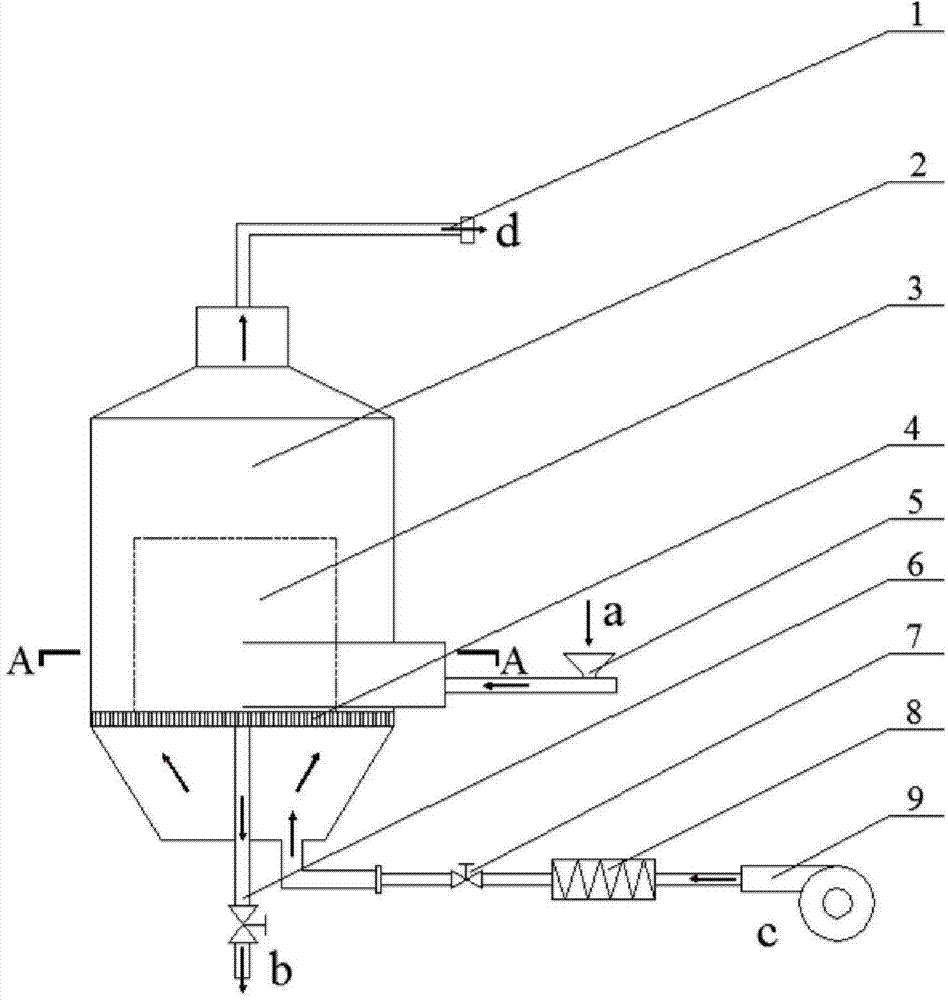

Screw type fluidized bed dryer

A fluidized bed dryer and fluidized bed technology are applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., to achieve the effects of convenient operation, simple manufacturing, and suppression of channeling and surging phenomena.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

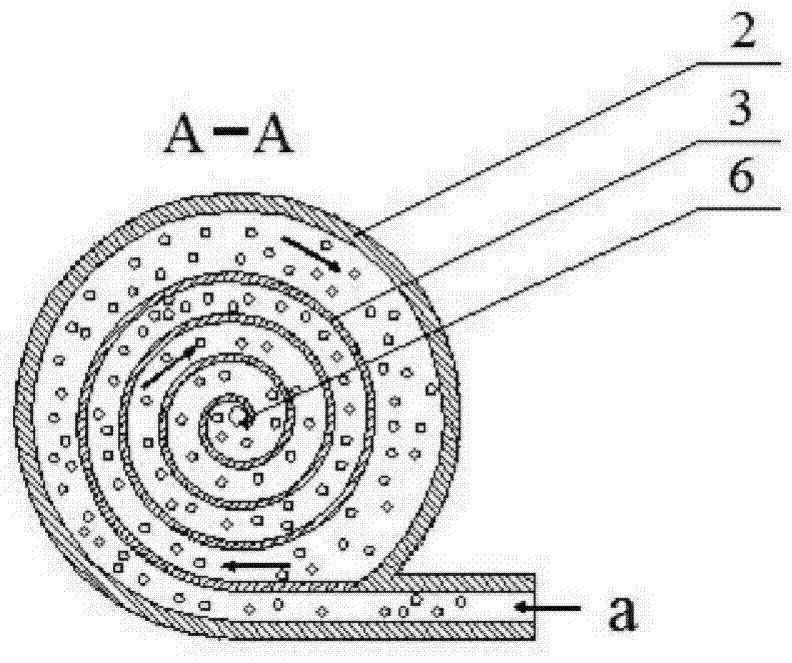

[0026] The screw feeder 5 conveys the wet material particles to the entrance of the annular channel of the screw plate 3. The air conveyed by the blower 9 is heated by the heater 8 and becomes hot air, and enters the fluidized bed dryer from the bottom of the air distribution plate 4 to dry the wet material particles entering the passage of the spiral plate 3. The hot air makes the wet material particles reach a fluidized state and removes the moisture in the wet material particles. The exhaust gas is discharged to the purification system through the exhaust port 1 through the upper part of the fluidized bed dryer.

[0027] The wet material particles enter the outlet through the annular channel of the spiral plate 3, and are gradually dried. Finally, the dry material with humidity reaching the standard flows out through the discharge pipe 6. The height of the spiral plate 3 is greater than the height of the fluidized bed layer, which avoids backmixing and bonding of dry and wet m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com