High-whiteness coated ivory board and preparation method thereof

A technology of white cloth cardboard and high whiteness, applied in the field of high whiteness coated white cardboard and its preparation, can solve the problems of difficult treatment of bleaching wastewater, aggravate environmental pollution, increase production costs, etc., and reduce the difficulty of treatment , Promote bleaching and prevent pulp from returning to yellow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

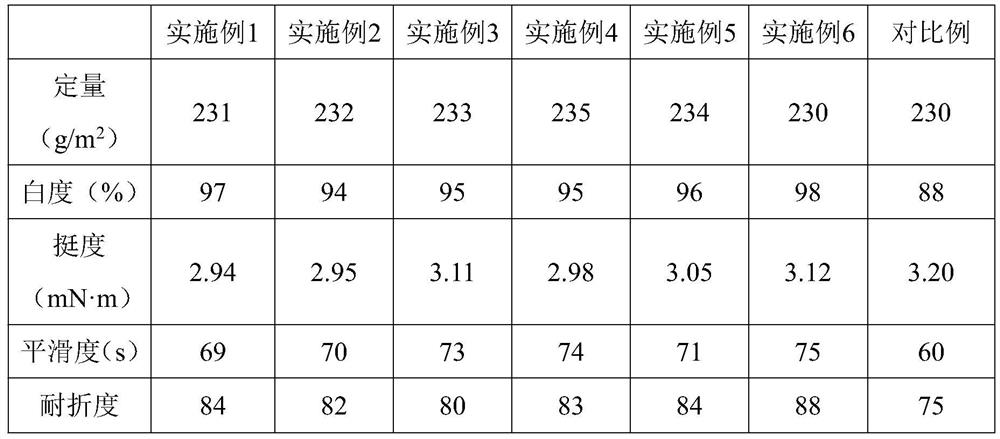

Examples

Embodiment 1

[0033] A kind of preparation method of high whiteness coated white cardboard provided by the invention, according to the following steps:

[0034] S1, pulp preparation: the coniferous wood and broad-leaved wood are prepared, pulped, washed, and screened to make natural color pulp, and then biological enzymatic bleaching: the compound enzyme liquid (the compound enzyme liquid includes alkaline pectinase, wood polymer Carbohydrase, mannanase, ligninase and whiteness stabilizer, the activity of alkaline pectinase in the compound enzyme liquid is 1300u / ml, the activity of xylanase is 2000u / ml, the activity of mannanase 800u / ml, the activity of ligninase is 120u / ml) into the natural color paste through a metering pump, make it mix with the natural color paste evenly to carry out the enzymolysis reaction, the amount of compound enzyme liquid added and the mass percentage of the absolute dry natural color paste is 0.40%, the enzyme treatment conditions are: the concentration of the o...

Embodiment 2

[0042] A kind of preparation method of high whiteness coated white cardboard, according to the following steps:

[0043] S1, pulp preparation: the coniferous wood and broad-leaved wood are prepared, pulped, washed, and screened to make natural color pulp, and then biological enzymatic bleaching: the compound enzyme liquid (the compound enzyme liquid includes alkaline pectinase, wood polymer Carbohydrase, mannanase, ligninase and whiteness stabilizer, the activity of alkaline pectinase in the compound enzyme liquid is 800u / ml, the activity of xylanase is 1500u / ml, the activity of mannanase 400u / ml, the activity of ligninase is 30u / ml) into the natural color paste through a metering pump, make it mix with the natural color paste evenly to carry out the enzymolysis reaction, the amount of compound enzyme liquid added and the mass percentage of the absolute dry natural color paste is 0.20%, the enzyme treatment conditions are: the concentration of the original color paste is 7%, t...

Embodiment 3

[0051] A kind of preparation method of high whiteness coated white cardboard, according to the following steps:

[0052] S1, pulp preparation: the coniferous wood and broad-leaved wood are prepared, pulped, washed, and screened to make natural color pulp, and then biological enzymatic bleaching: the compound enzyme liquid (the compound enzyme liquid includes alkaline pectinase, wood polymer Carbohydrase, mannanase, ligninase and whiteness stabilizer, the activity of alkaline pectinase in the compound enzyme liquid is 1000u / ml, the activity of xylanase is 1800u / ml, the activity of mannanase 600u / ml, the activity of ligninase is 80u / ml) into the natural color paste through a metering pump, and mix it with the natural color paste evenly to carry out the enzymolysis reaction. 0.30%, the enzyme treatment conditions are: the concentration of the original color paste is 8%, the temperature is 52°C, the pH is 7.0, and the enzymatic hydrolysis time is 45 minutes. The pulp is prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com