is a smooth rotating surface, the lower valve body 3 is barrel-shaped, and the floating ball is a hollow ball. The upper valve body 1 and the lower valve body 3 have the same diameter, and the two are screwed together to form a valve body. The floating ball 5 can move up and down in the valve body under the action of buoyancy, and drives the straight rod 6 to disturb the water at the bottom of the valve body to prevent mud and sand from accumulating. The diameters of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com