Dryer

A dryer and unit technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of affecting drying capacity and drying efficiency, small transfer range, insufficient material supply, etc., so as to avoid affecting drying. Dry quantity and drying efficiency, avoid small transfer range, and prevent insufficient feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

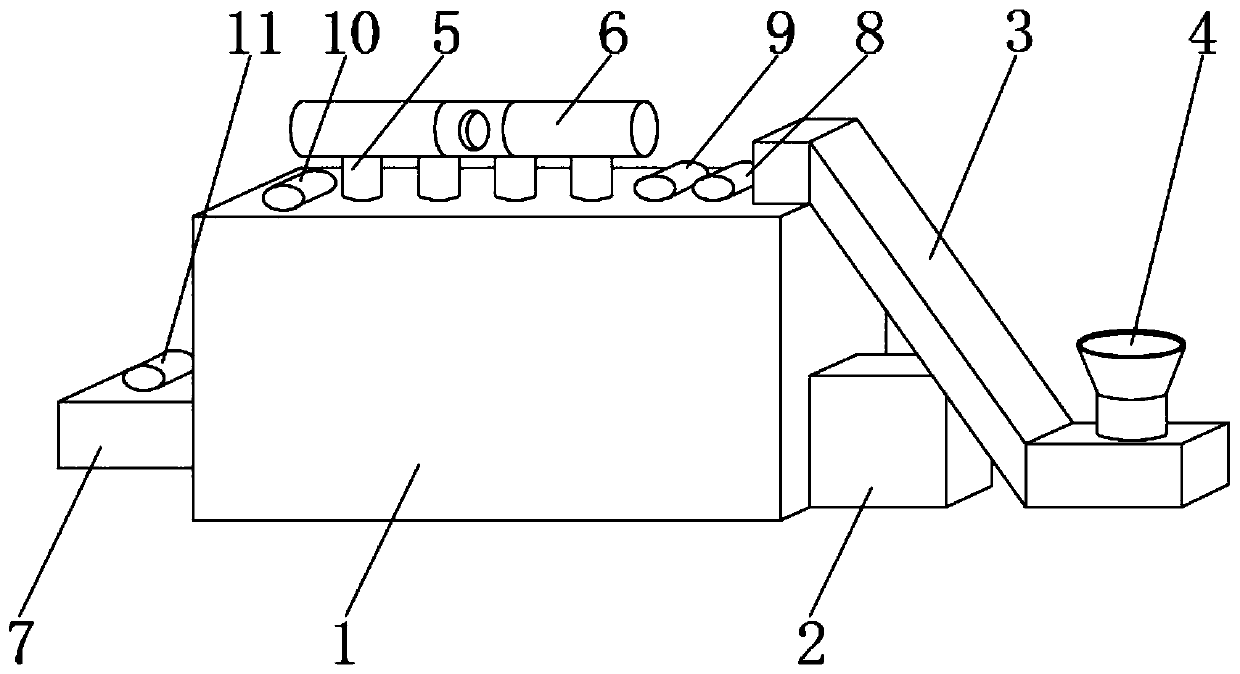

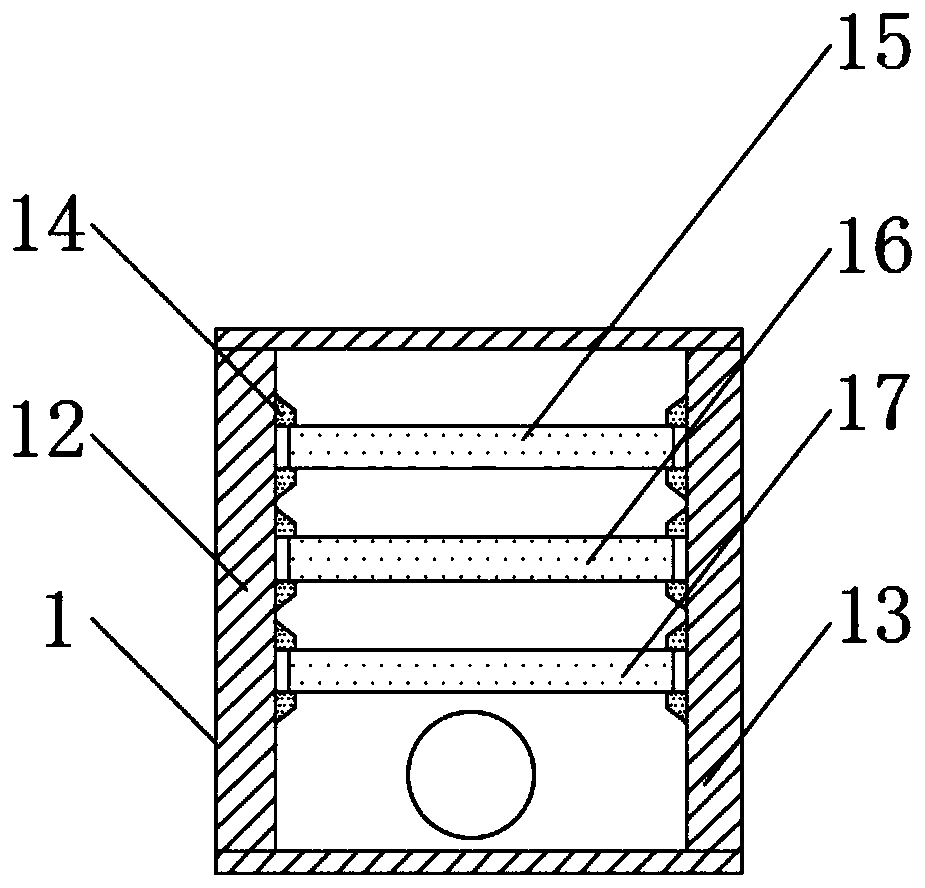

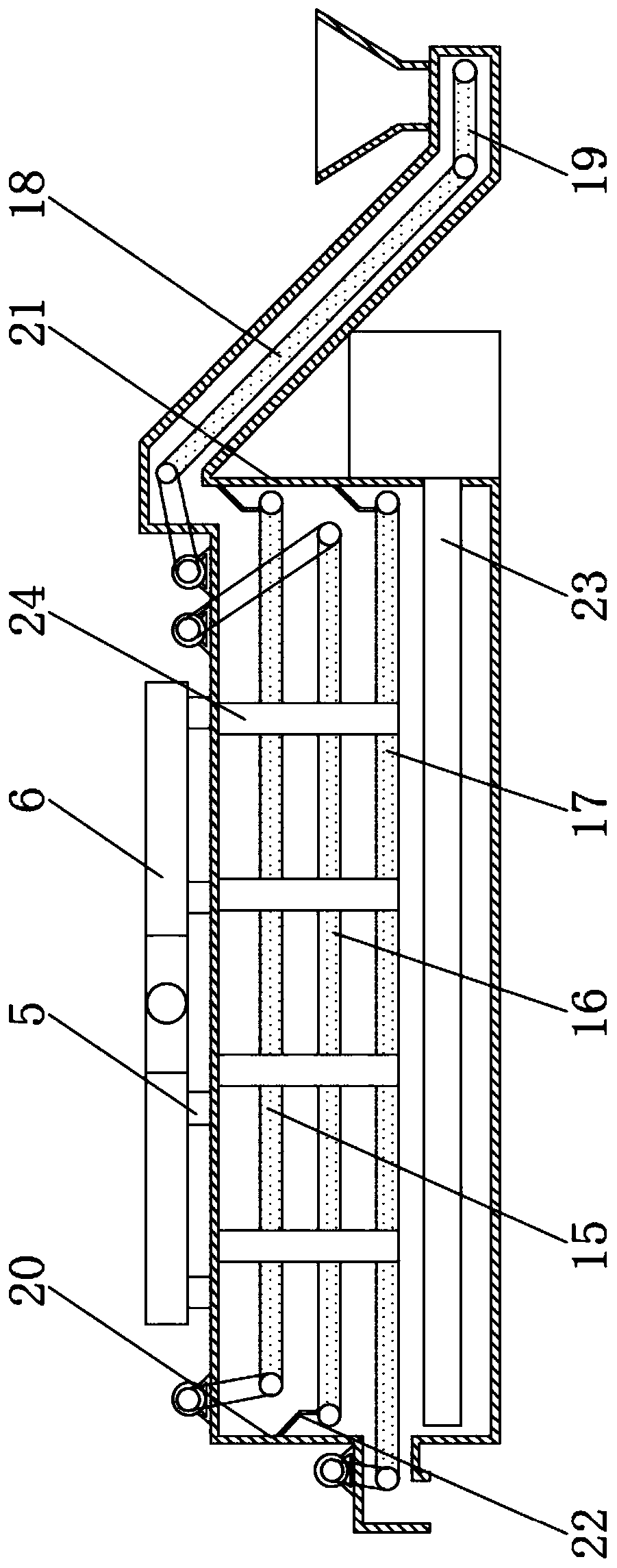

[0023] Such as Figure 1-6 As shown, a dryer includes a main body box 1 of the dryer and a drying unit 2, the drying unit 2 is composed of an evaporator, a compressor, a condenser and an expansion valve, and the main body box 1 of the dryer is surrounded by The front box board 12, the rear box board 13, the left box board 20 and the right box board 21 are composed. The drying unit 2 is fixedly installed on the bottom side of the dryer main box 1, and on the upper side of the dryer main box 1. The feeding cylinder 3 is fixedly installed, and the feeding cylinder 3 is located at the upper end of the drying unit 2, the feeding hopper 4 is fixedly installed at the bottom of one end of the feeding cylinder 3, and the upper end of the main body box 1 of the dryer is fixedly installed with four sets of air-inducing ducts 5 , the upper ends of the four groups of air-introduction ducts 5 are fixedly installed with an air collecting pipe 6, the other side of the main body box 1 of the d...

Embodiment 2

[0025] Such as Figure 1-6 As shown, one end of the No. 1 conveyor belt 15 is positioned at the lower end of the material retaining plate 22 near the right box plate 21 inwall, and the other end of the No. 1 conveyor belt 15 is 20 centimeters away from the left box panel 20. The No. 1 conveyor belt 15 and the No. 3 motor 10 Connected by a transmission belt, one end of the No. 2 conveyor belt 16 is located at the lower end of the material retaining plate 22 near the inner wall of the left caseboard 20, and the other end of the No. 2 conveyor belt 16 is 20 centimeters away from the right caseboard 21. The No. 2 conveyor belt 16 and the No. 2 motor 9 is connected by a transmission belt, one end of the No. 3 conveyor belt 17 is located at the lower end of the material baffle plate 22 on the inner wall of the right box plate 21, and the other end of the No. 3 conveyor belt 17 is located inside the discharge cylinder 7. The No. 3 conveyor belt 17 and the No. 4 motor 11 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com