Mushroom drying equipment

A technology for drying equipment and shiitake mushrooms, which is applied in drying, drying machines, lighting and heating equipment, etc., which can solve the problems of uneven heating of shiitake mushrooms, avoid uneven drying, facilitate installation and removal, and improve drying efficiency. The effect of dry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

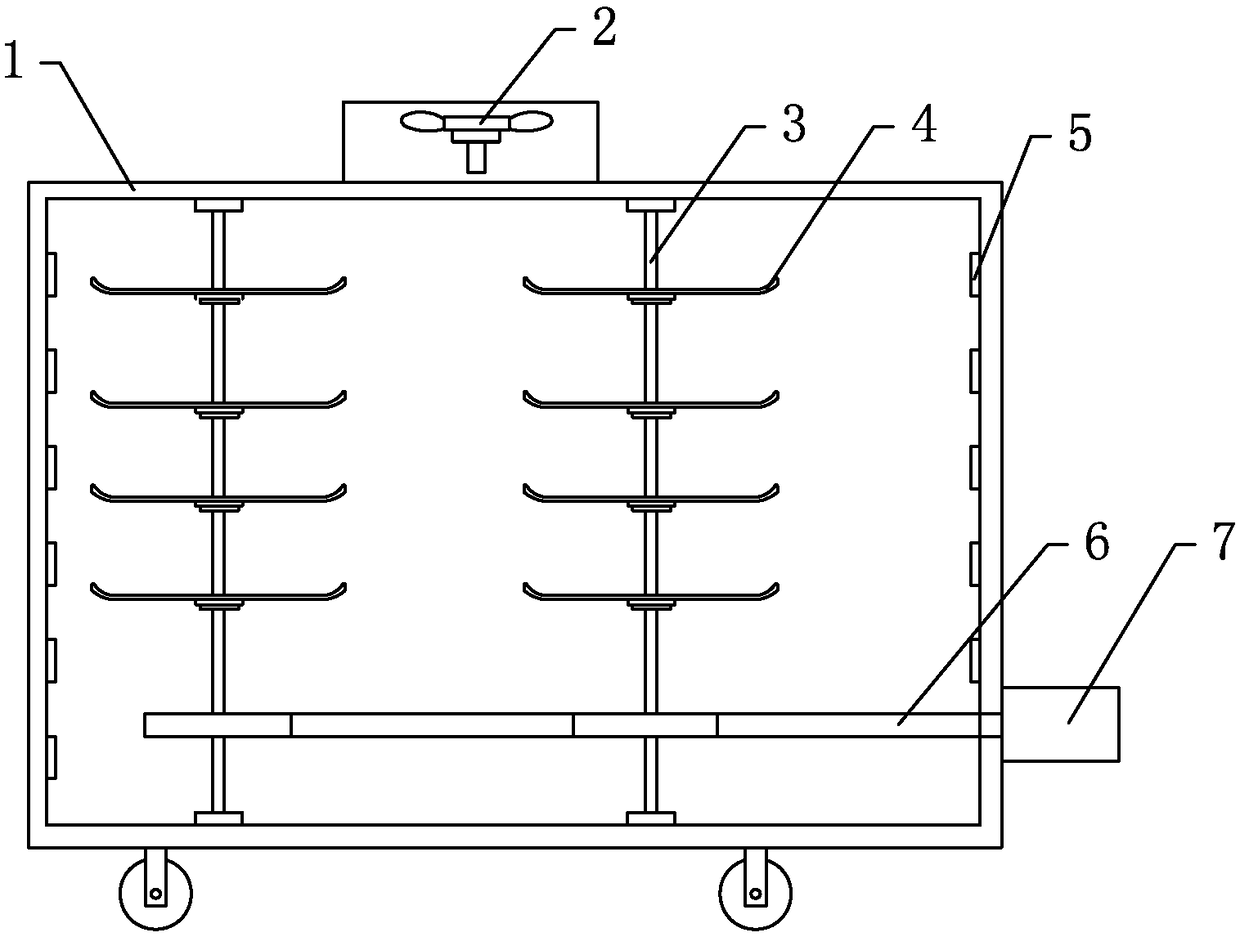

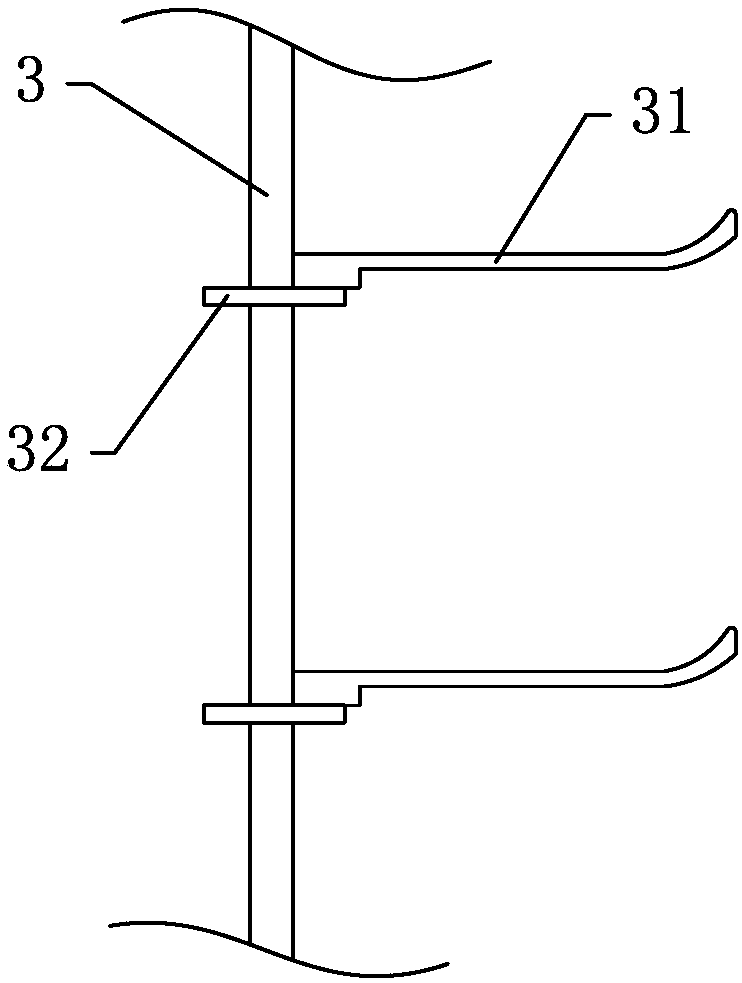

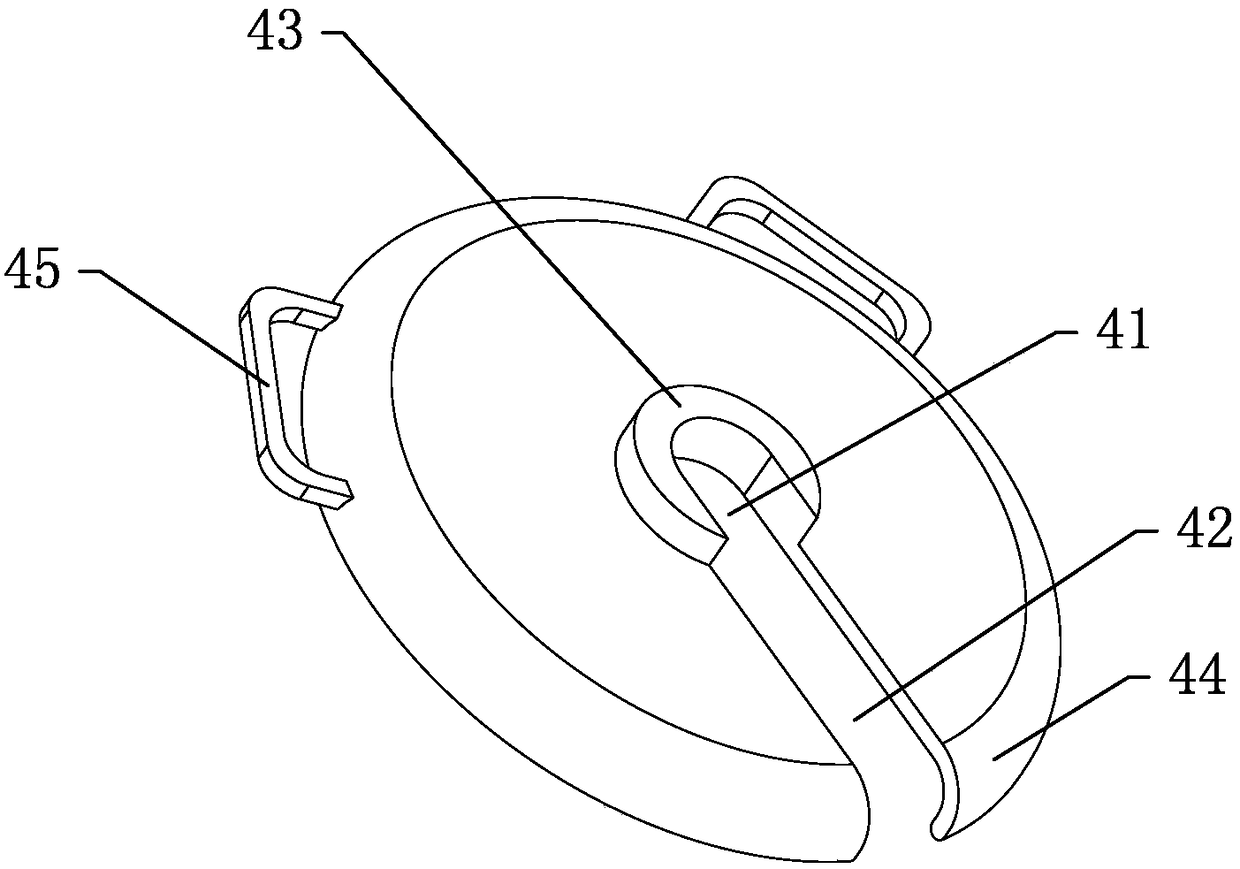

[0026] A shiitake mushroom drying equipment, comprising a box body 1, the box body 1 is provided with a rotating shaft 3, a material tray 4, a driving mechanism 7, a transmission structure 6, and a heating structure 5, and the driving mechanism 7 passes through the transmission structure 6 Connect the rotating shaft 3, the rotating shaft 3 is vertically fixed inside the box body 1, the rotating shaft 3 is provided with a fixed step 32 and a positioning part 31 at intervals, the fixed step 32 is a first magnetic part, and the charging tray 4 includes a middle part and a positioning part 31. The fixed ring 41 adapted to the rotating shaft 3, and the slot 42 engaged with the positioning part 31, the slot 42 extends to the outer edge of the fixed ring 41 and the tray 4, the width of the slot 42 is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com