Preparation method of flexible biosensor electrode

A biosensor, electrode technology, applied in the direction of instruments, scientific instruments, material electrochemical variables, etc., can solve the problems of physiological pain and psychological pressure of patients, and achieve the effect of low price, simple process and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of chemical gold plating solution:

[0027] Mix the potassium bicarbonate aqueous solution and the glucose solution uniformly at a volume ratio of 1:1:2, and finally add an aqueous chloroauric acid solution to form an electroless gold plating solution.

[0028] The potassium bicarbonate aqueous solution concentration used for mixing above is 200g / L, the glucose solution concentration is 0.1M, and the chloroauric acid aqueous solution concentration is 1 wt.%.

[0029] 2. Preparation of dopamine hydrochloride solution:

[0030] Tris-HCl buffer solution with a concentration of 10 mM and a pH of 8.0 was used to prepare a dopamine hydrochloride solution with a concentration of 1 mg / mL.

[0031] 3. Preparation of polydimethylsiloxane:

[0032] The polydimethylsiloxane prepolymer and curing agent (both purchased from Dow Corning, USA) were mixed at a mass ratio of 10:1, and a crosslinking reaction occurred to form polydimethylsiloxane.

[0033] 4. Preparation...

Embodiment 2

[0049] Referring to the preparation method of Example 1, the difference is that in the preparation of the PDMS film, the mixture of the polydimethylsiloxane prepolymer and the curing agent is degassed.

[0050] The specific operation is as follows: when the polydimethylsiloxane prepolymer and the curing agent are mixed until many dense small bubbles appear, the mixture is placed in a vacuum oven for degassing treatment. Then the degassed mixture was evenly spin-coated onto a glass slide by a spin coater, and finally cured in an oven at 60° C. for 2 hours. No small air bubbles are generated in the fully cured PDMS film prepared by the method, which can avoid the influence on the deposition of subsequent gold nanoparticles.

Embodiment 3

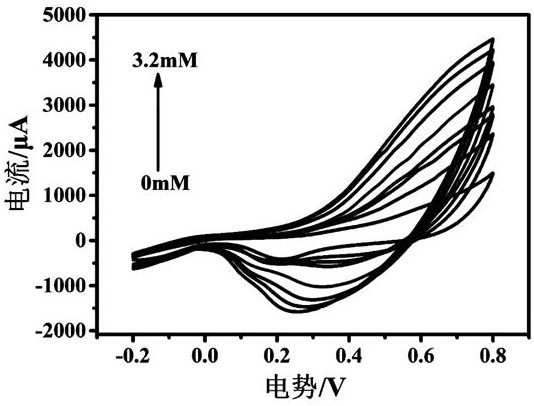

[0052] Referring to the preparation method of Example 1, the difference is that in the preparation of the working electrode, the concentration of Ni / Co-MOF in the Ni / Co-MOF dispersion is adjusted.

[0053] The details are as follows: 1 mg, 2 mg, 3 mg, 4 mg, and 5 mg of Ni / Co-MOF powder were dissolved in 100 μL of 1% Nafion ethanol solution, and ultrasonicated for 5 minutes at room temperature until different Ni / Co-MOFs were formed. concentrated dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com