Fly ash dryer

A dryer and fly ash technology, applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problems of affecting later use and uneven drying, so as to improve uniformity and avoid affecting use , to avoid uneven drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

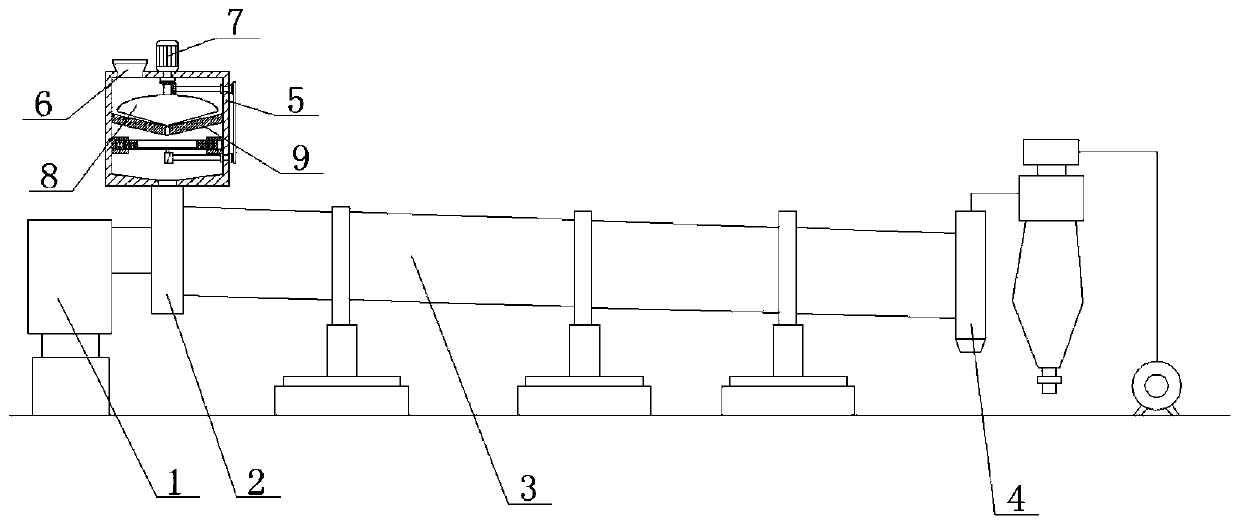

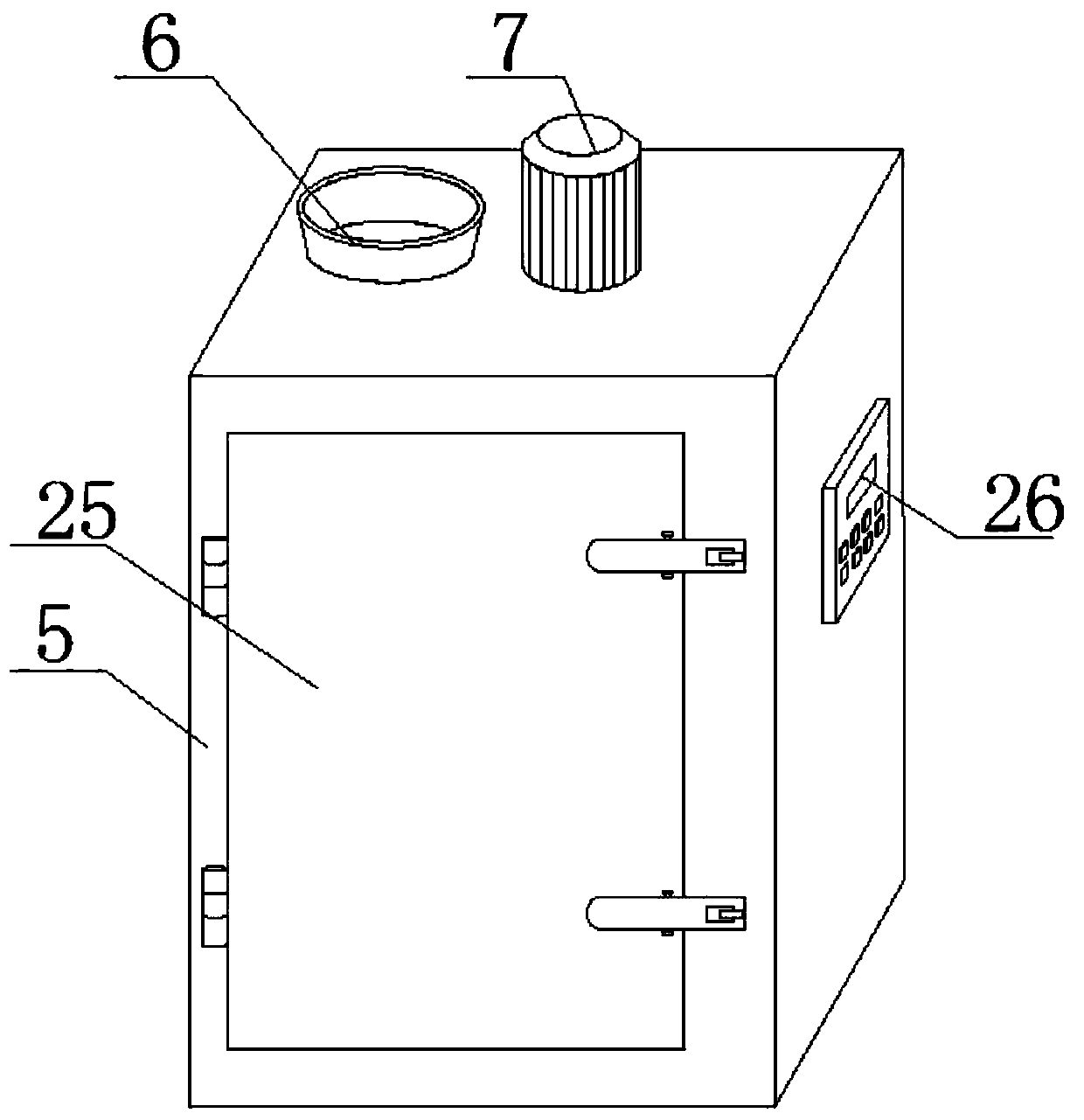

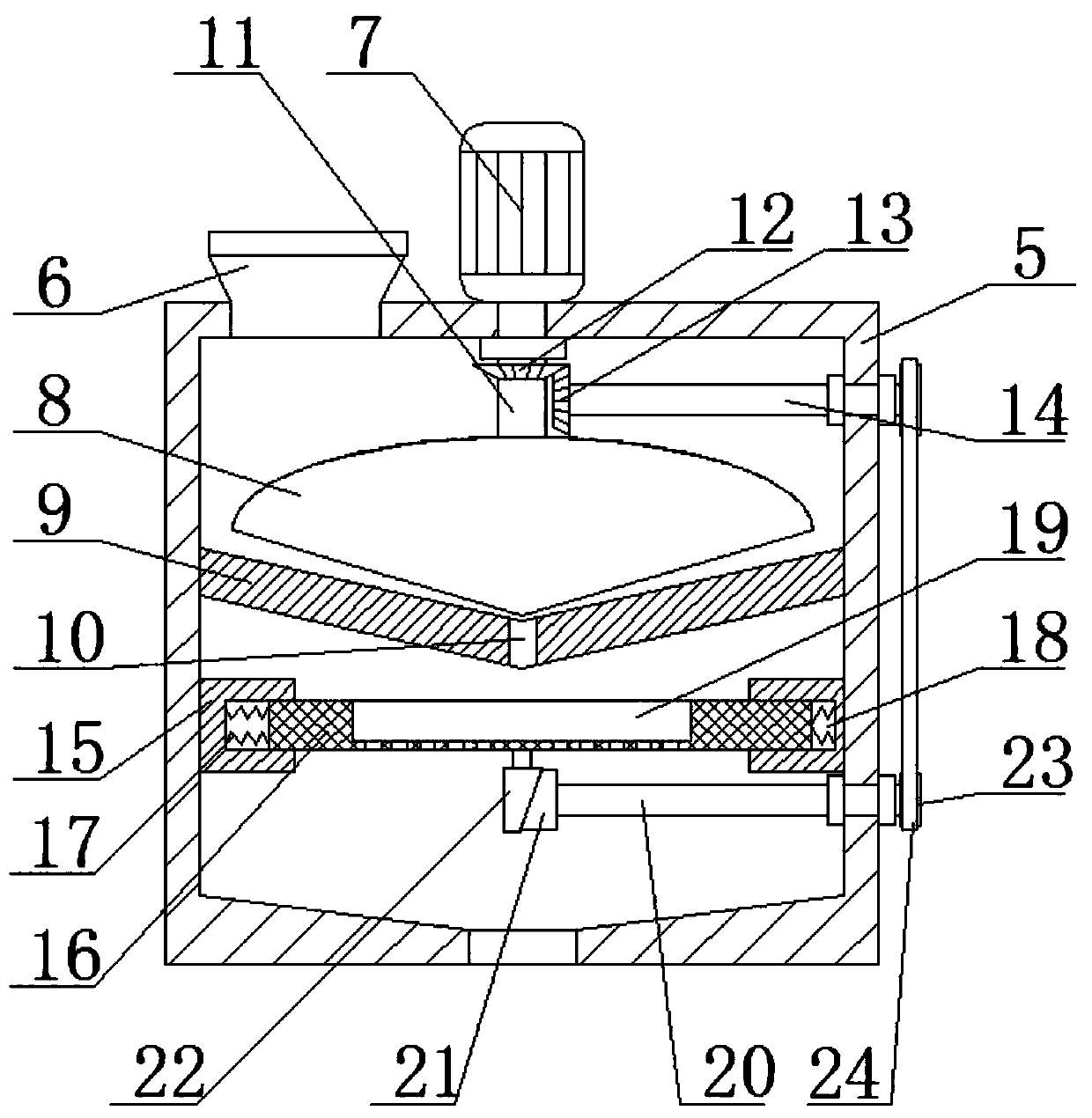

[0023] refer to Figure 1-4 , Fly ash dryer, including heating equipment 1, feeding equipment 2, supporting roller equipment, drying kiln body 3, transmission equipment, gear supporting roller equipment, discharging equipment 4, cyclone separation equipment and induced draft fan, feeding equipment 2 A charging box 5 is connected to it, and a fixed rolling disc 9 is fixedly installed in the charging box 5. The top of the feeding box 5 is fixedly connected with a servo motor 7, and the output shaft of the servo motor 7 is fixedly installed with a rolling shaft 11, and the rolling shaft 11 is connected with the feeding box. 5 Rotational connection, the bottom of the rolling shaft 11 is fixedly equipped with a conical milling disc 8, the conical milling disc 8 is compatible with the fixed milling disc 9, the conical structure of the fixed milling disc 9, the inclination angle of the conical milling disc 8 is greater than that of the fixed milling disc 9 Angle, the particles can be...

Embodiment 2

[0030] refer to Figure 1-4 , Fly ash dryer, including heating equipment 1, feeding equipment 2, supporting roller equipment, drying kiln body 3, transmission equipment, gear supporting roller equipment, discharging equipment 4, cyclone separation equipment and induced draft fan, feeding equipment 2 A charging box 5 is connected to it, and a fixed rolling disc 9 is fixedly installed in the charging box 5 by welding. The top of the charging box 5 is fixedly connected with a servo motor 7 by screws, and the output shaft of the servo motor 7 is fixedly installed with a rolling shaft 11 by welding. The finale shaft 11 is rotatably connected with the charging box 5, and the bottom of the rolling shaft 11 is fixedly installed with a conical milling disc 8 by welding. The conical milling disc 8 is compatible with the fixed milling disc 9. The angle of inclination is greater than the angle of inclination of the fixed mill pan 9, and the particles can be crushed. The central position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com