Air drying equipment for wig fibers

A fiber and equipment technology, applied in the field of wig fiber air-drying equipment, can solve the problems of uneven drying effect, large investment in equipment, and hair damage, etc., to achieve the effect of improving drying effect, improving drying efficiency, and avoiding hair breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

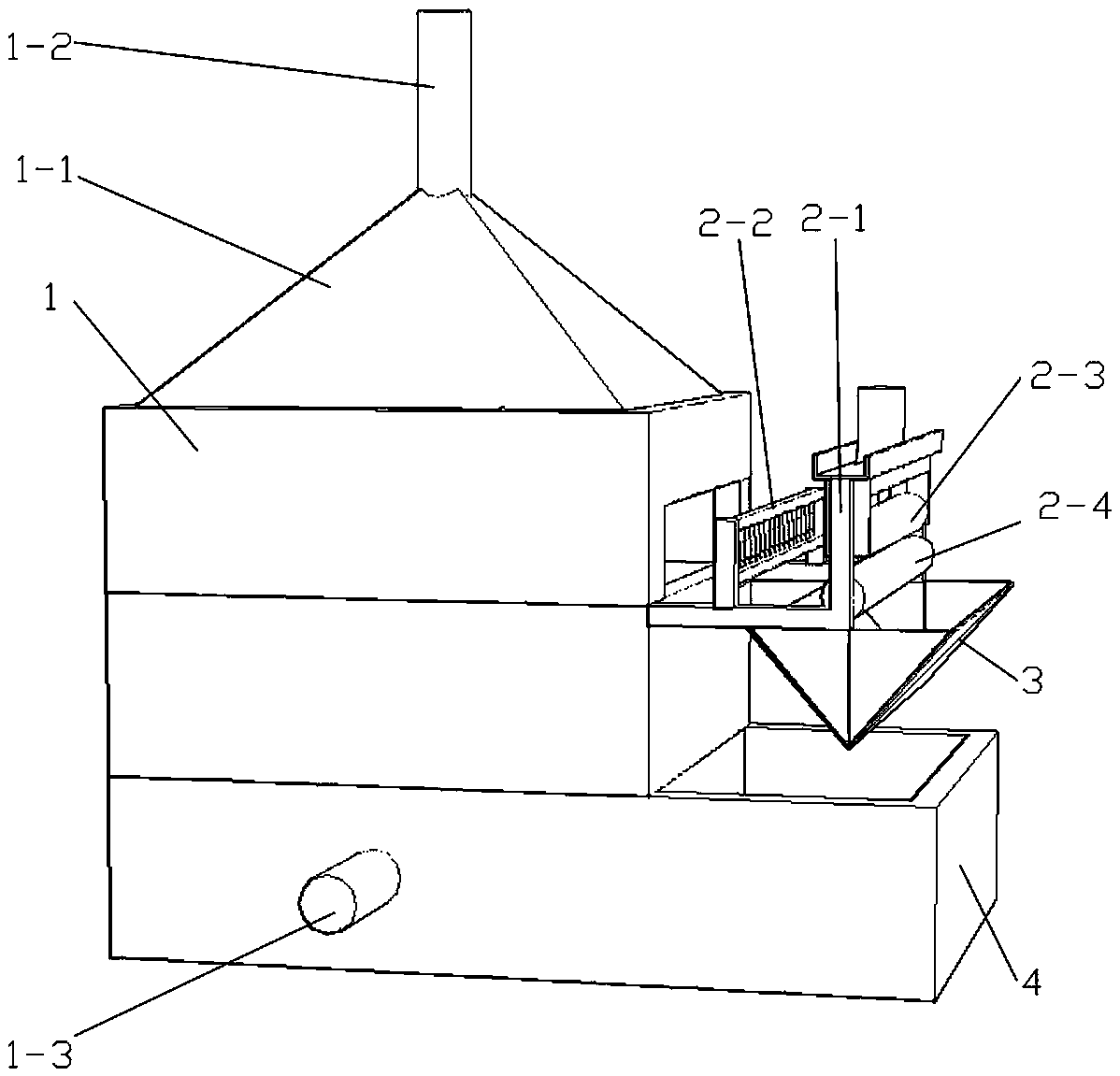

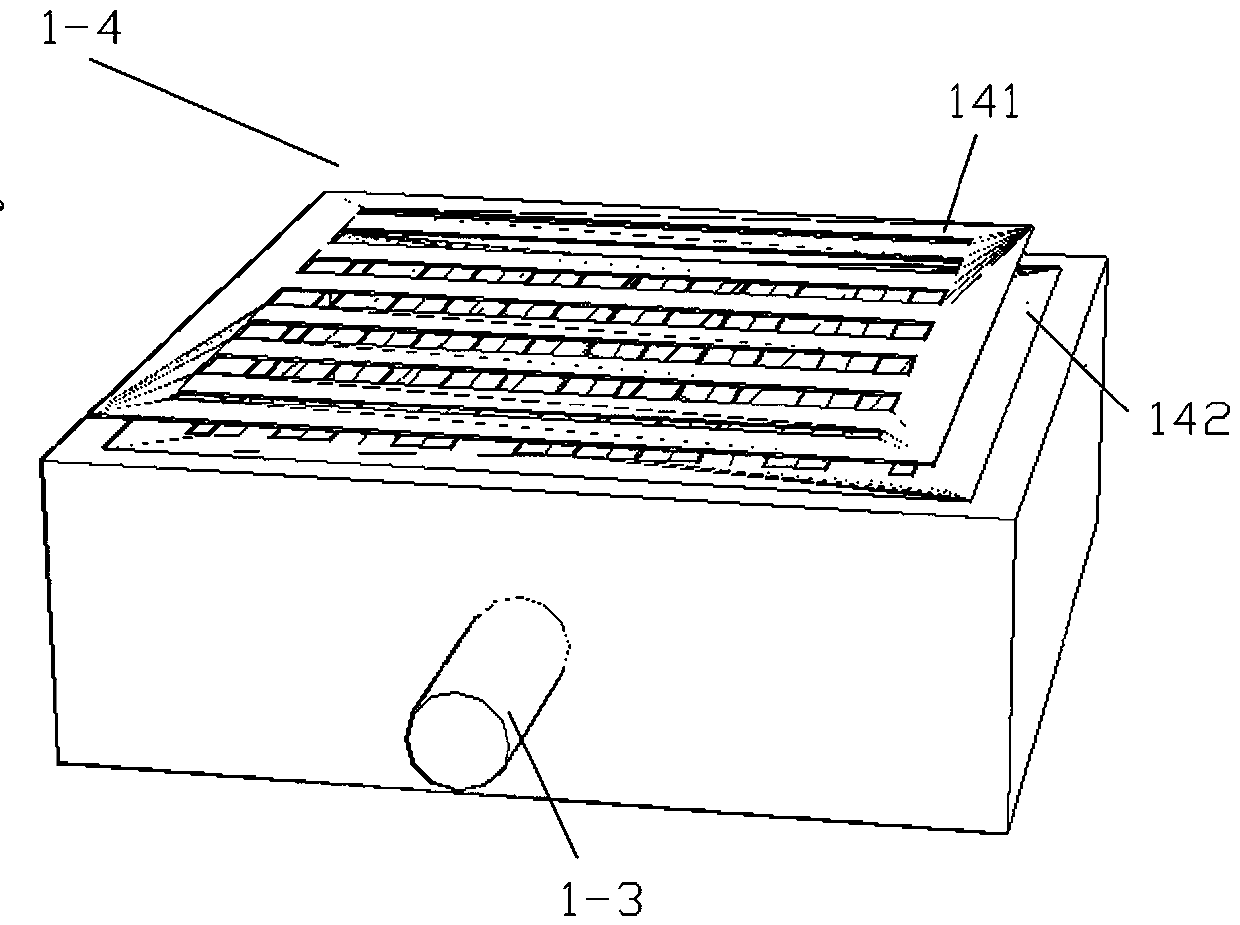

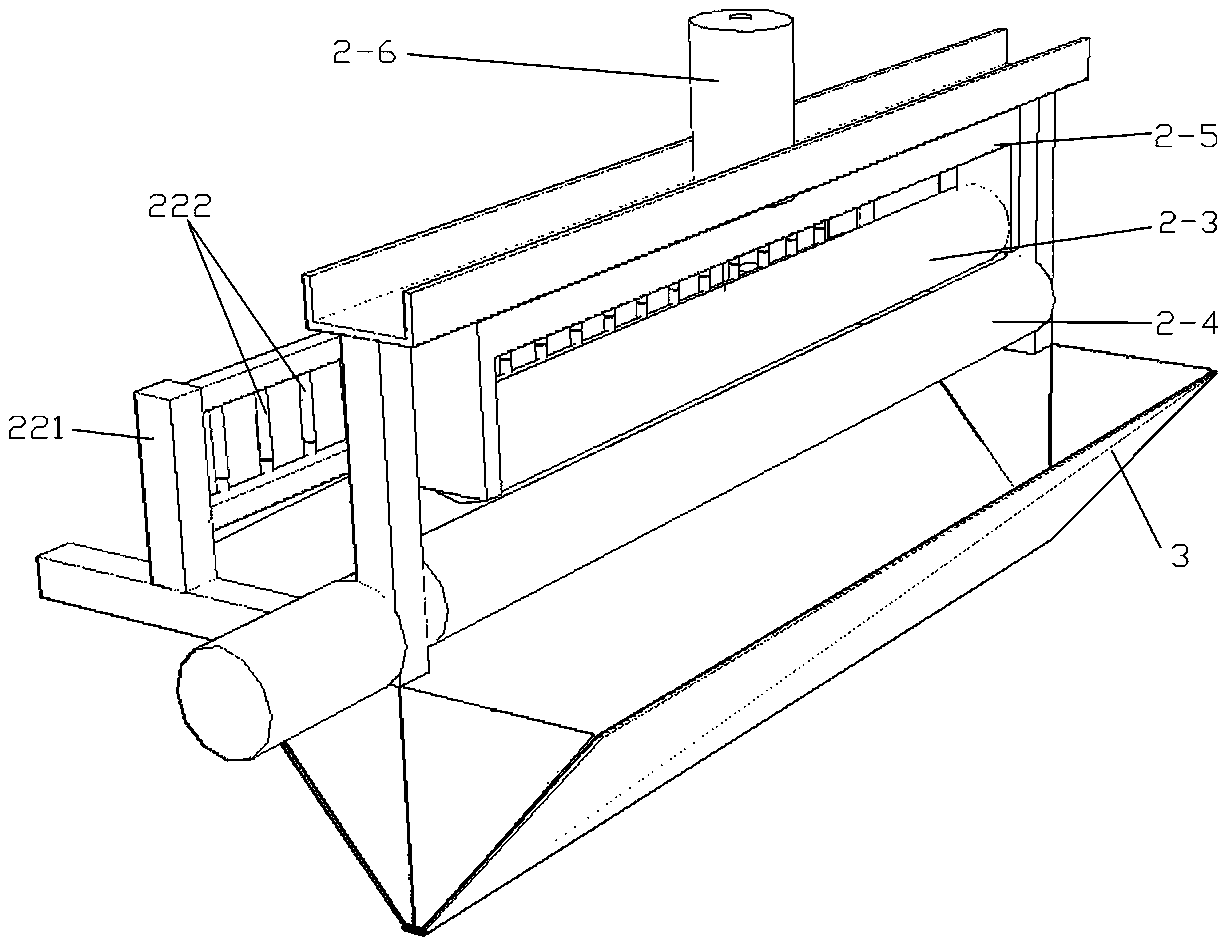

[0022] As shown in the figure, the embodiment of the present invention provides an air-drying device for wig fibers, including a bellows 1, the bellows 1 is a rectangular cabinet structure as a whole, and an exhaust chamber 1-1 is arranged on the top of the cabinet. The exhaust chamber 1-1 communicates with the outside through the exhaust pipe 1-2, openings for hair passing are provided on the two opposite side walls of the bellows 1, and an air inlet is provided at the lower section of the side of the bellows 1. The pipe 1-3 is provided with a hair dispersing assembly 2 at the hair inlet of the bellows 1, and the hair dispersing assembly 2 includes a mounting frame 2-1, a squeeze roller assembly and a hair dispersing row 2-2, the The hairline dispersing row 2-2 includes a rectangular frame 221 and partition bars 222 sequentially distributed in the rectangular frame 221. Each partition bar 222 is arranged vertically and arranged horizontally in sequence. A drum is sheathed on ...

Embodiment 2

[0025]As shown in the figure, the embodiment of the present invention provides a styling and air-drying device for wig fibers and a hair preparation method. The styling and air-drying device includes a styling device and an air-drying device. The air-drying device includes a bellows 1. It is a cuboid cabinet structure, and an exhaust cavity 1-1 is arranged on the top of the cabinet, and the exhaust cavity 1-1 communicates with the outside through the exhaust pipe 1-2, corresponding to the two opposite side walls of the bellows 1. An opening for hair to pass through is provided, an air inlet pipe 1-3 is arranged at the lower section of the side of the bellows 1, and a hair dispersing assembly 2 is provided at the hair inlet of the bellows 1, and the hair dispersing assembly 2 includes an installation Frame 2-1, extruding roller assembly and hairline dispersion row 2-2, described hairline dispersion row 2-2 comprises rectangular frame 221 and divider bar 222 that is distributed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com