Drying furnace for household garbage and drying method

A domestic garbage and drying furnace technology, applied in drying, drying machines, combustion methods, etc., can solve the problems of unsustainability, secondary pollution, high operating costs, etc., to facilitate recycling and utilization, improve drying speed, The effect of speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

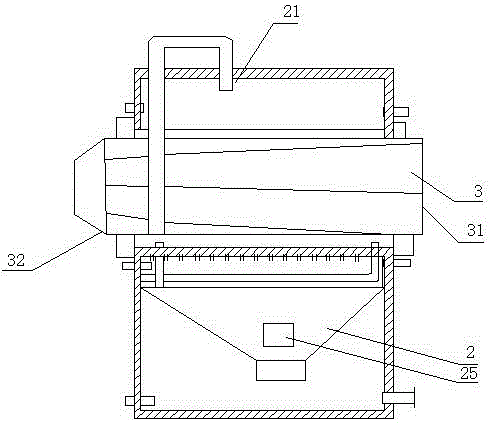

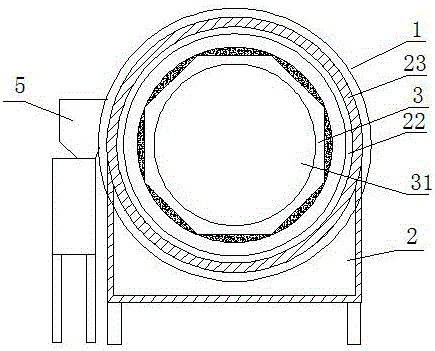

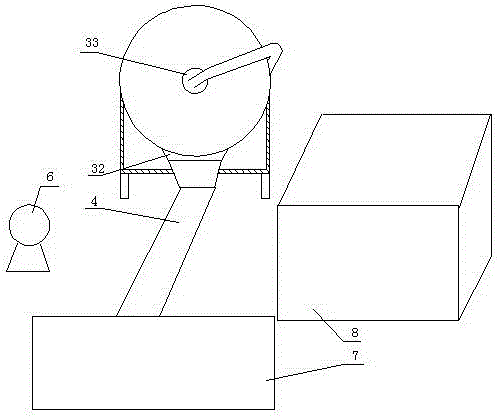

Image

Examples

Embodiment 1

[0040] A method for drying domestic garbage, comprising the following steps:

[0041] (1) Preprocessing:

[0042] a. add deodorizing disinfectant in house refuse, comprise following components, the percentage by weight of each component is: lime 40%, camphor powder 25%, peppermint powder 10%, fragrant mugwort powder 10%, peppercorns 5% ;

[0043] b. Use magnetic separation to separate and recycle metal garbage; use screening to separate glass, dregs, and bulky waste from lumpy garbage that is inconvenient to break; cut lumpy garbage; Bulk materials are crushed;

[0044] c. Obtain loose and uniform waste to be treated after crushing and shearing, wherein the average size of the waste obtained after shearing is length*width=50*10mm, and the average particle size of the obtained waste after crushing is 5mm;

[0045] (2) Drying: Put the garbage to be processed in a drying furnace for drying, and continuously add garbage to the drying furnace at a rate of 41kg / min. The drying te...

Embodiment 2

[0048] A method for drying domestic garbage, comprising the following steps:

[0049] (1) Preprocessing:

[0050] a. add deodorizing disinfectant in house refuse, comprise following components, the percentage by weight of each component is: lime 40%, camphor powder 27%, peppermint powder 15%, fragrant mugwort powder 12%, peppercorns 7% ;

[0051] b. Use magnetic separation to separate and recycle metal garbage; use screening to separate glass, dregs, and bulky waste from lumpy garbage that is inconvenient to break; cut lumpy garbage; Bulk materials are crushed;

[0052] c. Obtain loose and uniform waste to be treated after crushing and shearing, wherein the average size of the waste obtained after shearing is length*width=80*30mm, and the average particle size of the obtained waste after crushing is 10mm;

[0053] (2) Drying: Put the garbage to be processed in a drying furnace for drying, and continuously add garbage to the drying furnace at a rate of 50kg / min. The drying t...

Embodiment 3

[0056] A method for drying domestic garbage, comprising the following steps:

[0057] (1) Preprocessing:

[0058] a. add deodorizing disinfectant in house refuse, comprise following components, the percentage by weight of each component is: lime 43%, camphor powder 25%, peppermint powder 16%, mugwort powder 13%, peppercorns 9% ;

[0059] b. Use magnetic separation to separate and recycle metal garbage; use screening to separate glass, dregs, and bulky waste from lumpy garbage that is inconvenient to break; cut lumpy garbage; Bulk materials are crushed;

[0060] c. Obtain loose and uniform waste to be treated after crushing and shearing, wherein the average size of the waste obtained after shearing is length*width=60*40mm, and the average particle size of the obtained waste after crushing is 15mm;

[0061] (2) Drying: Put the garbage to be processed in a drying furnace for drying, and continuously add garbage to the drying furnace at a rate of 58kg / min. The drying temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com