Efficient drying device for rice seeds

A technology of rice seed and drying device, which is applied in the direction of drying, drying machine, drying gas arrangement, etc. It can solve the problems that the moisture content of rice is difficult to reach the standard, the moisture is not released in time, and the parameters are not properly selected, so as to avoid drying. The effect of uneven drying, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

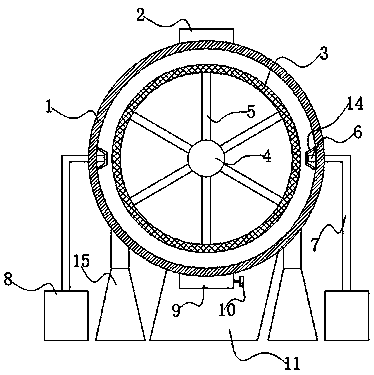

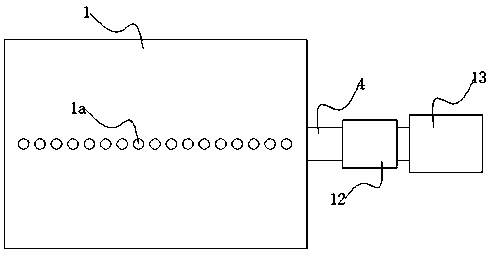

[0014] Such as Figure 1-2 As shown, the present invention discloses a high-efficiency drying device for rice seeds, comprising: a drying cylinder 1, a feed port 2, and a disturbing cylinder 3. The top of the drying cylinder 1 is fixedly welded and connected with an inlet The feed port 2, the feed port 2 is connected to the interior of the drying cylinder 1, and the interior of the drying cylinder 1 is provided with a disturbance cylinder 3, and the disturbance cylinder 3 is uniformly distributed through 6 equiangular The connecting rod 5 is connected with the central rotating shaft 4, one side shaft end of the central rotating shaft 4 is rotatably installed on the side wall of the drying cylinder 1, the other side shaft end of the central rotating shaft 4 is connected with the driving mechanism The disturbance motor 13 included in the drive mechanism is connected to the central shaft 4 through the reducer 12 .

[0015] Both side edge walls of the drying cylinder 1 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com