Reduced pressure drying device and reduced pressure drying method

A decompression drying device and drying technology, which can be used in devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., and can solve problems such as time extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

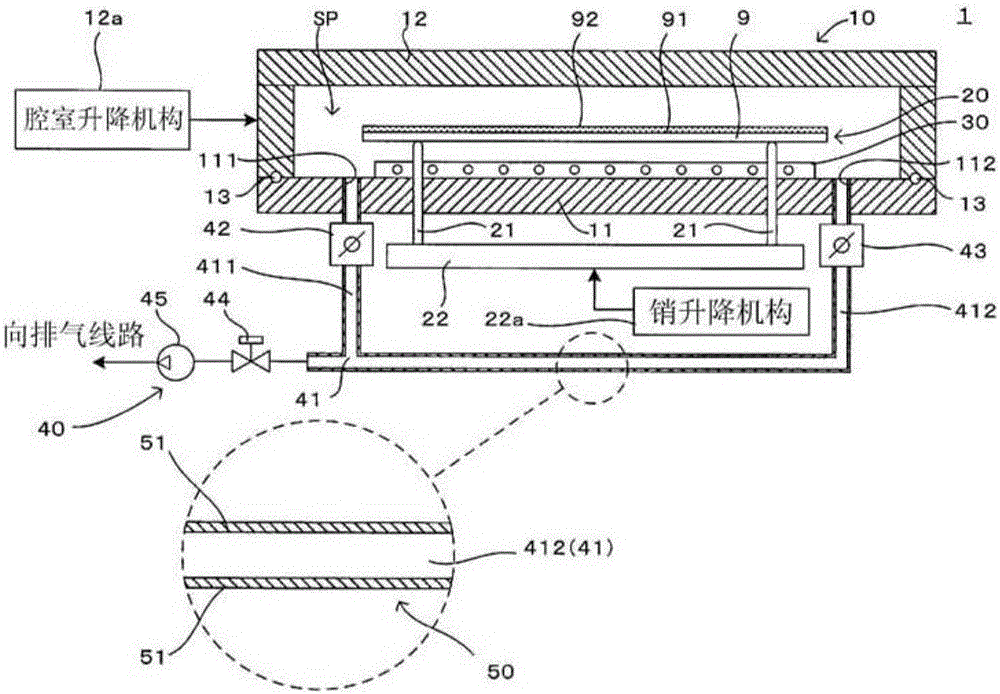

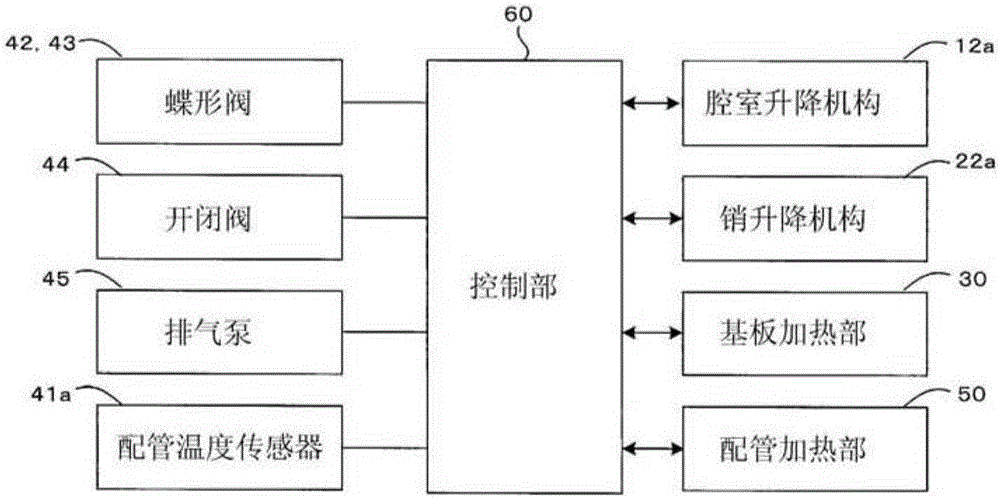

[0048] figure 1 It is a longitudinal sectional view showing the structure of one embodiment of the reduced-pressure drying apparatus of the present invention. and, figure 2 yes means figure 1 A block diagram of the composition of the vacuum drying apparatus shown. The reduced-pressure drying device 1 is a device for drying the coating film 92 by vaporizing the solvent component contained in the coating film 92 formed by coating the coating liquid on the upper surface 91 of the substrate 9 . For example, when forming a polyimide film on the upper surface 91 of the substrate 9, an organic solvent, such as N-methyl-2-pyrrolidone (N-Methyl-2-Pyrrolidone, NMB) will be utilized to make the precursor of polyimide (Precursor), that is, a polyamic acid solution obtained by dissolving polyamic acid, is used as a coating liquid. The coating liquid is applied to form about 10 times the desired thickness (for example, when forming a polyimide film of about 5 [μm] to 10 [μm], about 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com