Pressurized water conveying tunnel gravity self-locking one-way water drainage reducing valve

A technology for water conveyance tunnels, drainage and pressure reduction, applied in the directions of hydroelectric power generation, hydroelectric power station, control valve, etc., can solve the problems of reducing the water pressure outside the lining, affecting the performance of engineering benefits, and increasing the leakage loss of water in the water conveyance tunnel. , to reduce the external water pressure and reduce the stress on the lining structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

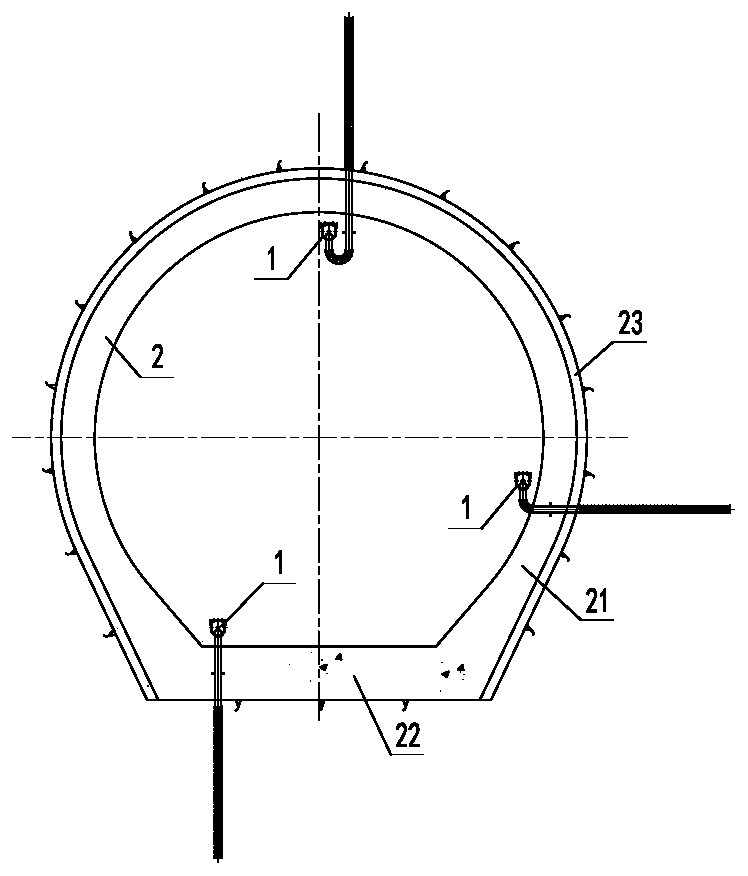

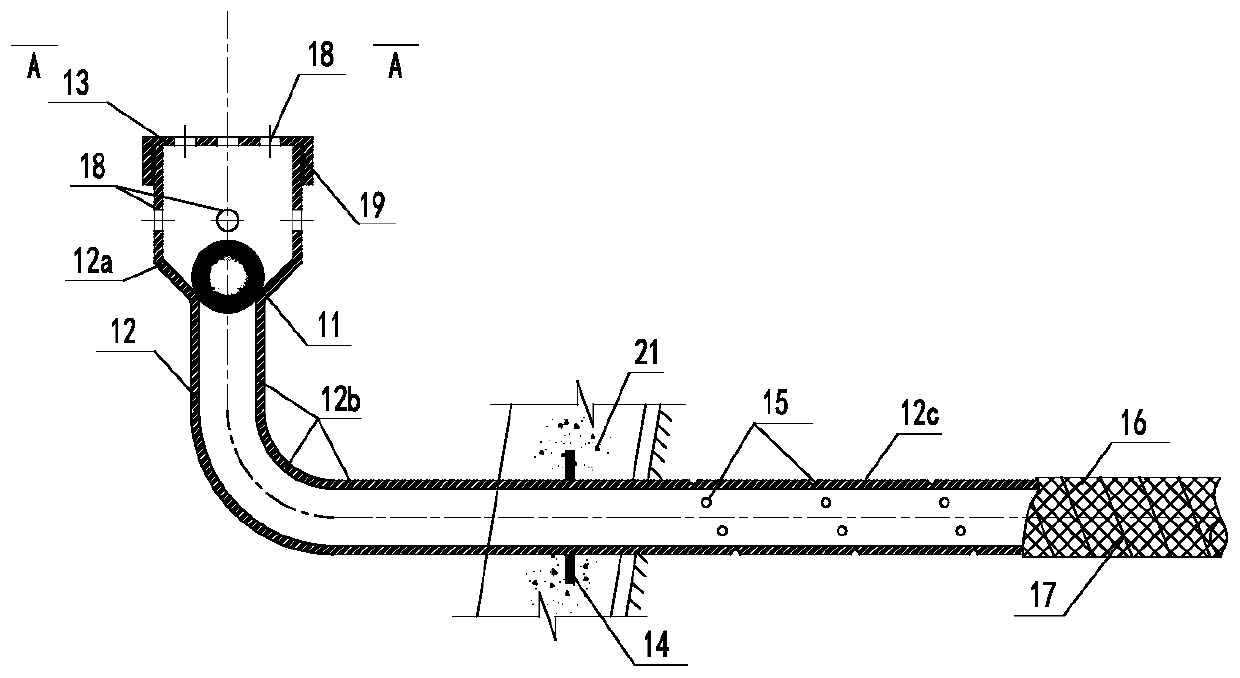

[0022] Such as Figure 1 to Figure 3 As shown, a gravity self-locking one-way drainage pressure reducing valve 1 of a pressurized water delivery tunnel according to the present invention is generally installed below the waist line of the side wall lining 21 of the pressurized water delivery tunnel 2 or on the floor lining 22. Drain relief hole arrangement, is made up of steel ball 11, sleeve pipe 12, valve cover 13.

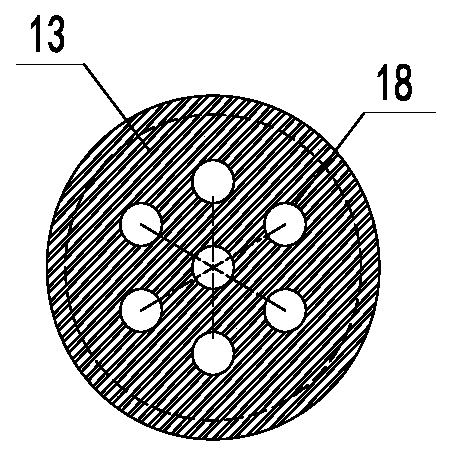

[0023] The sleeve 12 includes a container section 12a, a conduit section 12b and a flower tube section 12c. The container section 12a is located inside the pressurized water delivery tunnel 2, and a steel pipe with permeable holes 18 is provided for the pipe wall. The inner diameter of the steel pipe is larger than the diameter of the steel ball 11. Screw thread 19 is connected to valve cover 13; conduit section 12b is an impermeable stainless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com