Drying equipment for production of polycarboxylate superplasticizer

A technology of drying equipment and water reducing agent, which is applied in the direction of drying solid materials, drying chamber/container, drying gas arrangement, etc. It can solve the problems of polycarboxylate water reducing agent easy to agglomerate and other problems, so as to avoid uneven drying and prevent powder caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

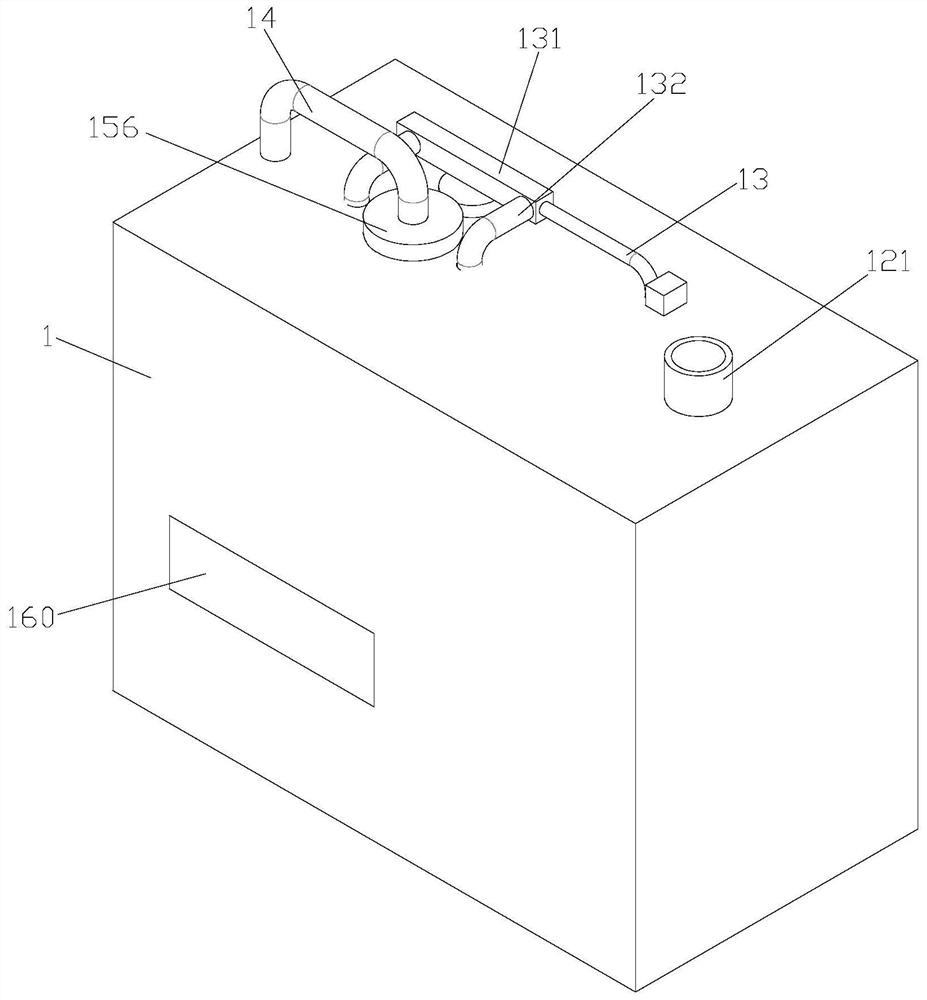

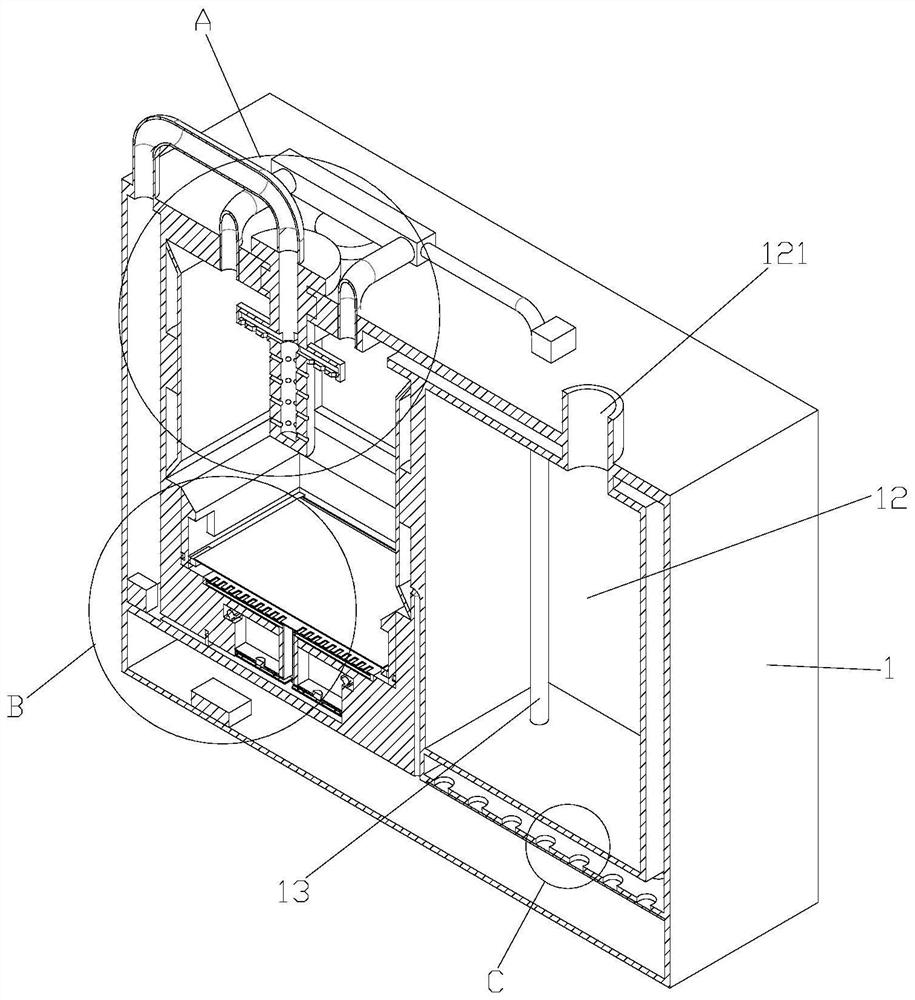

[0039] like Figure 1-23 As shown, a kind of drying equipment for the production of polycarboxylate superplasticizer includes a box body 1, and a first partition is arranged in the box body 1, and the box body 1 is divided into drying boxes by the first partition board. The dry chamber 11 and the liquid storage chamber 12, the top of the liquid storage chamber is provided with a liquid inlet pipe 121, the liquid storage chamber 12 is pierced with a first feeding pipe 13, and one end of the feeding pipe 13 is provided with a first A connection block 131, the first connection block 131 is provided with a first cavity communicated with the first delivery pipe 13, an atomizer is arranged in the first cavity, and the first connection block 131 A second feed pipe 132 communicating with the drying chamber 11 is provided on the top, a loading frame 2 is provided at the bottom of the drying chamber 11, and a connecting frame 28 is arranged in the loading frame 2, and a connecting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com