Blasting bead drying box

A drying oven and blasting bead technology, which is applied in the direction of drying gas arrangement, local stirring dryer, static material dryer, etc., can solve the problems of high labor cost, low efficiency, unclear drying characteristics of blasting beads, etc. Drying speed, avoiding the rupture of the capsular skin, and avoiding the effect of uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

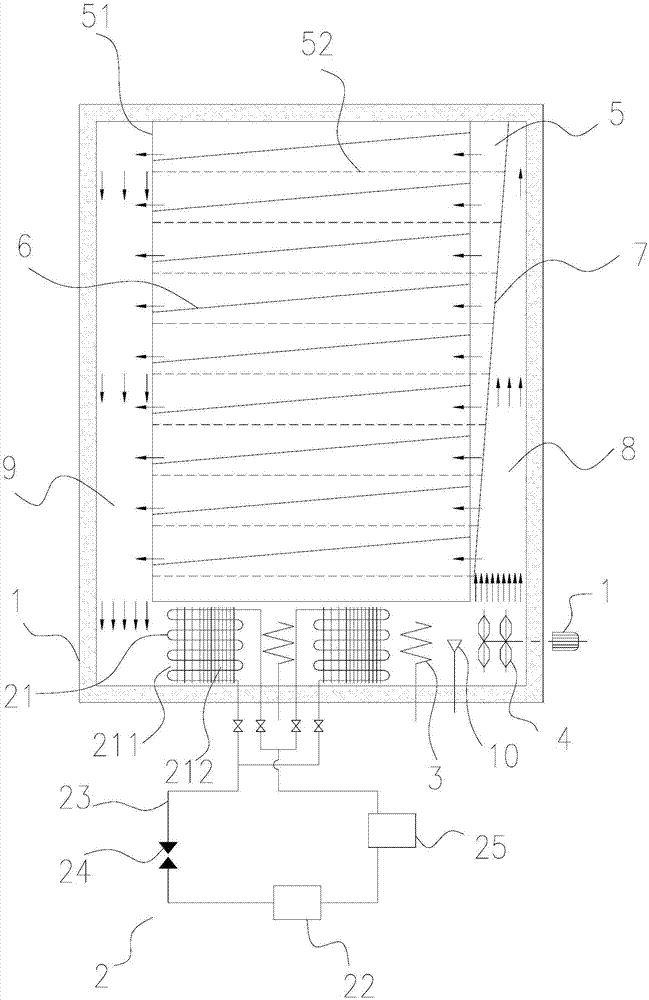

[0029] Such as figure 1 As shown, a bead blasting drying box includes a closeable box 1, a refrigeration unit 2, a heating unit 3, a blower fan 4 and a control system. The inside of the box body 1 is provided with an air duct and an accommodating space communicated with the air duct, and the accommodating space is provided with a baking pan 5 for placing explosive beads. The refrigerating device 2 has an evaporator 21 and a condenser 22, the evaporator 21 is arranged in the box body 1, and is used to condense the water vapor in the box body 1 to keep the inside of the box body 1 dry; the condenser 22 is set Outside the box body 1, heat is dissipated to the outside to realize heat exchange between the inside and outside of the box body 1. The heating device 3 is arranged downstream of the evaporator 21 along the airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com