Patents

Literature

141results about How to "Avoid uneven drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating apparatus

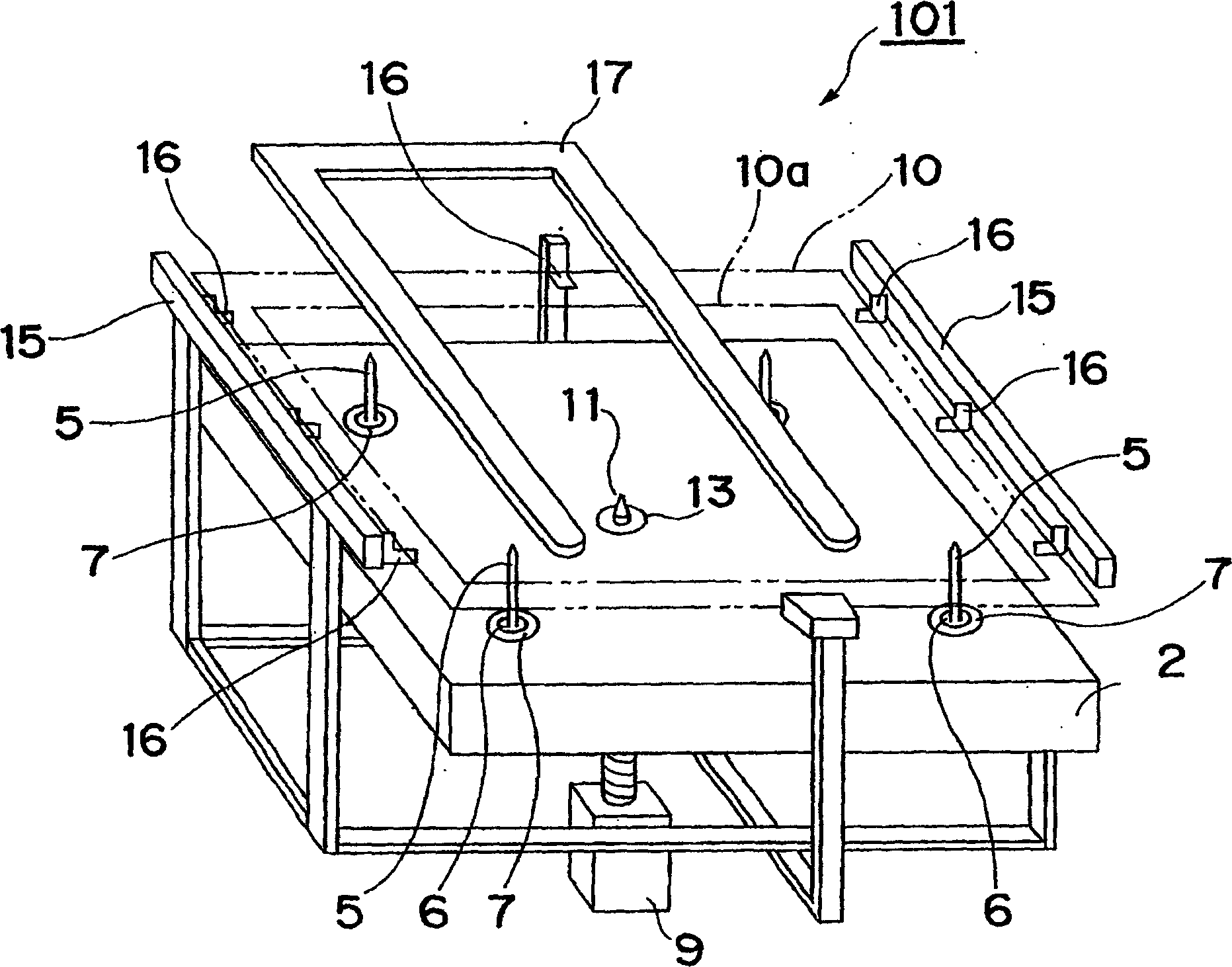

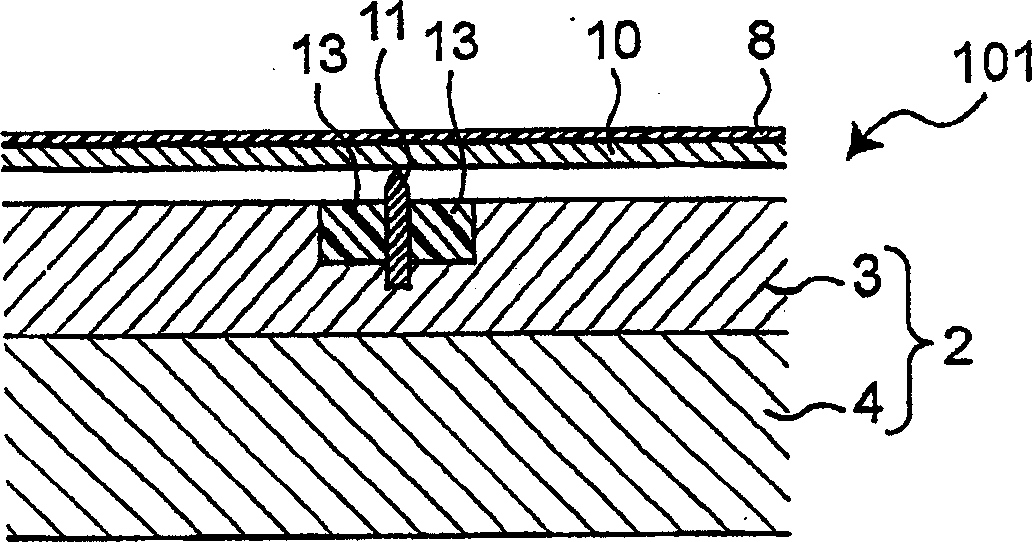

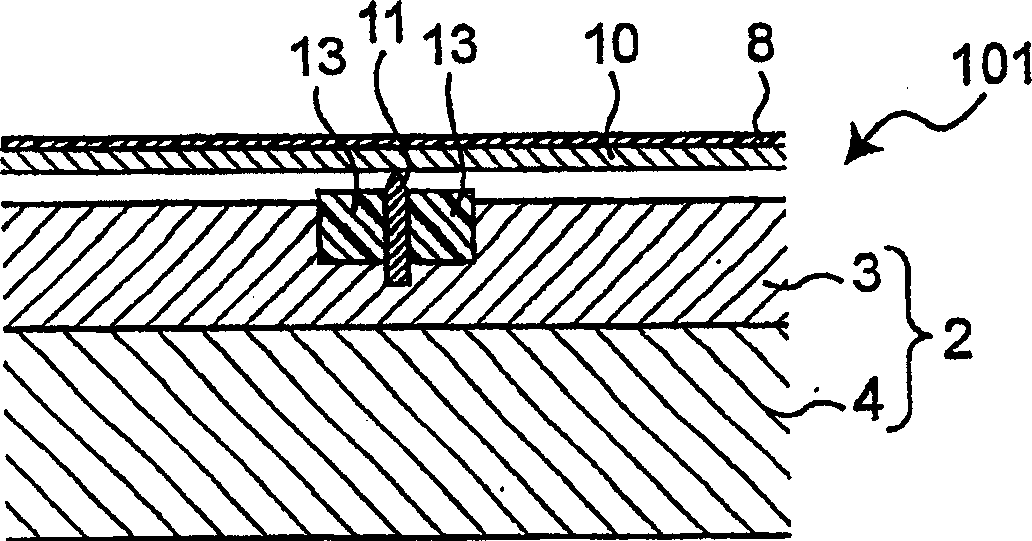

InactiveCN1745332AHeating evenlyAchieve homogenizationSemiconductor/solid-state device manufacturingHot plates heating arrangementsRadiant heatRadiant heating

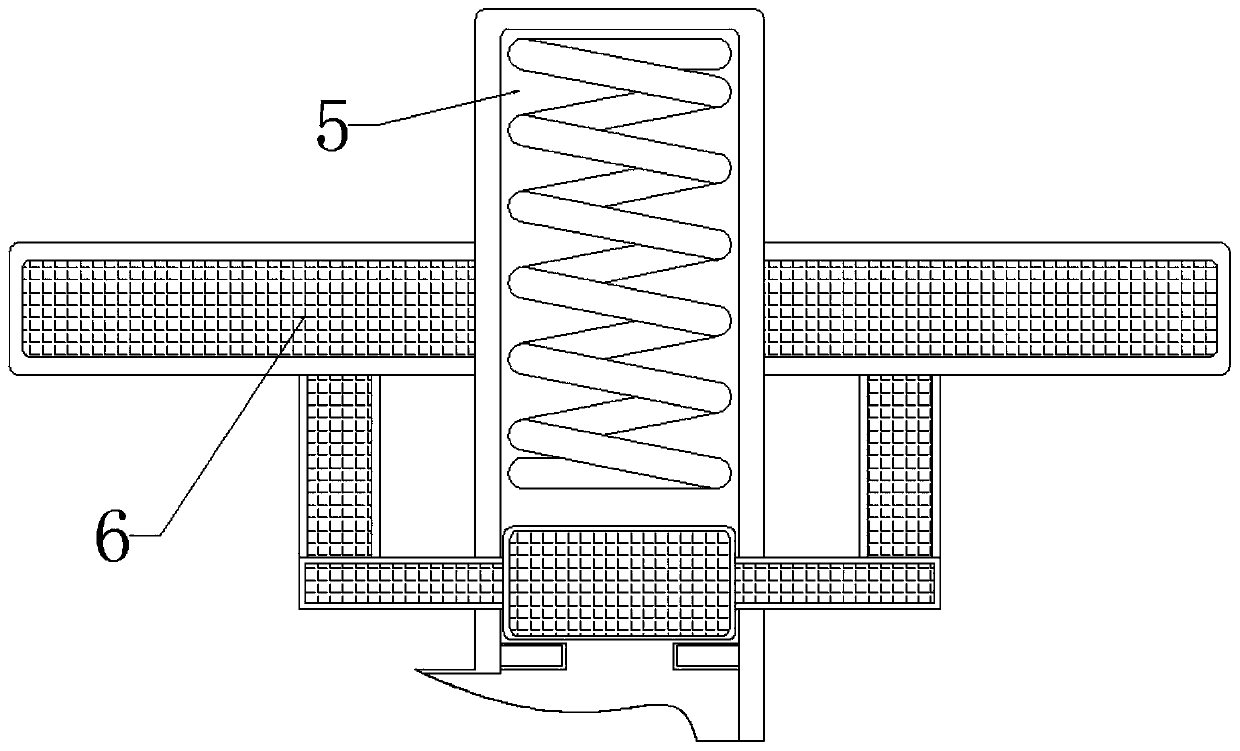

A heating apparatus (101), comprising a hot plate (2) heating a heated substrate (10) by radiation, lift pins (5) liftably disposed in through-holes (6) formed in the hot plate and lifting the heated substrate, and a proximity pin (11) fixed to the hot plate and holding the heated substrate so as to be separated from the hot plate while the heated substrate is heated. Heat reducing parts (13, 7) reducing radiant heat are installed in the hot plate around the proximity pin or around the through-holes.

Owner:NISSHA PRINTING COMPANY

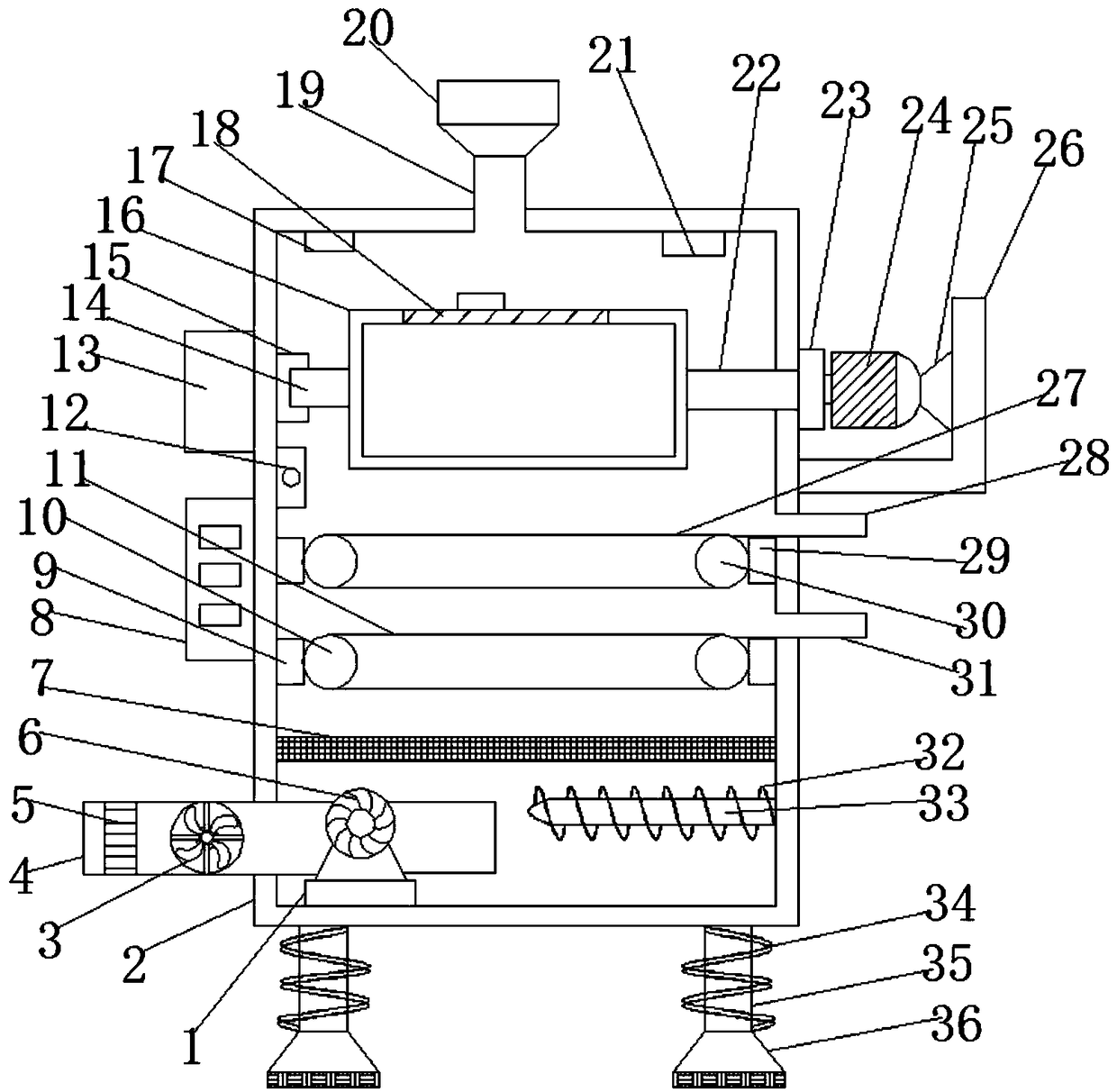

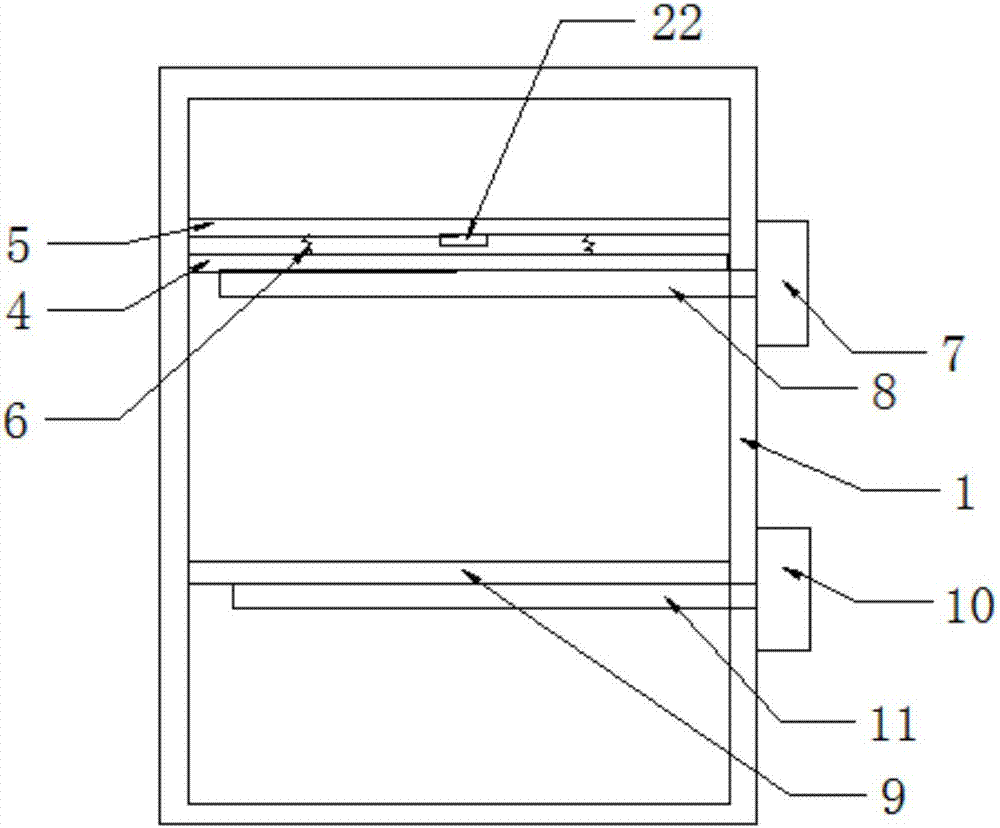

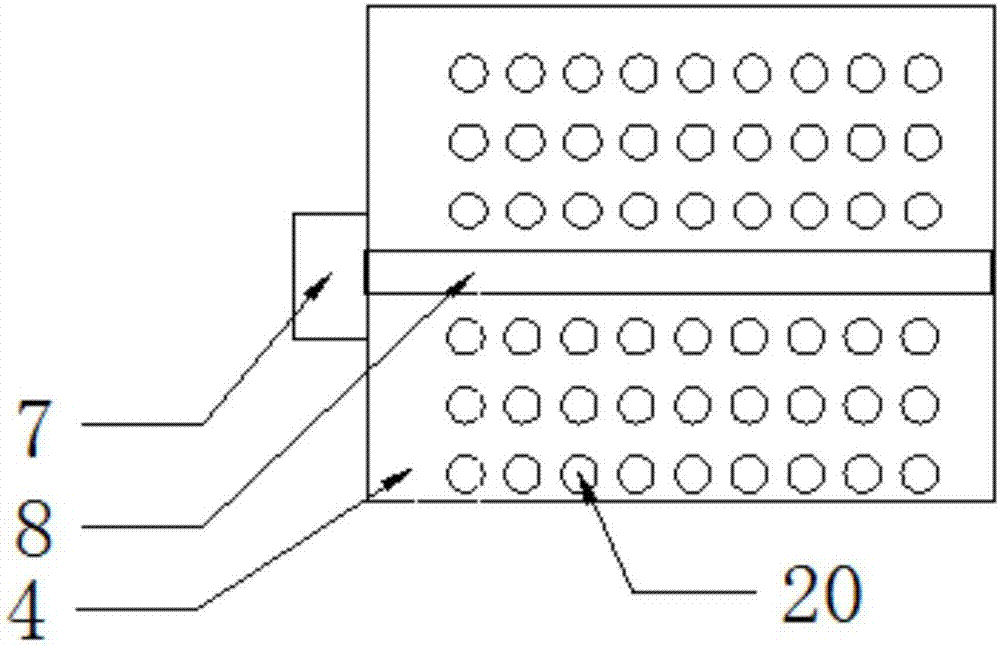

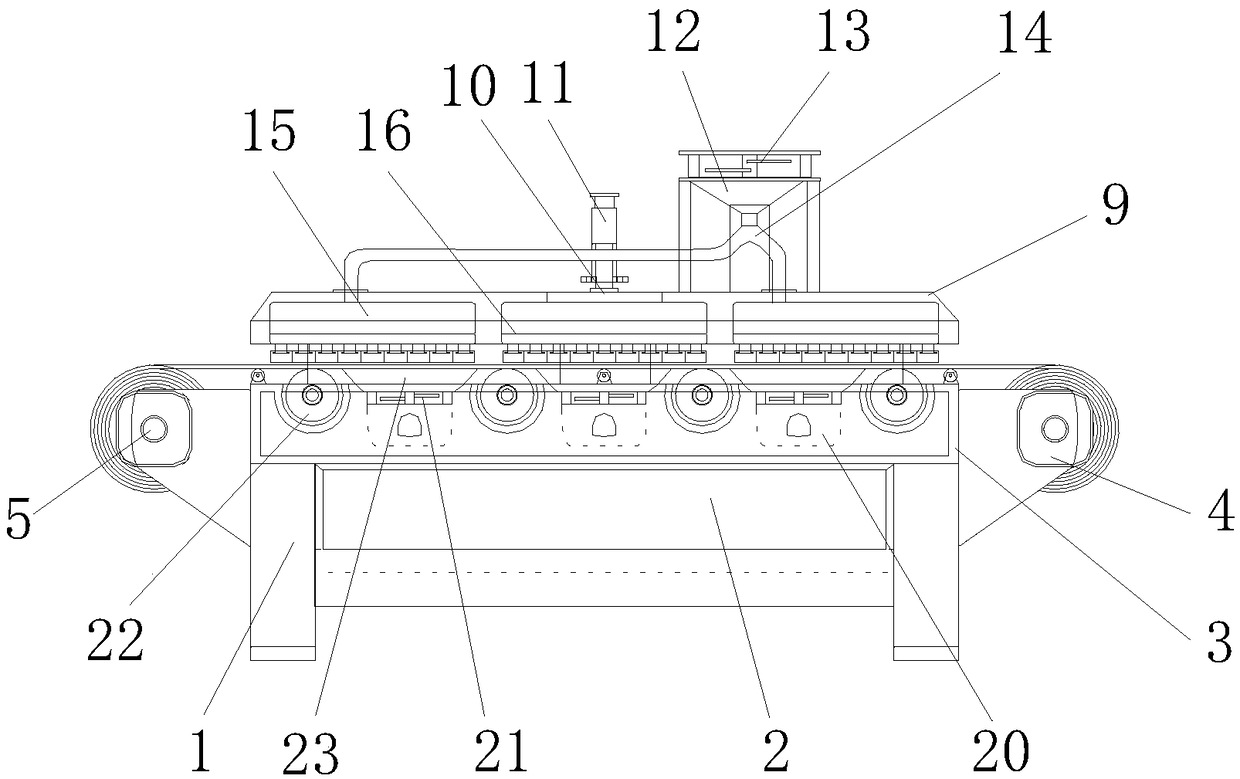

Drying device for traditional Chinese medicine processing

ActiveCN109059462AImprove efficacyHeat and dry evenlyDrying chambers/containersDrying machines with progressive movementsEngineeringDrying time

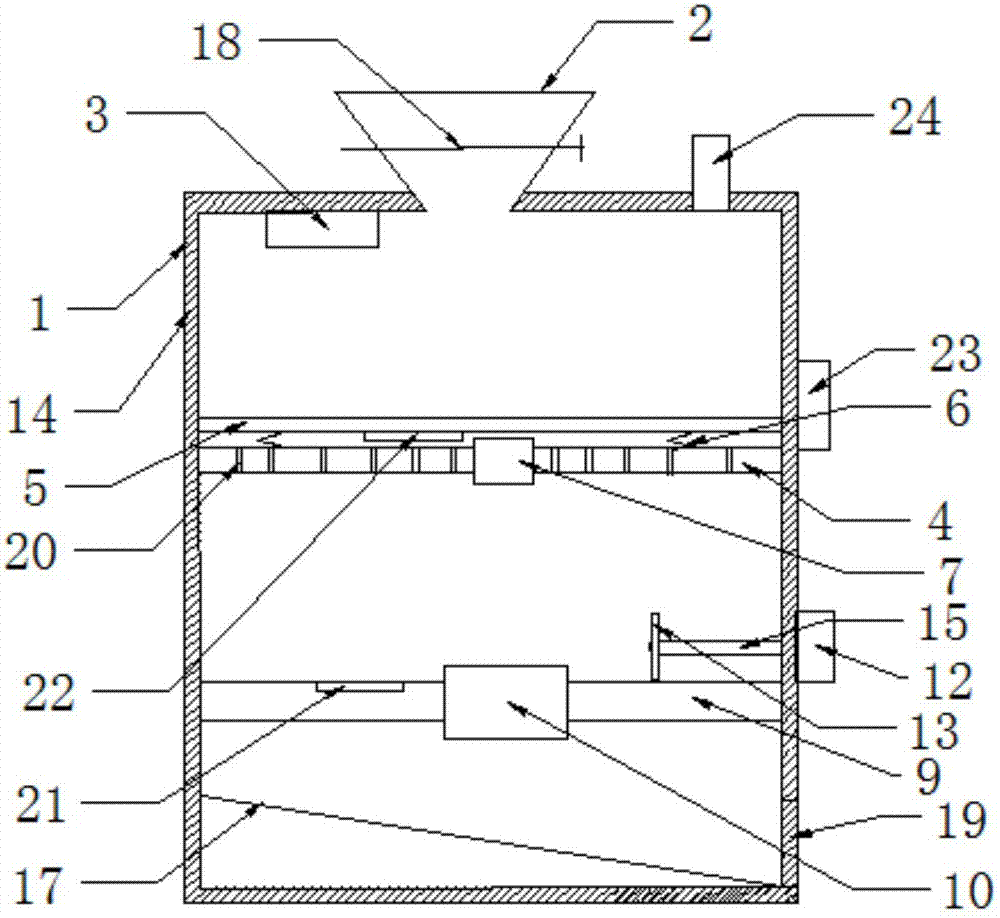

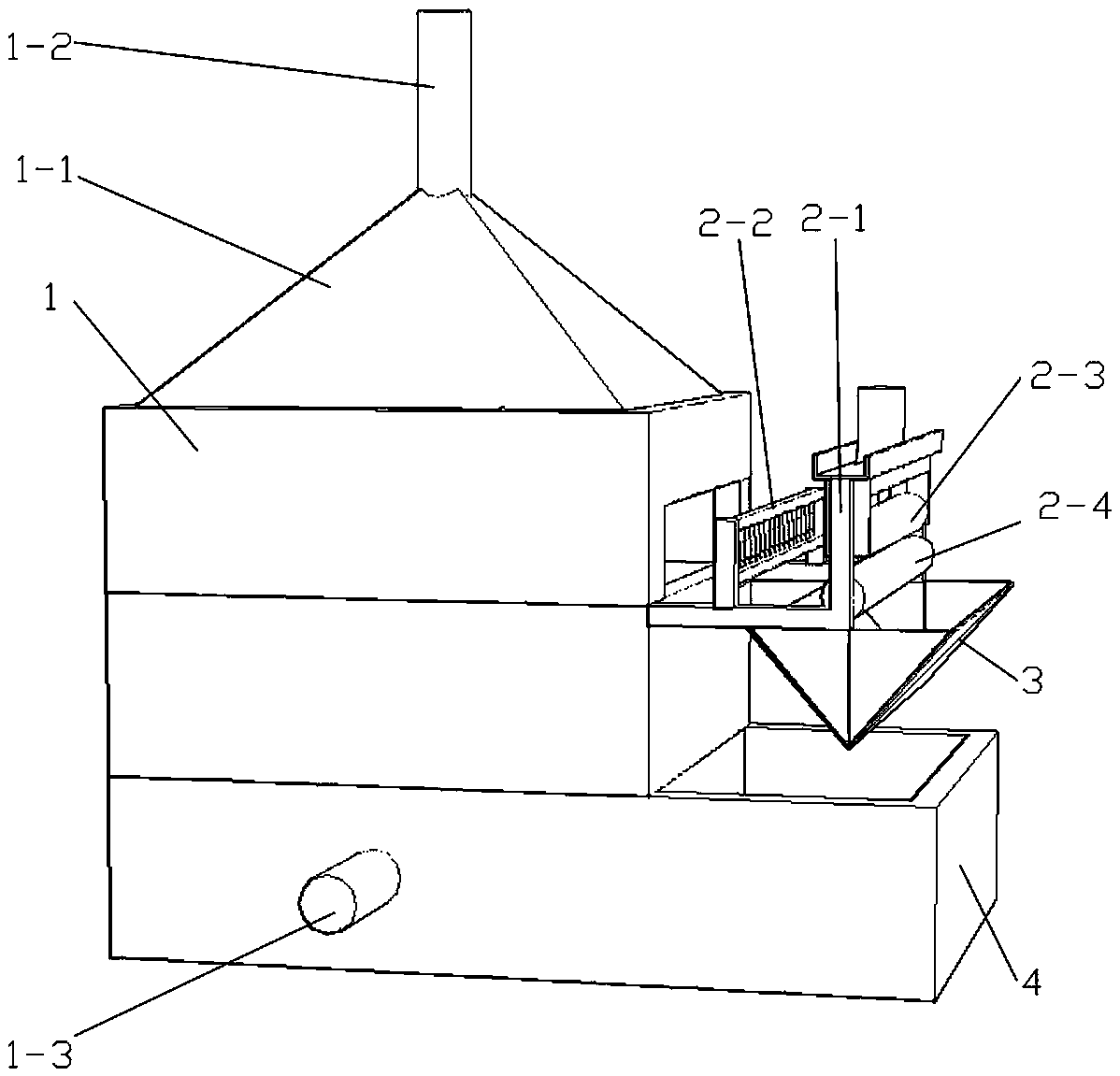

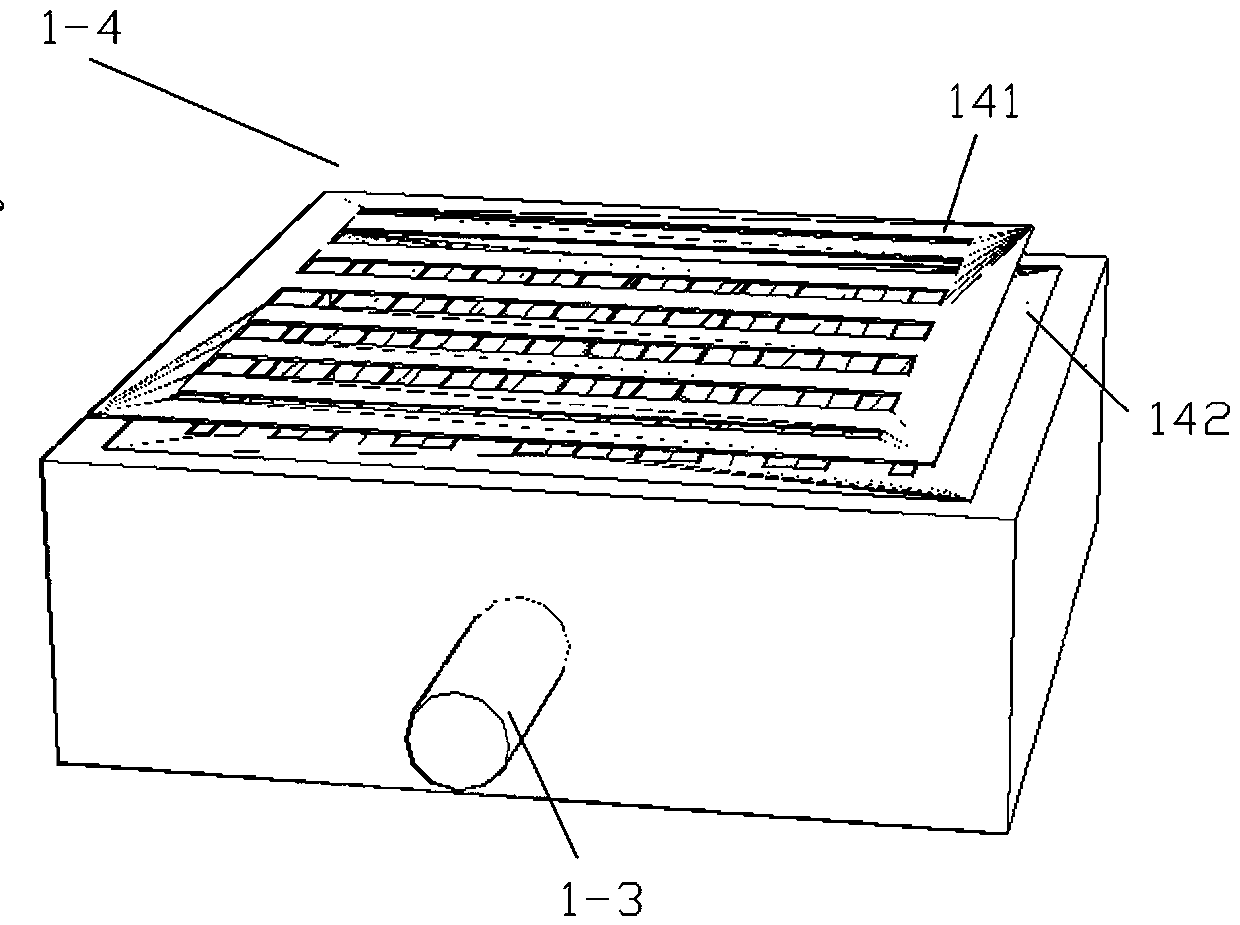

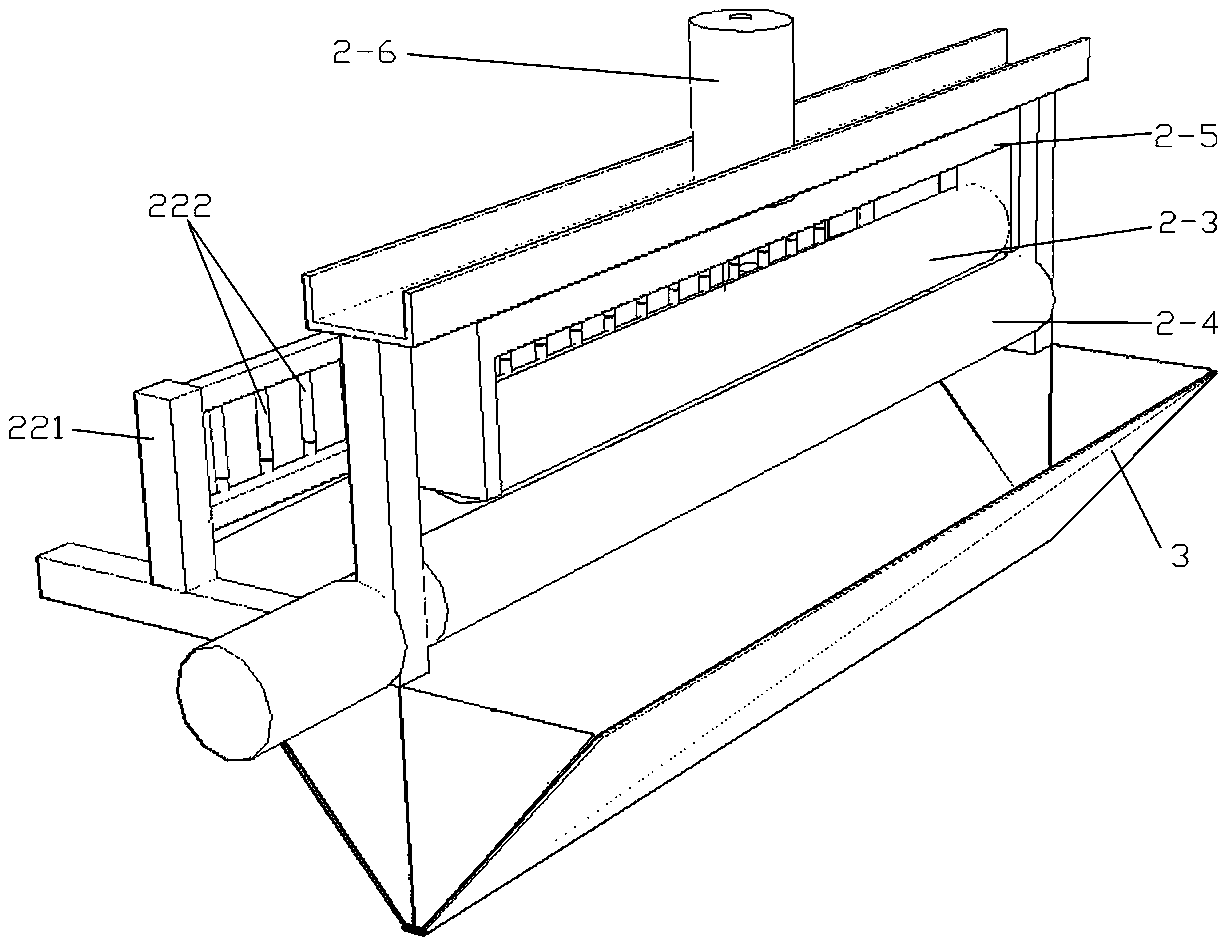

The invention discloses a drying device for traditional Chinese medicine processing. The drying device comprises a drying box body, two first mounting blocks are fixedly arranged at positions, close to the middle position, on the inner walls of the two sides of the drying box body through screws, two second mounting blocks are fixedly arranged under the two first mounting blocks through the screws, two first transmission wheels are fixedly arranged on the opposite sides of the two first mounting blocks through the screws, the outer walls of circumferences of the two first transmission wheels are connected with the same first conveying belt in a sleeved mode, screen holes which are distributed at equal intervals are formed in the outer wall of the first conveying belt, two second transmission wheels are fixedly arranged on the opposite sides of the two second mounting blocks through the screws, and the outer walls of the circumferences of the two second transmission wheels are connectedwith the same second conveying belt in a sleeved mode. The drying device has the advantages of being practical and novel, exquisite in appearance, diverse in function, convenient to uniformly heat and dry the medicines, capable of preventing drying from being uneven, facilitating control of drying time, therefore realizing optimal drying effect, and good in stability.

Owner:安徽中和堂制药有限公司

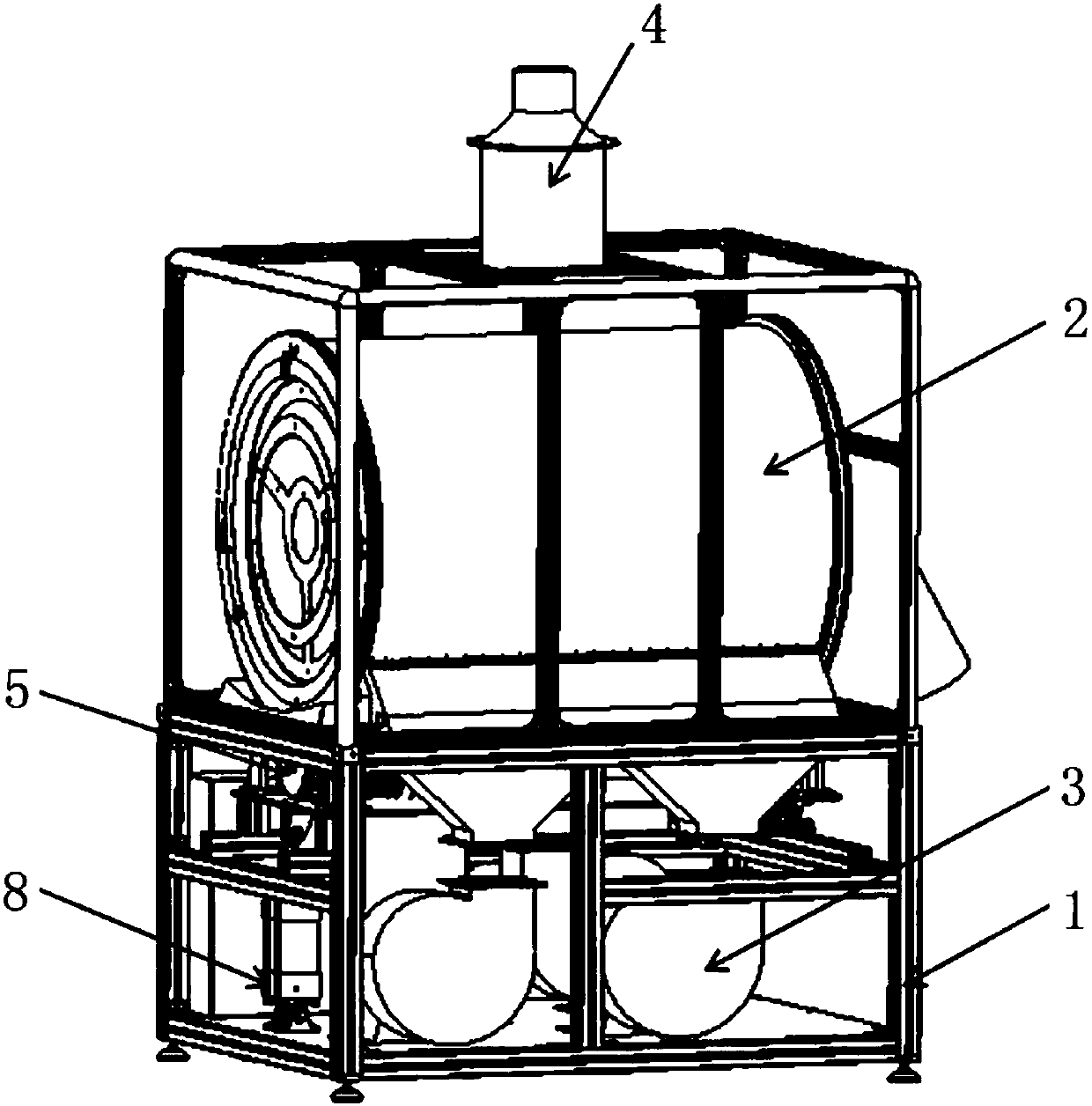

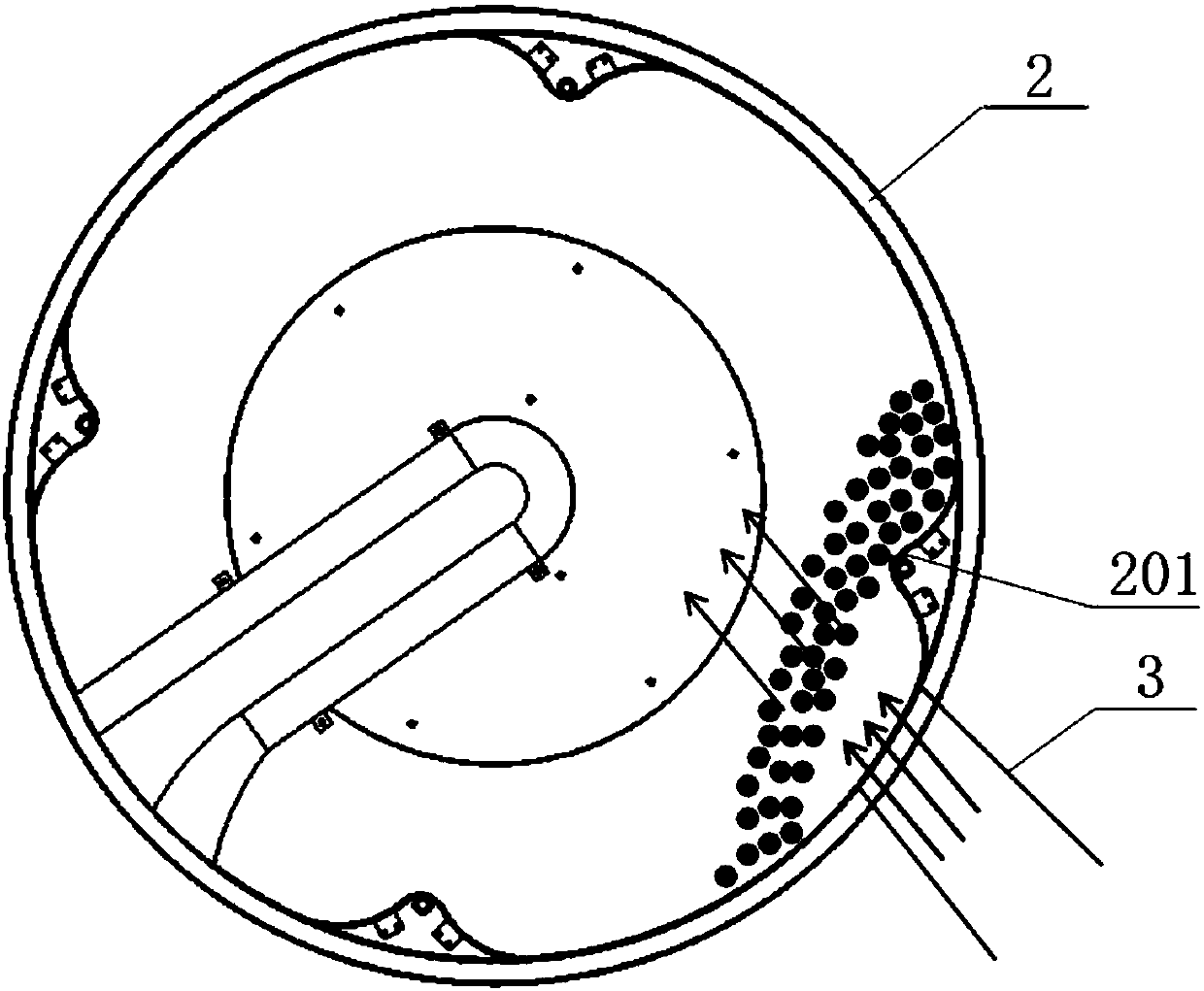

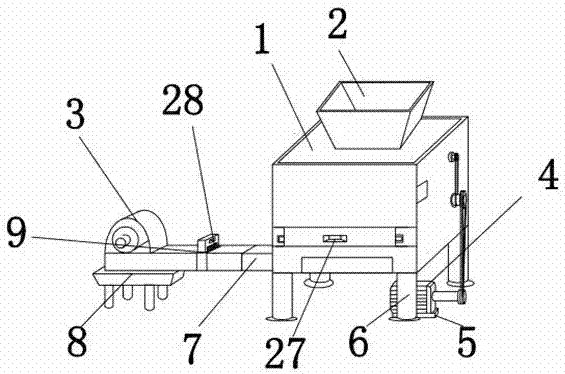

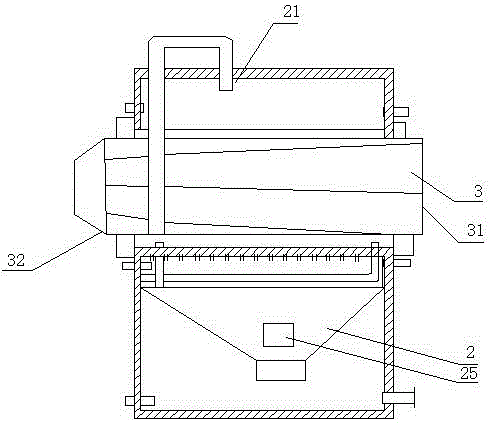

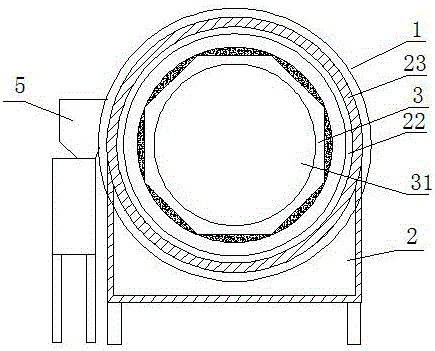

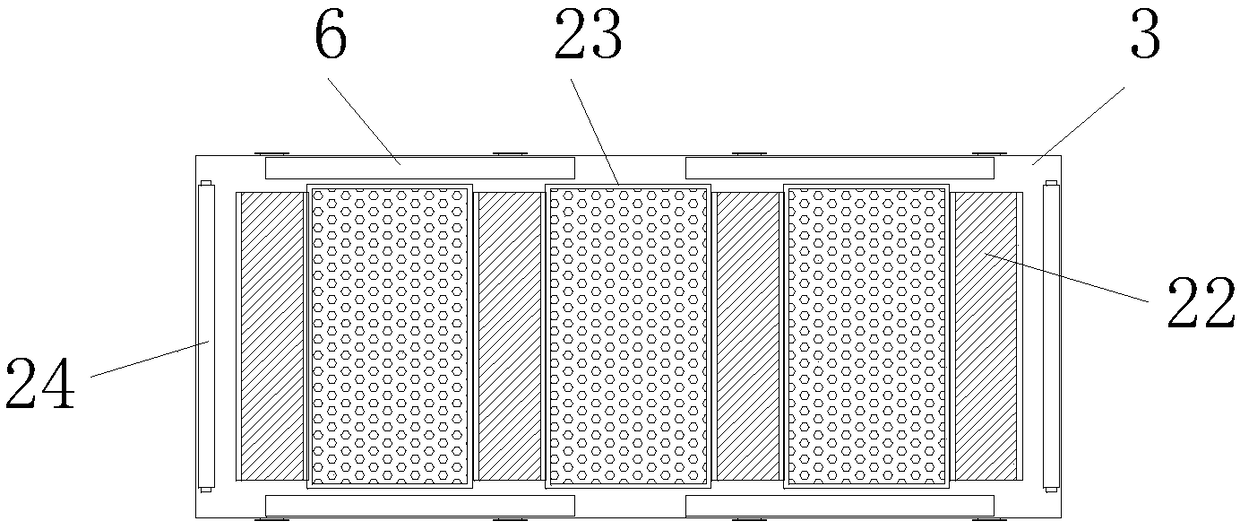

Cigarette blast bead machining equipment and shaping and drying device thereof

ActiveCN109883168ARealize turning operationEasy to fillTobacco smoke filtersDrying gas arrangementsEngineeringAir blower

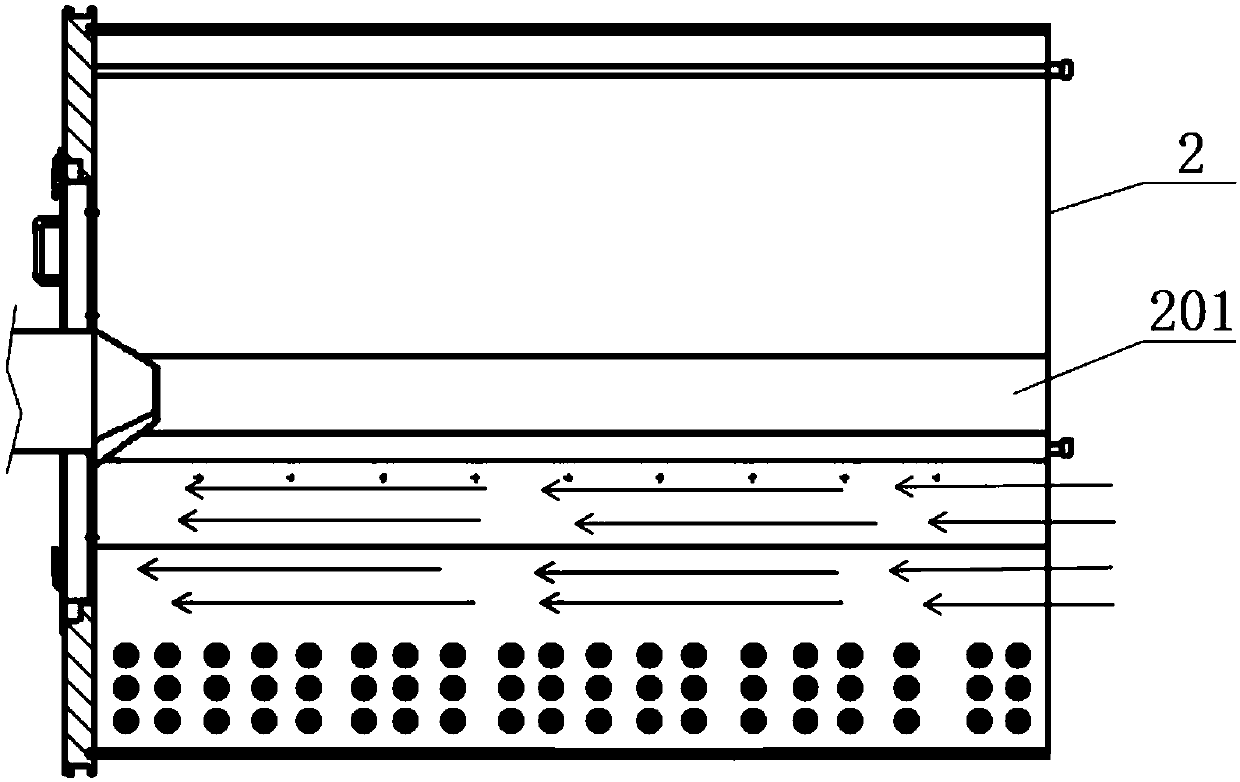

The invention discloses a shaping and drying device of cigarette blast bead machining equipment. The shaping and drying device of the cigarette blast bead machining equipment comprises a machine body,a drum circumferentially and rotationally arranged on the machine body and used for containing blast bead wet capsules, and side air blowers on the machine body; a plurality of bosses are arranged onthe inner wall of the drum in the circumferential direction, so that a temporary cavity is formed between the fallen blast bead wet capsules and the inner wall of the bottom of the drum when the drumrotates circumferentially; a plurality of vent holes are formed in the side wall of the drum; and an air outlet of each side air blower is aligned with the corresponding vent hole, within the side wall range corresponding to the temporary cavity, of the drum. The phenomena that blast bead wet capsules are stacked and the surfaces and inner layers are not even in drying can be effectively avoided;and at the same time, the drum continuously rotates in the drying operation process, the side air blowers continuously blow dry air inwards, and therefore the drying efficiency is greatly improved, and the product quality is ensured. The invention further discloses the cigarette blast bead machining equipment which has the abovementioned beneficial effects.

Owner:CHINA TOBACCO GUIZHOU IND

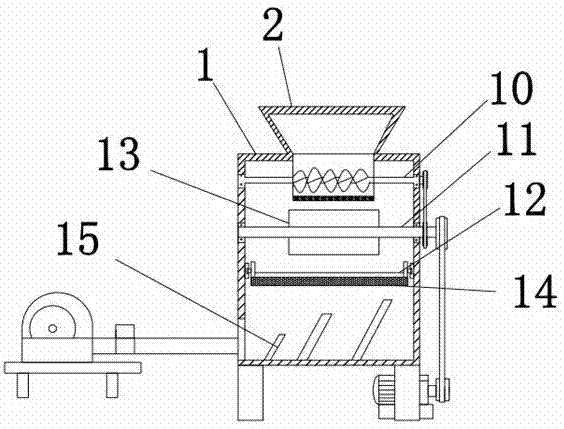

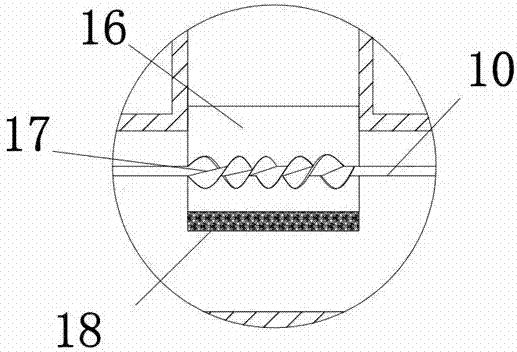

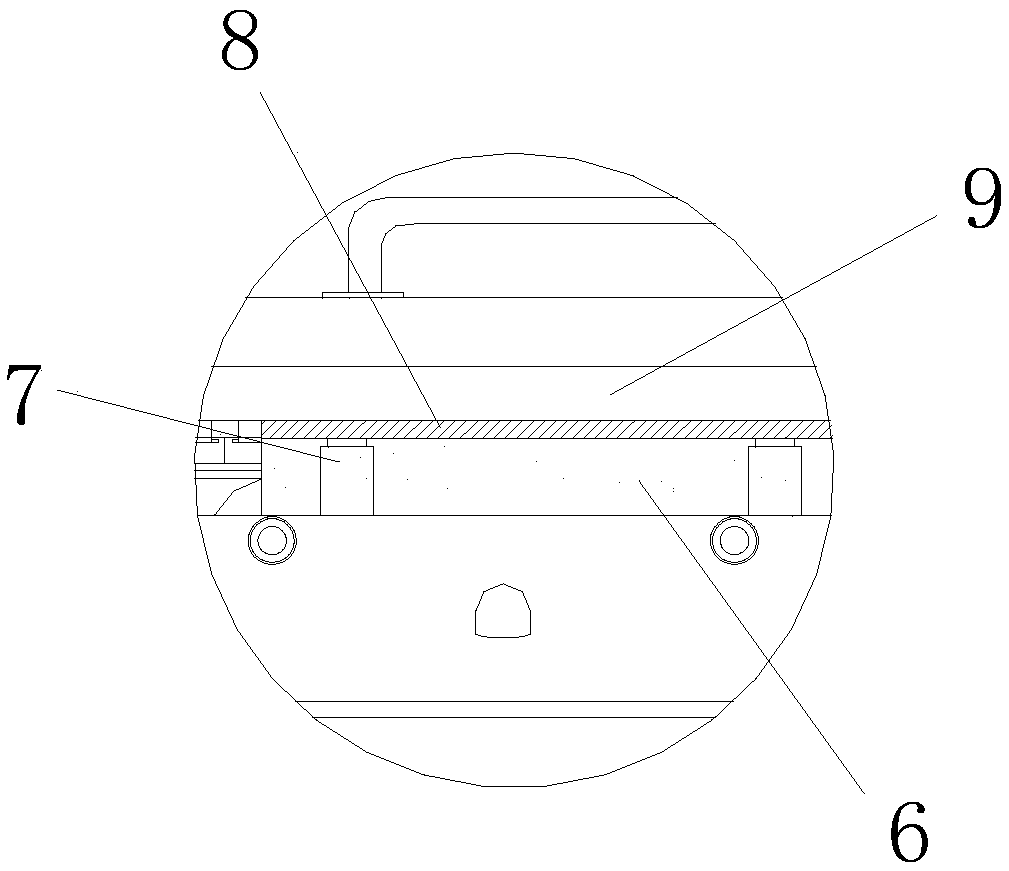

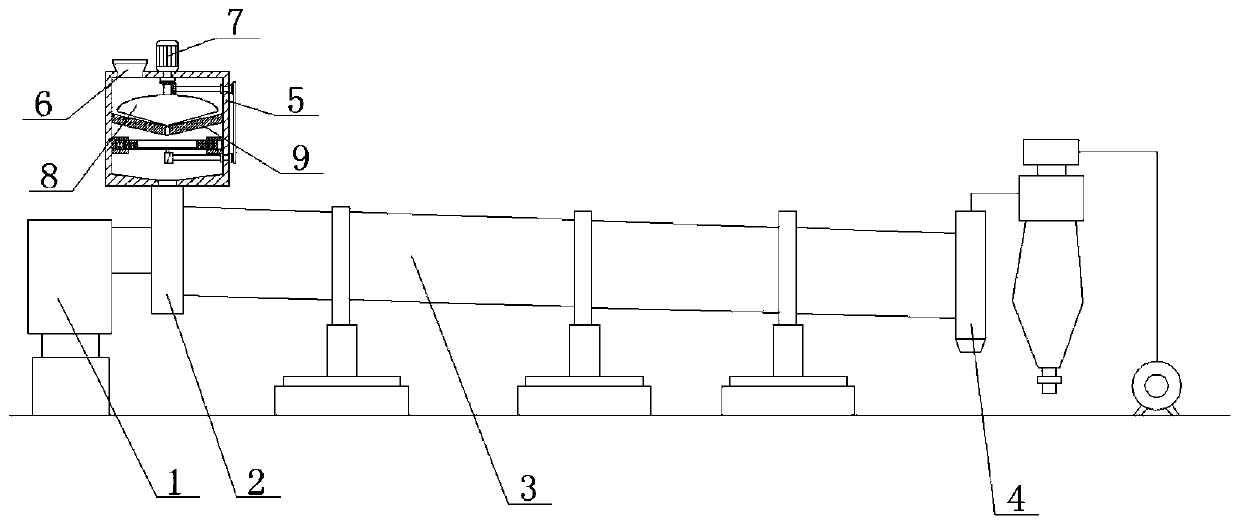

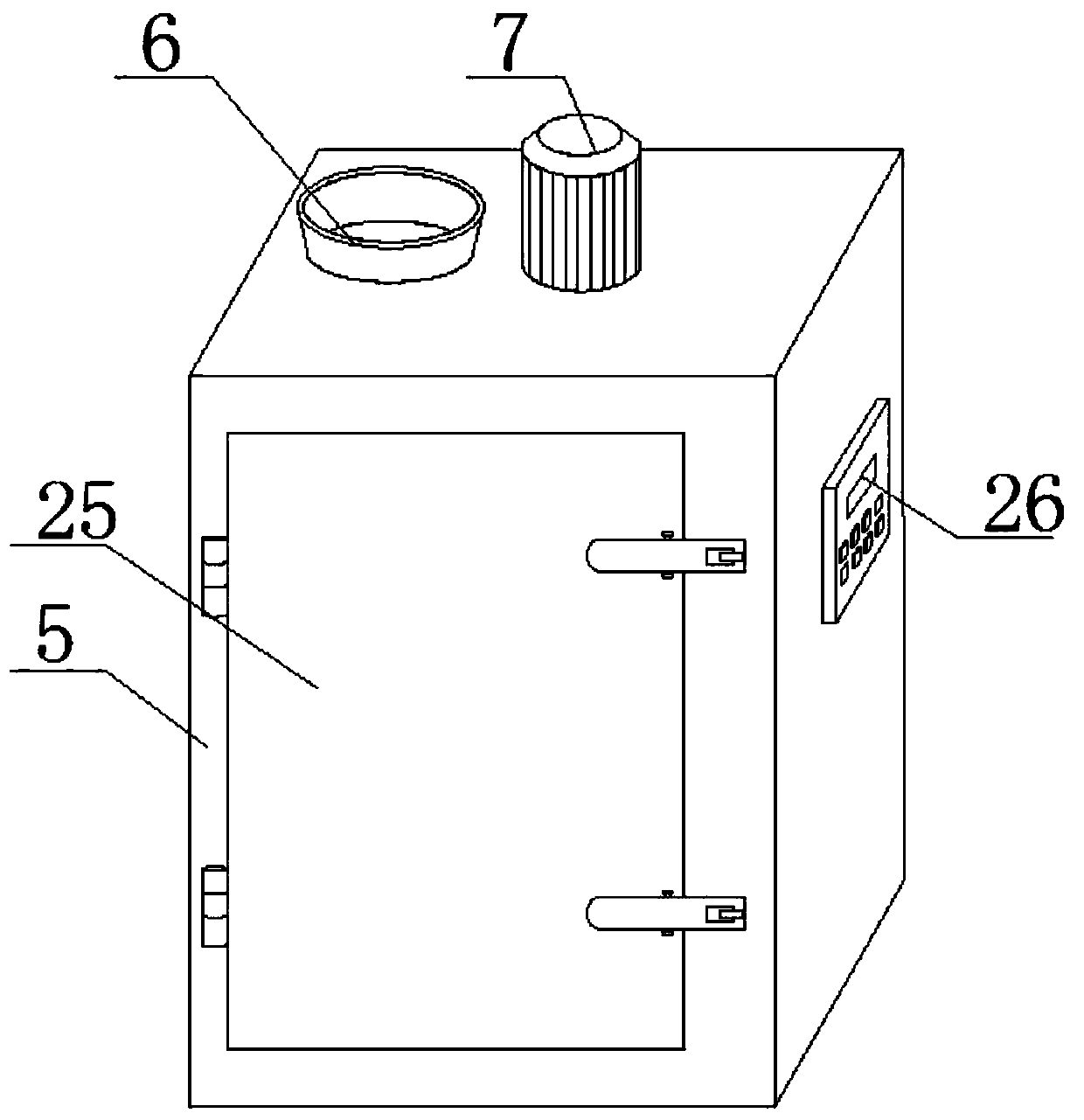

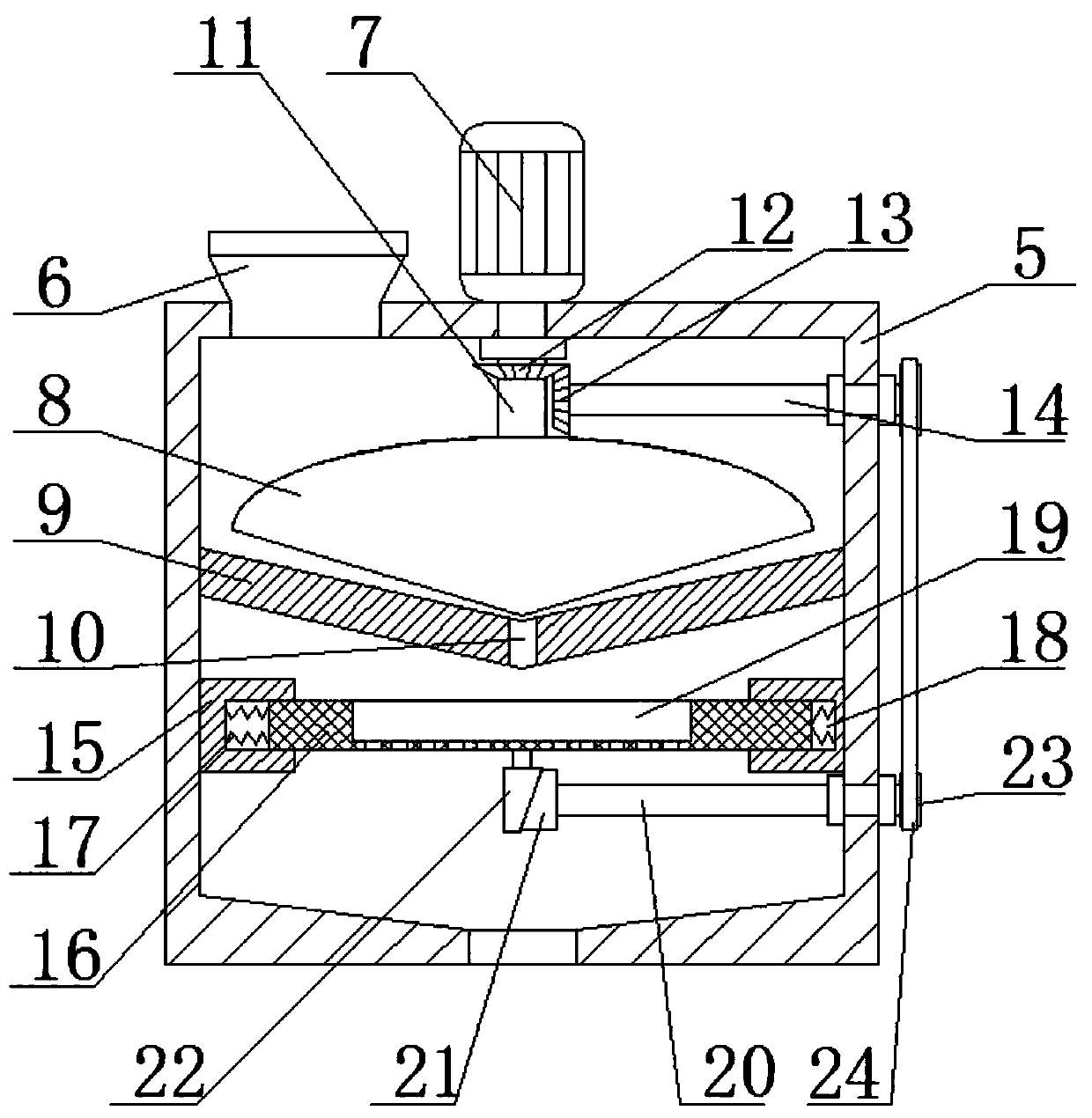

Chemical fertilizer dryer

InactiveCN106403567AAvoid uneven dryingImprove uniformitySievingManure dryingFertilizerElectric heating

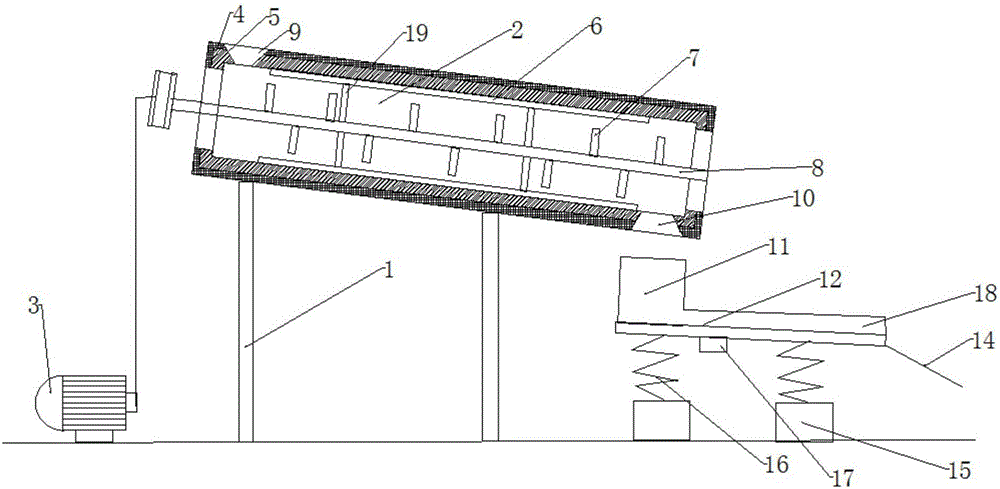

The invention provides a chemical fertilizer dryer. The chemical fertilizer dryer comprises a drying device and a sieving device, wherein the sieving device is located at a position below the right of the drying device; the drying device comprises a bracket, a drying cylinder, a motor, a rotating shaft, stirring blades, scrapers, an electric heating layer, and an insulating layer; the drying cylinder is located on the bracket; the motor is in transmission connection with the rotating shaft; the scrapers fitted to an inner side wall of the drying cylinder are also arranged in the drying cylinder; the stirring blades are also arranged on the rotating shaft; the electric heating layer is arranged on the outer side of the drying cylinder; and the insulating layer is arranged outside the electric heating layer. The chemical fertilizer dryer disclosed by the invention has the beneficial effects that the heat loss in the dryer can be effectively reduced by the insulating layer, so that energy resources are saved.

Owner:天津亚泰昊德科技有限公司

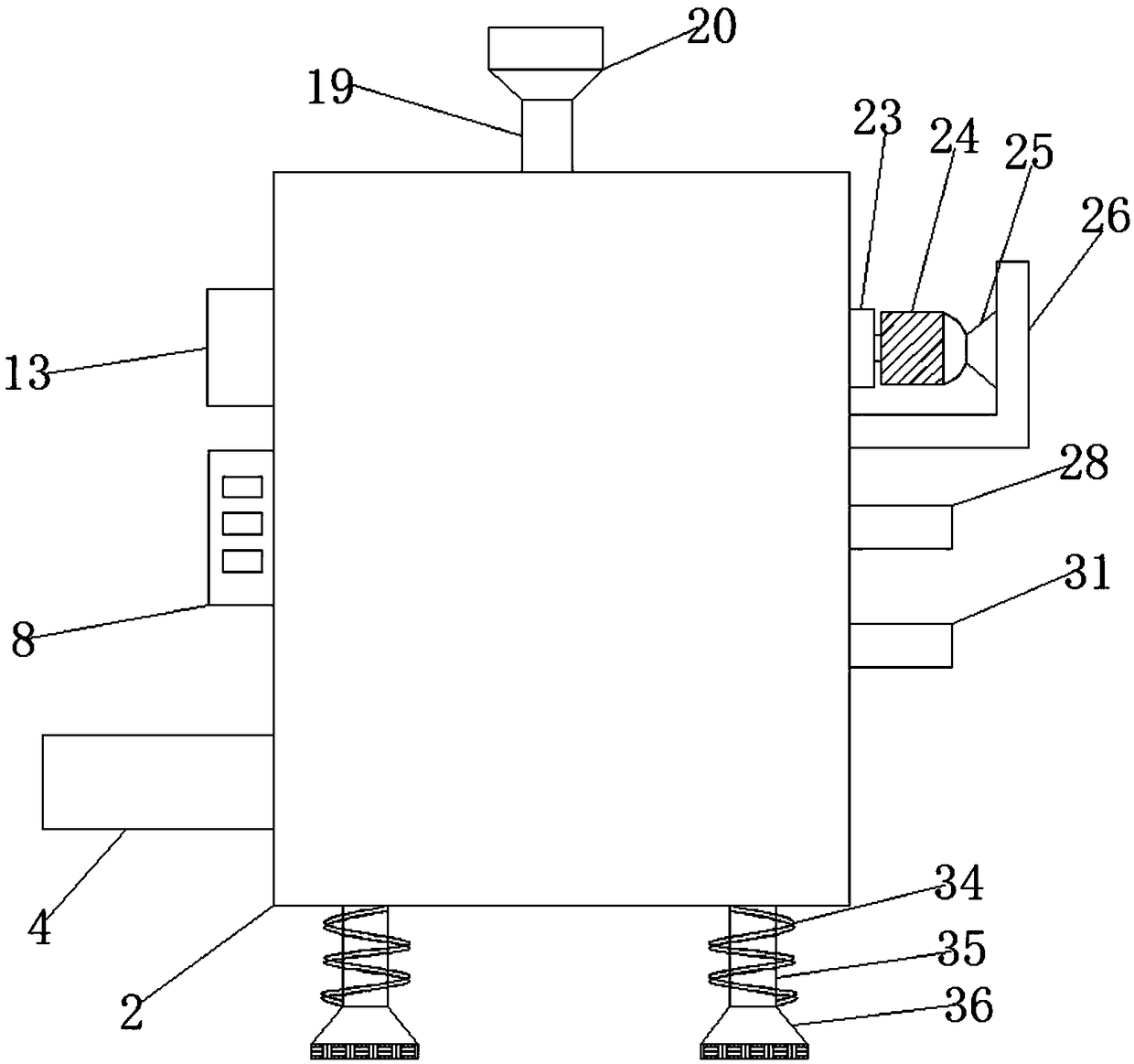

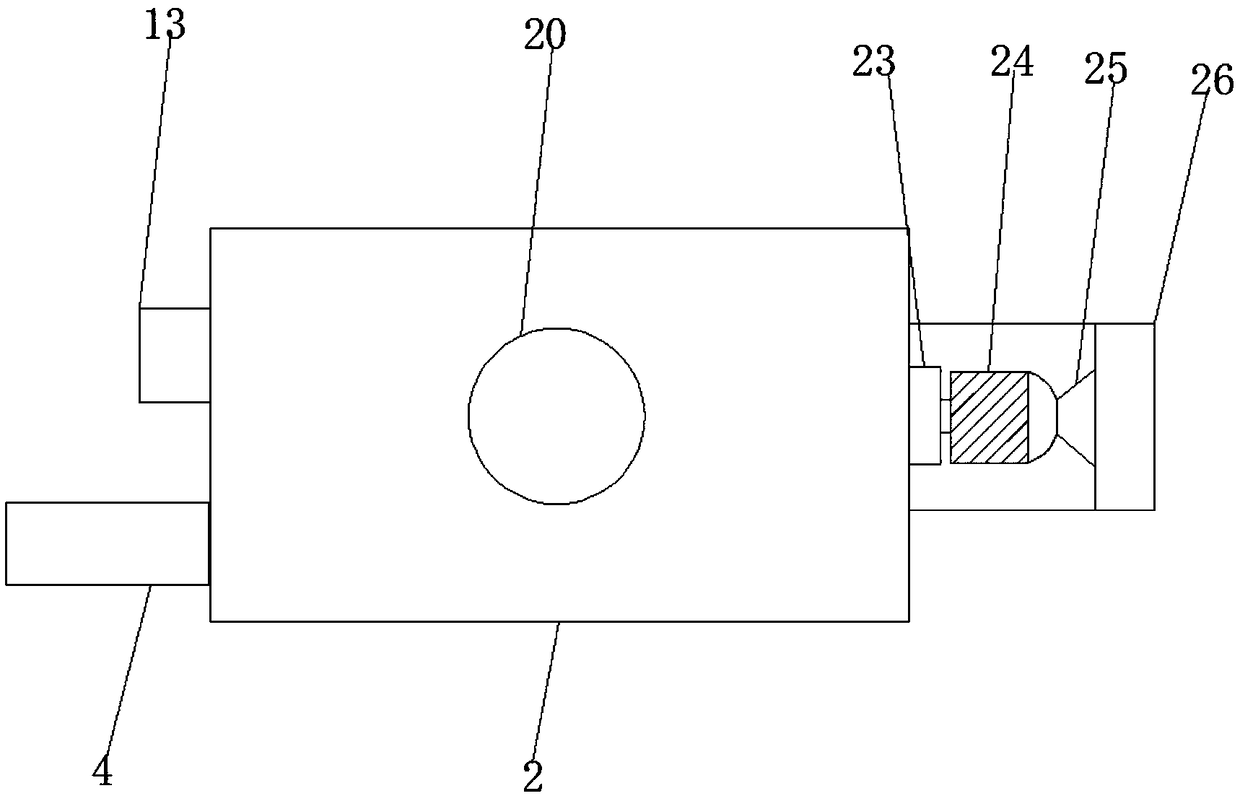

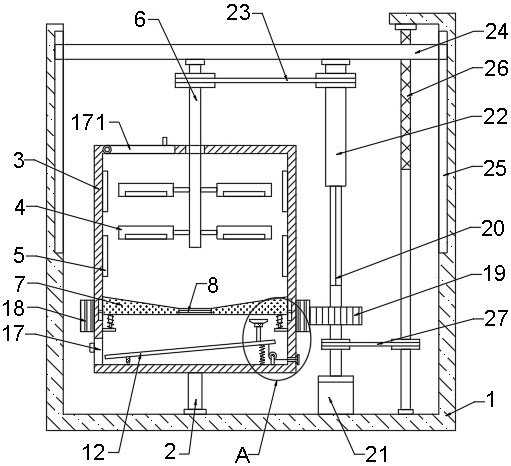

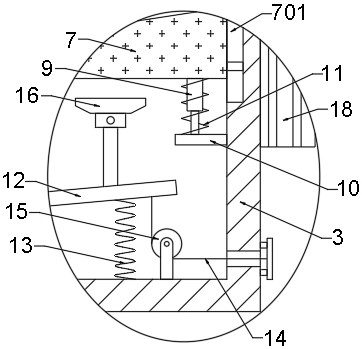

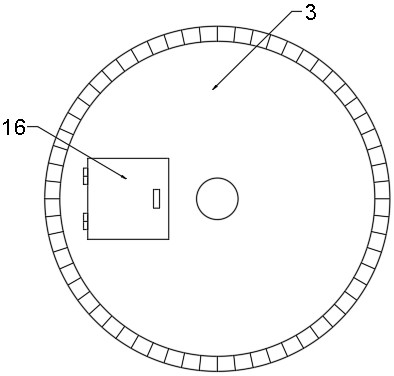

Turnover powder coating drying equipment

PendingCN107166900AAvoid accumulationReasonable designDrying solid materials with heatDrying machines with local agitationElectric machineryStructural engineering

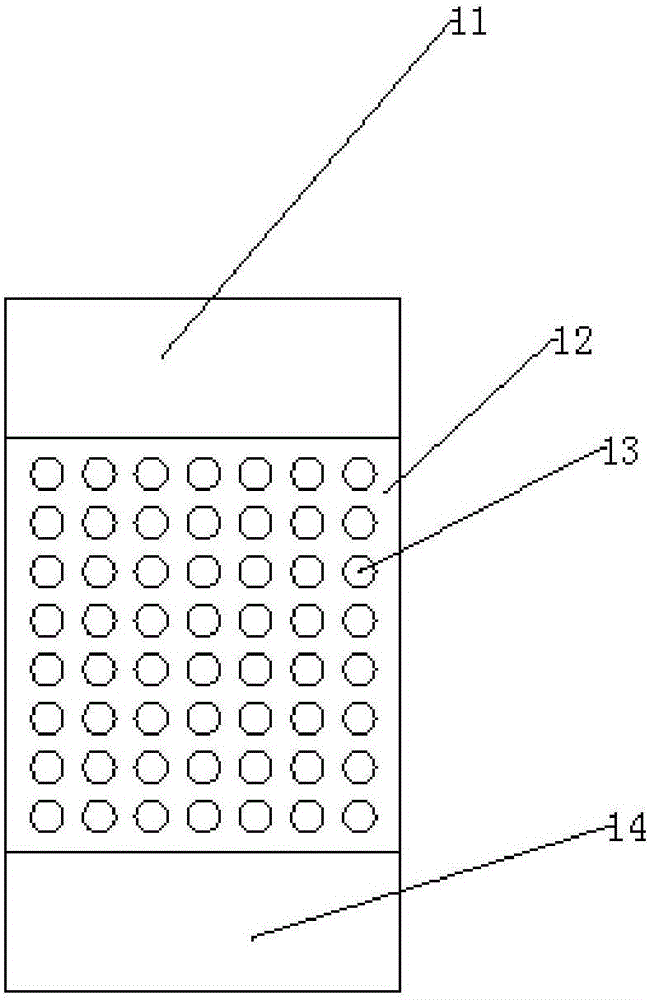

The invention provides turnover powder coating drying equipment. The turnover powder coating drying equipment comprises a box body in a cuboid shape. A feeding hopper and an air outlet are arranged at the top end of the box body. A discharging opening is formed in the bottom of the right side wall of the box body. A first rotary shaft is arranged in the box body. A first motor is fixedly arranged on the front side wall of the box body and drives the first rotary shaft to rotate. A horizontal plate is fixedly arranged on the upper surface of the first rotary shaft. A first storage plate is arranged above the horizontal plate. The horizontal plate and the first storage plate are connected through multiple supporting springs. A microwave heater is arranged at the top end of the box body. An electric heating sleeve is arranged on the outer side wall of the box body in a wrapping manner. The turnover powder coating drying equipment has the beneficial effects that design is reasonable, operation is convenient, the first storage plate and a second storage plate which can be turned over are arranged in the box body, and drying efficiency is improved; a vibration device is arranged on the first storage plate, powder coating accumulation can be avoided, and the drying efficiency is improved; and through a pushing plate above the second storage plate, powder coating can be pushed and spread on the second storage plate, drying is facilitated, and the drying efficiency is improved.

Owner:科威嘉粉末涂料(天津)股份有限公司

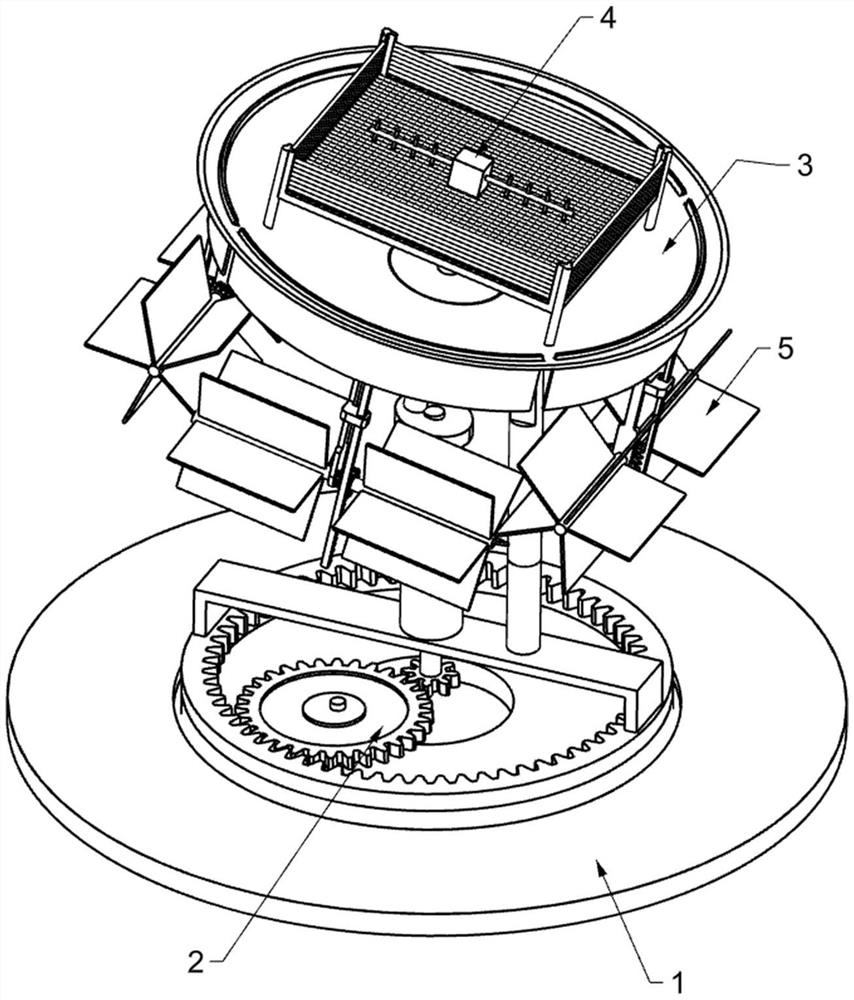

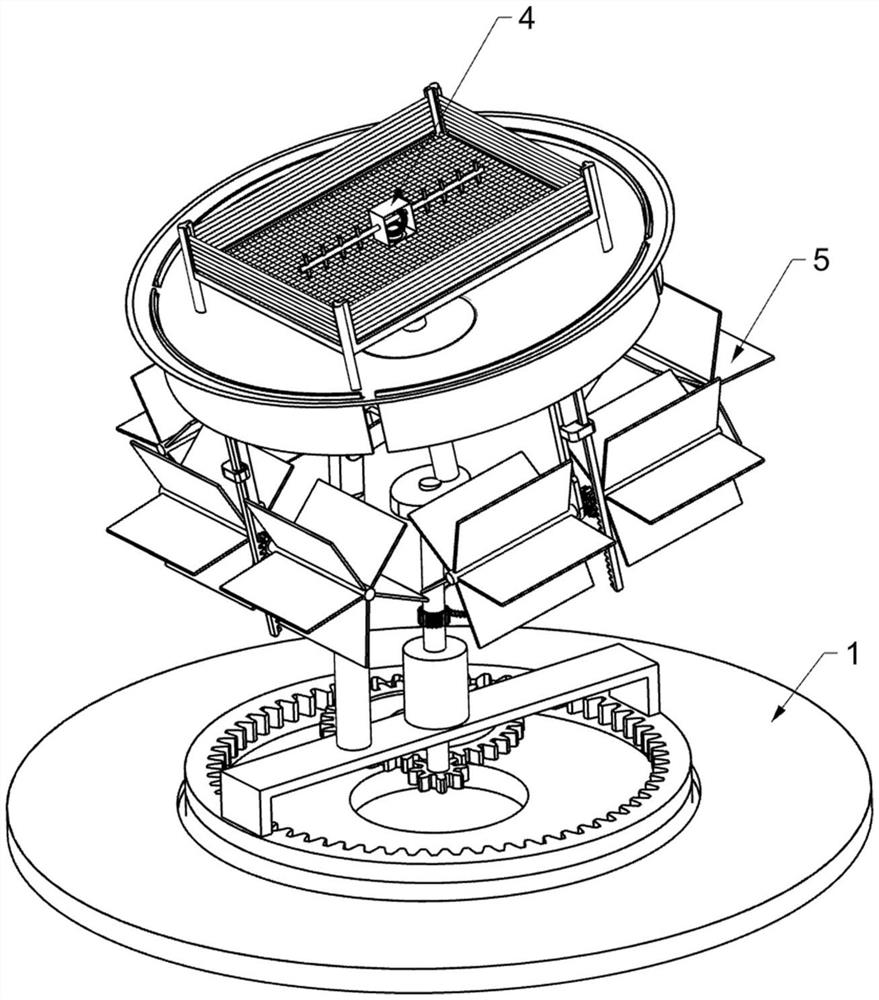

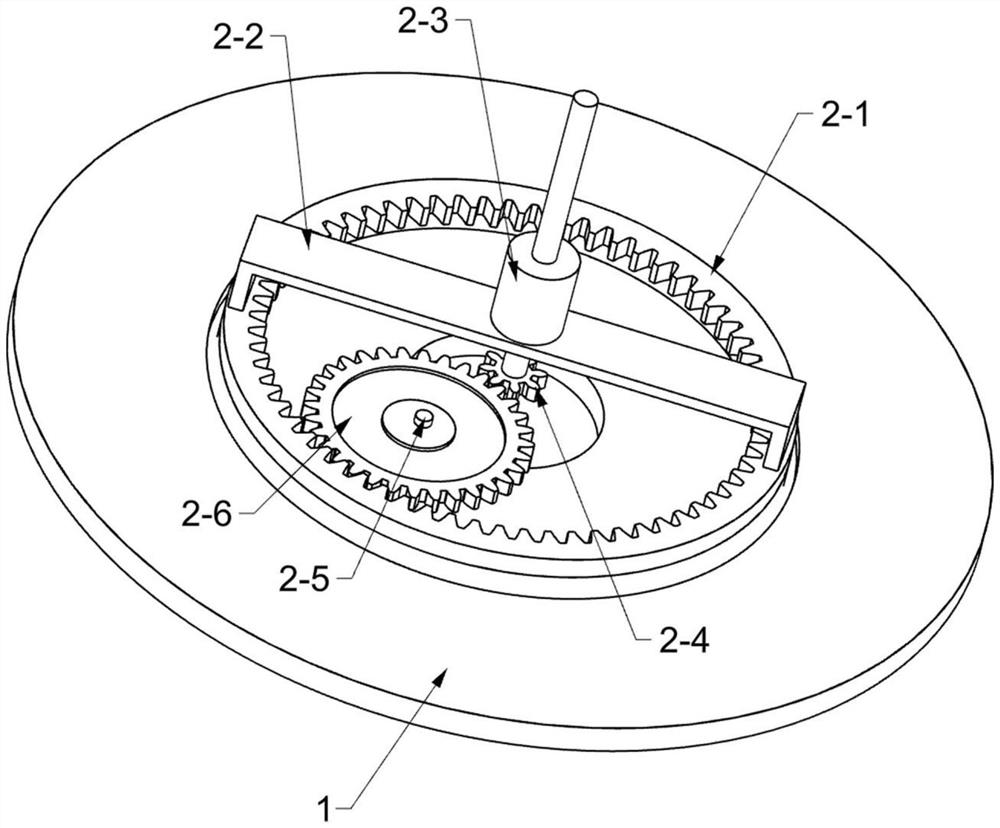

Crop airing device

ActiveCN111006467AAvoid uneven dryingImprove work efficiencyDrying gas arrangementsDrying chambers/containersAgricultural scienceAgricultural engineering

The invention discloses a crop airing device, and belongs to the field of airing devices. The crop airing device comprises a support and further comprises a connecting frame connected to the side wallof the support in a sliding mode, the airing device further comprises a plurality of airing plates connected to the support in a rotating mode, and a plurality of first gears are connected to the side wall of the support. A first collecting box is fixedly connected to the bottom of the support, a second collecting box is fixedly connected to the bottom of the first collecting box, a rotating shaft is rotatably connected to the bottom of the first collecting box, a sealing plate is fixedly connected to the rotating shaft, a second gear is connected to the side wall of the support, and second gear teeth are connected to the bottom of the connecting frame and engaged with the second gear teeth. According to the invention, the airing plane is formed by overturning the plurality of airing plates; according to the crop airing device, the airing plate is turned over to collect crops in a centralized mode after airing is completed, so that the working efficiency is improved, meanwhile, a heating assembly is additionally arranged in the first material collecting box, hot air exists at the bottom of the airing plate, and uneven airing caused by grain moisture regaining is prevented.

Owner:JILIN TEACHERS INST OF ENG & TECH

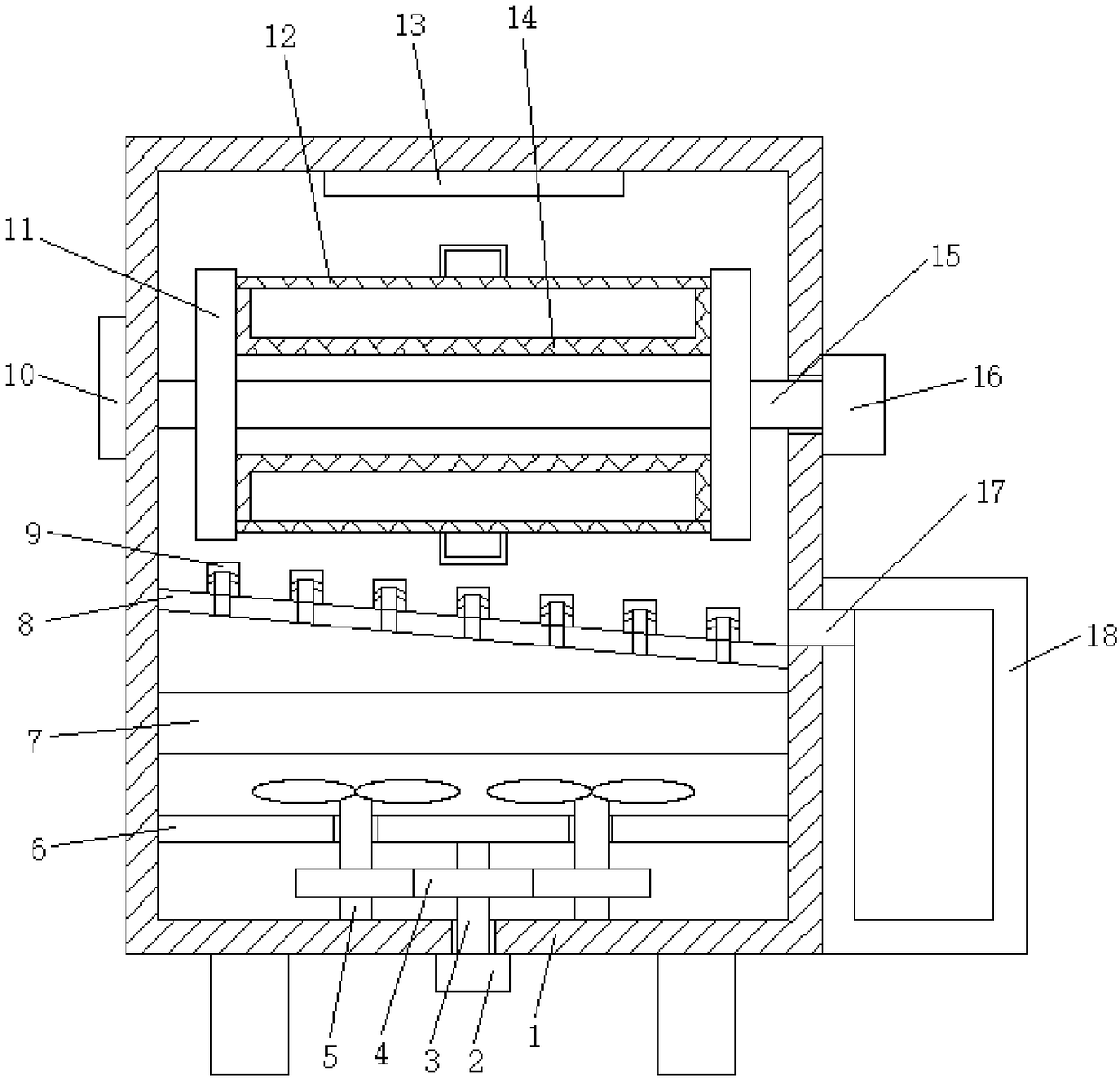

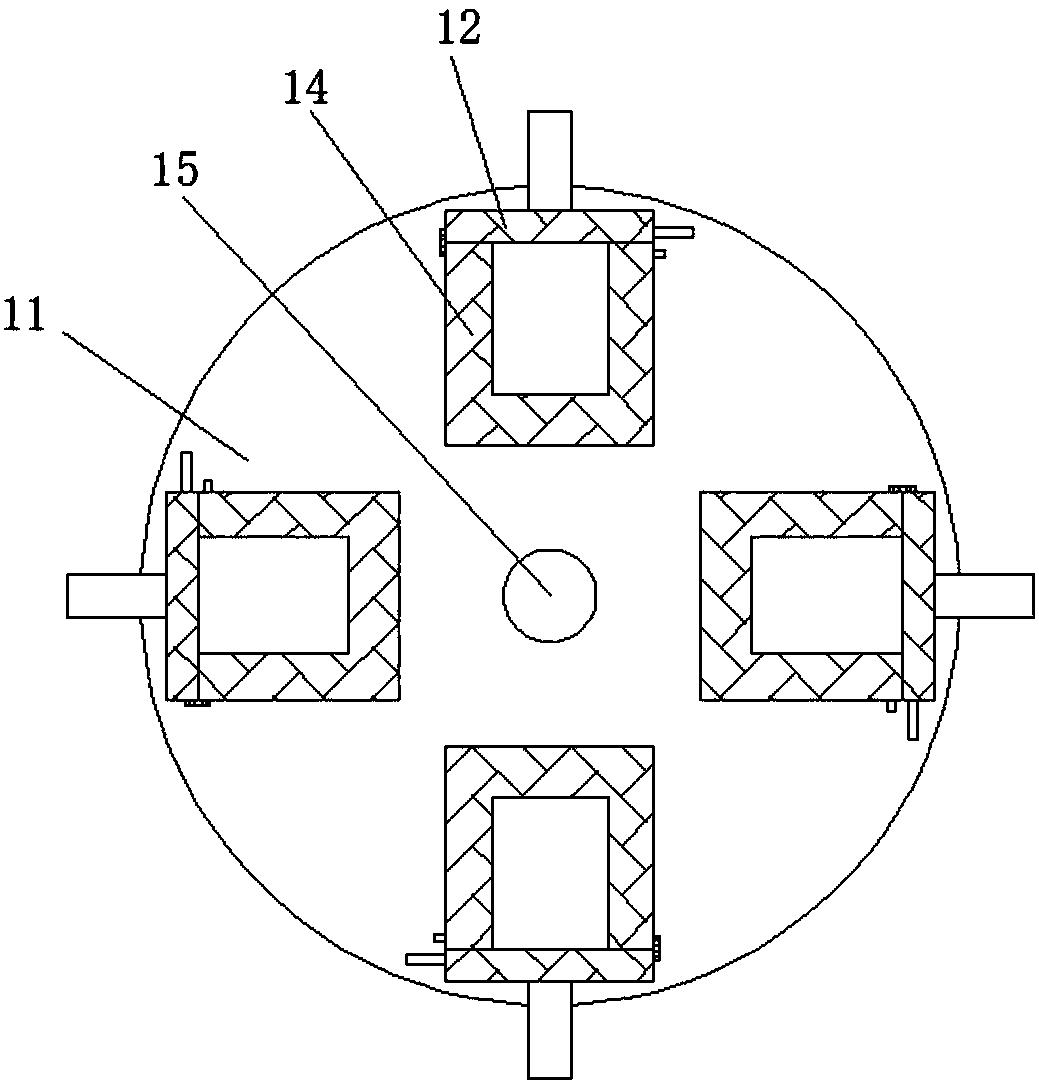

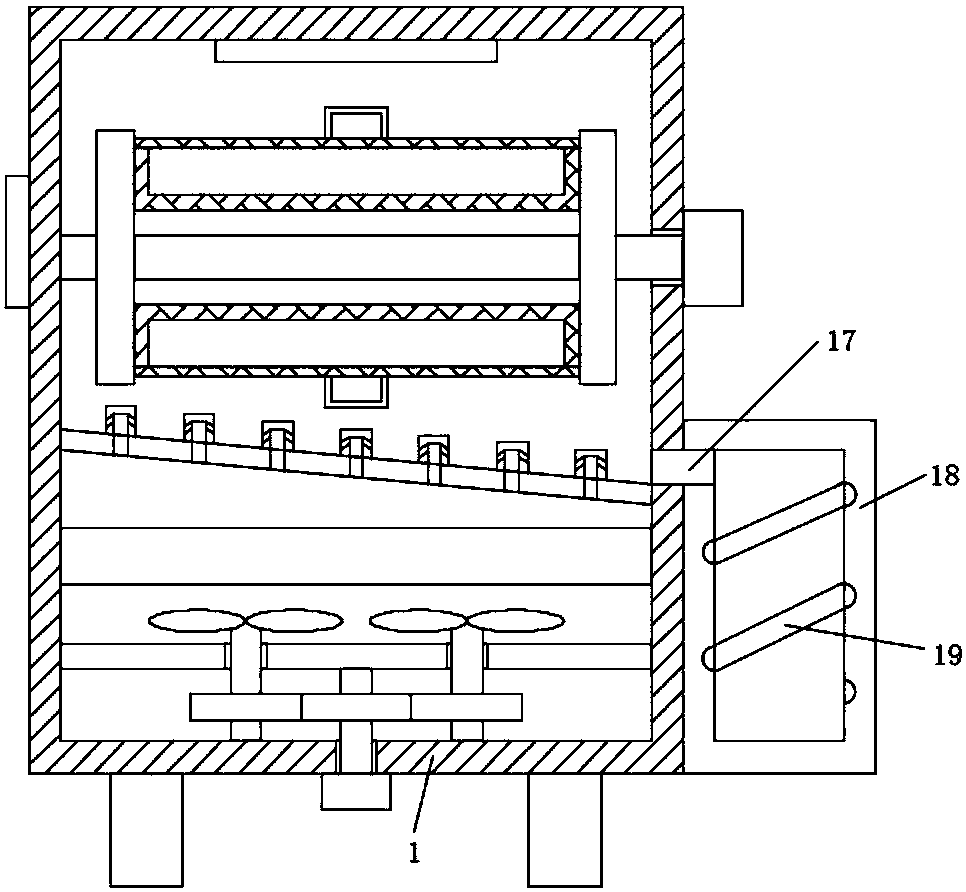

Drying device for medical apparatuses and instruments

InactiveCN108362093AAvoid damageImprove drying efficiencyDrying gas arrangementsDrying machines with non-progressive movementsElectric machineryEngineering

The invention discloses a drying device for medical apparatuses and instruments. The drying device comprises a drying oven, wherein a fixed plate which is horizontally arranged is fixedly arranged onthe bottom-end inner wall of the drying oven; a first motor is fixedly arranged on the bottom-end middle position of the drying oven; the output shaft of the first motor is connected with a first rotary shaft which is perpendicularly arranged; the top end of the first rotary shaft passes through the bottom-end outer wall of the drying oven and is rotatably connected on the fixed plate; rotary shafts which are perpendicularly arranged are rotatably connected on inner walls of the two sides of the bottom end of the drying oven; and a gear is arranged on each of the rotary rods and the first rotary shaft. The drying device can be used for drying instruments such as an operating knife in a mode of mutually combining air-drying and heating, and also can be used for collecting water drops generated during instrument drying, prevents the water drops from wetting a heating block to damage the heating block, is high in drying efficiency, further can turn over the instruments such as the operating knife, can effectively dry instruments such as the operating knives on different positions, prevents the instruments such as part of the operating knives from being dried unevenly as a result of along distance from a heat source, and is good in drying effect.

Owner:王华

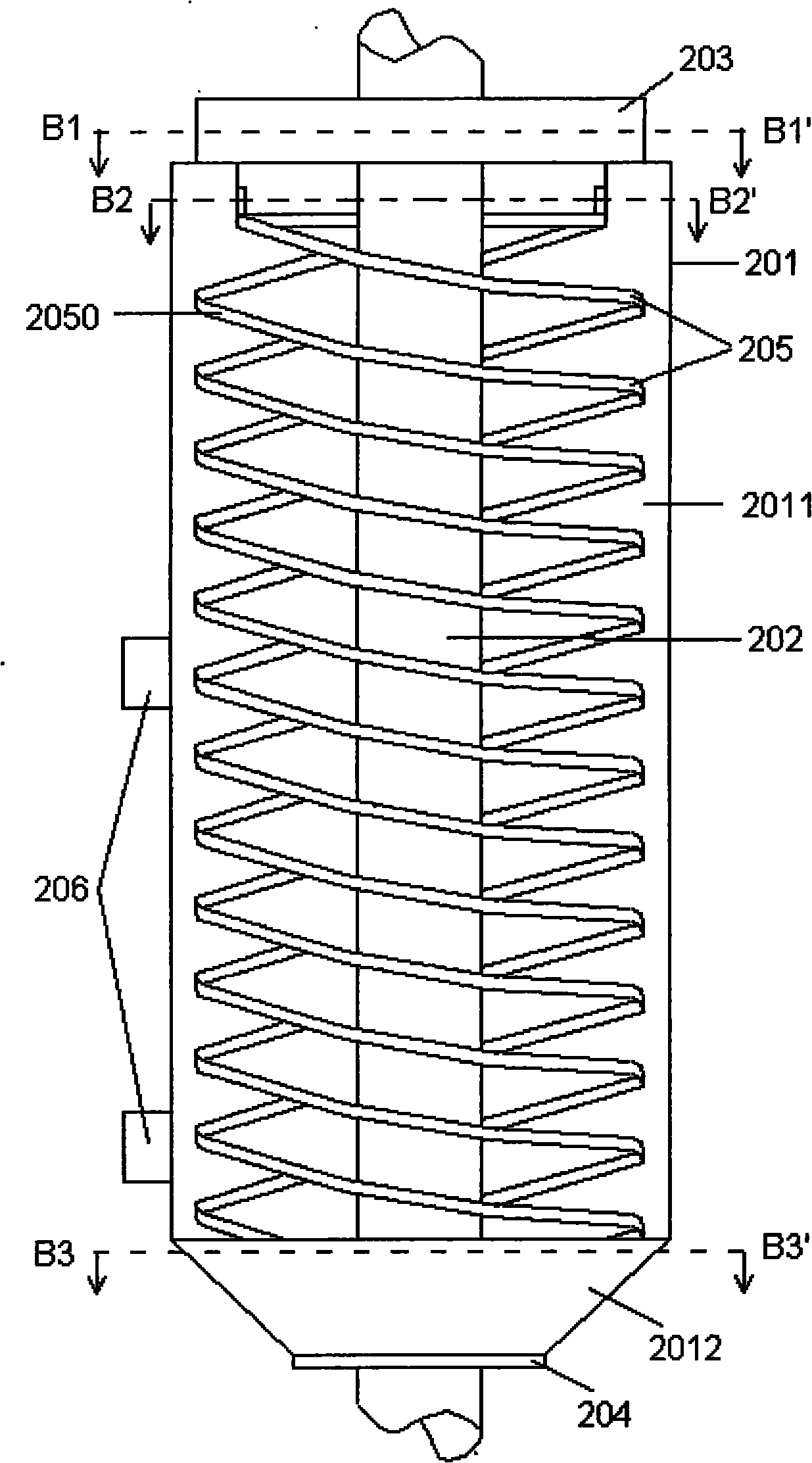

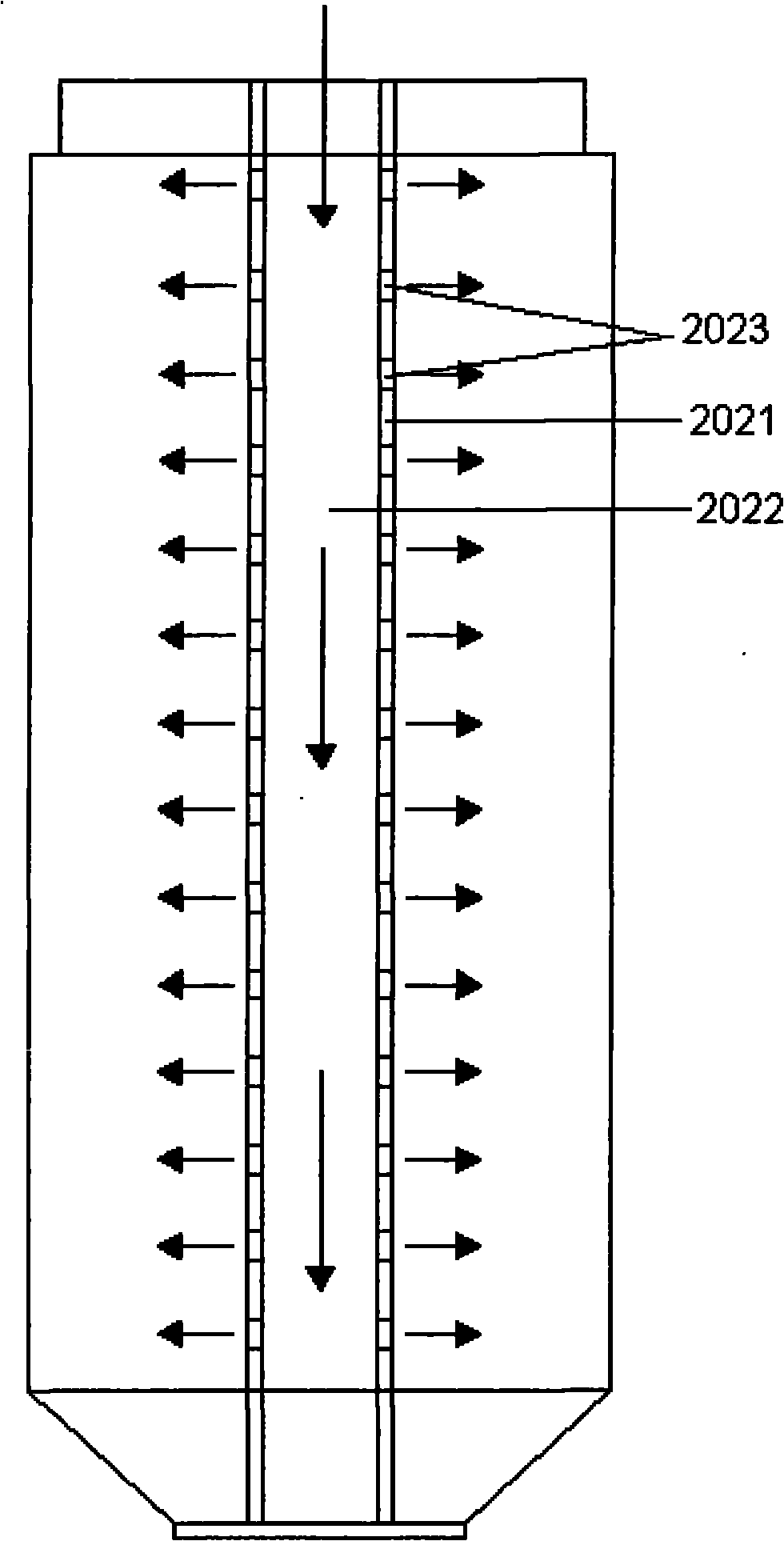

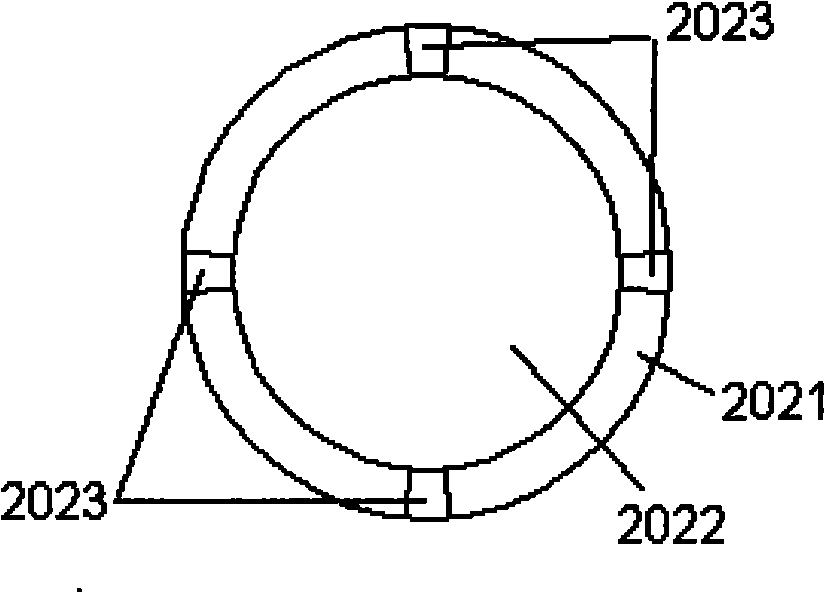

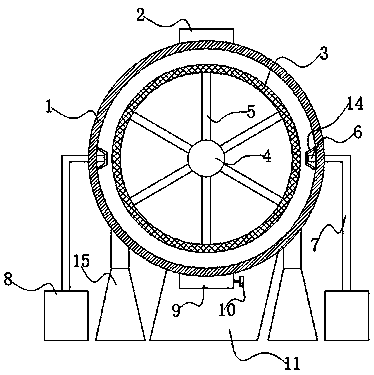

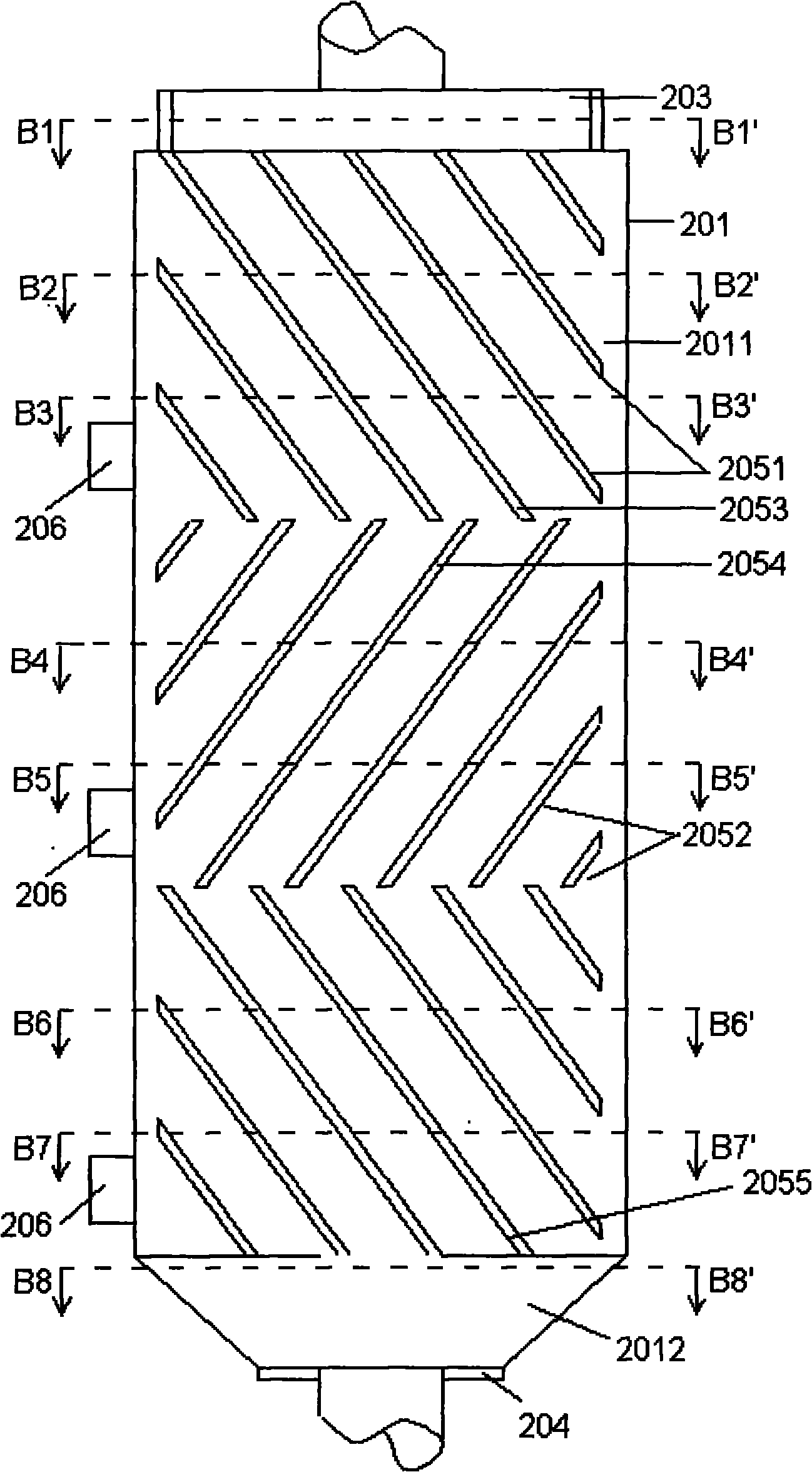

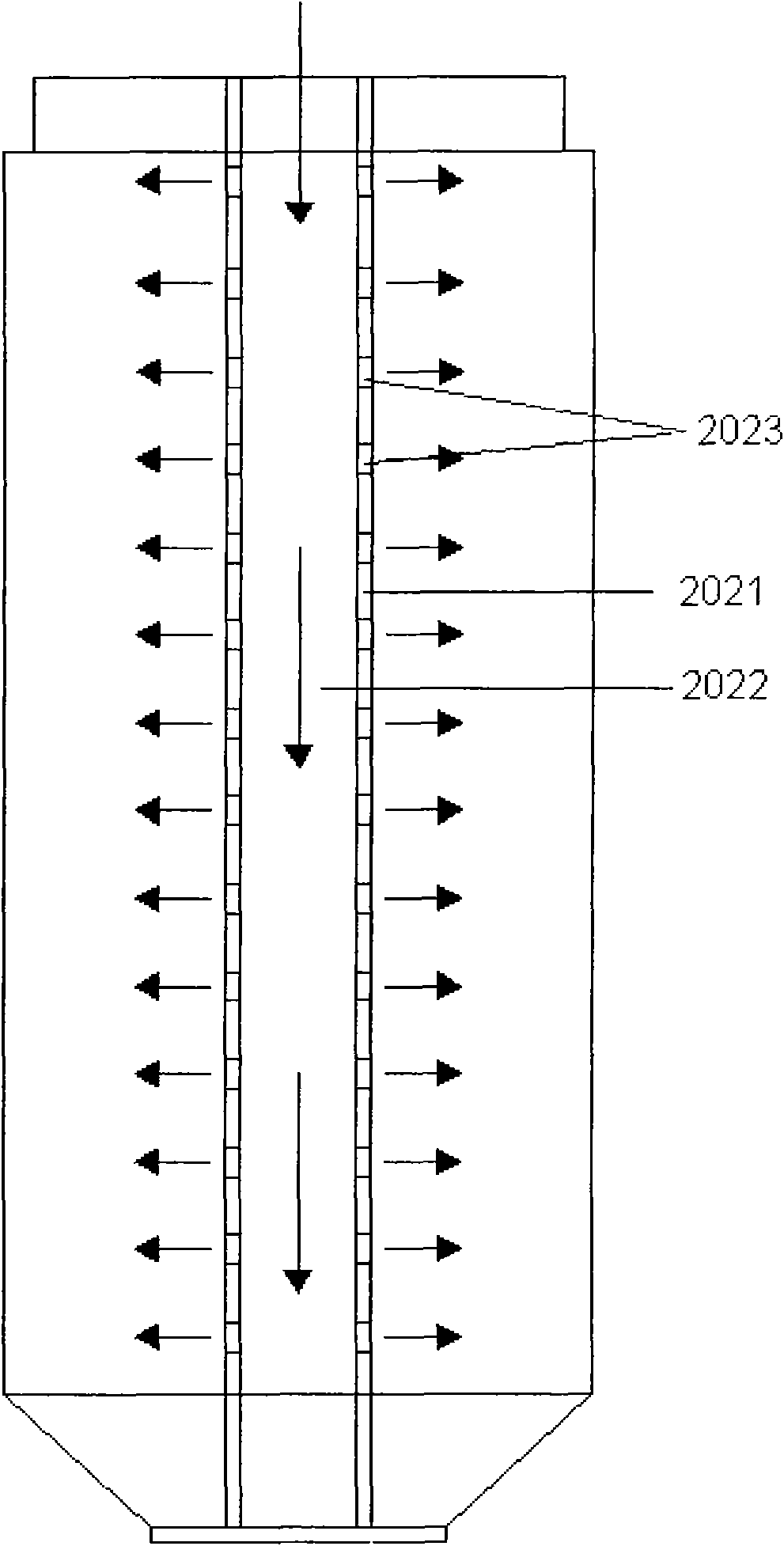

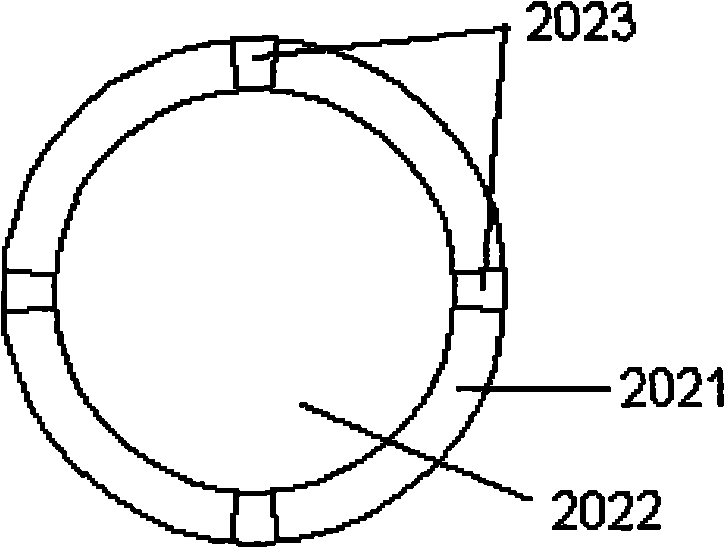

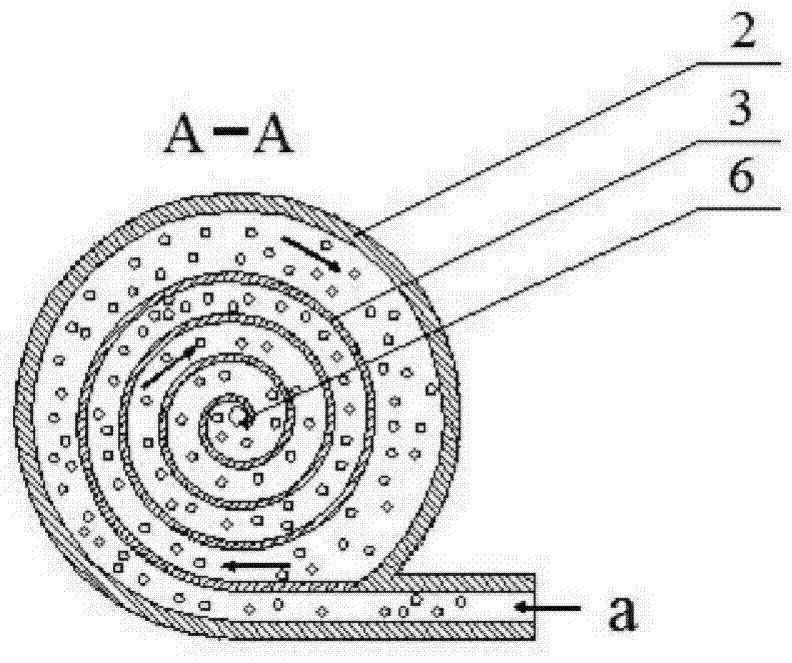

Drying tower with multi-helical structure and drying method

The invention discloses a drying tower with a multi-helical structure and a drying method thereof. The drying tower comprises a shell, a rotating shaft, a feed port, a discharge port, a helical material passage and a whirling wind generating device, wherein the rotating shaft is positioned in the centre of the shell and comprises a shaft shell, a shaft cavity enclosed by the shaft shell and a group of unidirectional holes arranged on the shaft shell; the helical material passage consists of a group of helical sliding ways which whirls around the rotating shaft and comprises 2 to 6 helical sliding ways; and the helical sliding way has a uniform-width band-like structure which whirls around the rotating shaft and comprises an inlet end, a helical structure and a material stopping structure.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

Cloth drying equipment for textile production

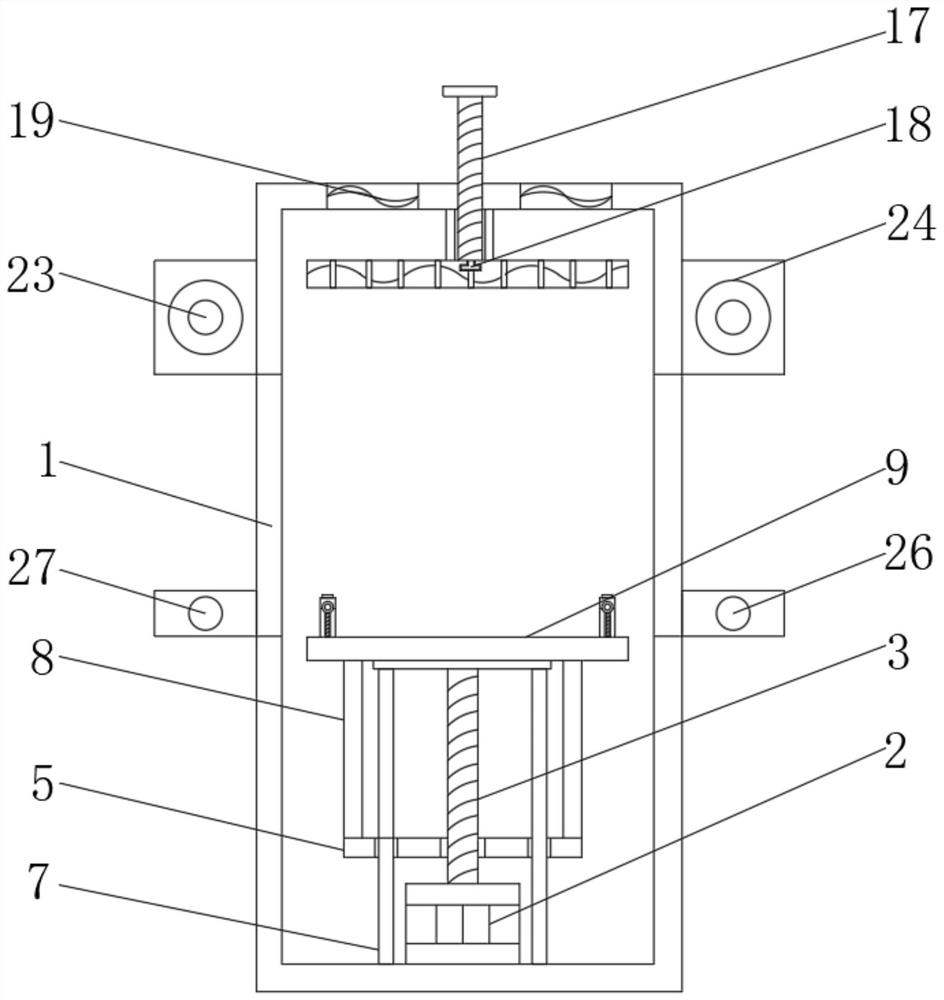

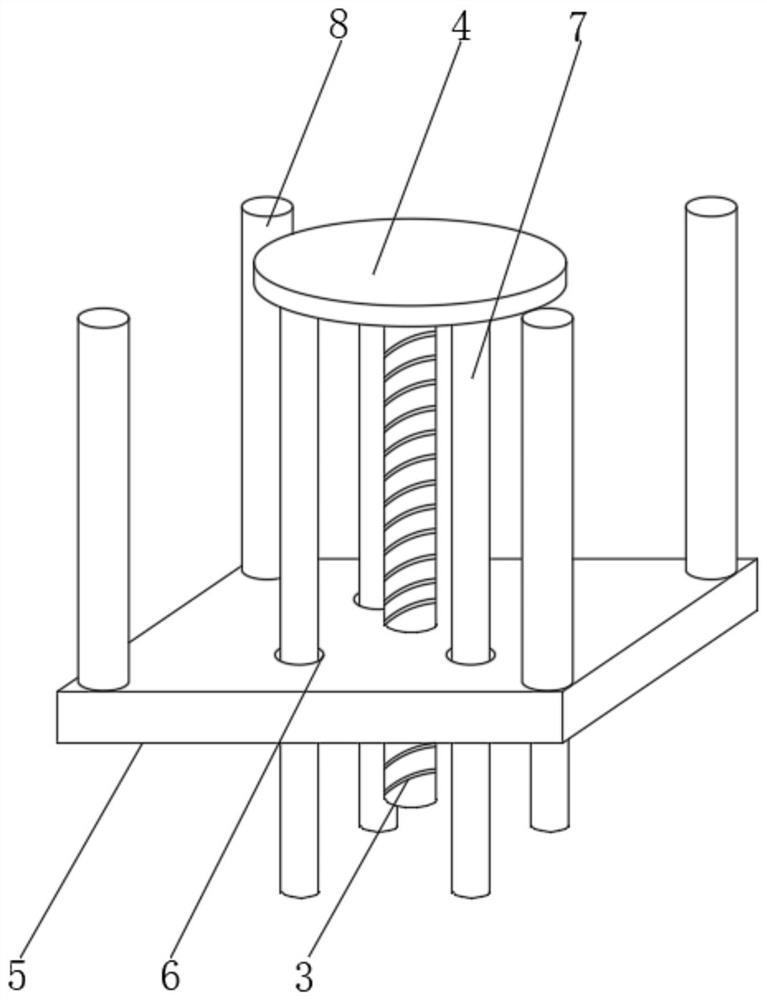

ActiveCN111623615AAdjust the wind speedGood adjustment functionDrying gas arrangementsDrying machines with progressive movementsAir velocityElectric machinery

The invention discloses cloth drying equipment for textile production. The cloth drying equipment comprises a main body; a lifting motor is fixedly mounted in the middle of the bottom end of the interior of the main body; a threaded shaft is mounted at the upper end of the lifting motor; a lifting plate is arranged on the outer side face of the threaded shaft in a sleeving manner; a limiting holeis formed in the upper end surface of the lifting plate in a penetrating manner; a limiting rod is fixedly mounted at the bottom end, close to the outer side of the lifting motor, of the interior of the main body; a baffle plate is fixedly mounted at the upper end of the limiting rod; a push rod is fixedly mounted on the upper end surface, close to the corner, of the lifting plate; a placing plateis fixedly mounted at the upper end of the push rod; and a heating plate is arranged right above the placing plate. The cloth drying equipment can avoid the situation that cloth is damaged or the drying time is long due to excessively high or low heat and air speed, has an excellent adjusting function, also can avoid the situation that drying is not uniform due to cloth deviation during the drying process and plays an excellent limiting role.

Owner:山东远腾环保设备有限公司

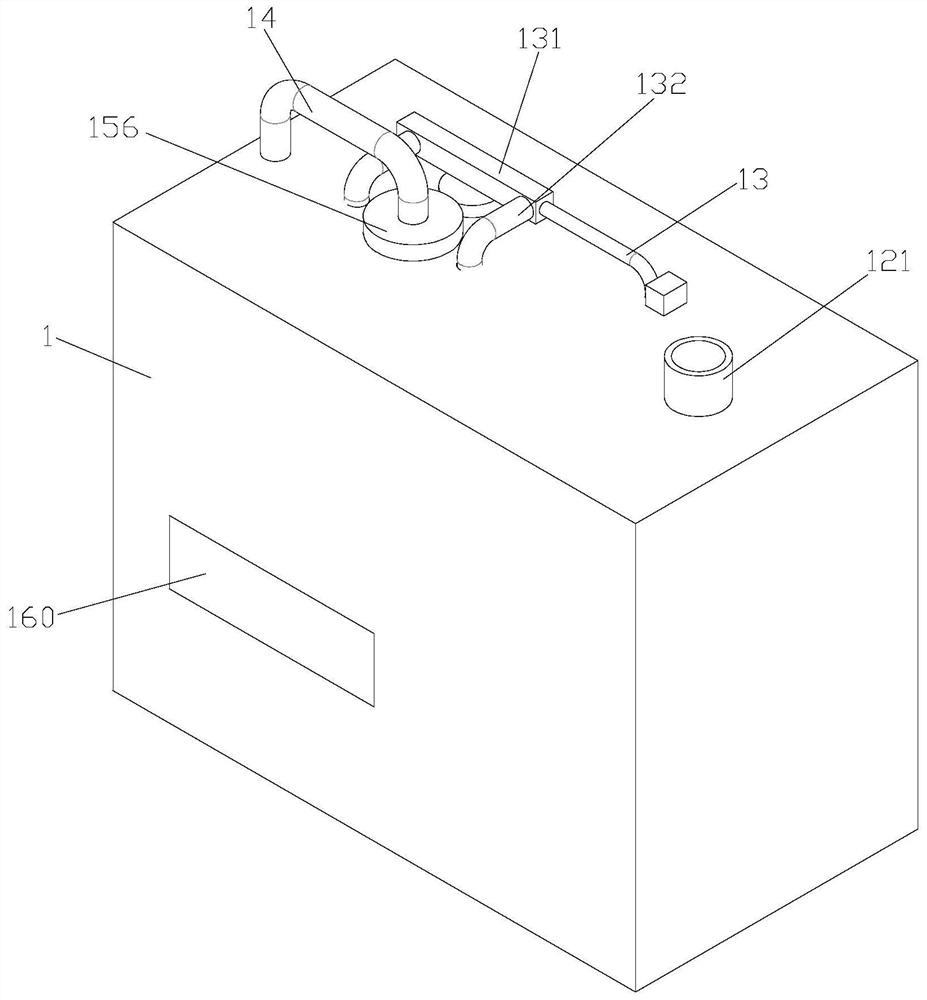

Drying equipment for production of polycarboxylate superplasticizer

ActiveCN111707068ALow boiling pointAvoid uneven dryingGranular material dryingEvaporator accessoriesDrive shaftSuperplasticizer

The invention discloses drying equipment for production of a polycarboxylate superplasticizer. The drying equipment comprises a box body. A first partition plate is arranged in the box body and partitions the box body into a drying cavity and a liquid storage cavity, a first conveying pipe is arranged in the liquid storage cavity in a penetrating mode, a first connecting block is arranged at one end of the conveying pipe, a first cavity communicating with the first conveying pipe is formed in the first connecting block, an atomizer is arranged in the first cavity, a second conveying pipe communicating with the drying cavity is arranged on the first connecting block, a loading frame is arranged at the bottom of the drying cavity and internally provided with a connecting frame, a bottom cloth is laid on the connecting frame, and a first push plate which can move up and down is arranged at the bottom of the drying cavity; and a transmission shaft is arranged in the drying cavity in a penetrating mode, a second cavity is formed in the transmission shaft, a plurality of first through holes are formed in the side wall of the second cavity, and a driving motor for driving the transmissionshaft to rotate is arranged at the top of the box body.

Owner:浙江汇翔新材料科技股份有限公司

Tea processing equipment

ActiveCN108826945AEasy to pass throughGood drying and water removal effectPre-extraction tea treatmentTea dryingAgricultural engineeringMoisture

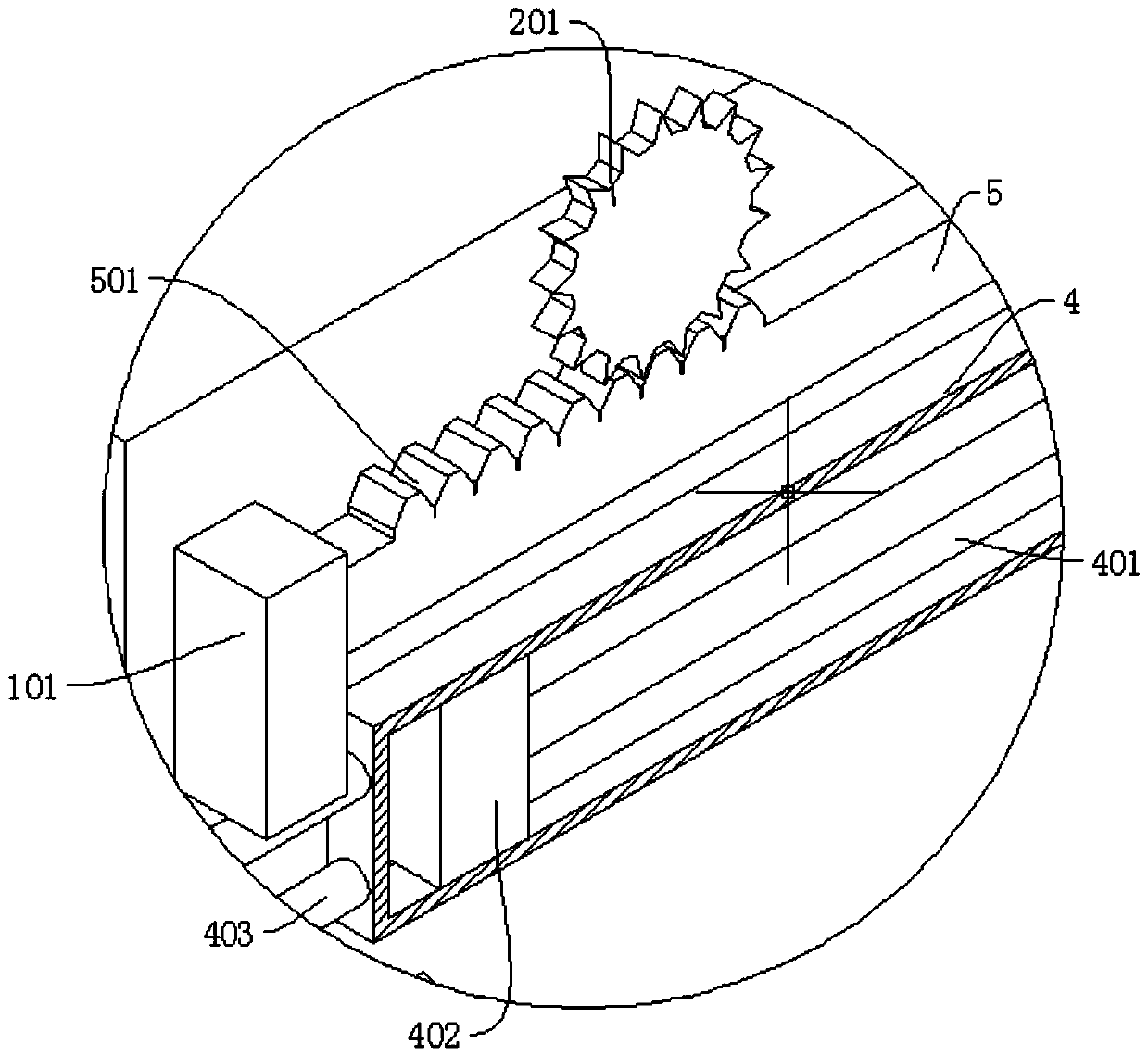

The invention relates to the field of tea processing, in particular to tea processing equipment. The tea processing equipment comprises a machine frame and a motor and further comprises a drying box slidably connected to the machine frame, and a rotary reciprocating mechanism which is rotationally connected to the machine frame and can drive the drying box to vertically move back and forth; the rotary reciprocating mechanism is driven by the motor; the bottom of the drying box is provided with a drying bearing mechanism, and the bottom of the interior of the drying box is obliquely provided with a bearing plate; a plurality of connection rods are vertically arranged on the bearing plate, an elastic tea stirring block is arranged between every two adjacent connection rods, the surface of each tea stirring block is provided with a magnet, and a plurality of drying holes are formed in each tea stirring block; and an air cavity is formed between the bearing plate and the bottom of the drying box, and the bearing plate and the bottom of the drying box are both provided with ventilation holes. According to the scheme, the mechanical structure and the magnets are in linkage fit to dry cleaned tea, uncertain factors occurring during natural drying are avoided, moisture in the tea is processed in time, the tea is not prone to going moldy and bad, and the quality of the tea is good.

Owner:FENGGANG XIUGU TEA CO LTD

Automatic household down jacket squeezing fast drying device

InactiveCN111411495AFully dryPrevent movementTextiles and paperLaundry driersStructural engineeringMechanical engineering

The invention relates to the technical field of clothes processing, and discloses an automatic household down jacket squeezing fast drying device. The automatic household down jacket squeezing fast drying device comprises a processing machine. A power track is movably connected into the processing machine. A reset spring is movably connected into the power track. A rotating table is movably connected into the processing machine. A squeezing track is movably connected into the processing machine. The lower side of the squeezing track is movably connected with a squeezing plate. The bottom of the inside of the processing machine is movably connected with water outlet tracks, and a pressure bin is movably connected between the two water outlet tracks. Air pressure inside the power track is increased to drive the rotating table to rotate through a T-shaped rod, down jackets can be dried completely, and therefore the cleaned down jackets can be squeezed automatically, and full drying can beachieved after water remaining inside the down jackets is squeezed out; and moreover, the down jackets can be roasted completely under the effect of the rotating table, and the phenomenon of drying unevenness is prevented.

Owner:义乌端服贸易有限公司

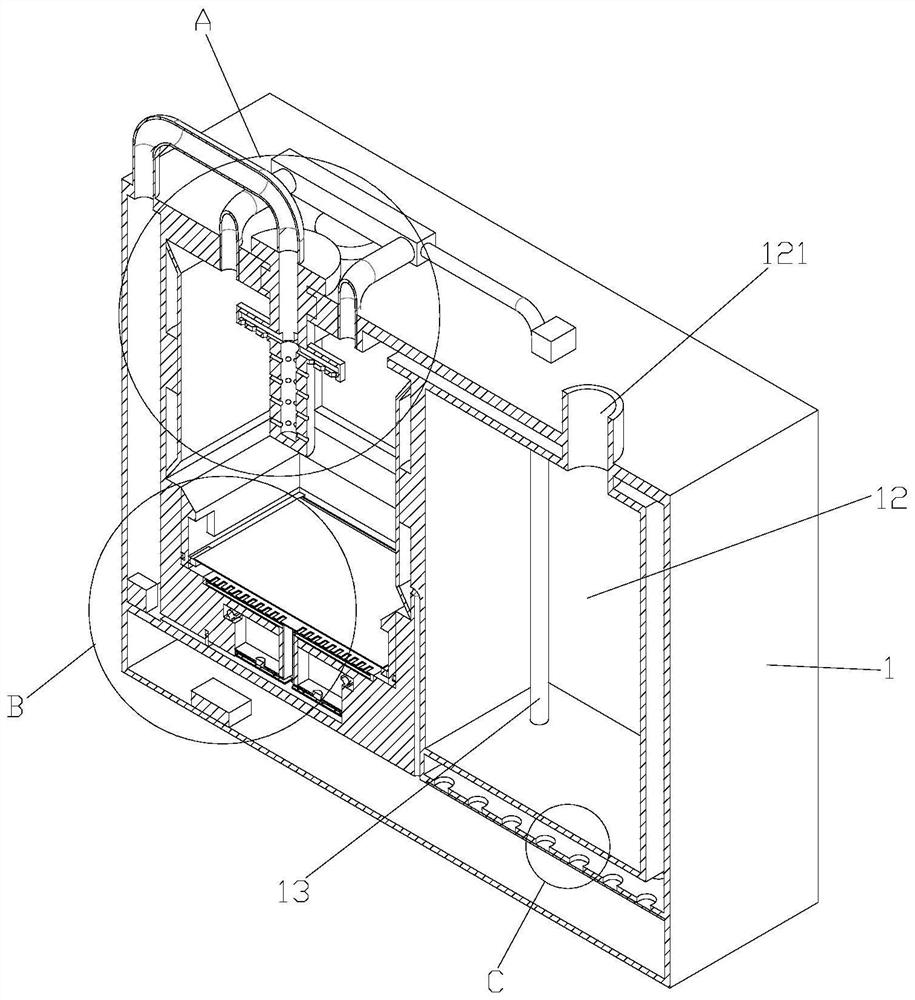

Air drying equipment for wig fibers

PendingCN110940171ADry fastEasy to storeDrying gas arrangementsDrying machines with progressive movementsFiberElectric machinery

The invention discloses air drying equipment for wig fibers. A wind box is included. The whole wind box is a cuboid cabinet body structure. An exhaust cavity is arranged in a top of a cabinet body. The exhaust cavity is connected with the outside world through an air exhaust pipe. Openings for hair to penetrate through are correspondingly arranged in two opposite side walls of the wind box. An airinlet pipe is arranged at a lower section of a side surface of the wind box. A hair dispersion component is arranged at a hair inlet of the wind box. The hair dispersion component comprises an installation frame, an extrusion roller component and a hair dispersion row. The extrusion roller component and the hair dispersion row are arranged on the installation frame. The extrusion roller componentis rotatably arranged on an outer side of the hair dispersion row, the extrusion roller component is used for extruding moisture in hair and comprises an upper extrusion roller and a lower extrusionroller, and a driving motor is installed at one end of the lower extrusion roller. The device is uniform in drying effect, the hair cannot be damaged, and operation efficiency can be effectively improved.

Owner:禹州市金博发制品有限公司

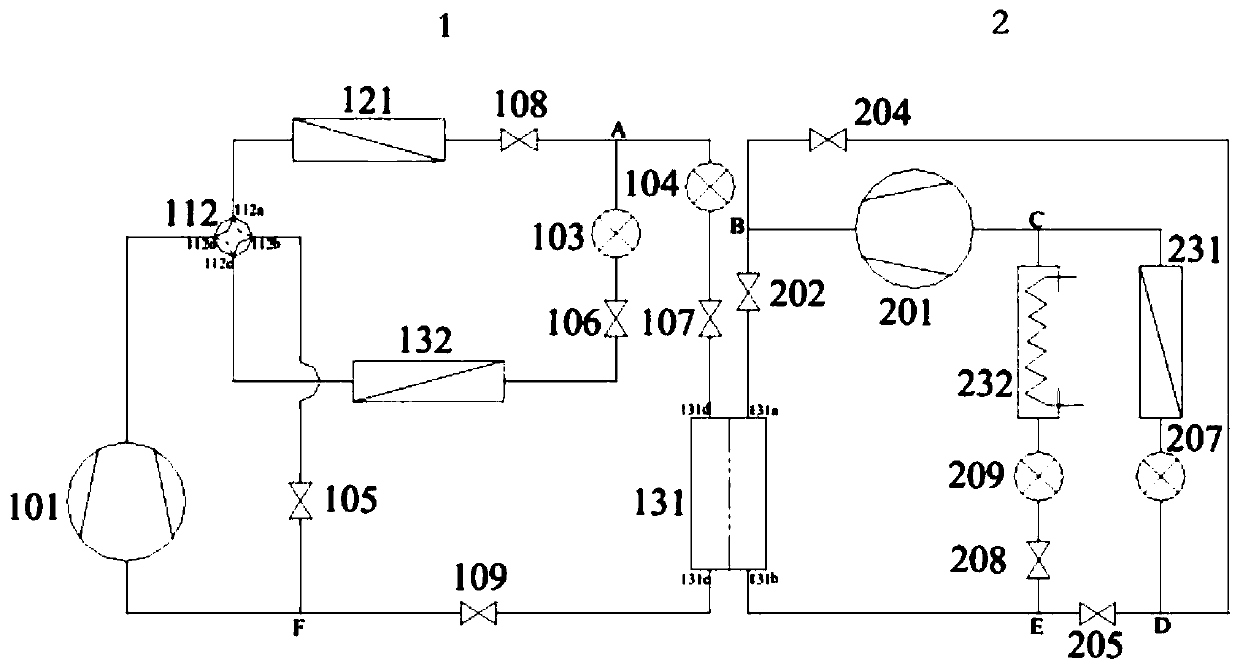

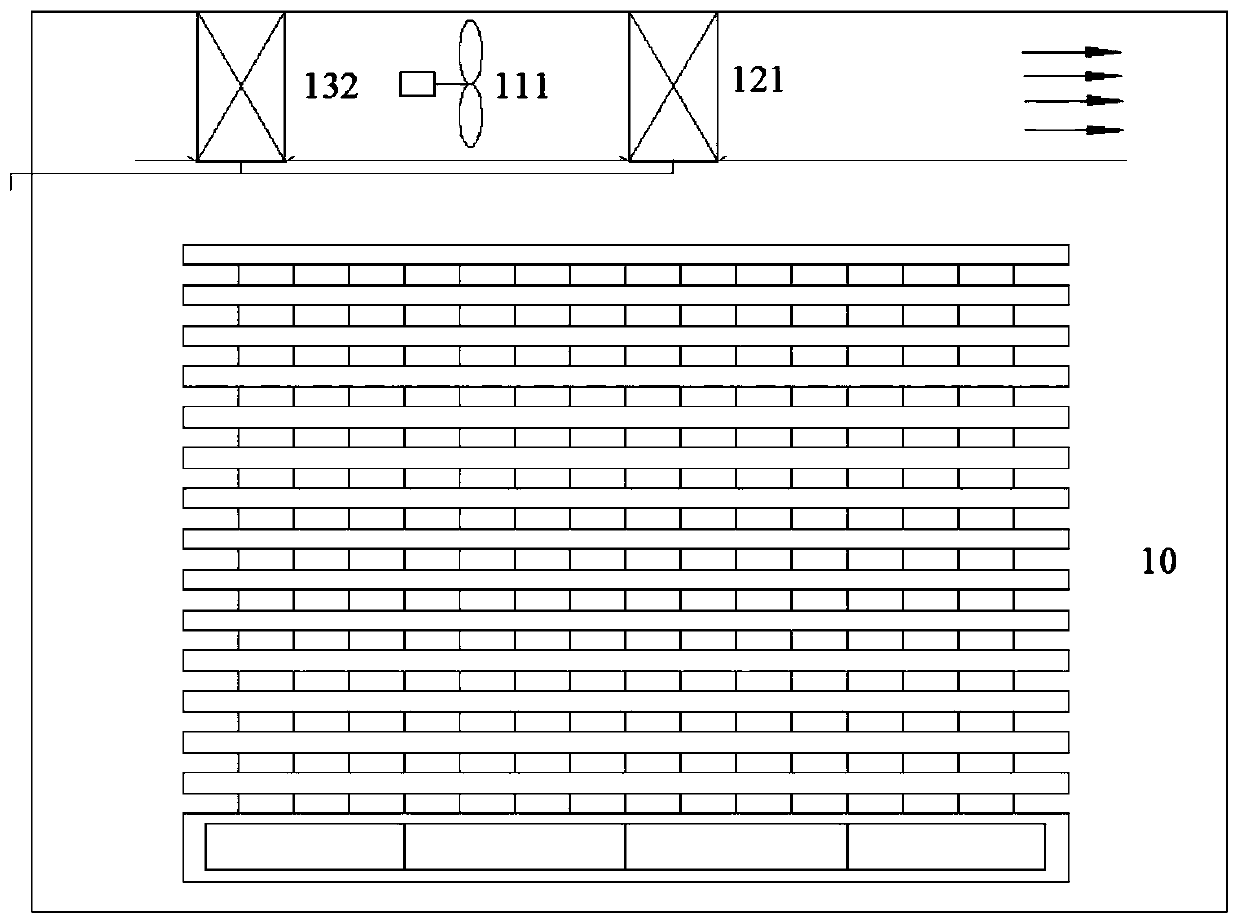

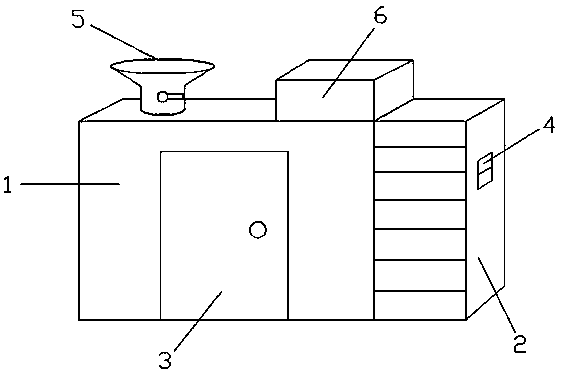

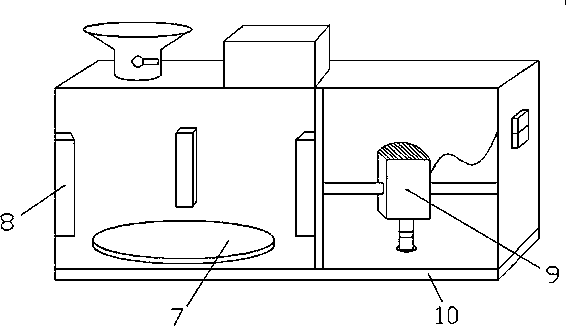

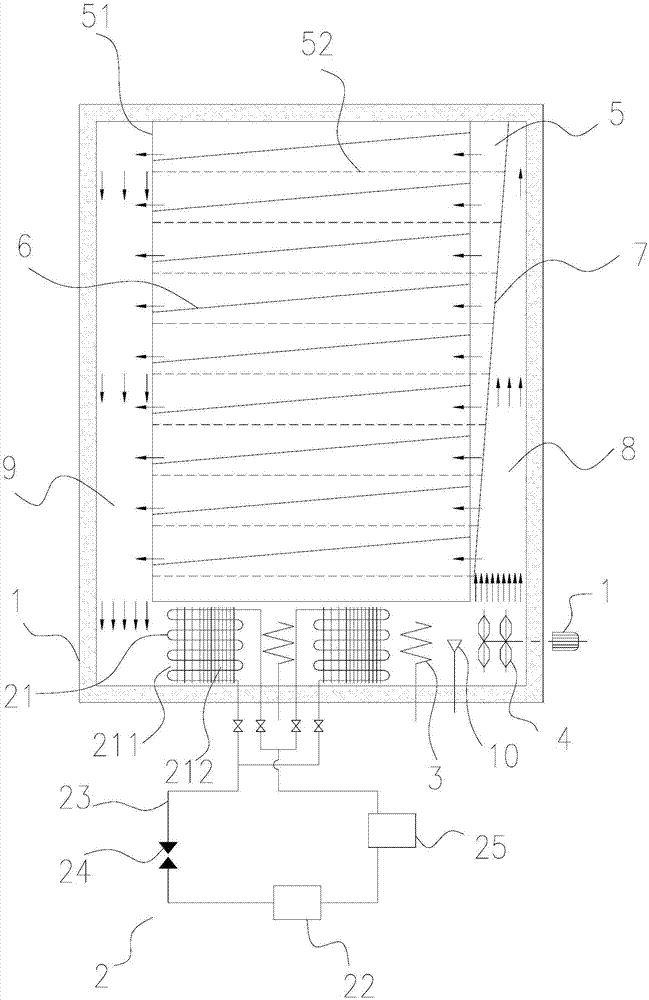

Refrigeration system with drying function, drying device and operation control method

PendingCN110207413AGuaranteed uptimeContinuous heatingMechanical apparatusDrying gas arrangementsFlueRefrigerant

The invention relates to a refrigeration system, in particular to a refrigeration system with a drying function, a drying device and an operation control method. Through switching between single-stageheat pump circulation and cascade heat pump circulation, as well as combination between the open heating mode and the closed dehumidification mode, efficient operation of the whole heat pump drying process is realized; an auxiliary heater meets the heat required for continuous heating in the defrosting process, the continuous heating process is ensured, and the problem that the heating process isslow due to defrosting is avoided; and the reversible circulation of the air supply mode is realized by changing the flowing direction of a refrigerant, and thus the phenomenon of non-uniform dryingcaused by complicated air flue design and unidirectional air supply is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

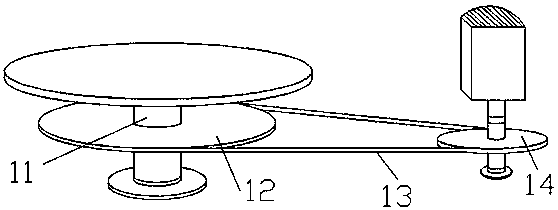

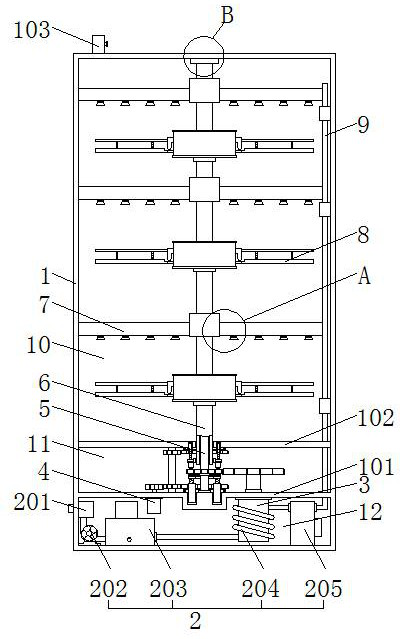

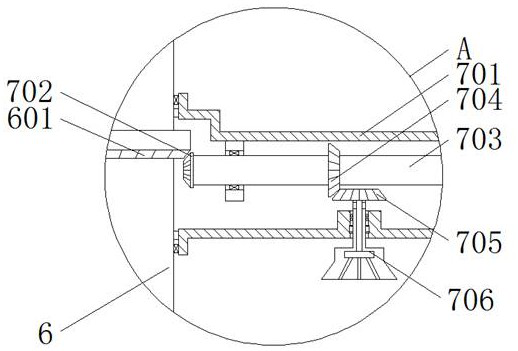

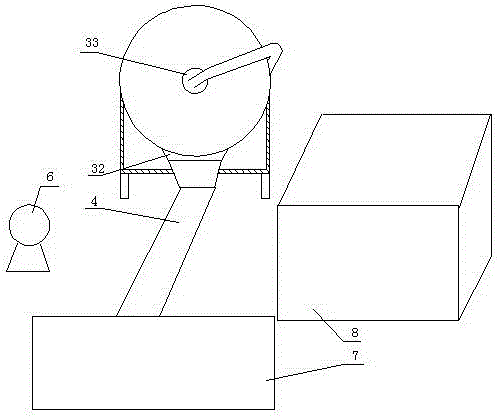

Novel bamboo drying device

InactiveCN107588630AAvoid uneven dryingImprove conduction efficiencyDrying gas arrangementsDrying machines with non-progressive movementsTemperature controlCold air

The invention discloses a novel bamboo drying device. The device is composed of a drying box and a power box, a door body is arranged outside the drying box, and a heat dissipation hole and a blower box are arranged on the top of the drying box; a blower is arranged in the blower box, and a rotary table and a laser heater are arranged in the drying box; a power switch is arranged on the outer portion of the lower box, a motor is arranged in the power box, and the motor is connected with a drive wheel in a baseplate through a bearing, and the drive wheel is connected with a driven wheel througha transmission belt; a connection column is arranged on the driven wheel, the driven wheel is fixedly connected with one end of the connection column, and the rotary table is fixedly connected with the other end of the connection column. Through a rotation heating mode, hot air in the drying box dries bamboo all around, and the situation of uneven drying is avoided. The novel bamboo drying deviceis high in laser heat conduction speed and free in temperature control, improves the conduction efficiency and shortens time. Through the arrangement of the blower and the heat dissipation hole, thenovel bamboo drying device has the function of reducing temperature and dissipating heat and avoids the situation that the high-temperature bamboo is in contact with cold air and accordingly the drying quality is influenced.

Owner:练淑荣

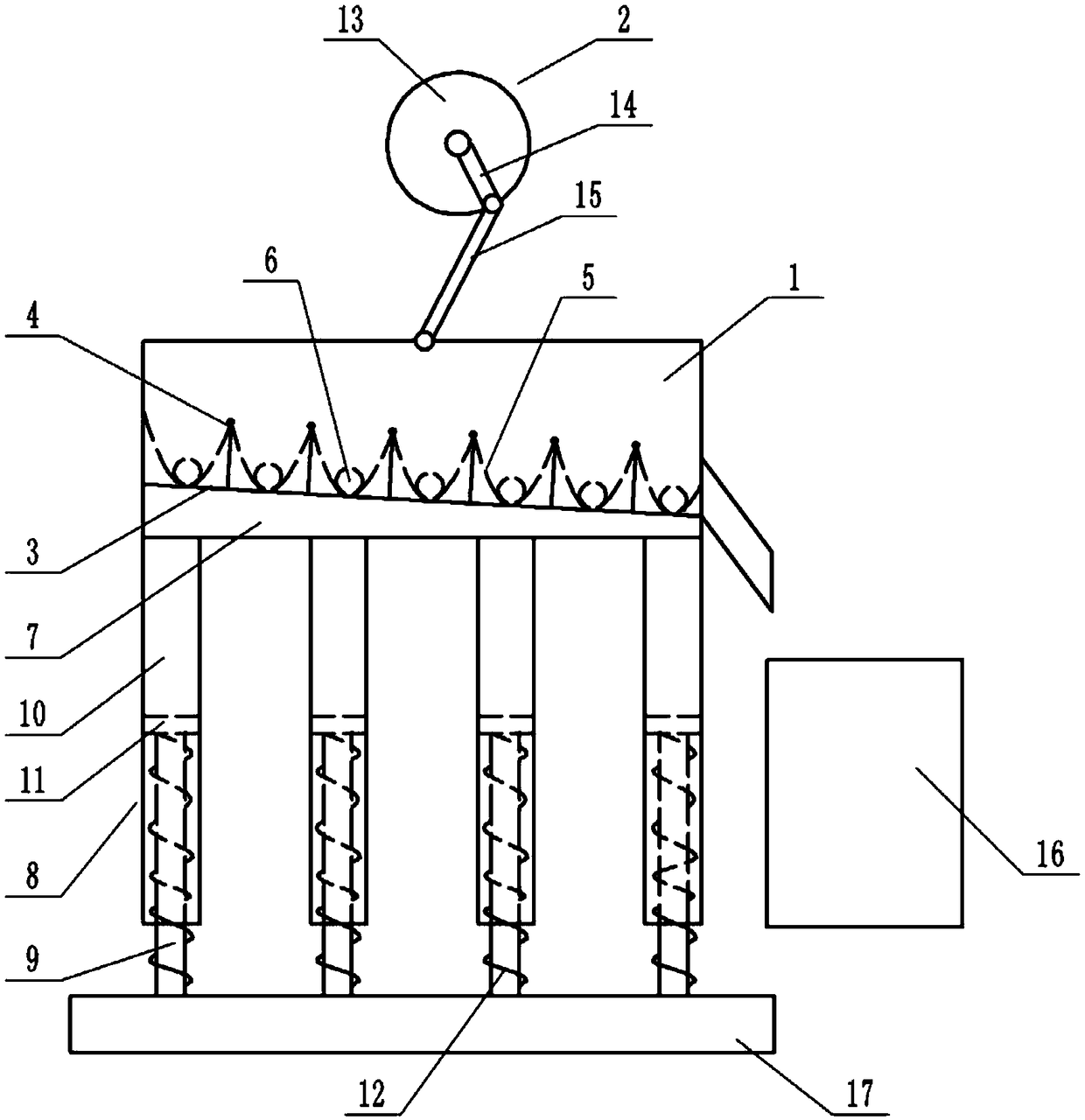

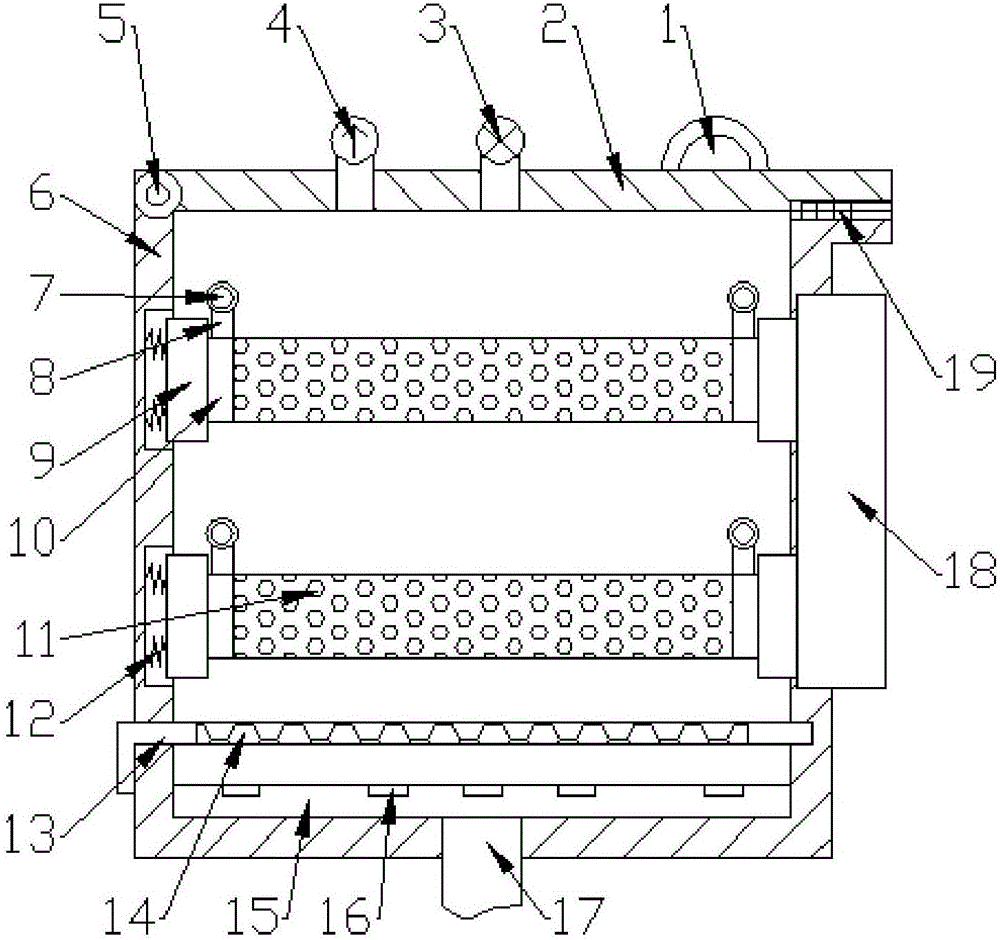

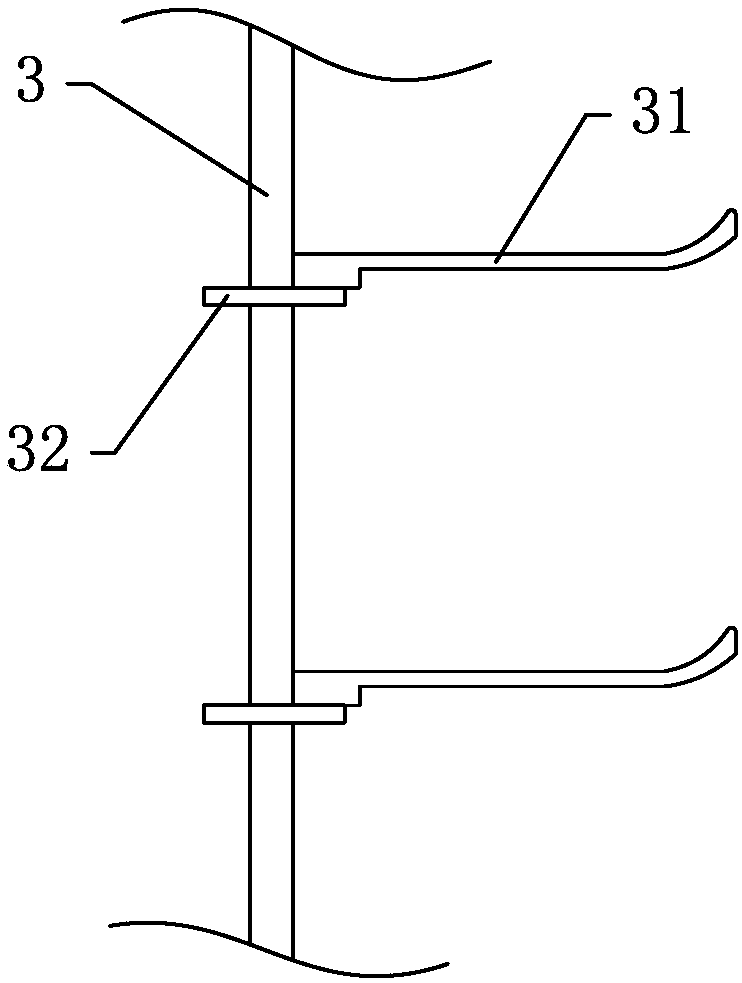

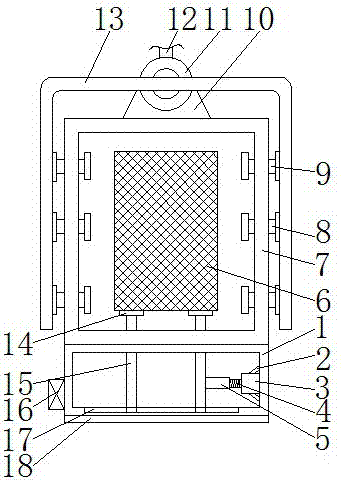

Vertical tealeaves vibration fixation apparatus

InactiveCN106819169AAvoid stickingImprove drying efficiencyPre-extraction tea treatmentEngineeringProduct gas

The invention provides a vertical vibration degreening device for tea leaves, which includes a drying box; the cross section of the drying box is rectangular, made of gray cast iron, and the top is provided with an upper cover; the upper cover is fixed on the drying box through hinges. On the box, and a hygrometer is provided on the top of the upper cover; the left end of the fixed block is fixed on the left inner wall of the drying box through a connecting spring, and its right end extends to the outside of the right side wall of the drying box to connect with the transmission box; The transmission box is installed on the outside of the right side wall of the drying box, and a pulley is arranged inside; the column is symmetrically arranged on the vibrating plate, and a pick-and-place ring is fixed on the top; The tea leaves are dried with high drying efficiency, which can effectively avoid the phenomenon of uneven drying; and the upper cover of the device is equipped with a thermometer and a hygrometer, which can monitor the situation inside the drying box in real time, so as to ensure the smooth progress of drying.

Owner:GUIZHOU KAIYANG NANGONGHE SE ENRICHED TEA

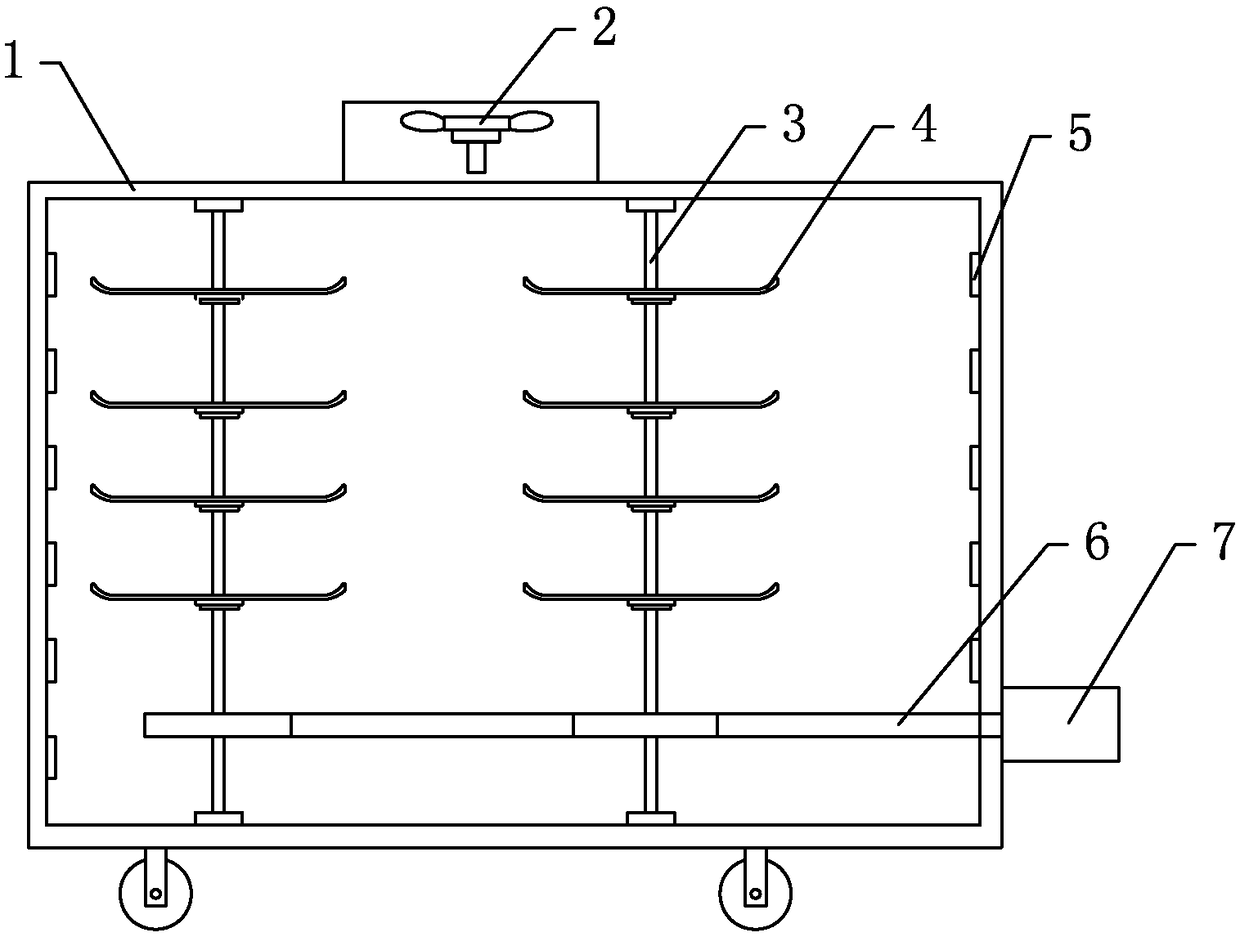

Drying equipment for agricultural and sideline products

ActiveCN113340085ADry evenlyEasy to fixFood processingDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention discloses drying equipment for agricultural and sideline products. The drying equipment is a drying machine for drying vegetables through dry hot air, wherein the drying machine comprises a main body; a vegetable drying chamber is arranged at the upper end of the interior of the main body; a driving chamber is arranged at the lower end of the vegetable drying chamber; a partition plate is arranged between the vegetable drying chamber and the driving chamber; an air drying chamber is arranged at the lower end of the driving chamber; a first mounting plate is arranged between the driving chamber and the air drying chamber; and an exhaust port is formed in the upper end of the main body. According to the drying equipment for the agricultural and sideline products, the air drying chamber and the vegetable drying chamber are arranged, the vegetables can be well fixed through the vegetable drying chamber, and meanwhile, the vegetables can be evenly dried, so that uneven drying of the vegetables is avoided.

Owner:ZHEJIANG ANJIJIAXIANG FOOD

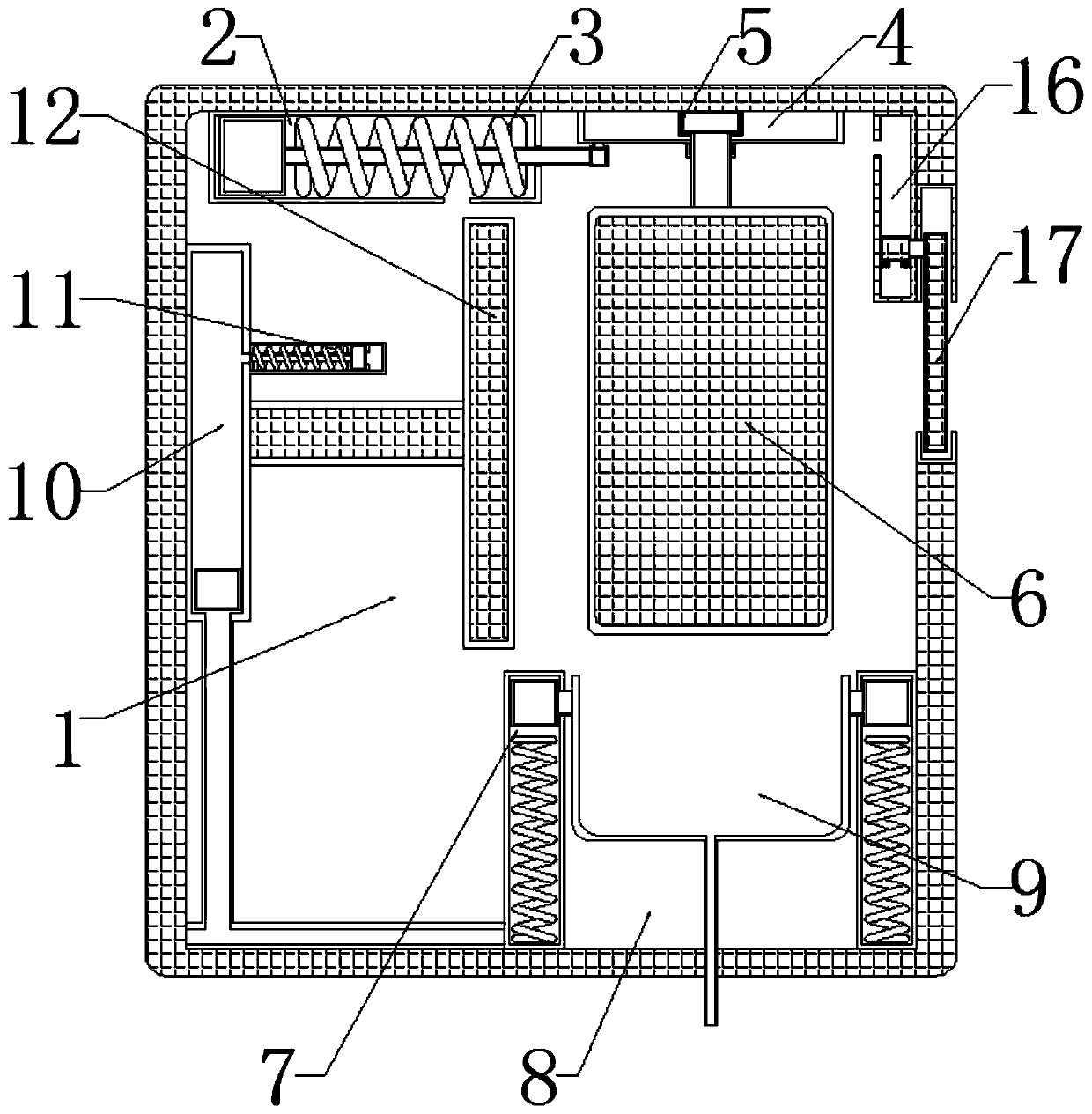

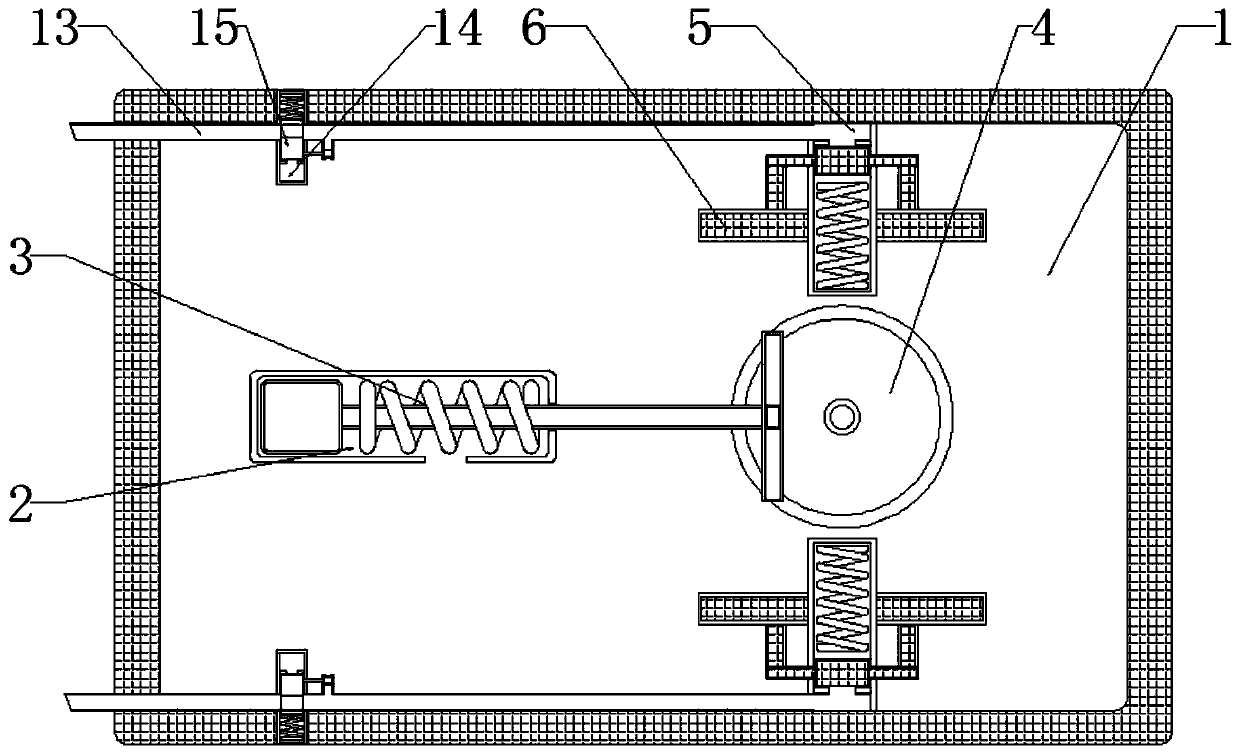

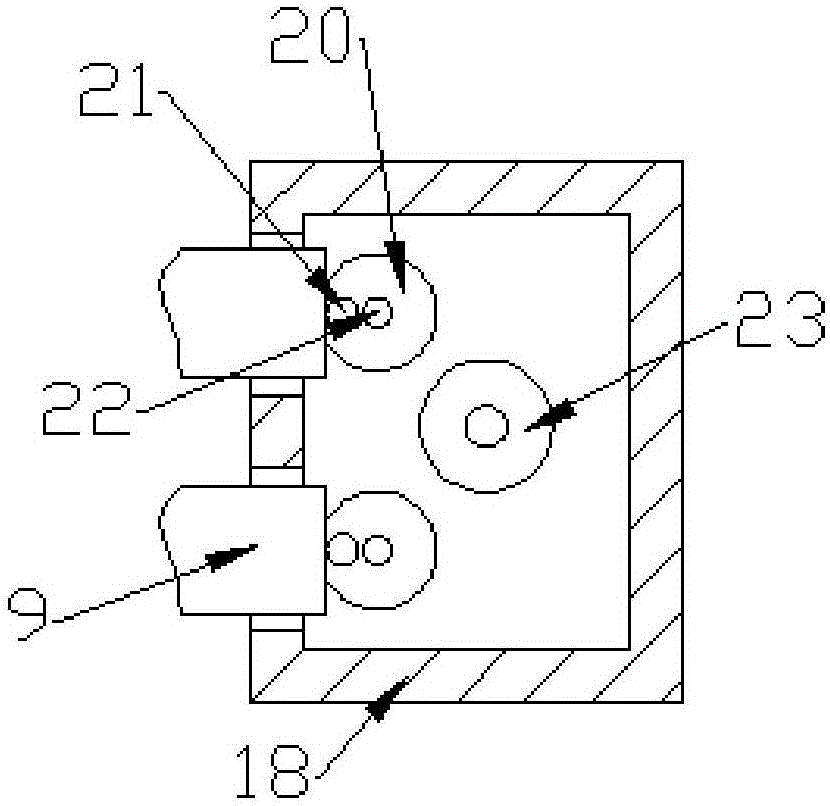

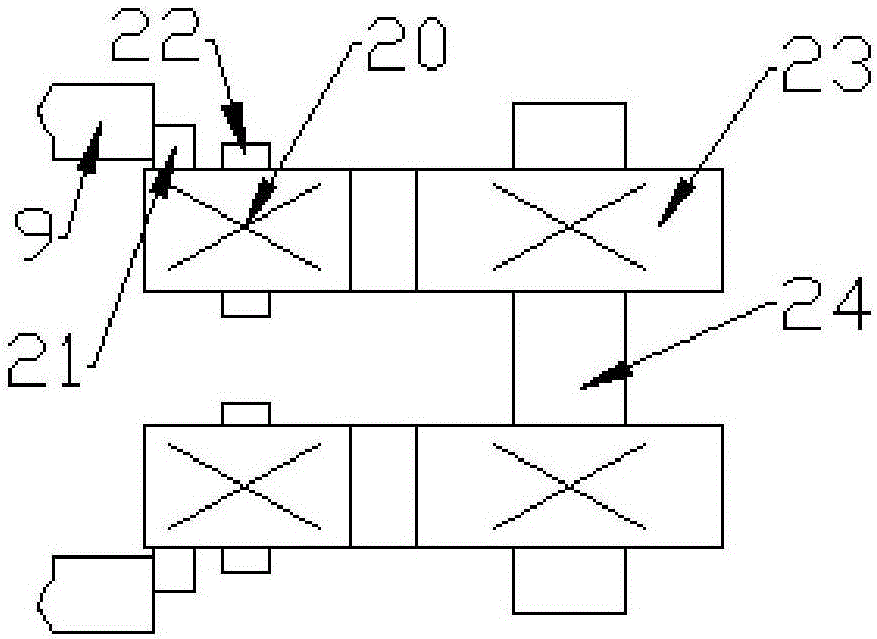

Mushroom drying equipment

InactiveCN108413747ADoes not dry poorlyEffective rotationDrying chambers/containersDrying machines with non-progressive movementsAutomatic controlMushroom

The invention provides mushroom drying equipment. The mushroom drying equipment comprises a box body; rotating shafts, material placing disks, a driving mechanism, a transmission structure and heatingstructures are arranged in the box body; the driving mechanism is connected with the rotating shafts through the transmission structure; the rotating shafts are vertically fixed to the interior of the box body; fixing steps and locating parts are arranged on the rotating shaft at intervals; the fixing steps are first magnetic pieces; the material placing disks comprise fixing rings and slots; themiddle parts of the fixing rings are in fit with the rotating shafts; the slots are connected with the locating parts in a clamping manner; the slots extend to the outer edges of the fixed rings andthe outer edges of the material placing disks; the widths of the slots are not less than the diameters of the rotating shafts; second magnetic pieces are arranged at the bottoms of the material placing disks; and polarities of upward faces of the first magnetic pieces and the second magnetic pieces are identical. The temperature in a drying oven can be automatically controlled, so that the poor drying effect of mushrooms due to too high or too low temperature is avoided; the mushrooms can be effectively rotated in the drying oven, so that nonuniform drying due to the fact the same part is heated for a long time is avoided; and the material placing disks are convenient to mount and dismount, so that the drying efficiency is improved.

Owner:衢州菁英科技有限公司

Blasting bead drying box

InactiveCN107449226AStable and dryFast dryingDrying gas arrangementsDrying machines with local agitationControl systemEngineering

The invention relates to a blasting bead drying box comprising a box body, a refrigerating device, a heating device, a draught fan and a control system. The box body is internally provided with an air channel and a containing space communicating with the air channel, and a baking disc for storing blasting beads is arranged in the containing space. The refrigerating device is provided with an evaporator and a condenser, the evaporator is arranged in the box body, and the condenser is arranged outside the box body. The heating device is arranged at the downstream of the evaporator in the direction of an air flow in the box body and used for heating air in the box body. The draught fan is configured to drive the air in the box body to flow along the air channel. The control system is used for controlling operation of the refrigerating device, the heating device and the draught fan. According to the blasting bead drying box, the constant-temperature and constant-humidity temperature can be provided, large wind power is provided to conduct air drying on the blasting beads, and the production efficiency and quality of the blasting beads are improved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Tea leaf dryer

InactiveCN107339857ADry evenlyAvoid uneven dryingDrying solid materials without heatTea dryingEngineeringAbsorbent cotton

The invention discloses a tea dryer, which comprises a box body, a feeding port is installed on the top of the box body, legs are installed at the four corners of the bottom of the box body, and a motor is installed inside the legs. A ventilation pipe is installed on the left side of the bottom end of the box body, a fan is installed on the left side of the ventilation pipe, a baffle plate is installed on the inner bottom end of the inlet, and a water absorbing plate is installed on the bottom of the baffle plate. Cotton, the inside of the box is equipped with a second rotating rod. In this tea drying machine, when the tea enters from the feeding port, it is squeezed by the spiral plate once, and a small amount of water is filtered out, and then it is dropped into the charging tank for drying. There is a stirring plate on the top of the charging tank, and the fan blows air from the bottom To dry the tea leaves, when the motor is connected to the external power supply, the dryer starts to operate, and the stirring plate keeps stirring the tea leaves to prevent uneven drying, so that the tea leaves can be fully dried. The slot allows easy removal of dried tea leaves.

Owner:郝彦明

Windproof multi-angle rotary tea leaf airing rack

PendingCN112244105AImprove the effectAvoid uneven dryingPre-extraction tea treatmentEngineeringTea leaf

The invention relates to the technical field of tea leaf processing, in particular to a windproof multi-angle rotary tea leaf airing rack. The problems that existing manual tea leaf airing is uneven,and the requirement that tea leaves are not blown away during wind blowing cannot be met are solved. The windproof multi-angle rotating tea leaf airing rack provided by the invention comprises a supporting base and the like. An airing rotating mechanism is connected to the supporting base in a sliding mode, and a swing airing mechanism is mounted above the supporting base and the airing rotating mechanism. Through cooperation of the airing rotating mechanism and the swing airing mechanism, tea leaves placed in a loading frame can be irradiated by sunlight at multiple angles.

Owner:陈奕伦

Drying furnace for household garbage and drying method

InactiveCN105823056AReduce moisture contentAchieve reductionDrying gas arrangementsIncinerator apparatusLitterResource utilization

The invention discloses a drying furnace for household garbage and a drying method. The drying method includes the following steps that firstly, the household garbage is preprocessed so that loose and uniform to-be-processed garbage can be obtained; secondly, the to-be-processed garbage is placed in the drying furnace to be dried, the drying temperature is 100 DEG C to 140 DEG C, the machine speed is 15 r / min to 20 r / min, the drying time is 3 min to 8 min, and the to-be-processed garbage is blown into a suspended state in the drying process; and thirdly, air separation is performed, wherein the dried garbage is subjected to air separation so that small-specific-gravity garbage and large-specific-gravity garbage can be obtained, and the small-specific-gravity garbage and the large-specific-gravity garbage are packaged and subjected to resource utilization. The drying furnace for the household garbage is further included in the invention. By means of the drying furnace for the household garbage and the drying method, firstly, secondary pollution in the processing process can be effectively eliminated; secondly, the processing cost can be greatly reduced, the processing efficiency is improved, and reduction, reclamation and harmlessness of the household garbage are efficiently and fast achieved.

Owner:龚亚强 +1

Quick-drying equipment for production and processing of bleached and dyed knitwear

InactiveCN109186225AQuick installationPlacement Condition AdjustmentDrying gas arrangementsDrying machines with progressive movementsWater vaporFixed frame

The invention discloses quick-drying equipment for the production and processing of bleached and dyed knitwear. The quick-drying equipment comprises a base and an air homogenizing member, wherein theinner lower end of the base is fixedly provided with a storage frame; an operation table is welded to the upper end surface of the base; both sides of the operation table are provided with winding rollers; the surfaces of the winding rollers are fixedly provided with a cloth roll; the front and rear sides of the operation table are fixedly provided with first fixing frames; the first fixing framesare internally provided with electric lifting rods; the upper end surfaces of the electric lifting rods are fixedly provided with second fixing frames; the air homogenizing member is connected with acovering member through an air hose group; the surface of the air homogenizing member is provided with an air hole group; and the inner lower end of the operation table is provided with a reserved cavity. According to the quick-drying equipment for the production and processing of the bleached and dyed knitwear, a fan heater and an electric heating roller heat cloth, then the water vapor is blownoff through a fan on the upper end, and finally the water vapor is sucked out of the equipment through a suction fan, so that quick air-exchange and drying for the cloth are achieved.

Owner:嘉兴福星智能针织装备制造有限公司

Efficient drying device for rice seeds

InactiveCN109282598AReduce moisture contentSimple structureDrying gas arrangementsDrying chambers/containersReducerPulp and paper industry

The invention discloses an efficient drying device for rice seeds. A feeding port is in fixed welded connection with the top end of a drying cylinder body, a disturbance cylinder body is arranged inside the drying cylinder body, the disturbance cylinder body is connected with a central rotating shaft through six connecting rods which are evenly distributed at equal angles, the shaft end of one side of the central rotating shaft is rotationally installed on the side surface wall of the drying cylinder body, the shaft end of the other side of the central rotating shaft is connected with a driving mechanism, the driving mechanism comprises a disturbance motor which is connected with the central rotating shaft through a speed reducer, a plurality of mounting through holes are formed in the edge walls of the two sides of the drying cylinder body, a plurality of hot air nozzles are fixedly installed in the plurality of mounting through holes, one ends, penetrating through the outer wall of the drying cylinder body, of the hot air nozzles are connected with one ends of air pipes, the other ends of the air pipes are connected with hot air source devices, and a discharging opening is fixedly installed on the bottom surface of the drying cylinder body. By the adoption of the technical scheme, the device has the advantages that the structure is simple, assembling and mounting are convenient, the moisture content of the rice seeds can be effectively reduced, and the drying efficiency is high.

Owner:舒城县文禾家庭农场

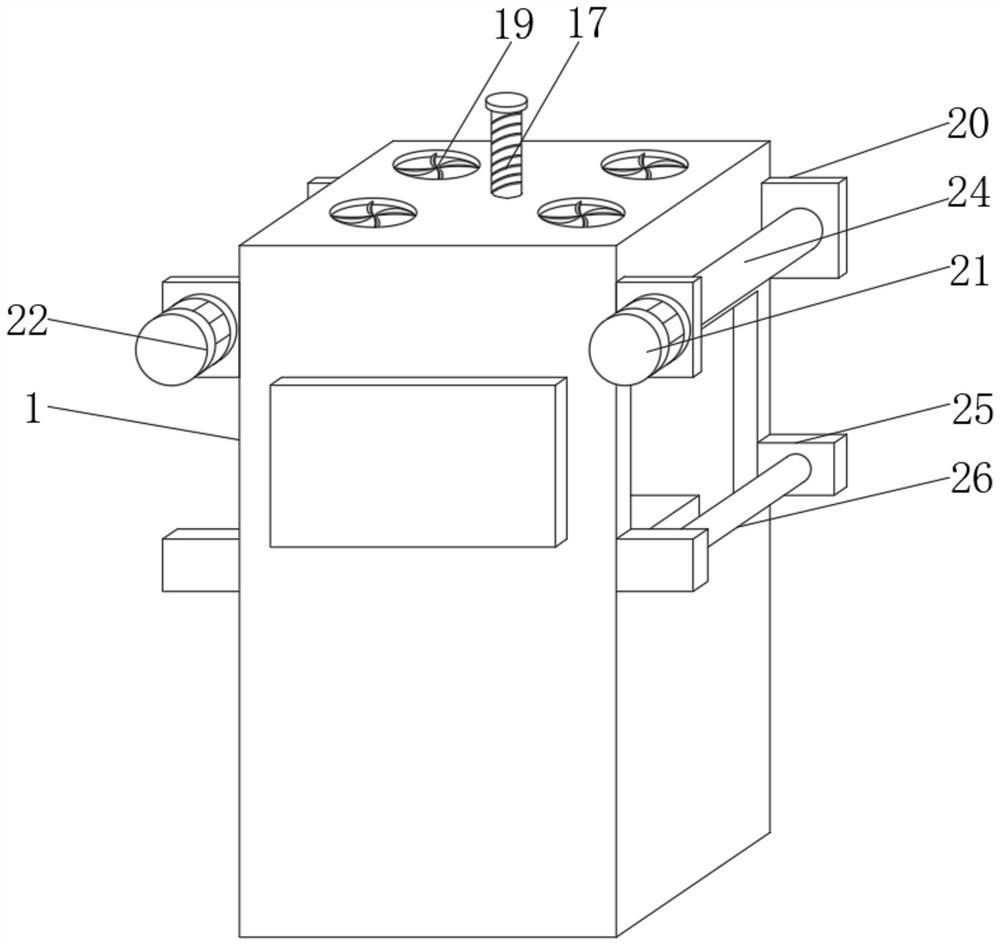

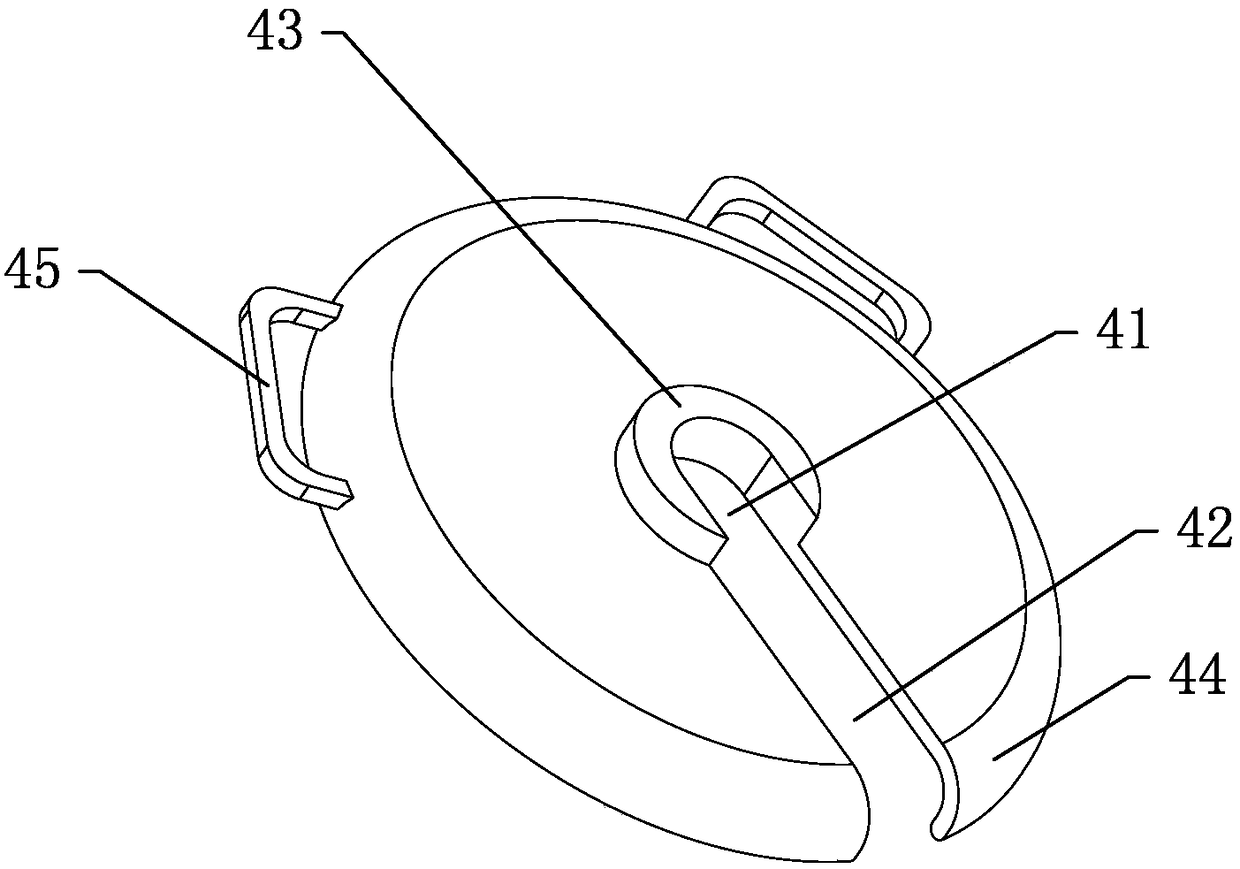

Drying tower with positive-negative shunt structures and drying method thereof

InactiveCN101779767AAvoid particle stickingAvoid uneven dryingFood preparationAxon structureEngineering

The invention discloses a drying tower with positive-negative shunt structures and a drying method thereof. The drying tower comprises a shell, a rotary shaft, a feed port, a discharge port, a shunt material channel and a rotational wind generation device, wherein the rotary shaft is arranged in the center of the shell and is provided with a shaft shell, a shaft cavity encircled by the shaft shell and a group of one-way holes arranged on the shaft shell; the shunt material channel is formed by a group of shunt structures which rotate around the rotary shaft serving as the shaft center, and the shunt structures are divided into the positive shunt structures and the negative shunt structures, which are alternately arranged; and the shunt structures are formed by a group of shunt gates comprising 4 to 32 shunt gates, and each shunt gate is an axon structure taking the rotary shaft as the shaft center and extending outward along the radial direction of the axon structure.

Owner:SHANGHAI YI CHEN INFORMATION TECH DEV

Novel agricultural product drying equipment

InactiveCN112556359AEasy dischargeAvoid residueDrying chambers/containersDrying machines with non-progressive movementsGear wheelAgricultural engineering

The invention discloses novel agricultural product drying equipment. The novel agricultural product drying equipment comprises an equipment body, a first rotating shaft and a drying box, the inner bottom end of the equipment body is rotationally connected with the first rotating shaft, the drying box is arranged at the upper end of the first rotating shaft, a plurality of stirring blades are arranged in the drying box, a plurality of heating blocks are arranged in the stirring blades and the drying box, and a second rotating shaft is arranged on the stirring blades. When the novel agriculturalproduct drying equipment is used, agricultural products are poured into the drying box from a feeding port, the heating blocks carry out drying on the agricultural products, a motor drives a third rotating shaft, a gear, a rack and the drying box to rotate, meanwhile the third rotating shaft drives a movable sleeve to rotate, the movable sleeve drives the second rotating shaft and the stirring blades to rotate through a first belt wheel assembly, a reciprocating screw rod is driven to rotate under the action of a second belt wheel assembly, the reciprocating screw rod drives a lifting plate,the second rotating shaft, the stirring blades and the movable sleeve to move up and down, and then the agricultural products are stirred, so that uneven drying is avoided, the drying quality and efficiency of the agricultural product are improved, time and labor are saved, and manpower is saved.

Owner:JISHOU UNIVERSITY

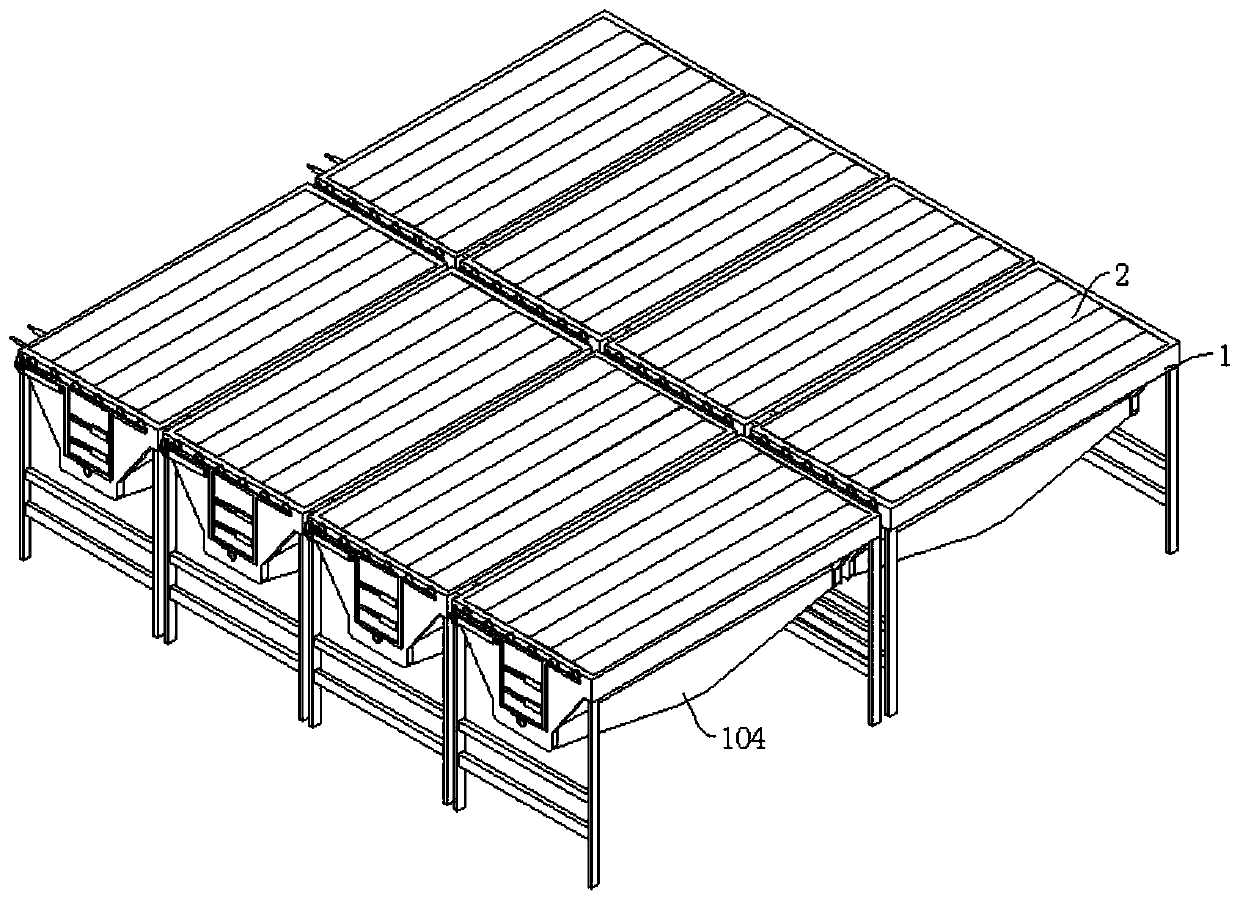

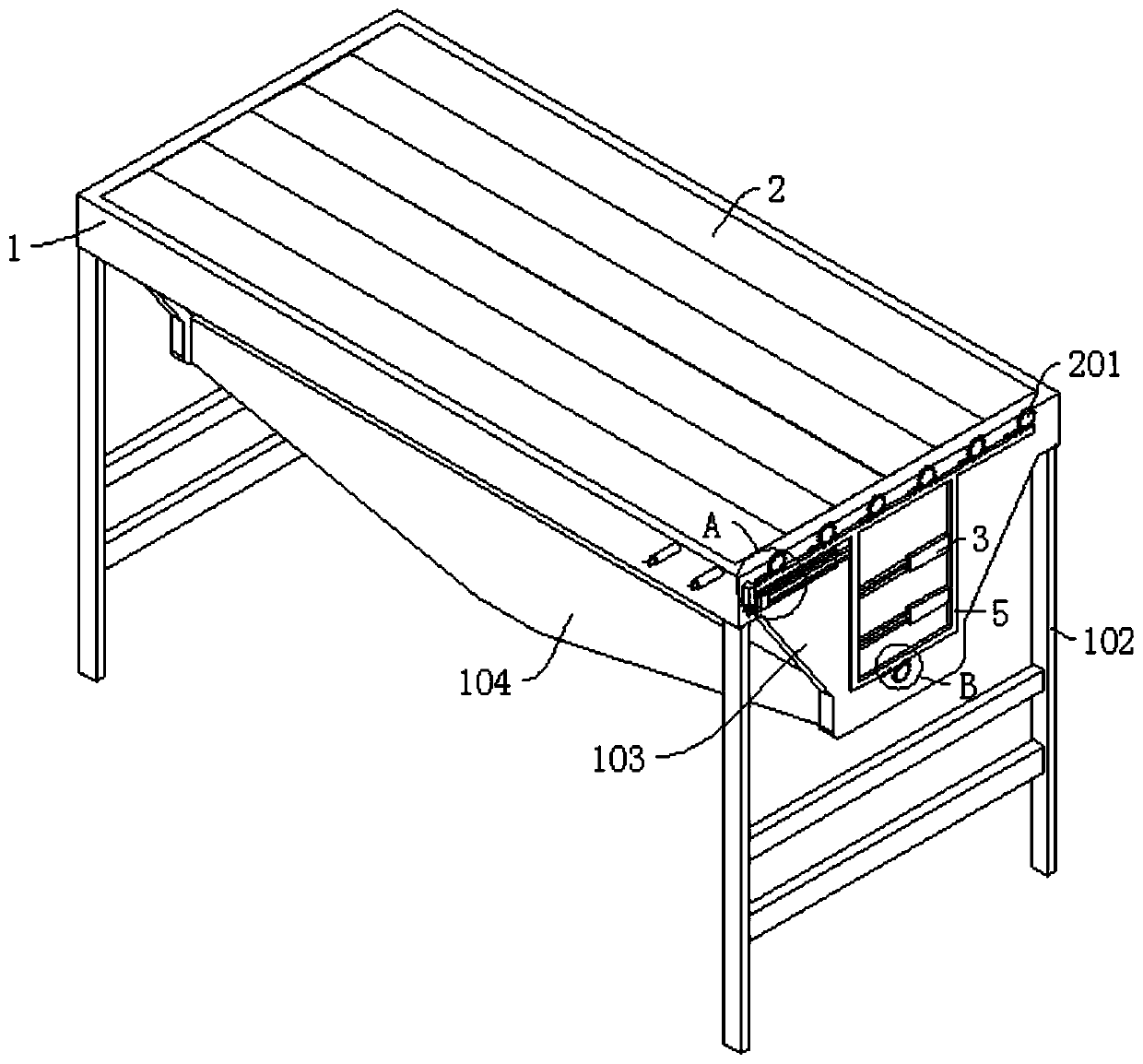

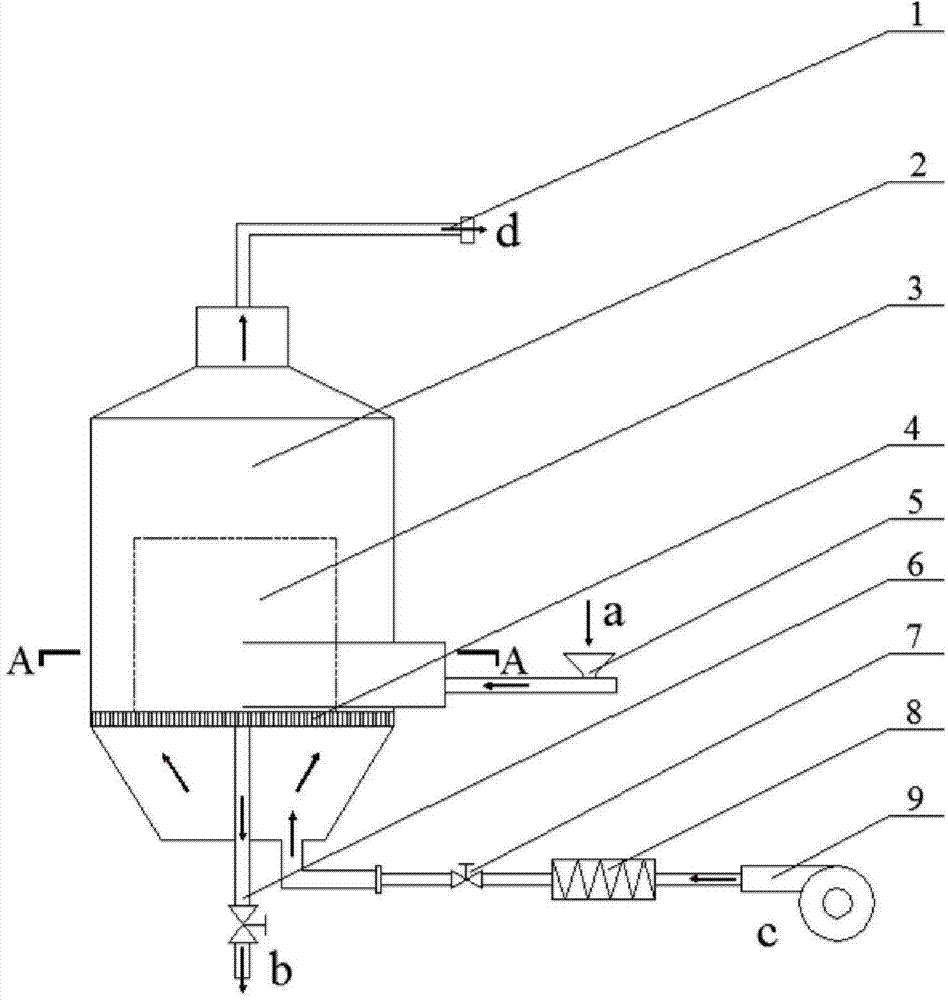

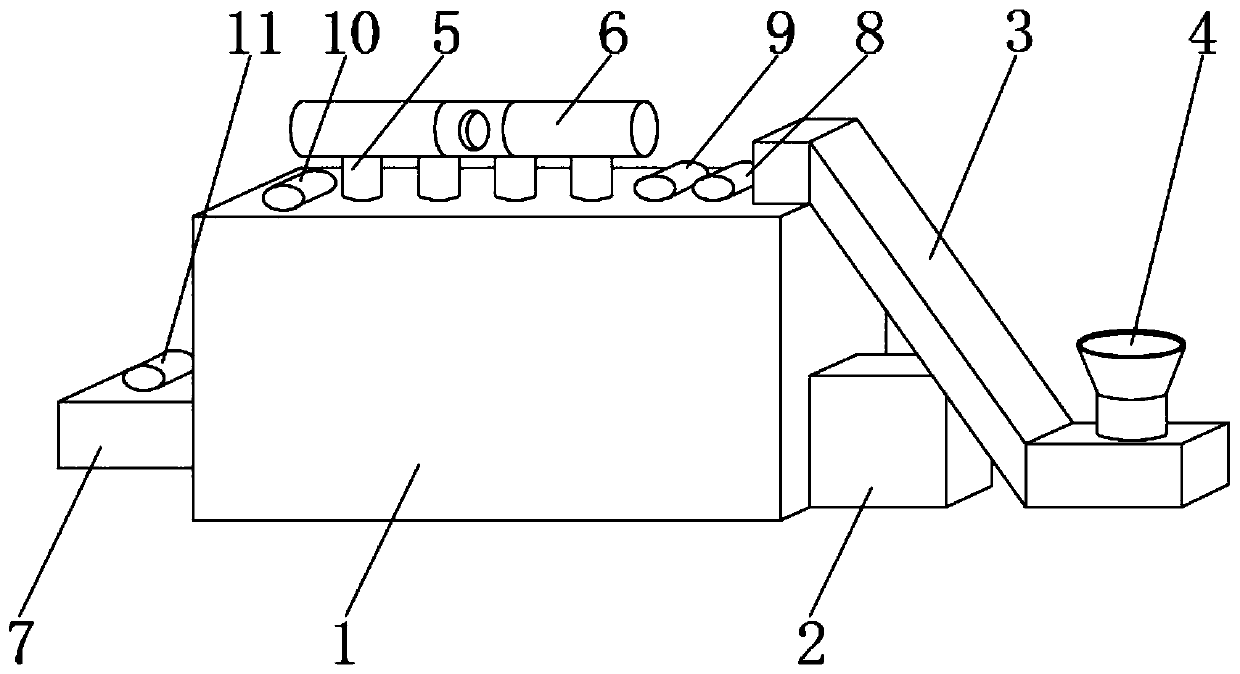

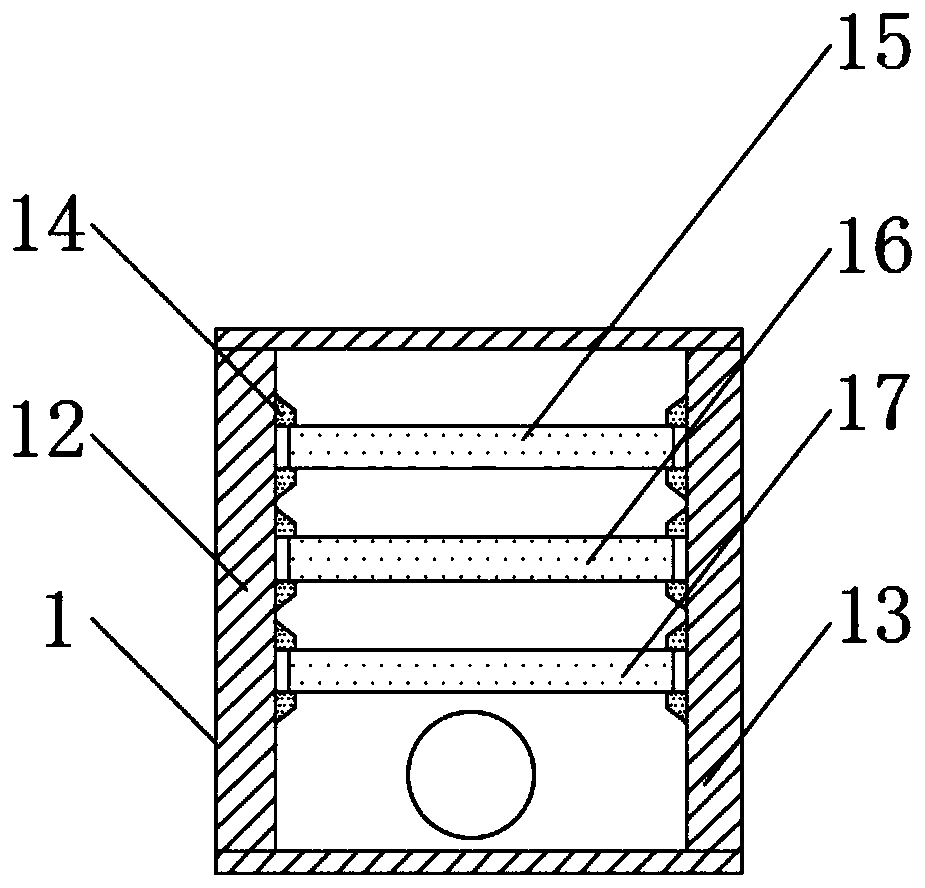

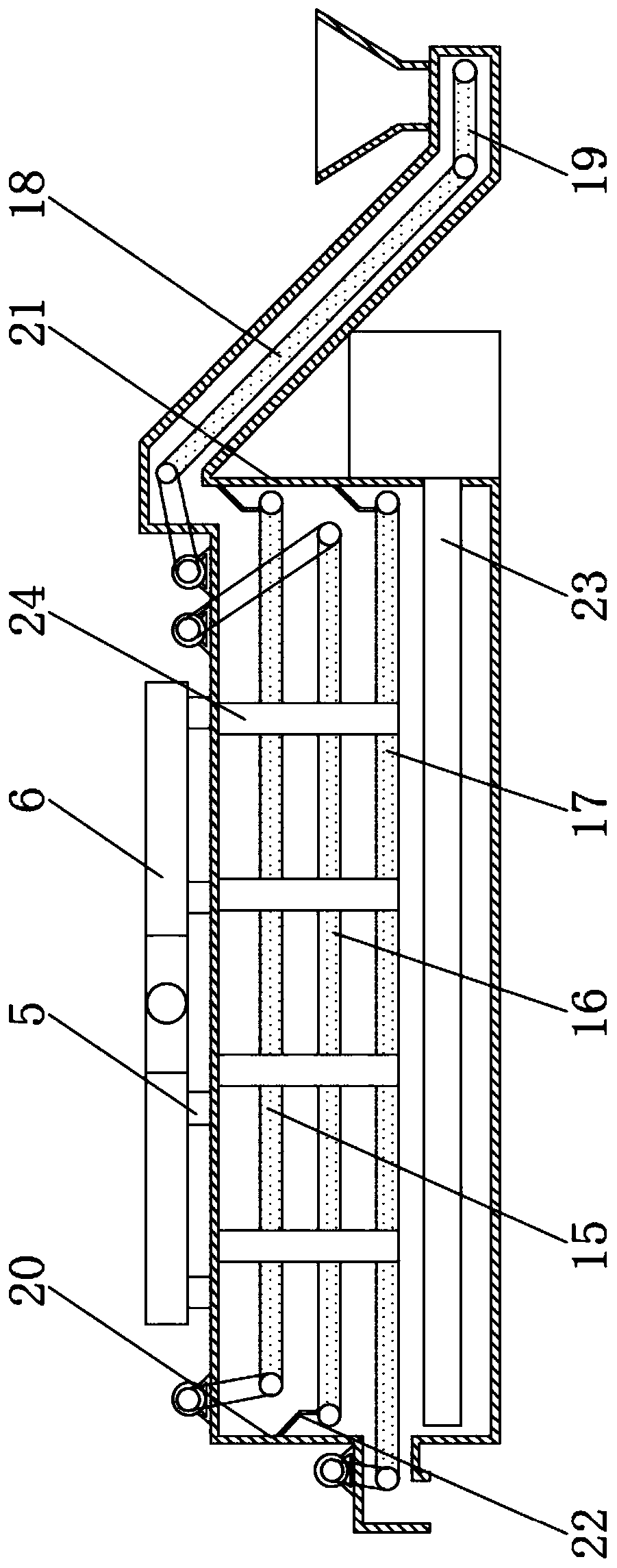

Screw type fluidized bed dryer

InactiveCN104729234ACompact structureEasy to manufactureDrying solid materials with heatHearth type furnacesFluidized bed dryingControl valves

The invention discloses a screw type fluidized bed dryer which comprises an exhaust opening (1), a fluidized bed outer shell (2), a spiral plate (3), an air distributing plate (4), a screw feeder (5), a discharging pipe (6), a control valve (7), a heater (8) and an air blower (9). The screw type fluidized bed dryer is characterized in that an annular channel of the spiral plate is placed above the air distributing plate, an inlet end of the annular channel is connected with the fluidized bed outer shell, an outlet end is connected with the discharging pipe, the screw feeder is connected with a spiral plate channel inlet, and the discharging pipe is place at the center of the spiral plate annular channel. According to the screw type fluidized bed dryer, the spiral annular channel is used, the structure is simple, manufacturing is easy, operation is convenient, the investment and the maintaining cost of additional equipment are reduced, continuous feeding of the drier during operation is achieved, the phenomenon of uneven drying due to dry-wet material returning mixing and bonding is avoided, drying energy loss is lowered, drying efficiency is improved, and the phenomena of channeling and slugging are effectively suppressed.

Owner:SOUTHEAST UNIV

Dryer

PendingCN109780842APracticalSimple structureDrying solid materialsHeating arrangementEngineeringEvaporator

The invention discloses a dryer. The dryer comprises a dryer main body box and a drying unit; the drying unit consists of an evaporator, a compressor, a condenser and an expansion valve; the peripheryof the dryer main body box consists of a front box plate, a back box plate, a left box plate and a right box plate; and the drying unit is fixedly mounted on one side of the bottom end of the dryer main body box. The dryer is provided with a support rod, a ventilation pipe, an exhaust port and a feeding cross bar; when grain particles are conveyed on a conveying belt after entering the dryer mainbody box, the particles can be prevented from falling from cracks, and meanwhile, the drying effect is improved; hot steam generated by the drying unit can be uniformly transferred up to prevent nonuniform drying caused by narrow transfer range; and the grain particles can be preferably loaded, so that the supply insufficiency caused by slippage is prevented, the influence on the drying quantityand the drying efficiency is prevented, a certain practicability is achieved, and the better application prospect is achieved.

Owner:ANHUI PROVINCE YINGSHANG COUNTY SANJIN GRAINS ANDOILS CO LTD

Fly ash dryer

PendingCN111457673AImprove drying uniformityImprove filtering effectDrying machines with non-progressive movementsGrain treatmentsThermodynamicsCyclonic separation

The invention belongs to the technical field of coal ash grinding and filtering and particularly discloses a fly ash dryer. The following scheme is proposed against the problems that an existing dryeris unavailable to grind coal ash, consequently some coal ash with large particles and coal ash with small particles are mixed together, drying is prone to being non-uniform, and subsequent use is affected. According to the scheme, the fly ash dryer comprises heating equipment, charging equipment, riding wheel equipment, a drying kiln, transmission equipment, geared riding wheel equipment, discharging equipment, cyclone separation equipment and an induced draft fan, wherein a charging box is arranged on the charging equipment in a communicating mode, a fixed grinding disk is fixedly mounted inthe charging box, a servo motor is fixedly connected to the top of the charging box, a grinding shaft is fixedly mounted on an output shaft of the servo motor, the grinding shaft is rotationally connected with the charging box, a conical grinding disk is fixedly mounted at the bottom of the grinding shaft, and the conical grinding disk is matched with the fixed grinding disk. Through the fly ashdryer, the coal ash can be ground and screened, the uniformity of the coal ash can be improved, and drying non-uniformity in a later period is avoided.

Owner:盐城市双泰热能设备科技有限公司

Drying device for crops

InactiveCN107270688AGood effectAvoid uneven dryingDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringElectric machinery

The invention discloses a drying device for crops. The drying device for crops comprises a movable box; a sliding groove is formed in the bottom of an inner cavity of the movable box; the two sides of an inner cavity of the sliding groove are each provided with a sliding rod, and the sliding rods are matched with each other; a positive and negative motor is arranged on the right side of the inner cavity of the movable box; the output end of the positive and negative motor is provided with a screw rod; the left side of the surface of the screw rod is provided with a screw sleeve; the left side of the screw sleeve is fixedly connected with the sliding rods; the top of the movable box is provided with a drying box; the top of each sliding rod penetrates the movable box and the drying box and extends into the inner cavity of the drying box; the tops of the sliding rods are provided with a drying net; the top of the drying box is provided with an air heater; and an air sucking pipe is arranged on the back side of the air heater. According to the drying device for crops, due to cooperation of the positive and negative motor, the screw rod, the screw sleeve, an air outflow head, the air heater, the air sucking pipe, an air outflow pipe, the sliding rods, a controller and sliding grooves, a uniform drying effect can be achieved on the crops when the drying device is used, and in this way, the effect is better when the drying device is used.

Owner:广东云印科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com