MVR band drying system and drying method thereof

A technology of belt drying and belt dryer, applied in the MVR belt drying system and its drying field, to achieve the effects of low drying temperature, short heating time and improved heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

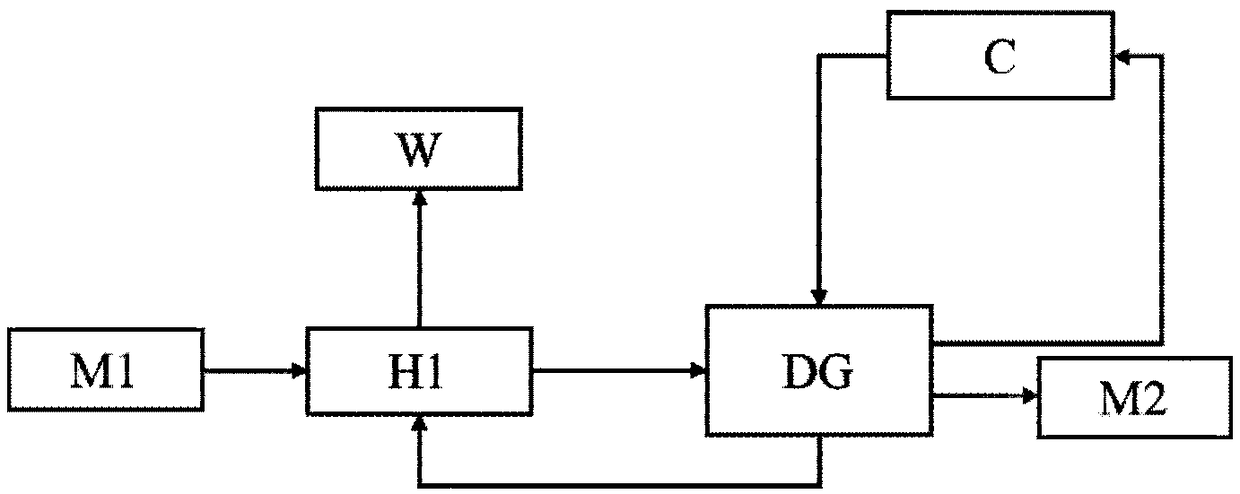

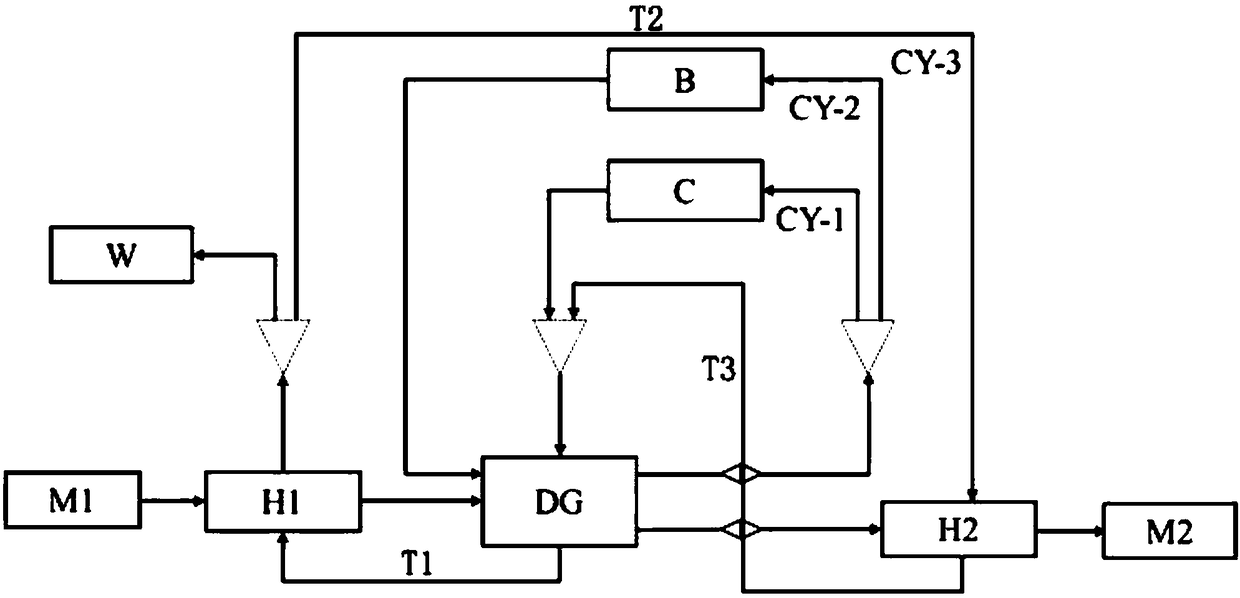

[0035] see figure 2 As shown, this embodiment provides an MVR belt drying system, which is especially suitable for drying paste materials, but is not limited to the drying of paste materials. Specifically, the MVR belt drying system of this embodiment includes: a belt dryer DG and a material inlet and outlet unit connected to the belt dryer DG, an MVR circulation unit CY-1, a steam recirculation unit CY-2 and a waste heat recovery cycle Unit CY-3.

[0036] The feeding and discharging unit includes a feeding part that is respectively connected with the belt dryer DG and is suitable for pre-processing the wet material M1 before entering the belt dryer DG, and is suitable for processing the dry material M1 after being processed by the belt dryer DG. The output part of M2 for post-processing. Wherein, the feed part includes a preheater H1 suitable for preheating the wet material M1; the discharge part includes a heat exchange device suitable for the dry material M2 processed by...

Embodiment 2

[0045] On the basis of the MVR belt drying system in Example 1, this embodiment provides a MVR belt drying method, using the MVR belt drying system in Example 1, specifically including:

[0046] Step S1: the belt dryer DG dries the wet material M1;

[0047] Step S2: MVR circulation unit CY-1 recompresses part of the secondary steam generated by the belt dryer DG to form compressed steam and then enters the heating chamber of the belt dryer DG for recycling;

[0048] Step S3: The steam recirculation unit CY-2 recirculates part of the secondary steam generated by the belt dryer DG and then enters the drying chamber of the belt dryer DG for recycling;

[0049] Step S4: The waste heat recovery cycle unit CY-3 performs preheat recovery on the high-temperature liquid condensed water condensed and phase-transformed in the heating chamber of the belt dryer DG and recovers the cooling heat of the dry material M2 dried by the belt dryer DG for reuse.

[0050] It should be noted that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com