Heating apparatus

A heating device and heated technology, applied in the direction of electric heating plate heating arrangements, optics, instruments, etc., can solve problems such as uneven drying, achieve uniformity, achieve film thickness, and suppress temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

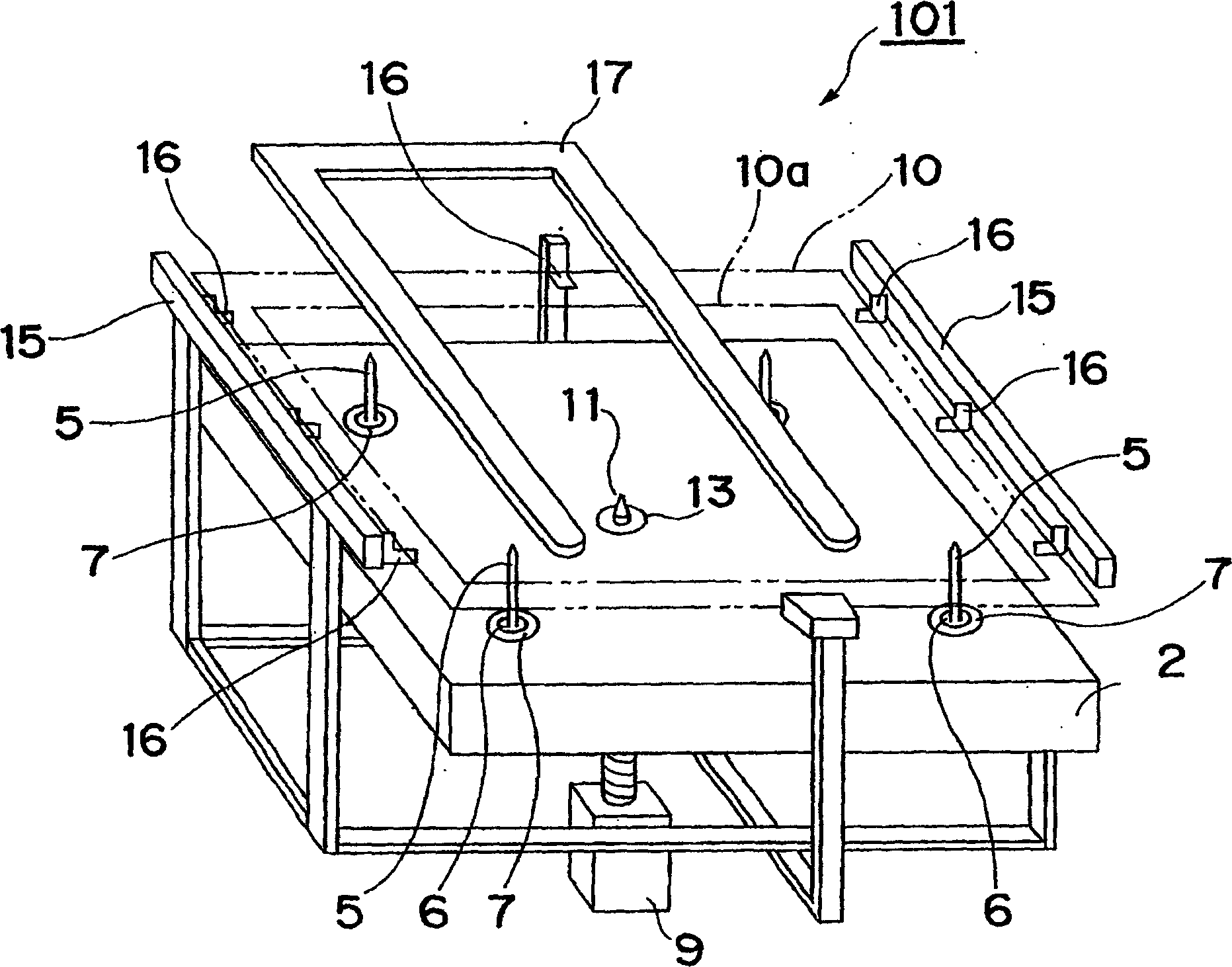

Embodiment 1

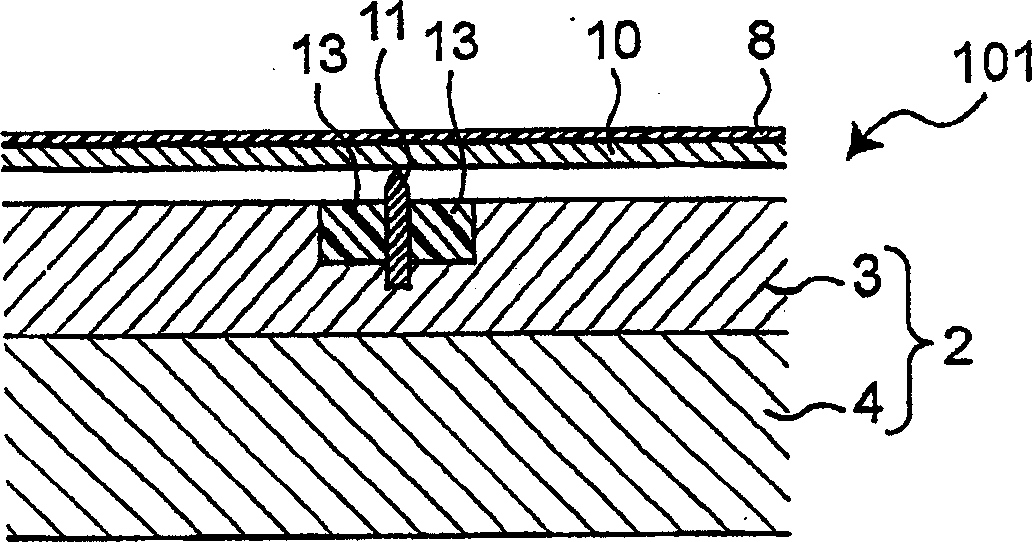

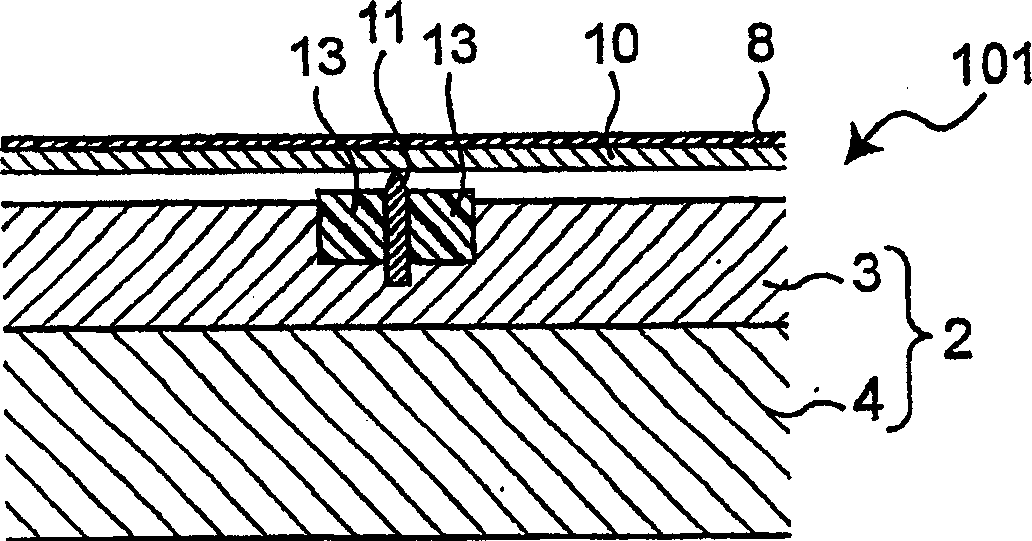

[0134] Next, an example of the approach pin 11 and the temperature adjusting member 13 used in the heating device 101 of the above-mentioned embodiment will be described as Example 1 below.

[0135] In this Example 1, the image 3 The structure of the heating device 101 shown in the schematic cross-sectional view of . Specifically, as image 3 As shown, the heating plate 2 is composed of a 10 mm thick aluminum top plate portion 3 and a heat generating portion 4 . In addition, as the approach pin 11, a tip made of Ultem (registered trademark: ULTEM: polyetherimide) and having a diameter of 3 mm was used. In addition, as the temperature adjustment member 13, a ring made of Ulutem (registered trademark) with an outer diameter of 10 mm and a thickness of 10 mm is used. below.

[0136] In addition, the substrate 10 is made of soda lime glass with a thickness of 0.7 mm. In addition, as the film raw material solution 8, that is, the coating material, an ink for liquid crystal al...

Embodiment 2

[0143] Next, an example of the lift pin 5 and the temperature adjustment member 7 used in the heating device 101 of the above-mentioned embodiment will be described as Example 2 below.

[0144] In this second embodiment, various means in the description of the above-mentioned embodiments are combined to form a Figure 22 The temperature regulating member 7 shown in the schematic cross-sectional view. Specifically, as Figure 22 As shown, the heating plate 2 is composed of an aluminum top plate portion 3 and a heat generating portion 4 having a thickness of 10 mm. In addition, the lift pin 5 is a front tip made of stainless steel as the main material and Ulutem (registered trademark) as the front end material. A through-hole 6 with a diameter of 15 mm was formed in the top plate portion 3 of the heating plate 2, and a temperature adjustment member 7 was embedded therein. The temperature adjustment member 7 is formed by stacking a lower temperature adjustment member 7a locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com