Patents

Literature

77results about How to "Heat and dry evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

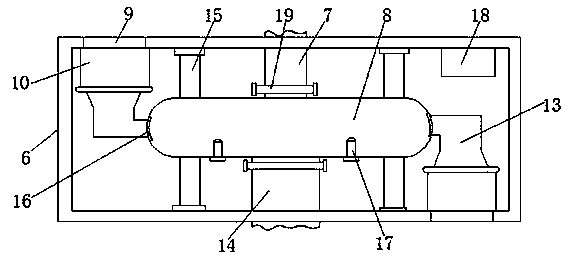

Grape drying machine

InactiveCN104970429AHeat and dry evenlySo as not to damageFood processingFood treatmentElectric machineryEngineering

The invention discloses a grape drying machine which comprises a base, wherein a storage battery and a motor are sequentially arranged from top to bottom in an inner cavity of the base; a solar panel is arranged on the upper surface of the base; a drying room is arranged on the upper part of the base; a solar panel is further arranged on the upper surface of the drying room; a heating device is further arranged in the lower part of the inner cavity of the drying room; an air injection cavity is formed on the upper part of the heating device; air injection holes are formed on two sides of the inner wall of a housing; a rotary shaft is arranged in the central position of the inner cavity of the drying room; the rotary shaft is connected with a motor through a bearing pedestal; a hanging pole is arranged at the upper end of the rotary shaft; a temperature sensor is arranged on the surface of the hanging pole. The grape drying machine is simple in structure. By additionally arranging the solar panels, solar energy can be directly collected without being converted into electric energy, so that the grape drying machine is energy-saving and environmental-friendly. Moreover, grapes in the drying process continuously rotate through the rotary shaft, so that the purpose of uniformly drying the grapes is achieved.

Owner:陈幸

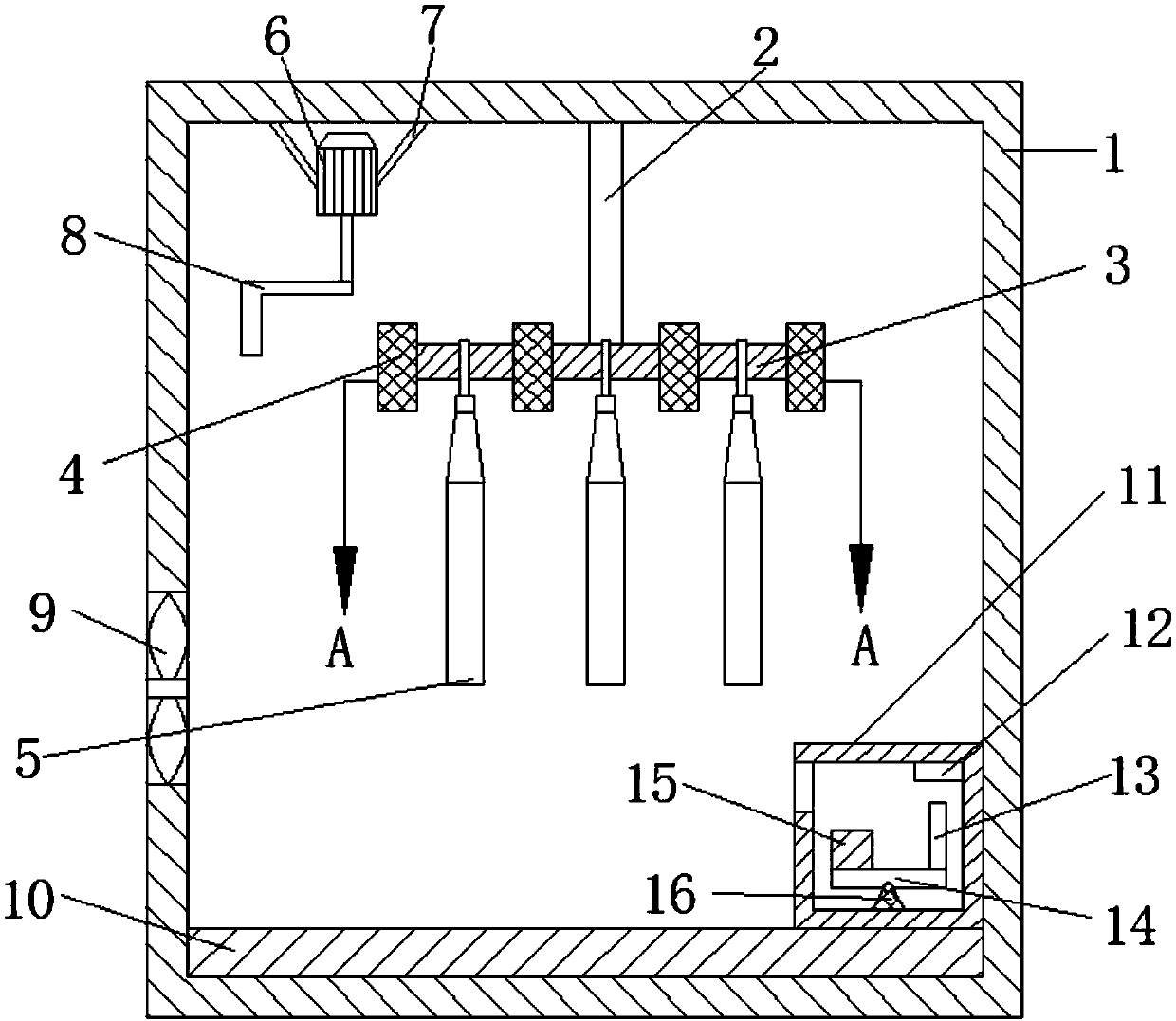

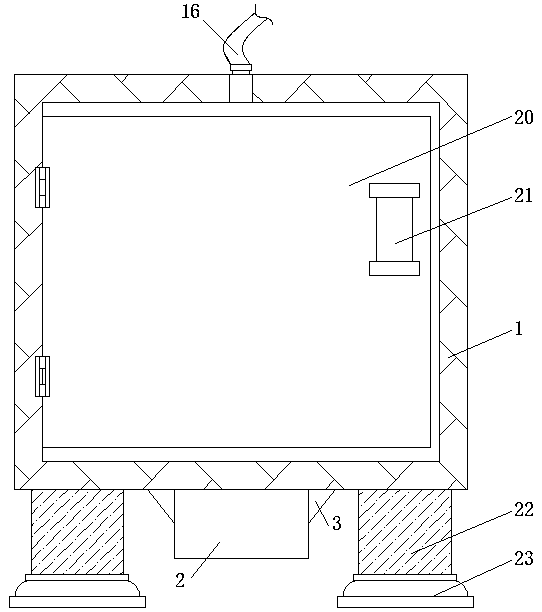

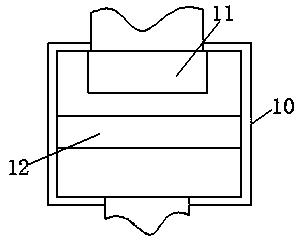

Automatic dehumidification wardrobe

InactiveCN108030262ASimple structureHeat and dry evenlyWardrobesFurniture partsWater vaporEngineering

The invention discloses an automatic dehumidification wardrobe. The wardrobe comprises a cabinet body, the cabinet body is of an inner hollow structure, the automatic dehumidification wardrobe is simple in structure, when the inner cavity of the cabinet body is overloaded with wet air, silica gel absorbent particles in a moisture absorbing box absorb moisture from the air, the increased weight ofthe silica gel absorbent particles in the moisture absorbing box drives the moisture absorbing box to drop, a metal guide plate at the other end of a connecting plate rises against a metal block, a circuit is connected, a heating plate gives out heat to evaporate water vapor, at the same time, a fan is started to discharge the damp and hot air in the inner cavity of the cabinet; a motor is startedto drive a vertical section of an L rod to rotate and be clamped between blocks on the outer edge of a ring-shaped turntable, then the ring-shaped turntable is driven to rotate, clothes hung at the lower end of the ring-shaped turntable rotate along with the rotation of the ring-shaped turntable, by the combination of the three parties of the heating plate, the fan and the ring-shaped turntable,the rotated clothes are uniformly heated and dried, the moisture is discharged, therefore the practicability is greatly improved.

Owner:郭姗姗

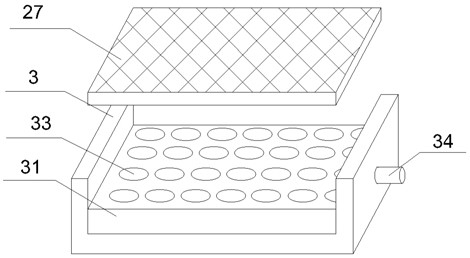

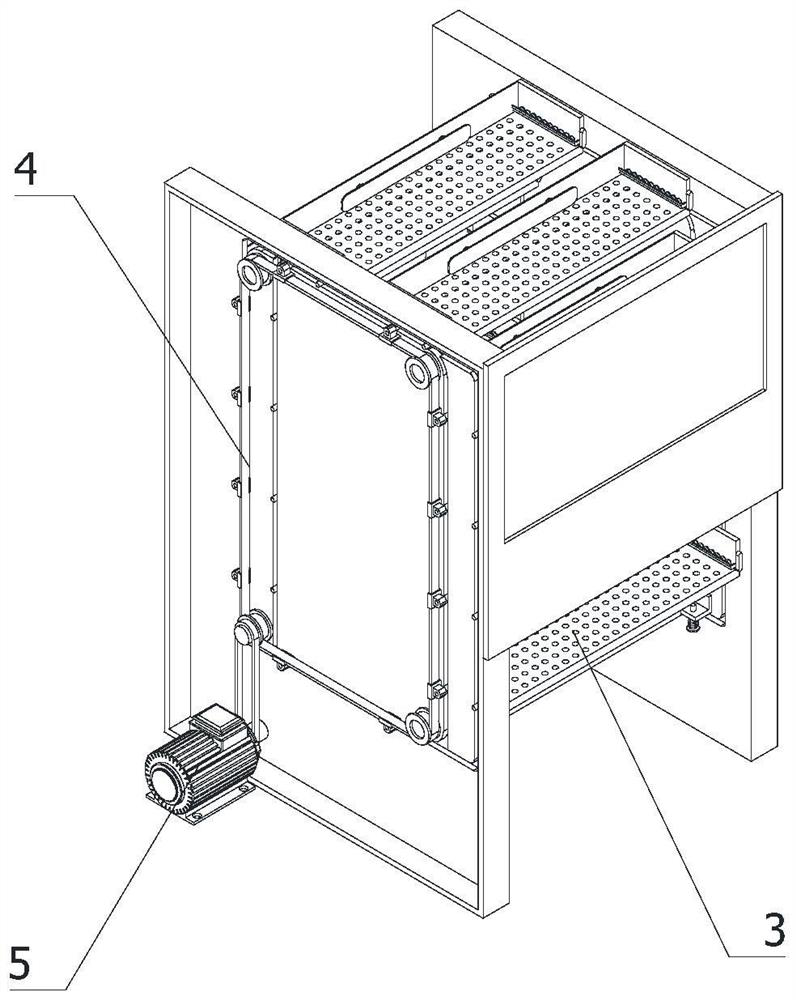

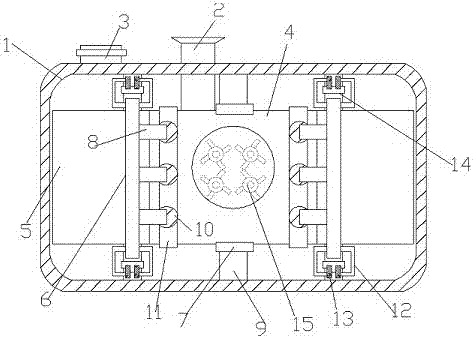

Drying device for traditional Chinese medicine processing

ActiveCN109059462AImprove efficacyHeat and dry evenlyDrying chambers/containersDrying machines with progressive movementsEngineeringDrying time

The invention discloses a drying device for traditional Chinese medicine processing. The drying device comprises a drying box body, two first mounting blocks are fixedly arranged at positions, close to the middle position, on the inner walls of the two sides of the drying box body through screws, two second mounting blocks are fixedly arranged under the two first mounting blocks through the screws, two first transmission wheels are fixedly arranged on the opposite sides of the two first mounting blocks through the screws, the outer walls of circumferences of the two first transmission wheels are connected with the same first conveying belt in a sleeved mode, screen holes which are distributed at equal intervals are formed in the outer wall of the first conveying belt, two second transmission wheels are fixedly arranged on the opposite sides of the two second mounting blocks through the screws, and the outer walls of the circumferences of the two second transmission wheels are connectedwith the same second conveying belt in a sleeved mode. The drying device has the advantages of being practical and novel, exquisite in appearance, diverse in function, convenient to uniformly heat and dry the medicines, capable of preventing drying from being uneven, facilitating control of drying time, therefore realizing optimal drying effect, and good in stability.

Owner:安徽中和堂制药有限公司

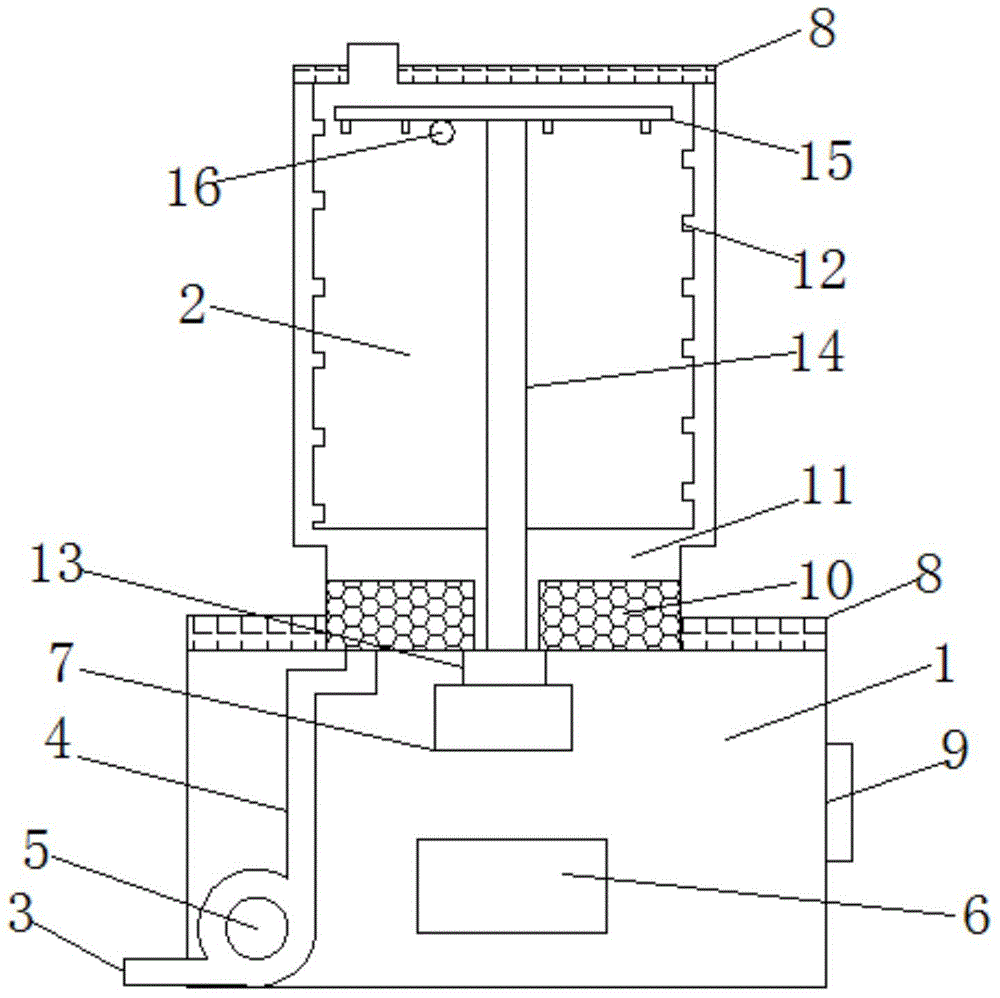

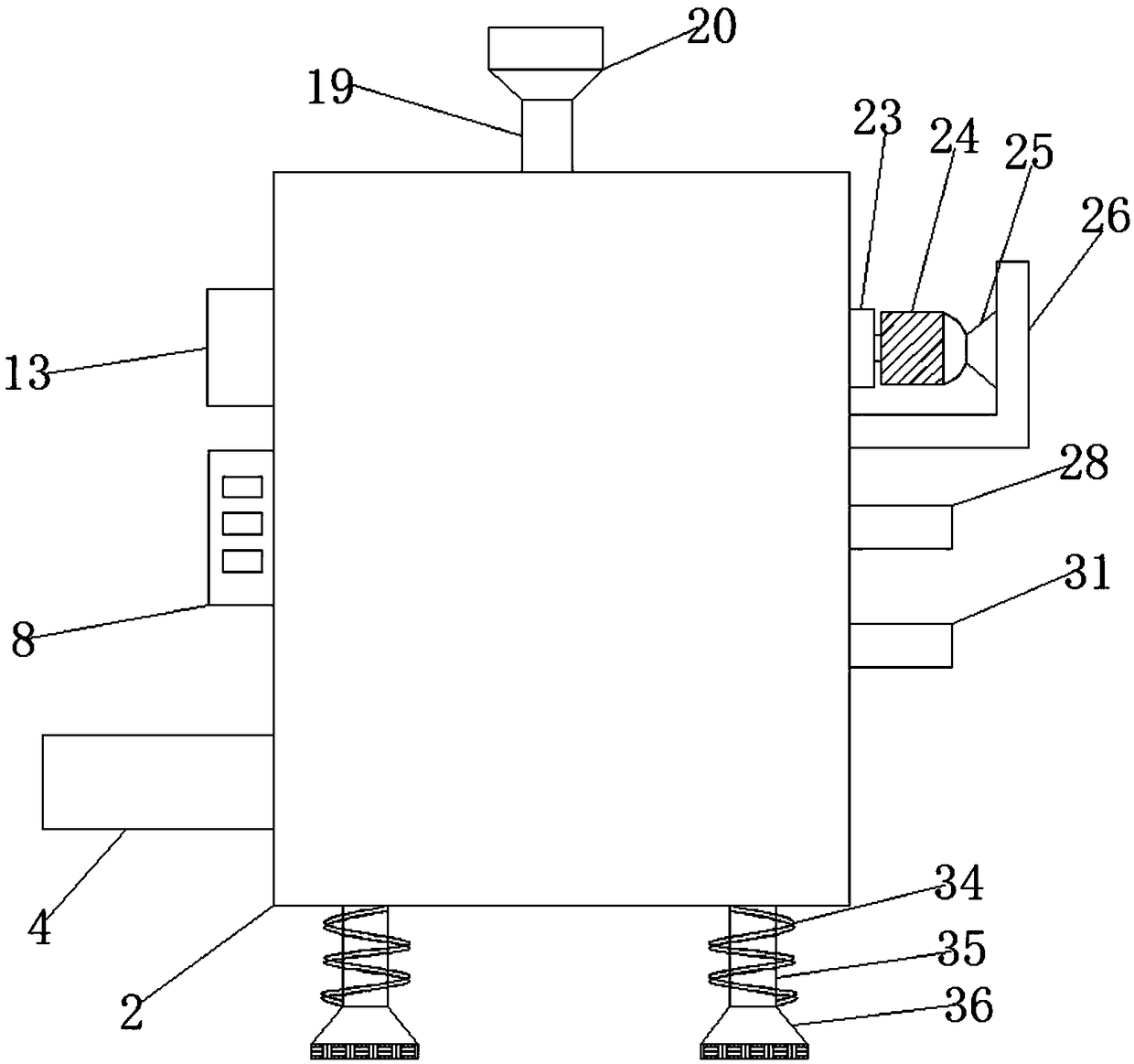

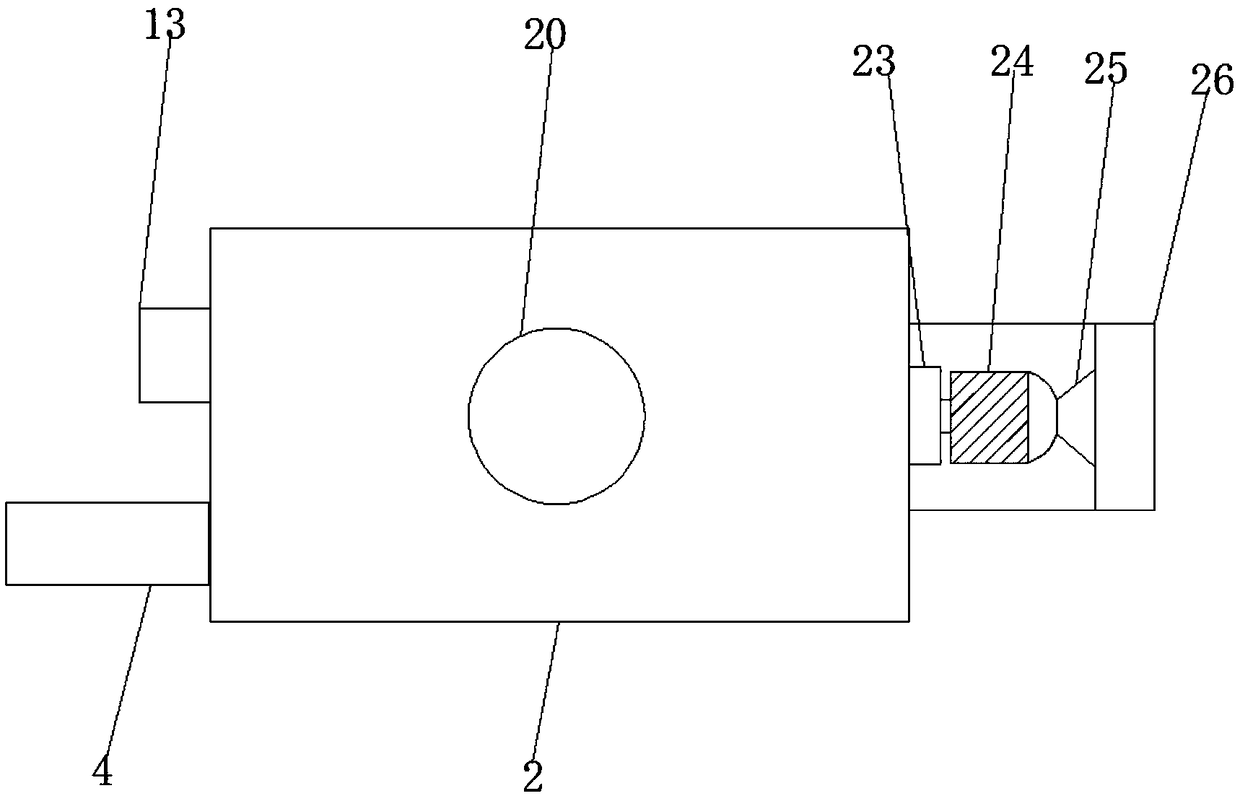

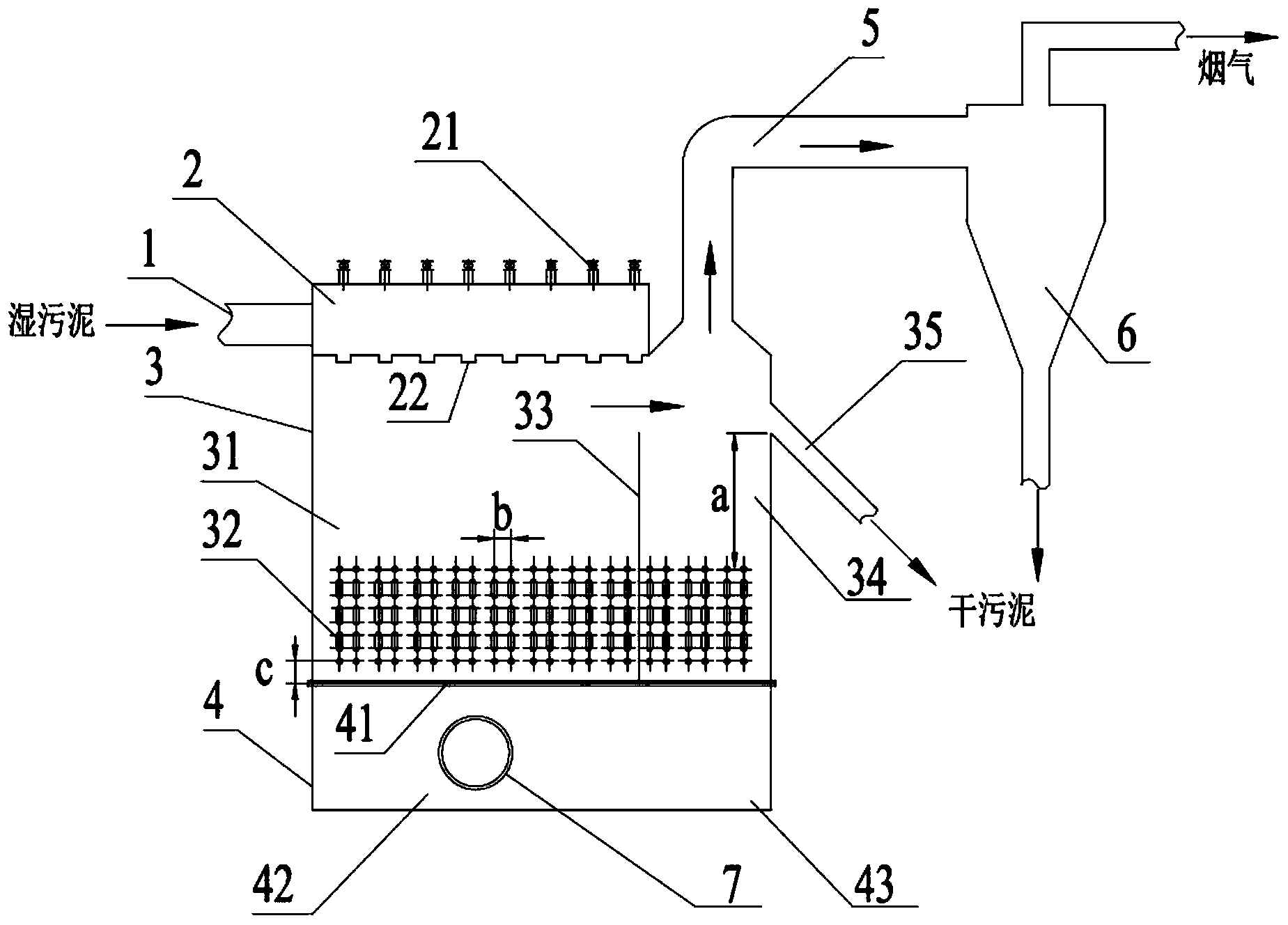

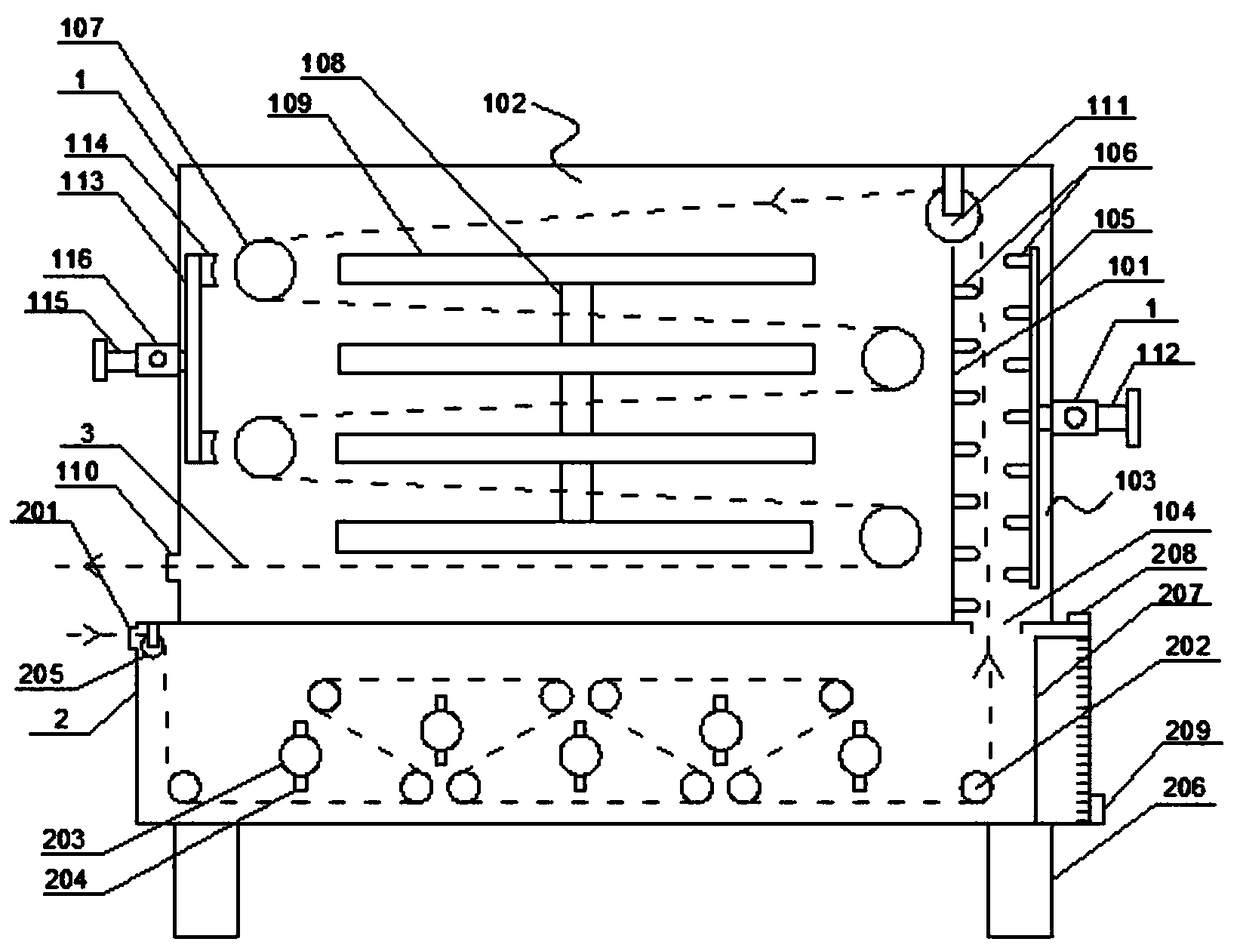

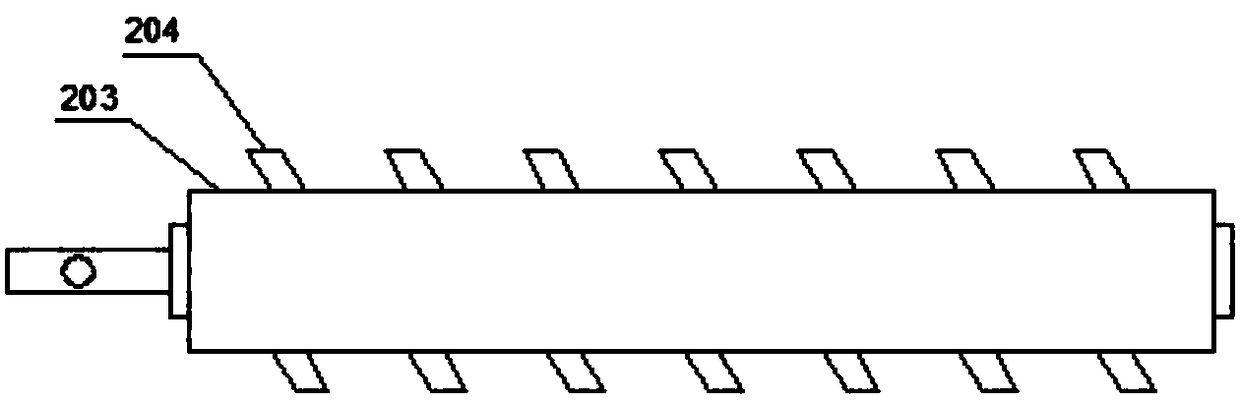

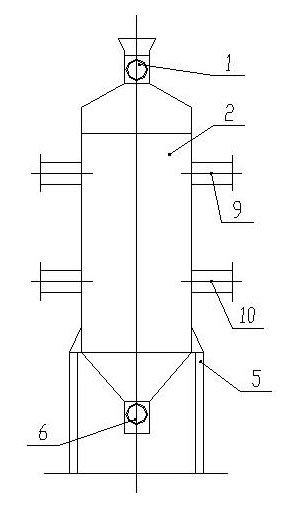

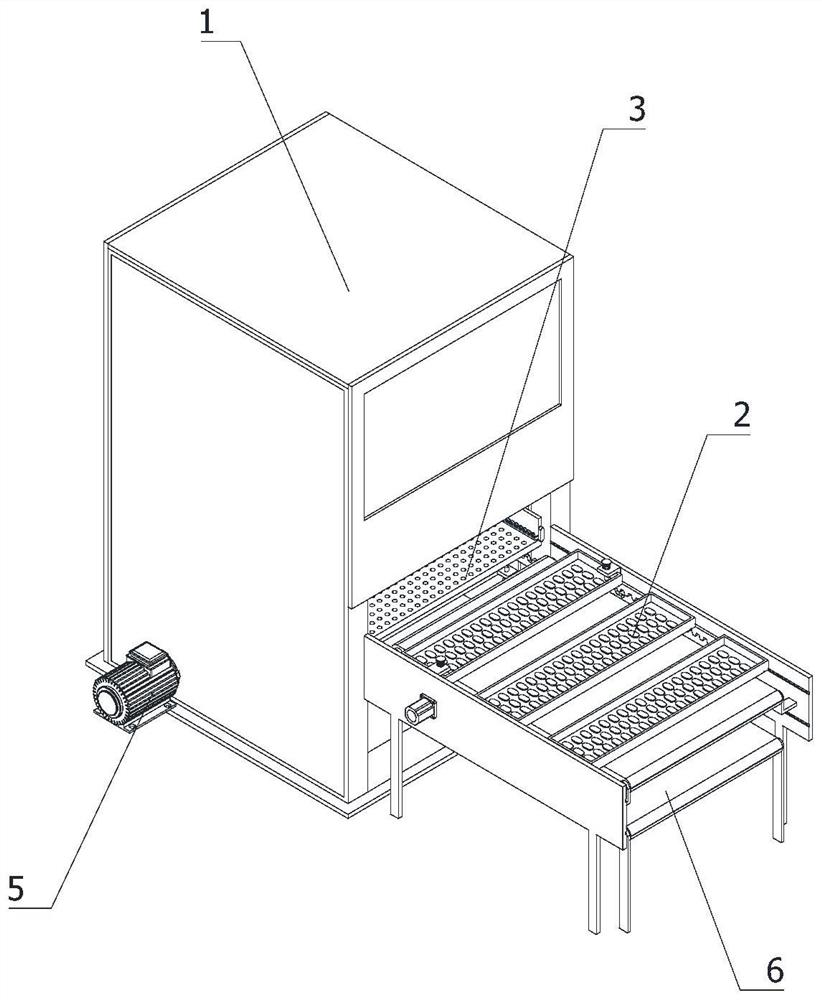

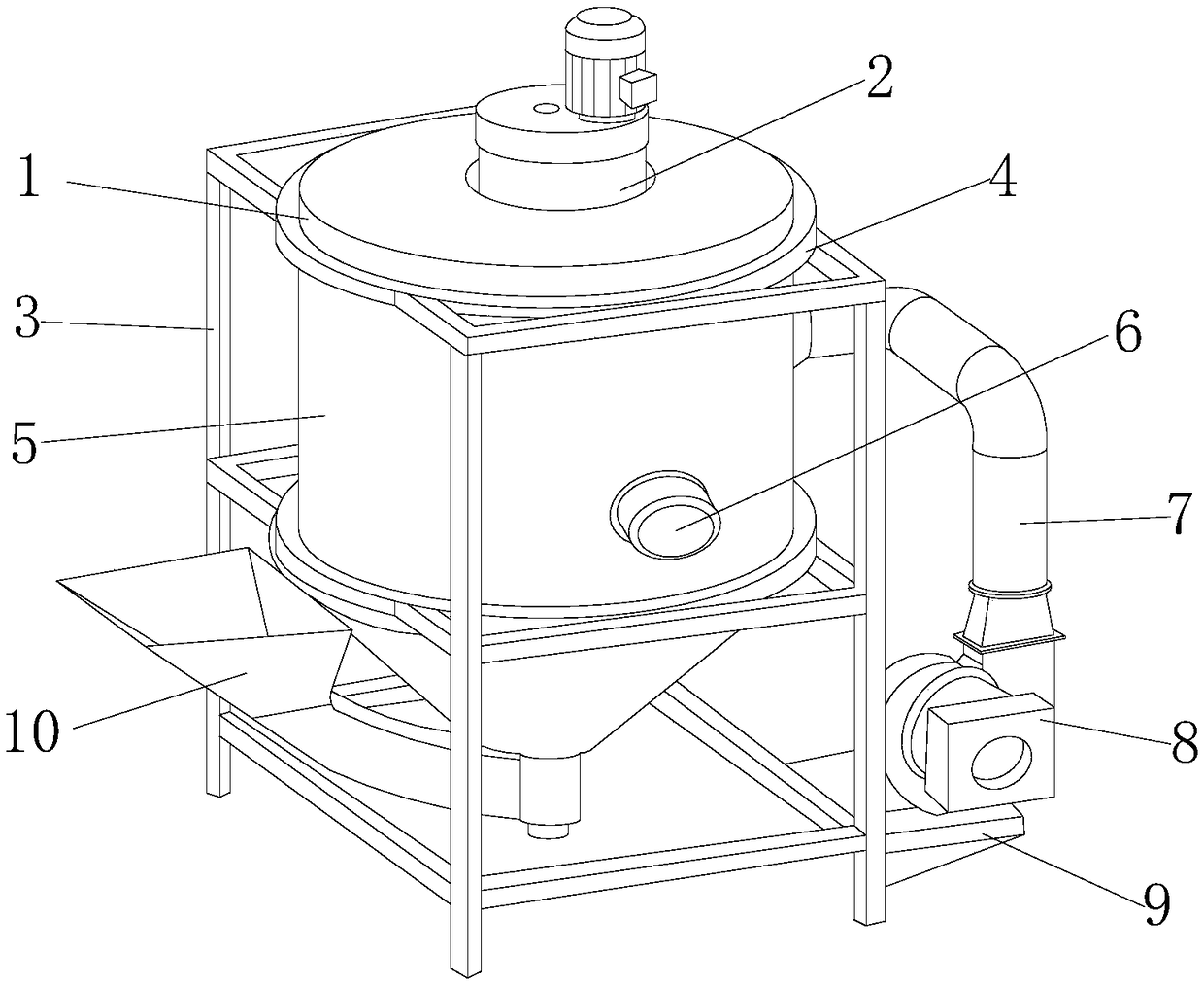

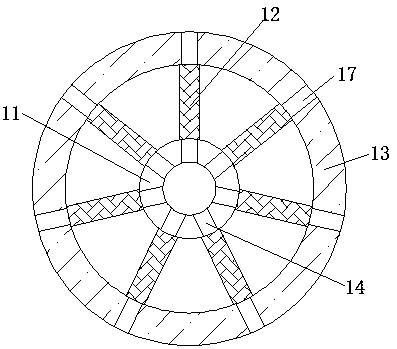

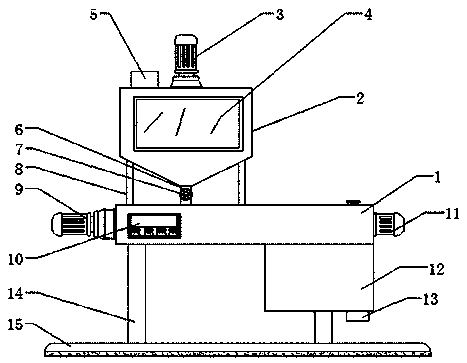

Drying system for dark green tea

InactiveCN104654757AImprove drying qualityMellow tasteDrying gas arrangementsDrying machines with non-progressive movementsAgricultural engineeringFood flavor

The invention discloses a drying system for dark green tea. A drying room is arranged in a shell; the inner side of the shell is provided with an air duct; an insulating layer is arranged between the shell and the air duct; air outlets are formed in the upper end of the air duct; an air intake fan is arranged in the air duct; the lower end of the air duct is provided with an infrared heating device; an air inlet is formed in the bottom part of the infrared heating device; a driving device is arranged at the bottom part of the drying room; the driving device is provided with a revolving shaft; the revolving shaft is provided with turnplates; an exhaust fan is arranged at the top part of the drying room; a first temperature sensor is arranged at the corner of the bottom face and the side face of the drying room; a second temperature sensor is arranged at the corner of the top face and the side face of the drying room; the outer side of the shell is provided with a display screen and a controller; the bottom part of the shell is provided with castors. The drying system for the dark green tea has the advantages that components in the tea are fully decomposed, the tea is heated and dried evenly, the drying speed is fast, the drying efficiency is high, the drying quality of the dark green tea is good, and the tea does not have a smoky flavor.

Owner:HUNAN AGRICULTURAL UNIV

Drying device for automobile parts

InactiveCN107262447AEasy to cleanReduce labor intensityDrying solid materials with heatDrying gas arrangementsEngineeringCleansing Agents

The invention relates to the technical field of automobile parts, and discloses a drying device for automobile parts. The drying device comprises a tank body, wherein a water tank, a tank cover and an agent tank are sequentially arranged on the upper surface of the tank body from left to right; one side of the water tank is fixedly connected with a pipeline, and the pipeline is fixedly provided with a valve; the two sides in the tank body are fixedly connected with fixing blocks, one side of each fixing block is fixedly connected with a cleaning tank, one side of the tank body is fixedly connected with a supporting plate, the upper surface of the supporting plate is fixedly connected with a first motor, and an output shaft of the first motor is fixedly connected with a first rotating rod. The drying device for the automobile parts is provided with the water tank, the agent tank, the first motor and the cleaning tank, the tank cover is opened, the automobile parts are put in the cleaning tank, water and cleaning agents are put in the cleaning tank, stirring blades in the cleaning tank are driven by the first motor to rotate, efficient cleaning of the automobile parts is realized, and the cleaning effect is improved.

Owner:合肥杰代机电科技有限公司

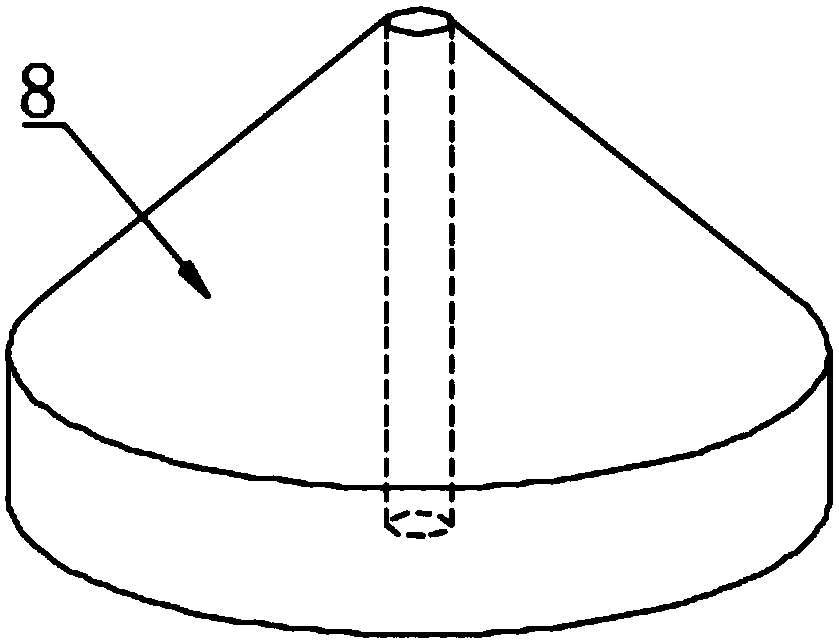

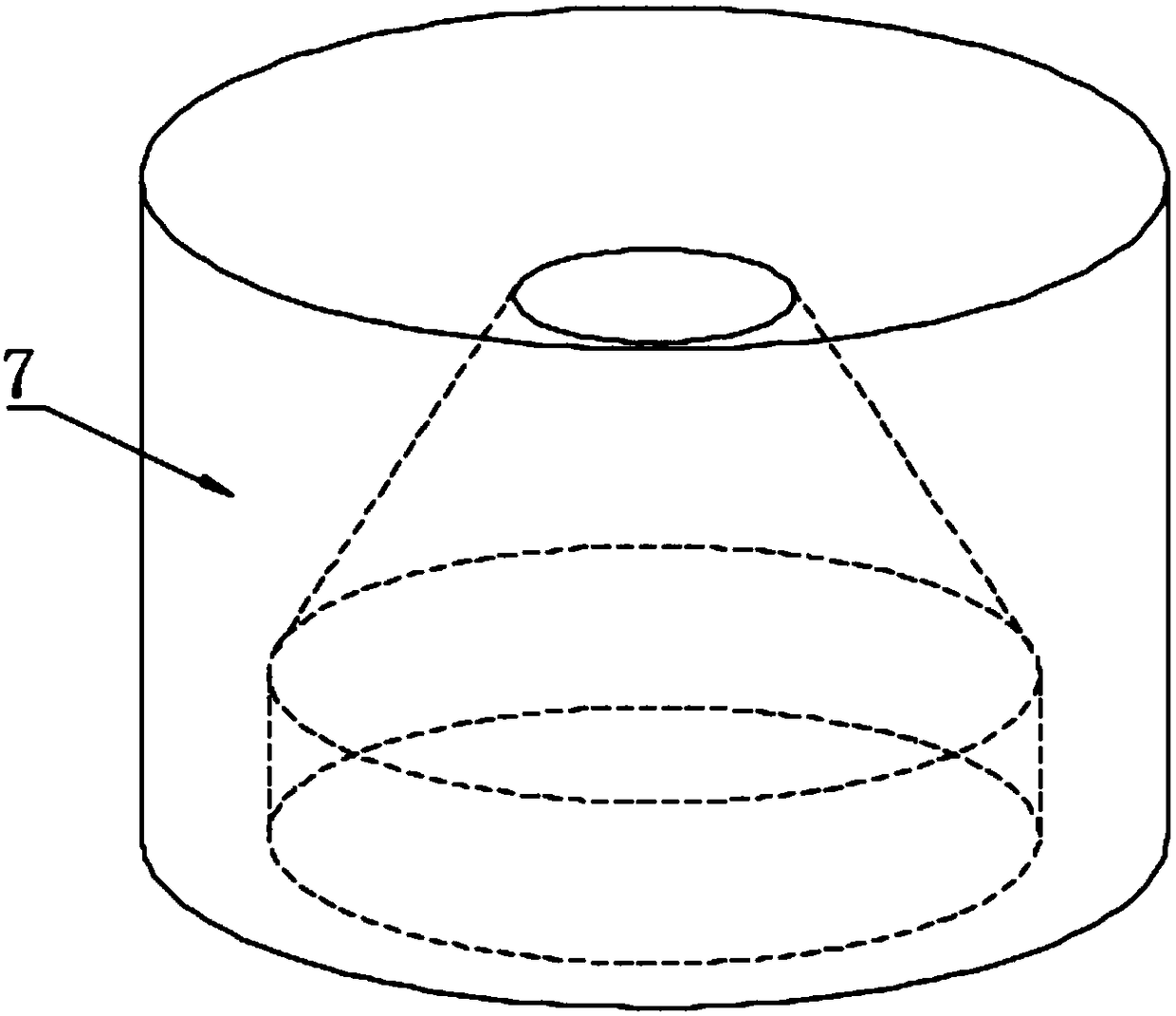

Drying and grinding device for agricultural soil testing

InactiveCN108579873AEasy grinding and testingGood grinding effectDrying solid materialsGrain treatmentsMotor shaftEngineering

The invention discloses a drying and grinding device for agricultural soil testing. The drying and grinding device comprises a base, a grinding cylinder is fixedly arranged on the base through a bracket, the bottom of the grinding cylinder is in a funnel shape, and a discharging pipe is connected to the center of the bottom of the grinding cylinder; a first deceleration motor is fixedly disposed at the center of the top of the grinding cylinder, and a motor shaft at the bottom end of the first deceleration motor penetrates through the top wall of the grinding cylinder and is fixedly connectedwith a first rotating shaft; a grinding roller is fixedly mounted on the first rotating shaft, and the top of the grinding roller is in a taper shape; and grinding seats are fixedly arranged on the inner wall of the grinding cylinder, the grinding seats are provided with up-and-down penetrating cavities matched with the grinding roller, and the tops of the cavities of the grinding seats are in a circular truncated cone shape. Through the cooperation of the grinding seats and the grinding roller, soil is grinded, the distance between the circular truncated-cone-shaped cavities of the grinding seats and the tapered portion of the grinding roller is gradually decreased from top to bottom, so that the soil is gradually grinded from top to bottom, and the grinding effect is better.

Owner:孙利成

Dried shiitake mushroom production equipment with sterilization action

ActiveCN112385866ARealize automatic layoutRealize automatic de-handlingSievingScreeningBiotechnologyEngineering

The invention relates to the technical field of food processing equipment and discloses dried shiitake mushroom production equipment with a sterilization action. The dried shiitake mushroom productionequipment comprises a box body, wherein a top seat is arranged at the internal upper end of the box body, a cutting box is arranged at the lower end of the top seat, a screen plate is arranged at thelower end of the cutting box, a cleaning tank is arranged at the lower end of the screen plate, a drying chamber is arranged at one side, far away from the cleaning tank, inside the box body, supporting columns are arranged inside the drying chamber, and ultraviolet sterilizing lamps are arranged on internal walls of the drying chamber. According to the dried shiitake mushroom production equipment with the sterilization action, through matching between the cutting box and the screen plate, shiitake mushrooms can be subjected to automatic stem removing and automatic screening separation; the shiitake mushrooms are cleaned through rubber sleeves, and thus, damage to appearance of the shiitake mushrooms is reduced; and the ultraviolet sterilizing lamps are arranged in the drying chamber, sothat uniform baking and sterilizing of the shiitake mushrooms are facilitated, the space usage of the equipment is saved, and procedure flows of manual transferring are also reduced.

Owner:河南天中亿龙食品有限公司

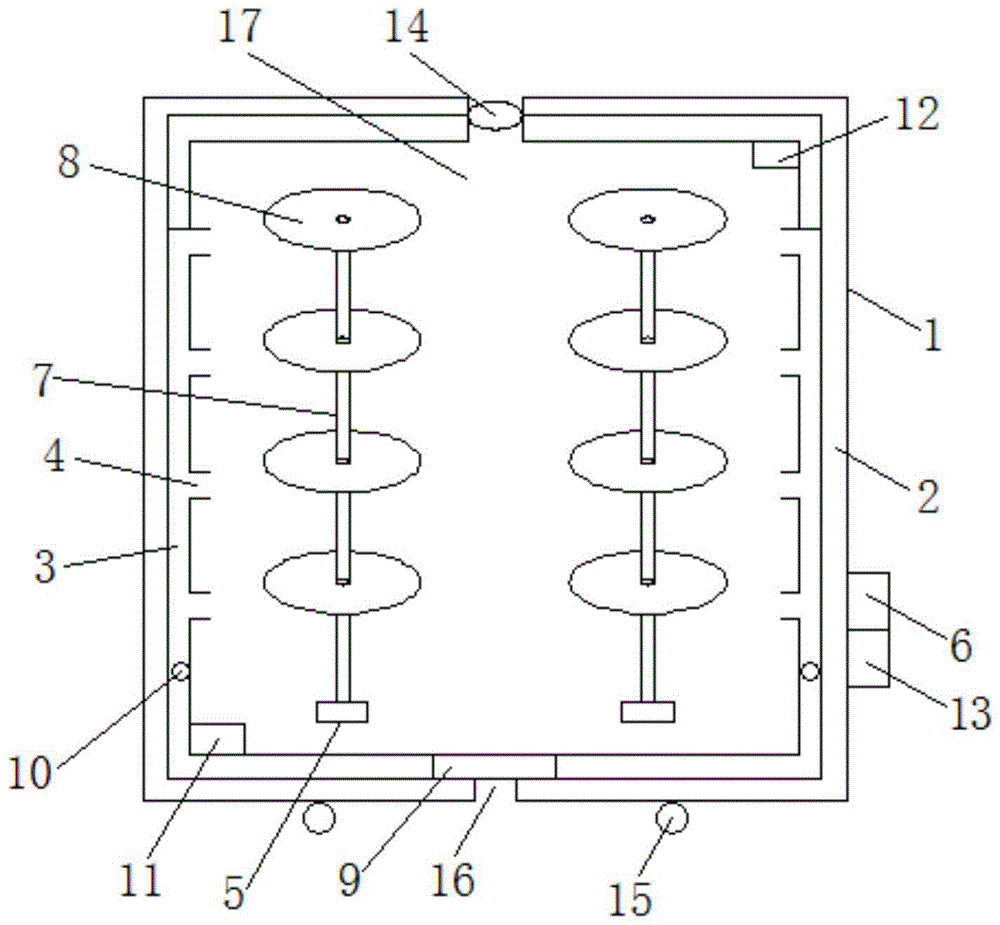

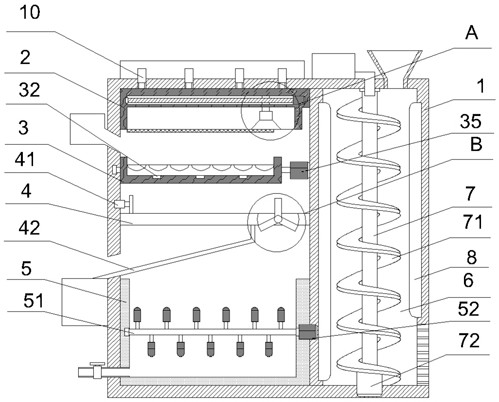

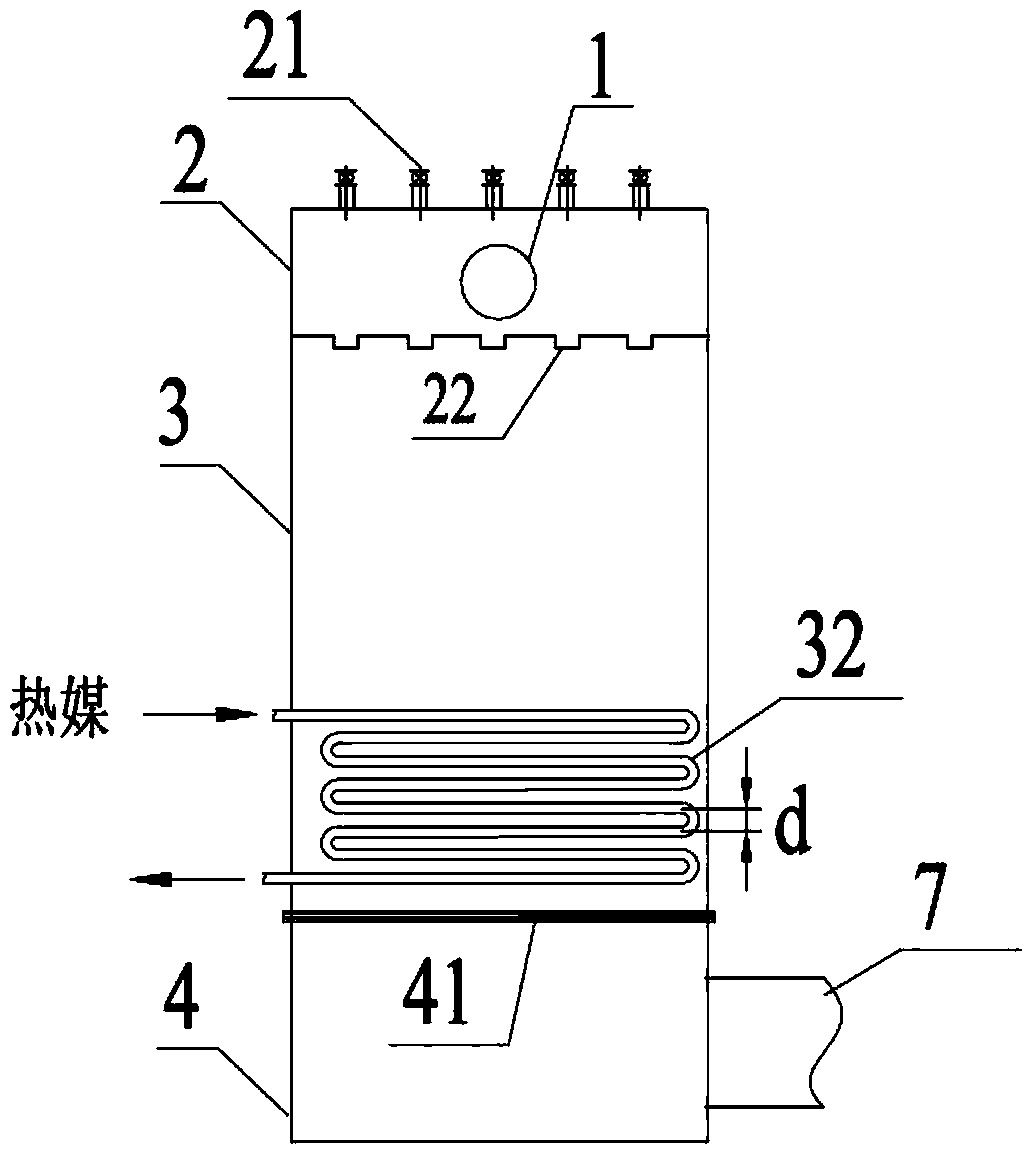

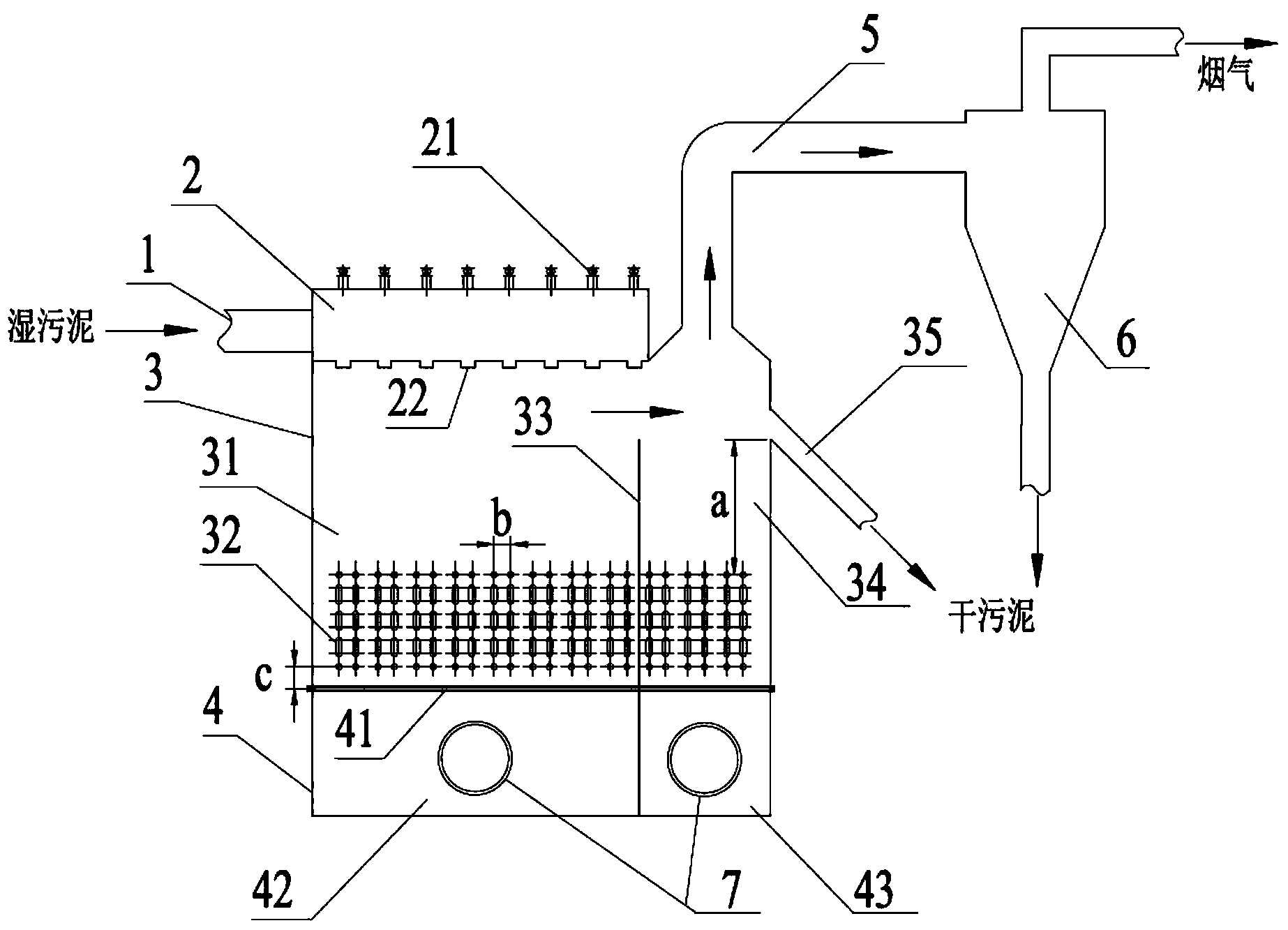

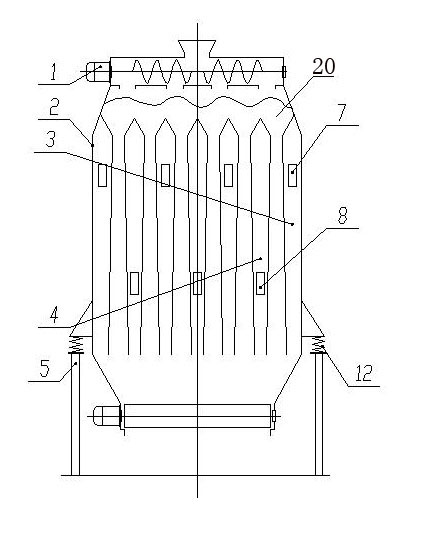

Double-chamber fluidized bed sludge dryer

ActiveCN104058571AGuaranteed uptimeUnblock in timeSludge treatment by de-watering/drying/thickeningWater contentSpray nozzle

A double-chamber fluidized bed sludge dryer comprises a distribution chamber, an air chamber, a drying chamber, a cyclone separator and the like. The double-chamber fluidized bed sludge dryer is mainly characterized in that the side end surface of the distribution chamber is connected with a wet sludge feeding pipe, a plurality of ball valves are arranged on the upper end surface of the distribution chamber, a plurality of sludge spraying nozzles are arranged on the lower end surface of the distribution chamber, the centers of the ball valves coincide with the centers of the sludge spraying nozzles in the vertical direction, the air chamber and the drying chamber are respectively divided into two corresponding sub-chambers, the first air sub-chamber is filled with 67%-75% of total air, and 67%-75% of the total heat exchange surface of a heater is formed in the first drying sub-chamber. Under the condition that the work of the dryer is not influenced, the sludge spraying nozzles blocked by sundries like braided straps mixed in sludge can be quickly unblocked. In addition, the double-chamber fluidized bed sludge dryer has the advantages that feeding is uniform, dry sludge particulates are uniform in water content, the energy consumption is low, the drying efficiency is high, and operation is reliable.

Owner:SOUTHEAST UNIV

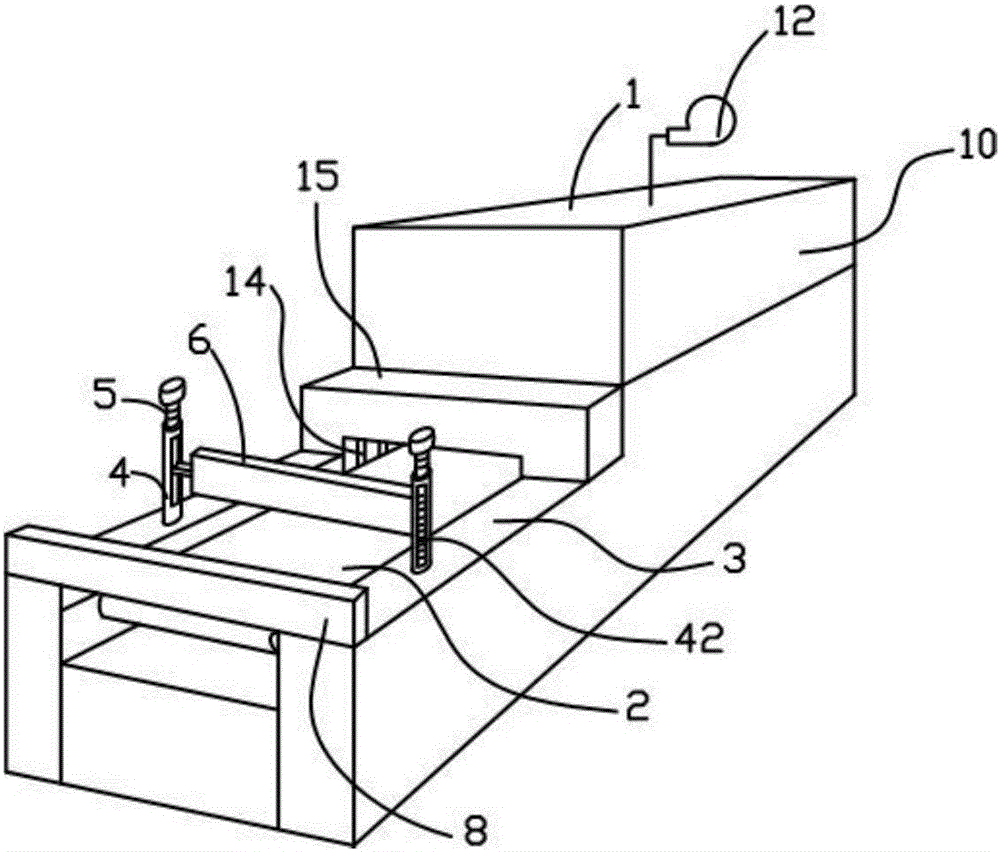

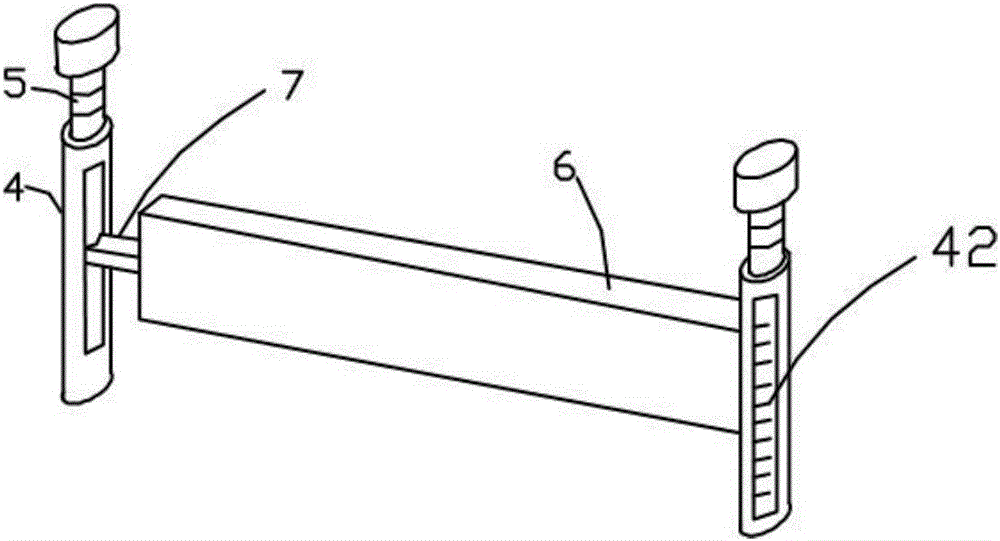

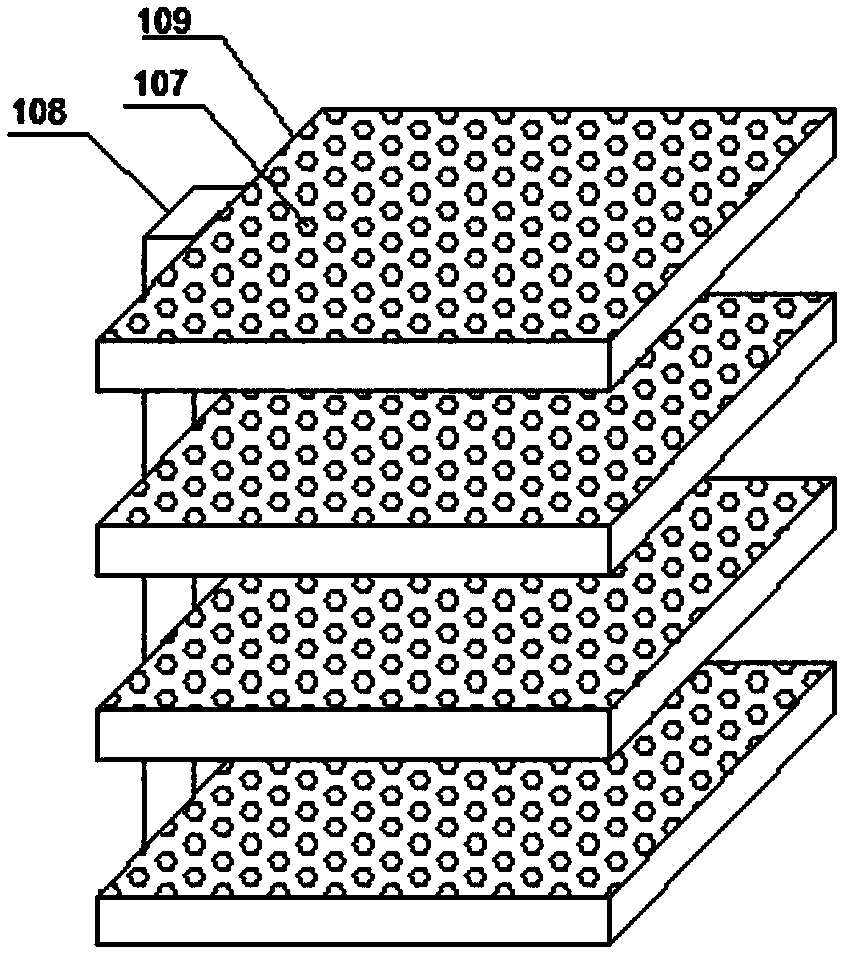

Tea dryer facilitating full use of heat

InactiveCN106766811AEvenly heatedTake advantage ofPre-extraction tea treatmentTea dryingThermal energyPulp and paper industry

The invention discloses a tea dryer facilitating full use of heat, comprising a drying box body, a conveying meshed belt, a rack and a retainer mechanism; the retainer mechanism comprises fixing bushes arranged on the rack at two ends of the conveying meshed belt; adjusting rods are inserted into the free ends of the fixing bushes, each adjusting rod includes a fixing post and a bolt which are axially overlapped and linearly and fixedly connected, the fixing posts are movably inserted into the fixing bushes, the bolts are in fitting connection with an internal thread of the open ends of the fixing bushes, the sidewall of each fixing bush is provided with a slide slot, two ends of a moving retainer are fixed to the fixing posts through connection rods passed through the slide slots, and the surface of the moving retainer is perpendicular to the conveying direction of the conveying meshed belt. A heating box is arranged on the upper portion of the drying box body, an infrared heating plate is arranged in the heating box, a blower is arranged at the top of the heating box, the bottom of the heating box is provided with a partition in which air holes are distributed, and the bottom of the heating box is communicated with the drying box body. Tea leaves can be heated and baked evenly, energy can be fully utilized, and resource waste and environmental pollution are decreased.

Dyeing and drying machine for cotton and linen cloths

ActiveCN108708110AGuaranteed liquidityLiquidityLiquid/gas/vapor removalTextile treatment machine arrangementsPolymer scienceEngineering

The invention provides a dyeing and drying machine for cotton and linen cloths, comprising a baking chamber and a dyeing chamber below the same. A plurality of transmission rollers are arranged in thedyeing chamber; an air pipe is arranged in an area enclosed by the transmission rollers; a partition is arranged on the inner right of the baking chamber and divides the baking chamber into a dryingchamber and a flattening chamber; the bottom of the flattening chamber is provided with an opening that is communicated with the top of the dyeing chamber; the right side of the flattening chamber ismovably penetrated by a flat plate; a plurality of flattening strips are arrayed on the right of the partition; a plurality of guide rollers are staggered in the drying chamber from top to bottom; theinner rear wall of the drying chamber is provided with an intake pipe; the inside of the drying chamber is provided with an air guide chamber corresponding to each guide roller; the rear ends of theair guide chambers are communicated with the intake pip. The dyeing and drying machine for cotton and linen clothes has good uniform dyeing effect of cloths; a dyeing liquid has good mobility; the dyeing and drying machine for cotton and linen cloths also has excellent flattening effect and tensioning effect and high drying efficiency, front and back of cloth are uniformly heated and dried, multiple flatten-compressing can be performed during drying, and cloths have good comprehensive quality.

Owner:安徽职业技术学院

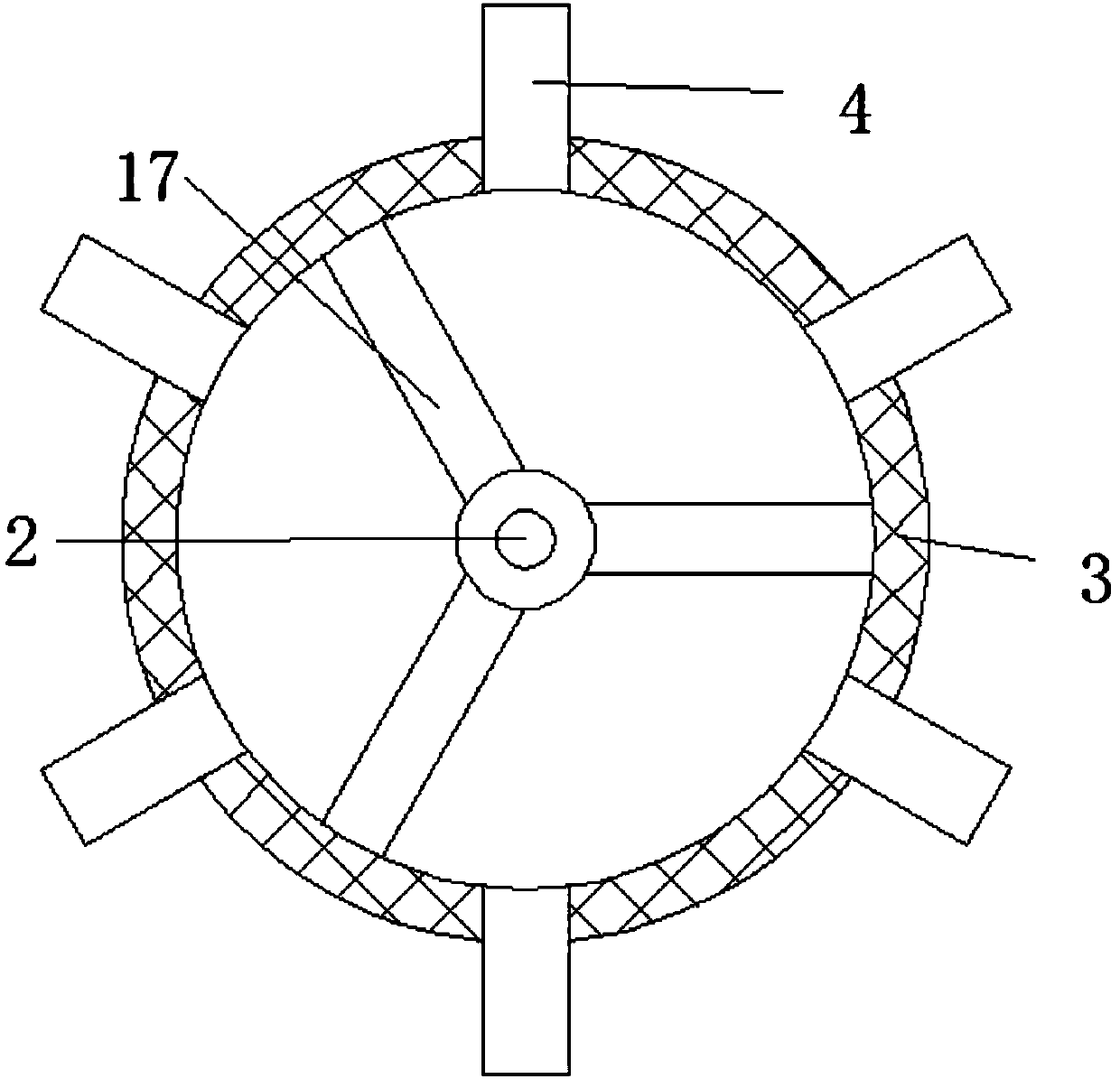

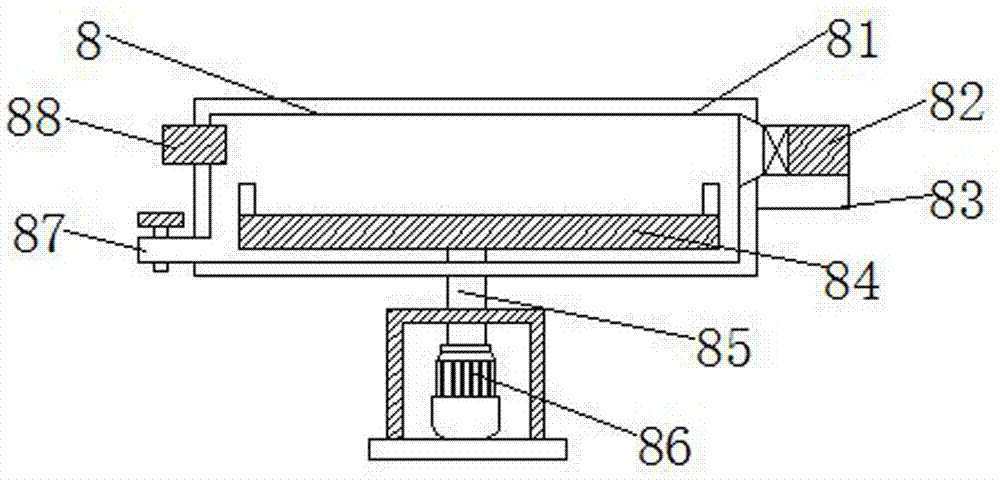

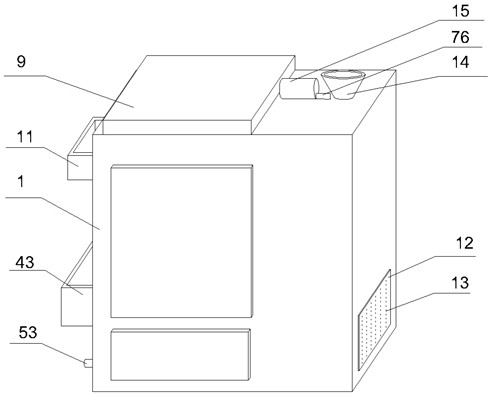

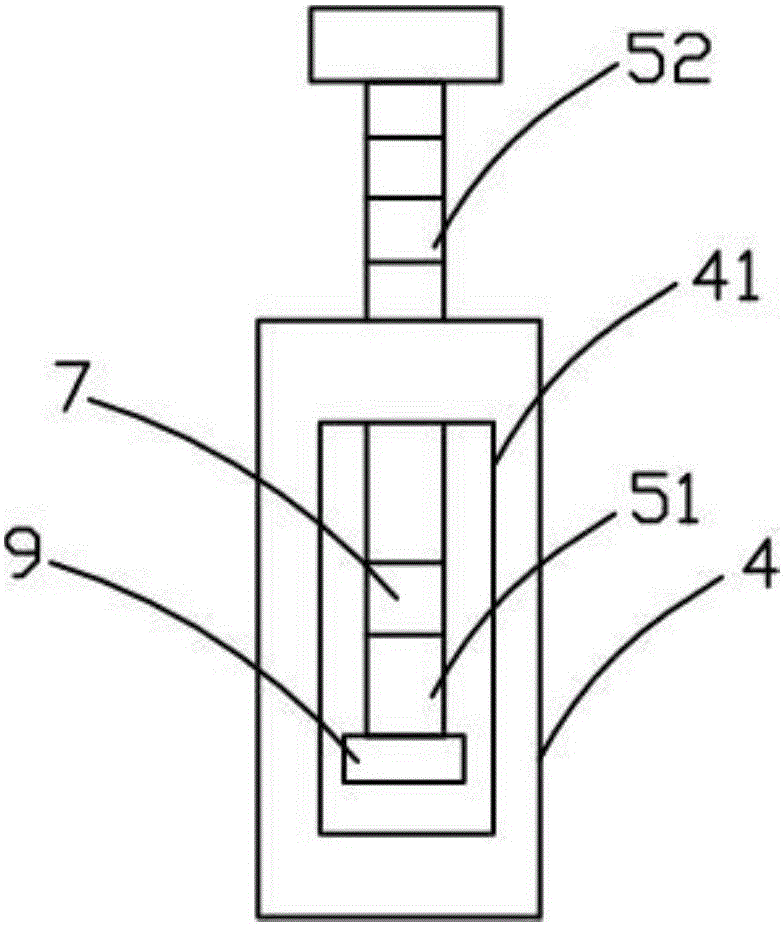

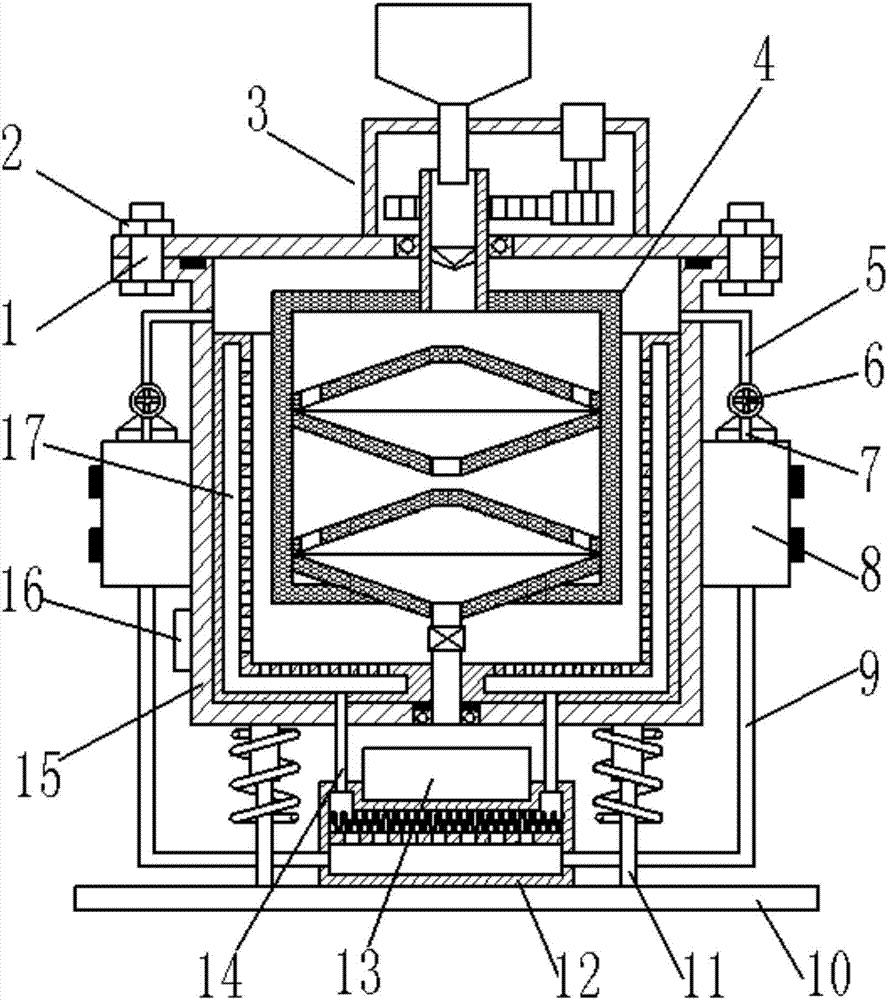

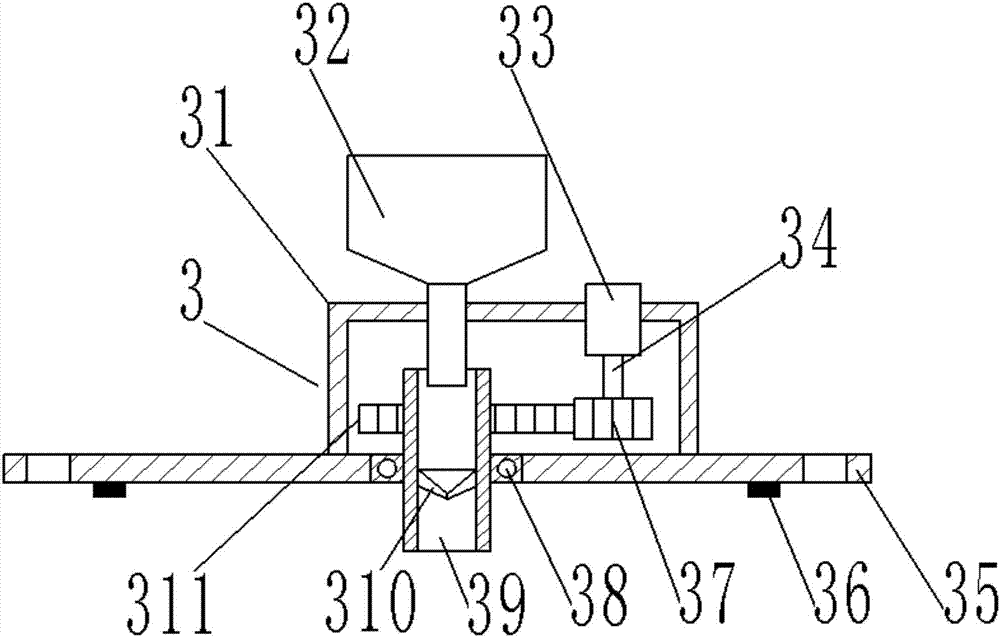

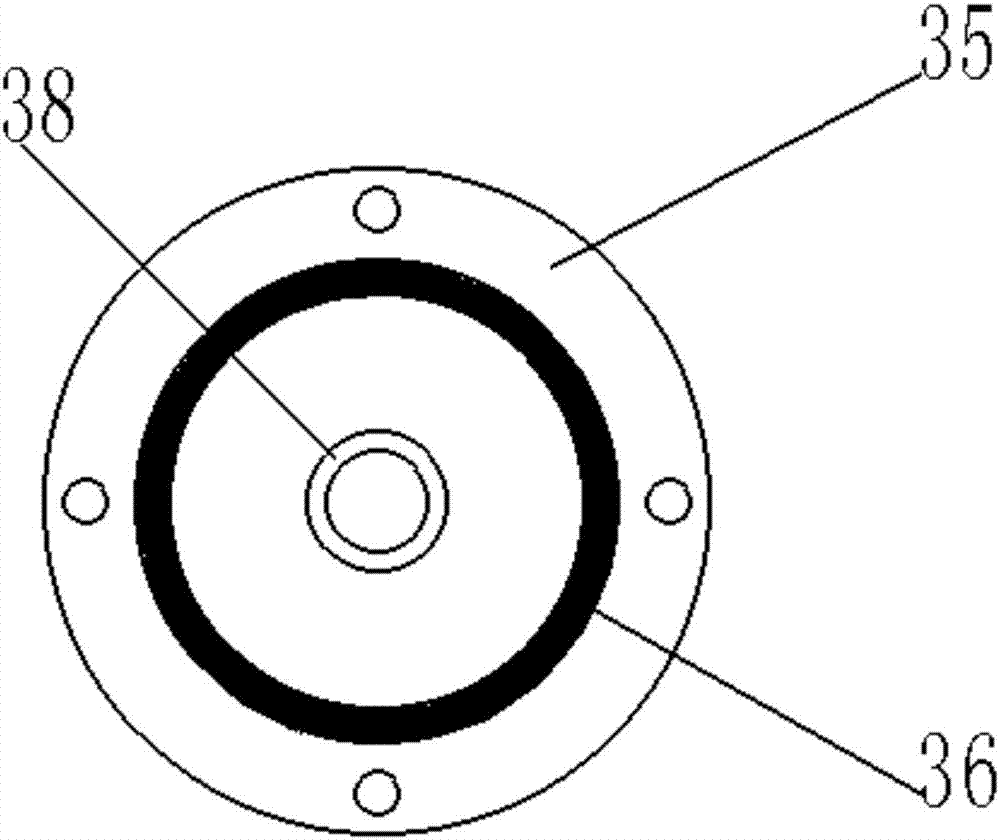

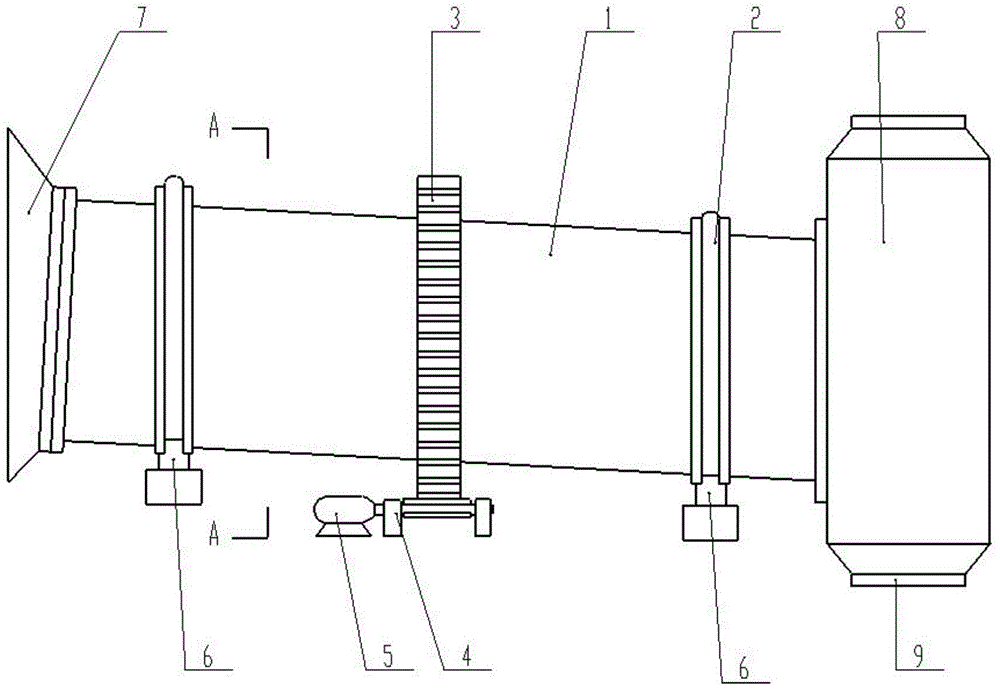

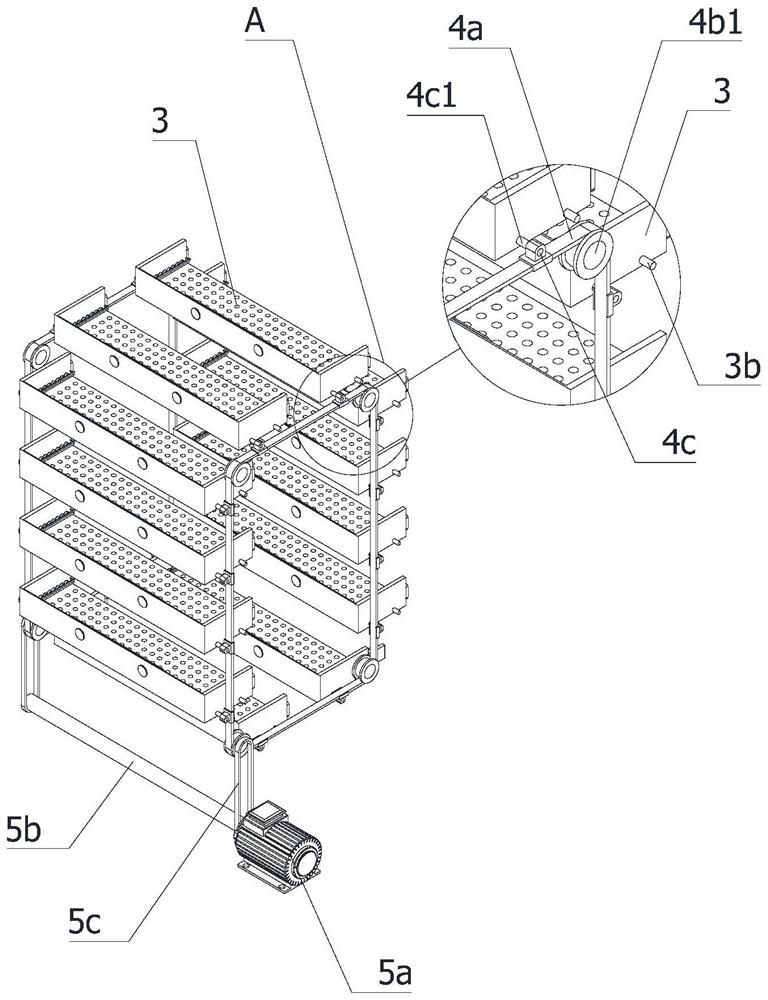

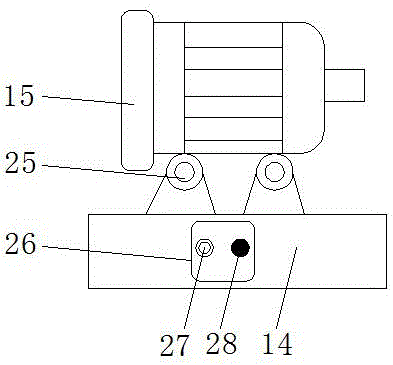

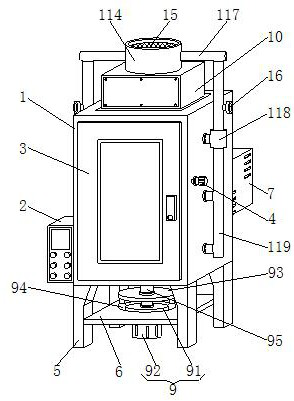

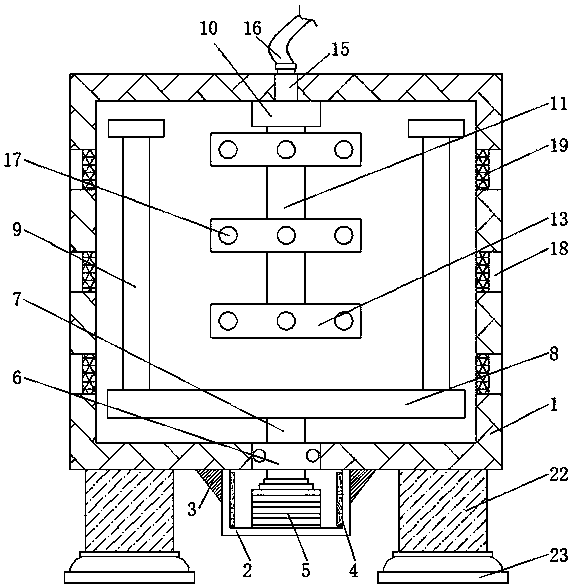

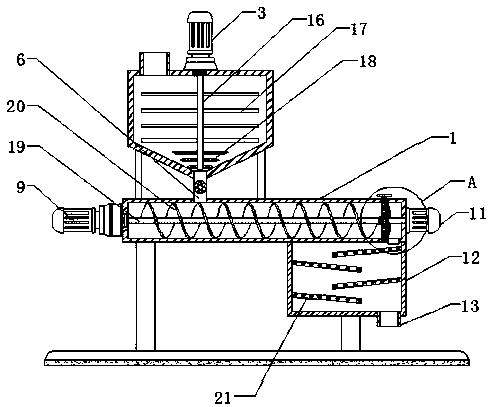

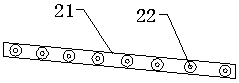

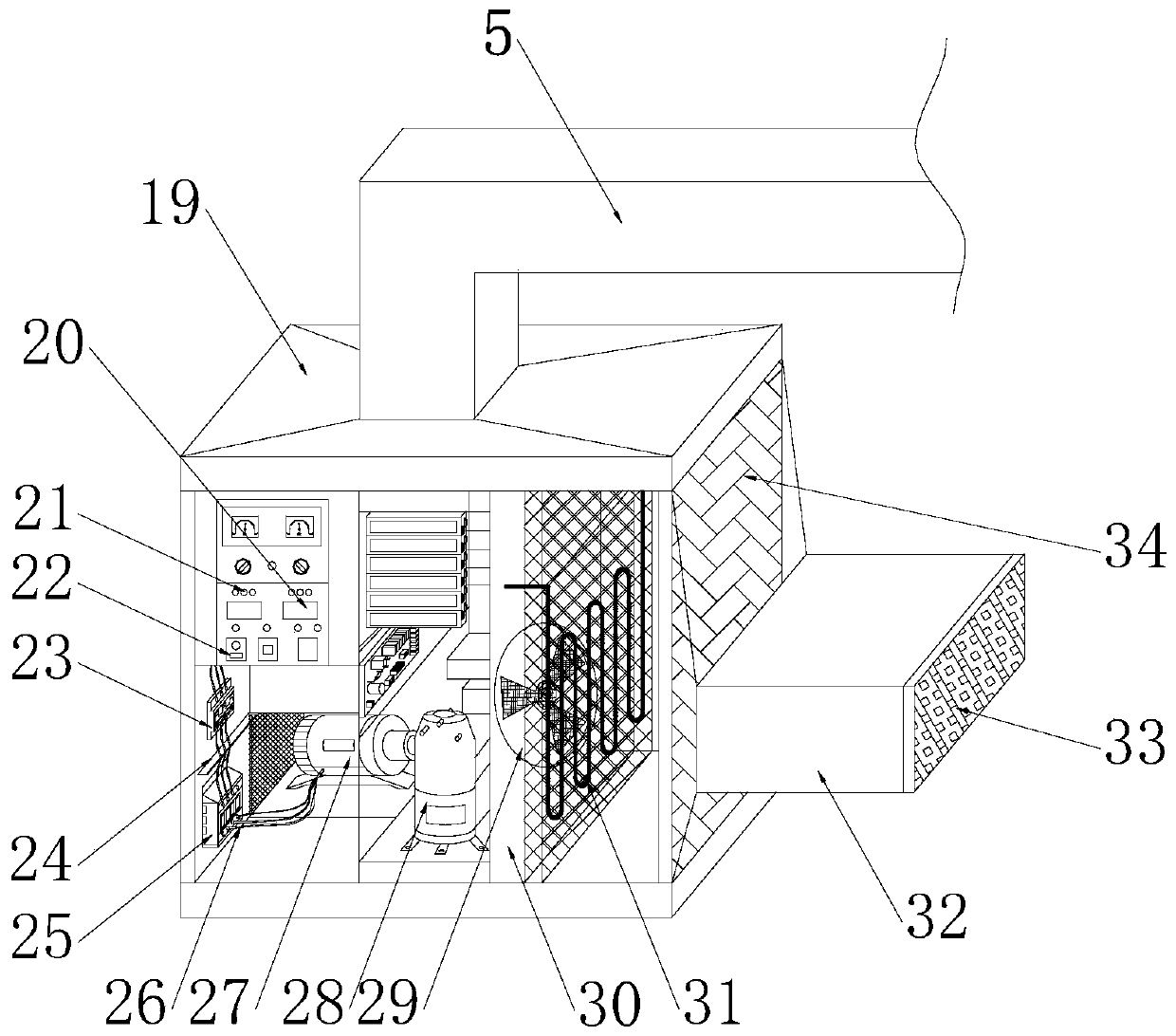

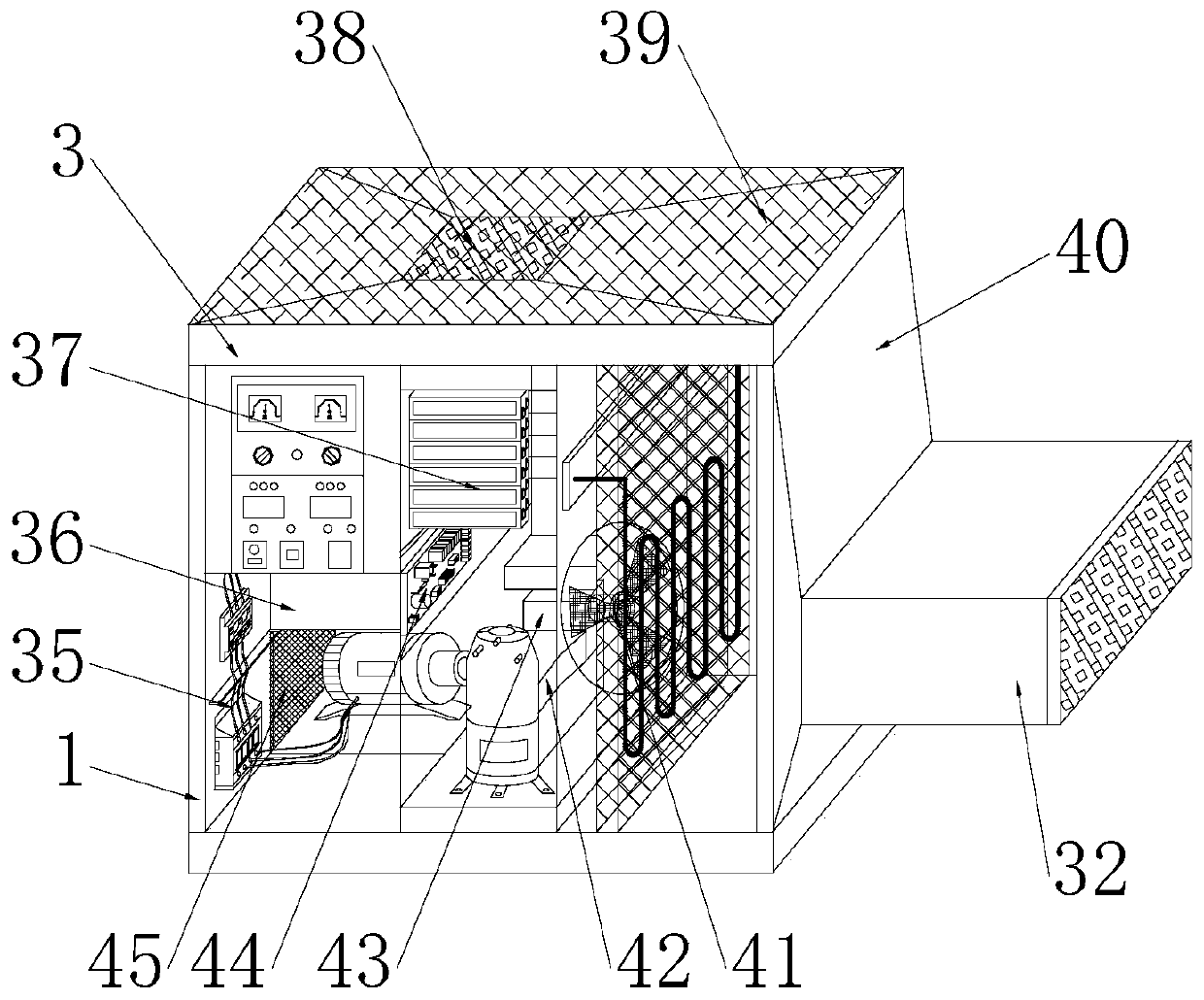

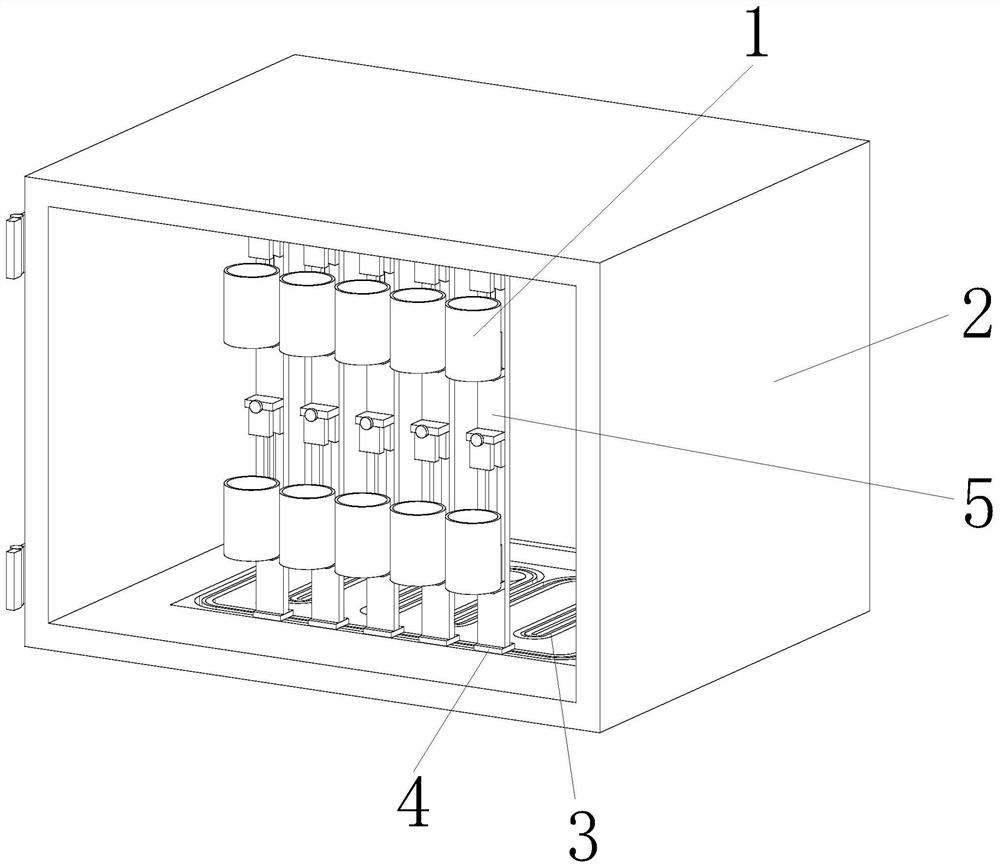

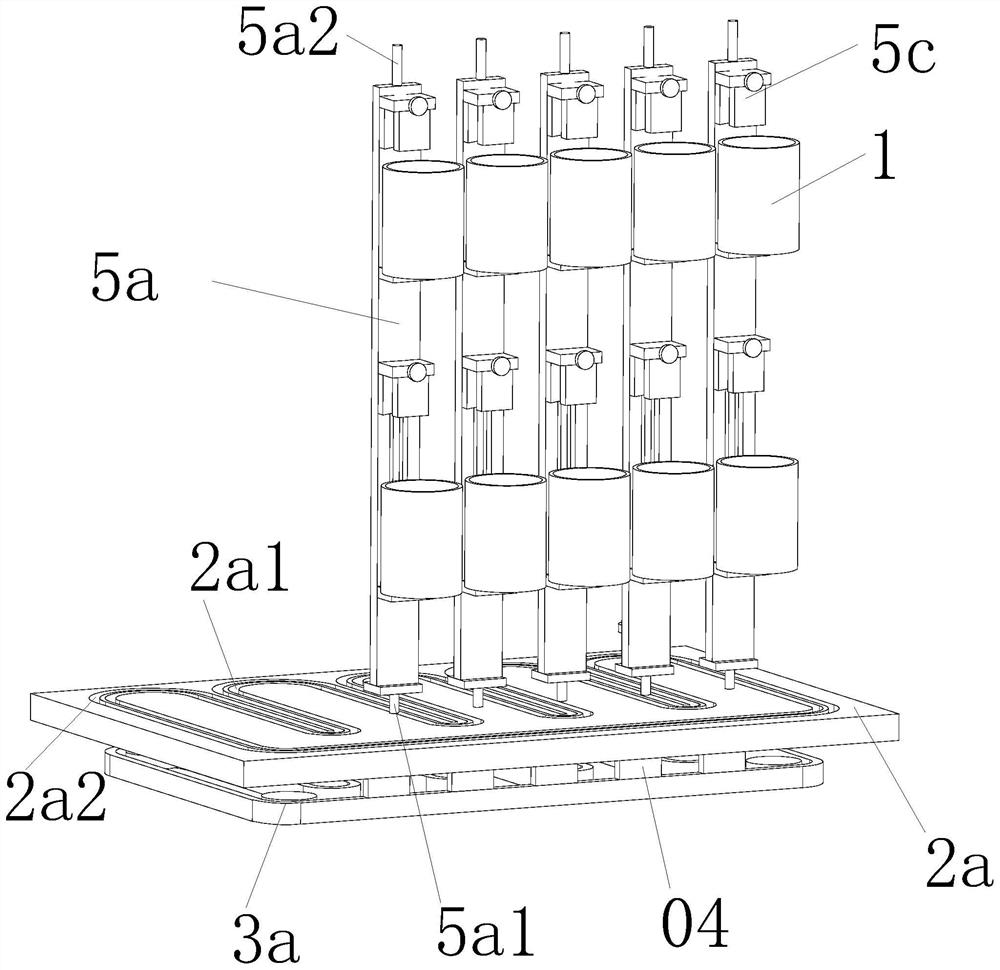

Rotary circulating drying device for new material masterbatch

The invention provides a rotary circulating drying device for new material masterbatch and belongs to the field of masterbatch drying. The rotary circulating drying device comprises a transmission rotating and feeding device (3), a masterbatch storage device (4), an air heating device (12) and a hot air uniform dissipation box (17). The transmission rotating and feeding device (3) is fixedly arranged on a masterbatch drying box (15) through nuts (1) and bolts (2). The hot air uniform dissipation box (17) is fixedly arranged in the masterbatch drying box (15). The upper end of the masterbatch storage device (4) is arranged in the transmission rotating and feeding device (3) and located at the lower end of a transmission rotating shaft (39). The air heating device (12) is arranged in the center position of a fixing bottom plate (10). The rotary circulating drying device is reasonable in design, the masterbatch is uniformly dispersed and rotationally and uniformly heated, uniform heating and drying of the masterbatch are achieved, continuous feeding and discharging are achieved, the machining efficiency of the masterbatch is high, meanwhile the hot air circulating drying is achieved, environment protection is achieved, and the energy is saved.

Owner:合肥多智科技开发有限公司

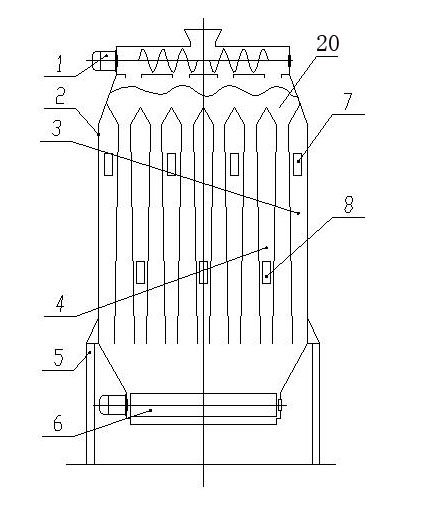

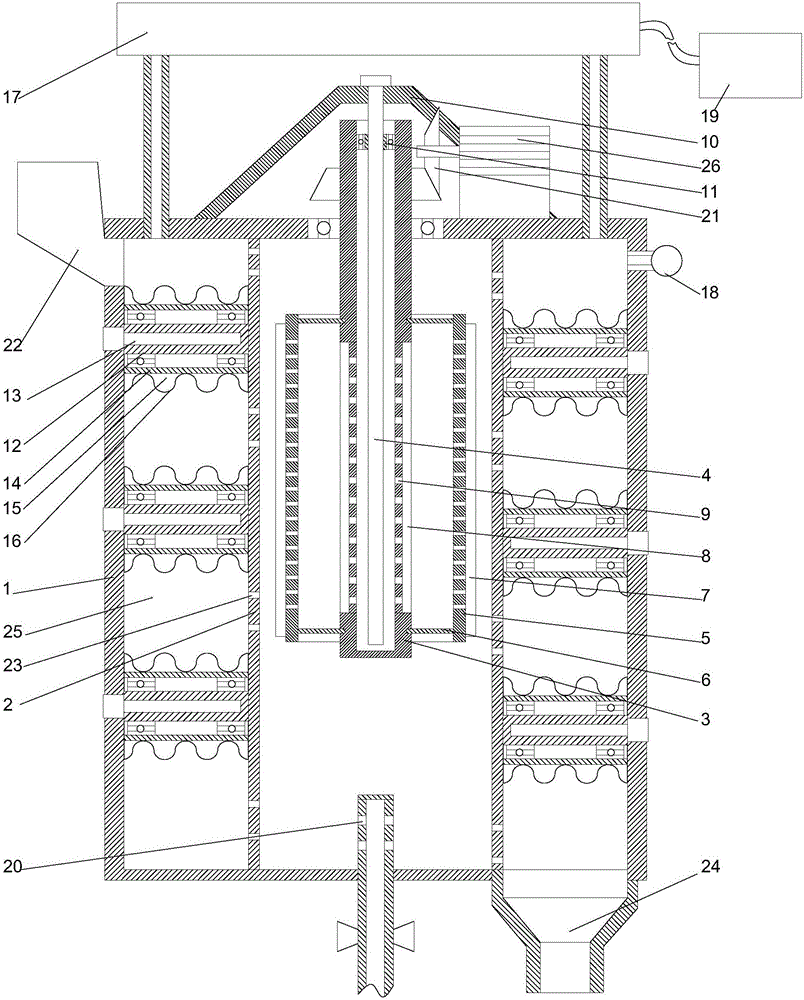

Vertical gravity conveying enforced cross-flow drying method and device

InactiveCN101793457AEnhanced flow capacityReduce disturbanceDrying solid materials with heatDrying solid materials without heatFlaky pastryPositive pressure

The invention relates to a vertical gravity conveying enforced cross-flow drying method and a device. The invention is suitable for removing surface moisture from particle materials by utilizing hot air in the industries of mine, building materials, metallurgy, ceramics, chemical engineering and the like, and is also suitable for removing moisture from particle materials by utilizing hot air in the industries of foodstuff and feedstuff. The invention has the following technical scheme: hot airflow suitable for the dried material temperature is enforced into a storehouse; under the positive action of the external pressure, the hot airflow penetrates through the voids among the granules and is discharged out of the storehouse; the hot airflow and the material contact each other and exchange heat when the hot airflow penetrates through the voids among the granules; thus, the material temperature is increased, the moisture is evaporated, and the generated water vapor is discharged out of the storehouse along with the airflow; and under the action of gravity, the material on the same cross section in the drying storehouse continuously descends, and is continuously penetrated through and dried by the hot air in the descending process. Due to the adoption of the vertical gravity descending conveying, the invention is simple and reliable in structure; due to the adoption of the drum suction mode with multiple sets of positive pressure chambers and negative pressure chambers which are vertically arranged, the invention strengthens the airflow penetration capability, so that the airflow completely penetrates through the material, thereby enhancing the thermal efficiency; the flaky pastry mode increases the flow penetration drying area and enhances the yield; and since the material is dried in the descending process, the invention has the advantages of small disturbance, little exhaust dust and low pollution.

Owner:王文民

Drum drier

InactiveCN104132515AHeat and dry evenlyAvoid drying effectsDrying machines with non-progressive movementsDrying solid materialsGear driveElectric machinery

The invention relates to the technical field of drying machinery, in particular to a drum drier comprising a drum obliquely arranged. Lining strips are evenly fixed to the inner wall of the drum in the axial direction. Large rolling rings and a toothed rolling ring are fixed on the outside of the drum. Each side of the bottom of the toothed rolling ring is provided with a gear drive device and a drive motor, which drives a gear of the gear drive device to rotate. The tooted rolling rings mesh with the gears of the gear drive devices. A carrier wheel device is disposed at the bottom of each large rolling ring. A sealing device is disposed at an opening arranged in the higher end of the drum; a discharge box is fixed to an opening arranged in the other end of the drum; the lower end of the discharge box is provided with a discharge outlet. The drum drier has the advantages that the drum rotates at a uniform speed in the process of drying material, the material in the drum is evenly heated and dried, drying is effective and efficient, and the problem that dead corners resulting from accumulation of the material in the drum affects the drying effect is solved.

Owner:潘纪鸿

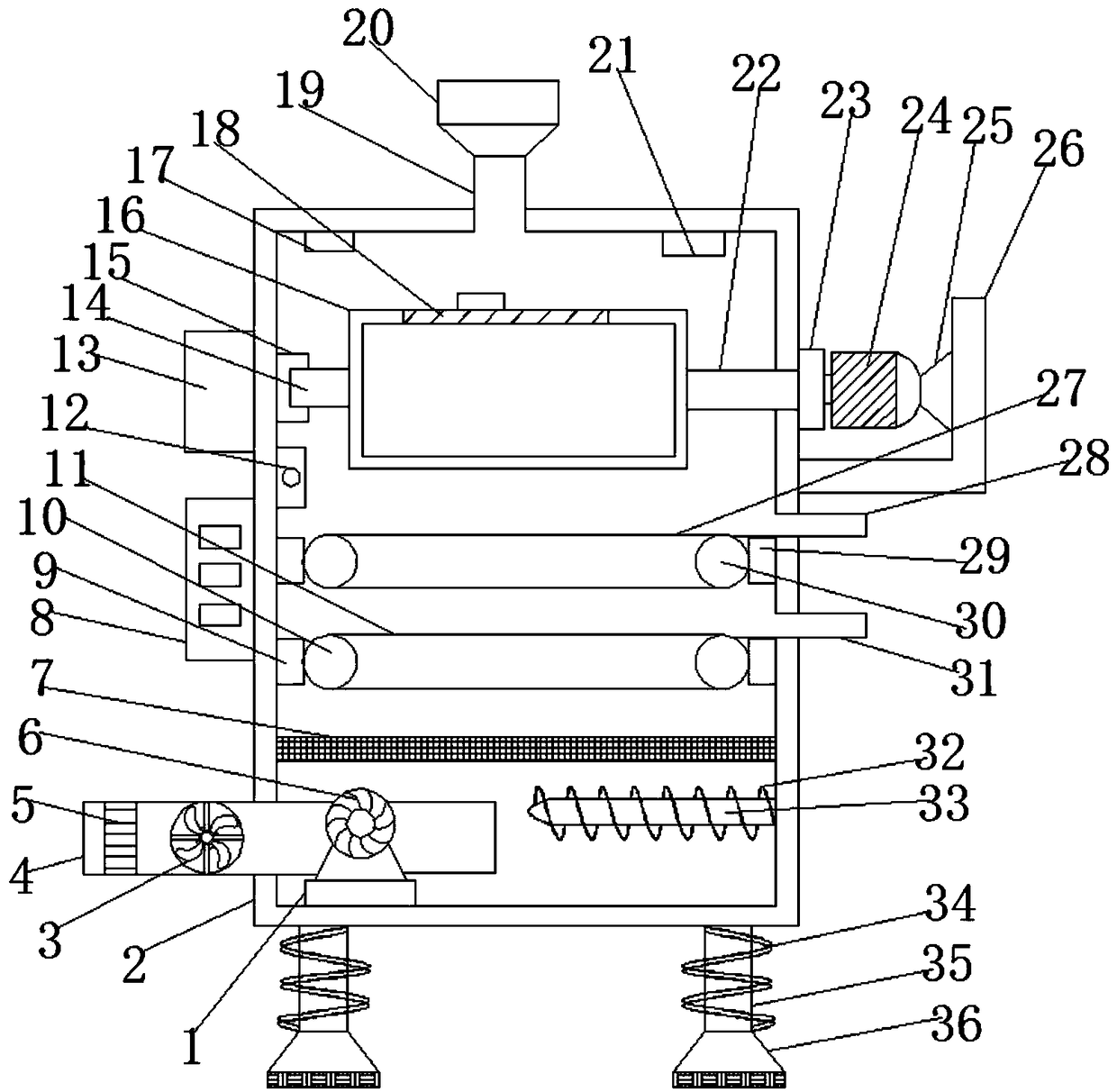

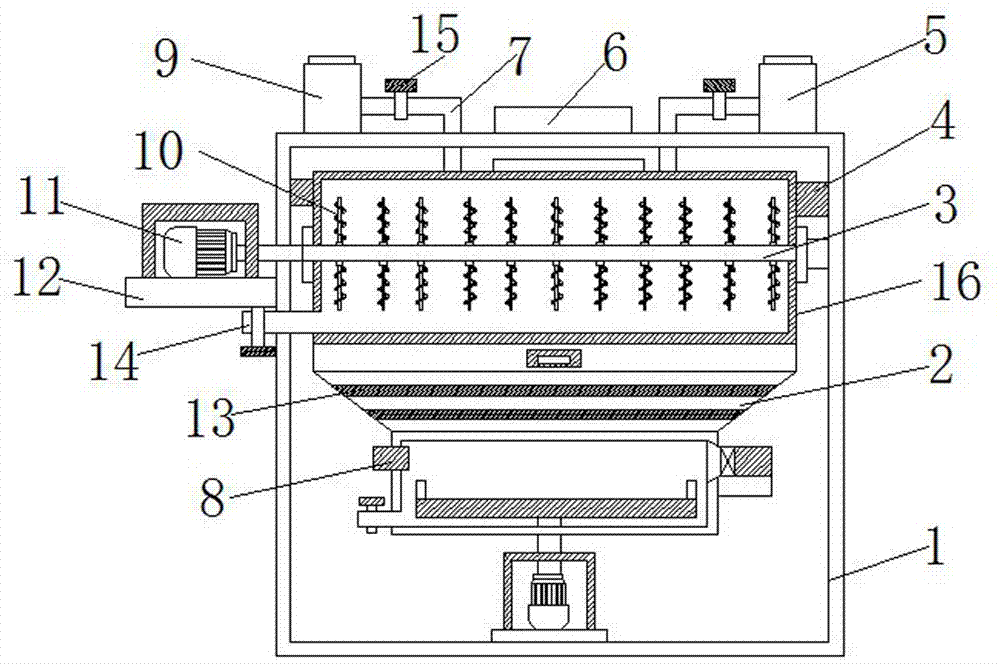

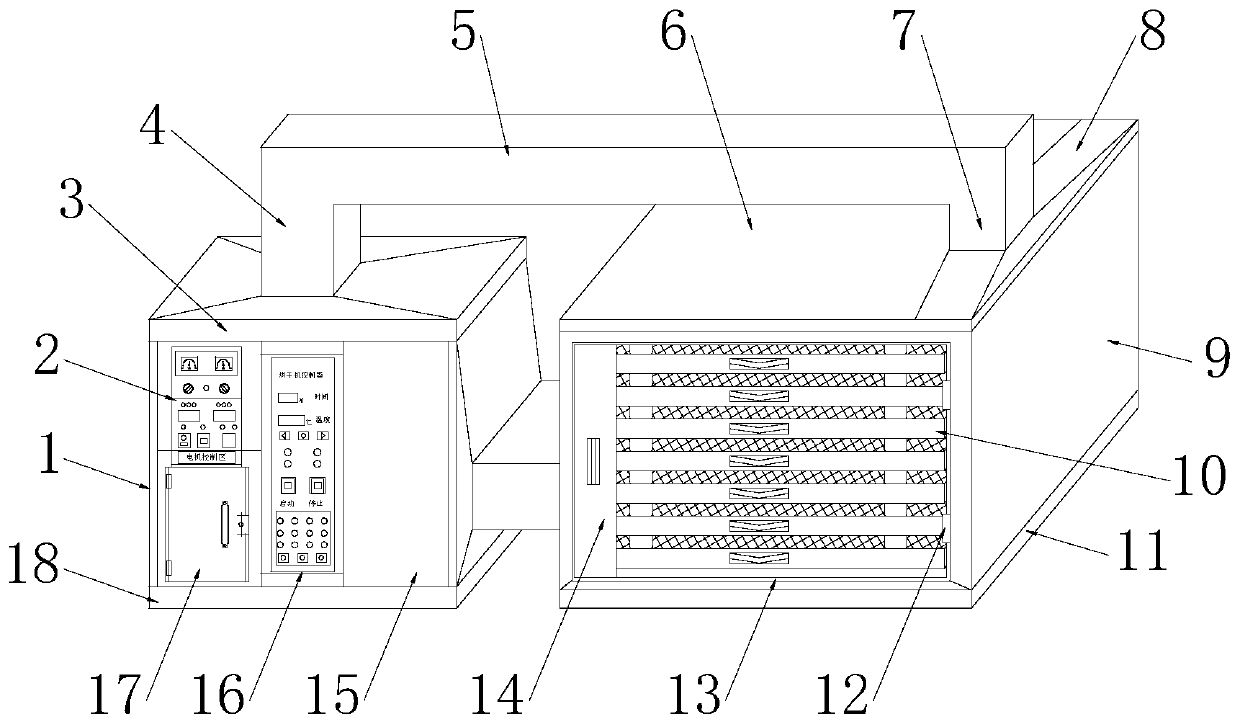

Efficient continuous biscuit automatic baking equipment

ActiveCN114451431AHeat and dry evenlyHigh synchronization rateCharging/discharging ovensBaking-tinsProcess engineeringIndustrial engineering

The invention relates to the technical field of biscuit baking, in particular to efficient continuous automatic biscuit baking equipment which comprises a baking oven, a plurality of trays and a plurality of supporting frames. Trays containing biscuits are sequentially placed on the bearing frames in the baking oven through the material moving assembly, the driving assembly drives the two conveying assemblies to operate at the same time, all the bearing frames are driven to move up and down in the baking oven through the conveying assemblies on the two sides of the baking oven, and therefore the trays placed on the bearing frames are driven; according to the cookie baking device, the tray moves up and down in the baking oven, cookies on all the trays can be evenly heated and dried in the up-and-down moving process, the baking quality of the baking oven is improved, the baking efficiency is improved, the baked cookies are taken down from the bearing frame through the material moving assembly, and the baked trays are transported away; therefore, the biscuits can be continuously baked, and the efficiency of producing the biscuits is improved.

Owner:江中食疗科技有限公司

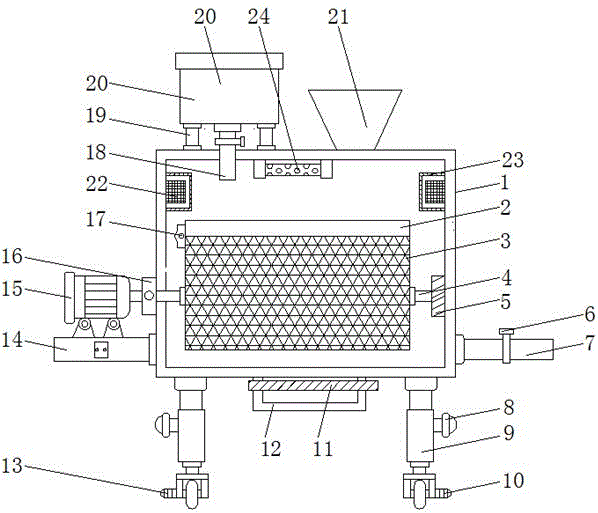

Vegetable drying box capable of conducting cleaning

InactiveCN106733818AUse regulationAdjust the use heightFeeding-stuffFruits/vegetable preservation by irradiation/electric treatmentCouplingEngineering

The invention discloses a vegetable drying box capable of conducting cleaning. The vegetable drying box comprises a drying box body and ascending-and-descending support pillars. A water tank and a feeding funnel are mounted at the top of the drying box body. A motor mounting seat is mounted at one side of the drying box body. A motor is mounted at the top of the motor mounting seat. A screen is arranged inside the drying box body. Rotating shafts are mounted at the two sides of the screen correspondingly. One end of each rotating shaft penetrates the drying box body and is connected with the motor through a coupling. Drying devices are mounted on the inner wall of the drying box body. Ascending-and-descending support legs are mounted at the bottom of the drying box body. The vegetable drying box is capable of conducting sterilization on vegetables, and edible safety of the vegetables is guaranteed; cleaning and drying can be integrated into a whole; work time and investment cost of feeders are greatly saved; meanwhile, labor intensity of the feeders is lowered, and work efficiency is improved; and the vegetable drying box is simple in structure, convenient to operate and capable of moving at will according to use requirements.

Owner:耒阳市丁先生农业发展有限公司

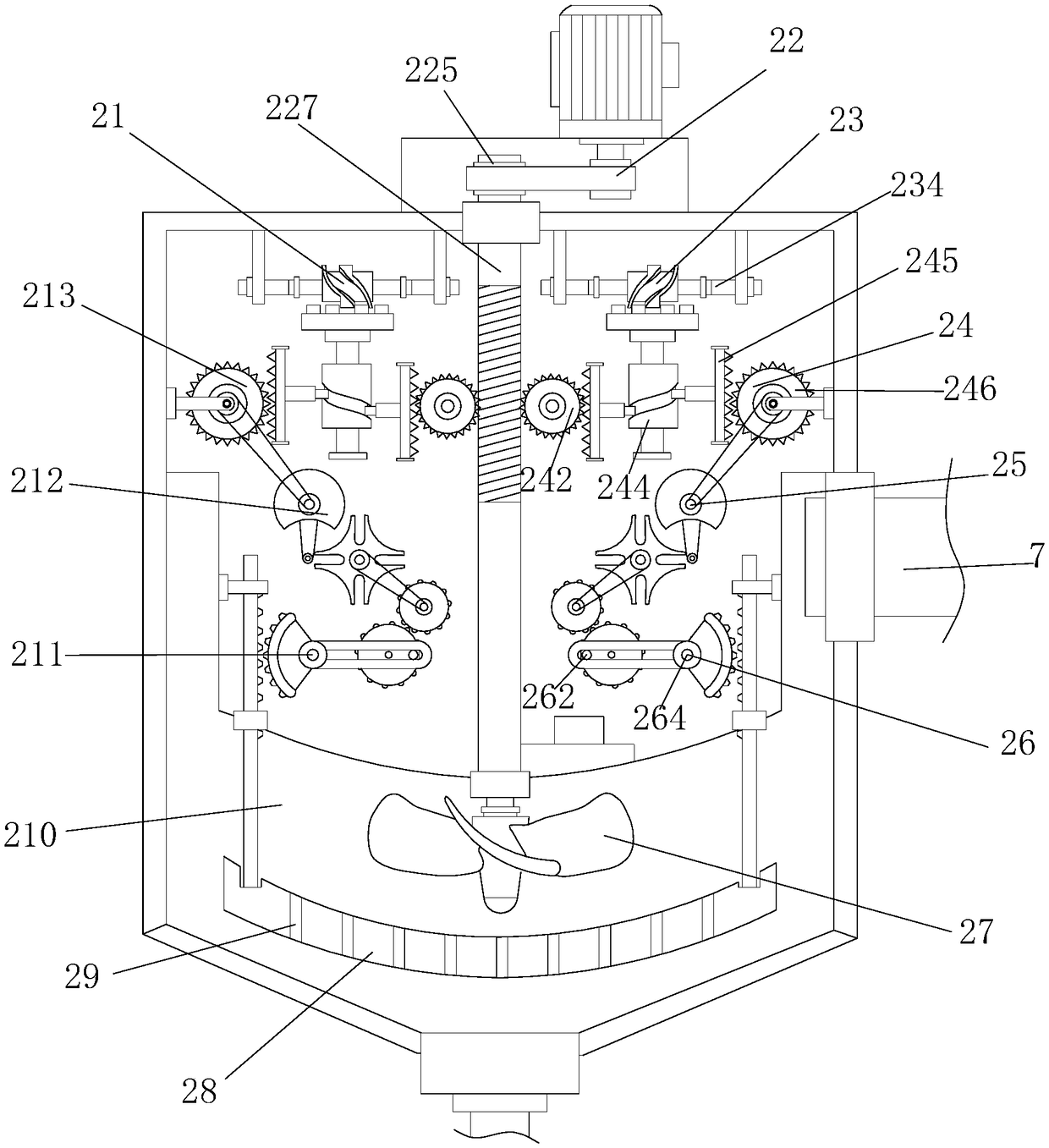

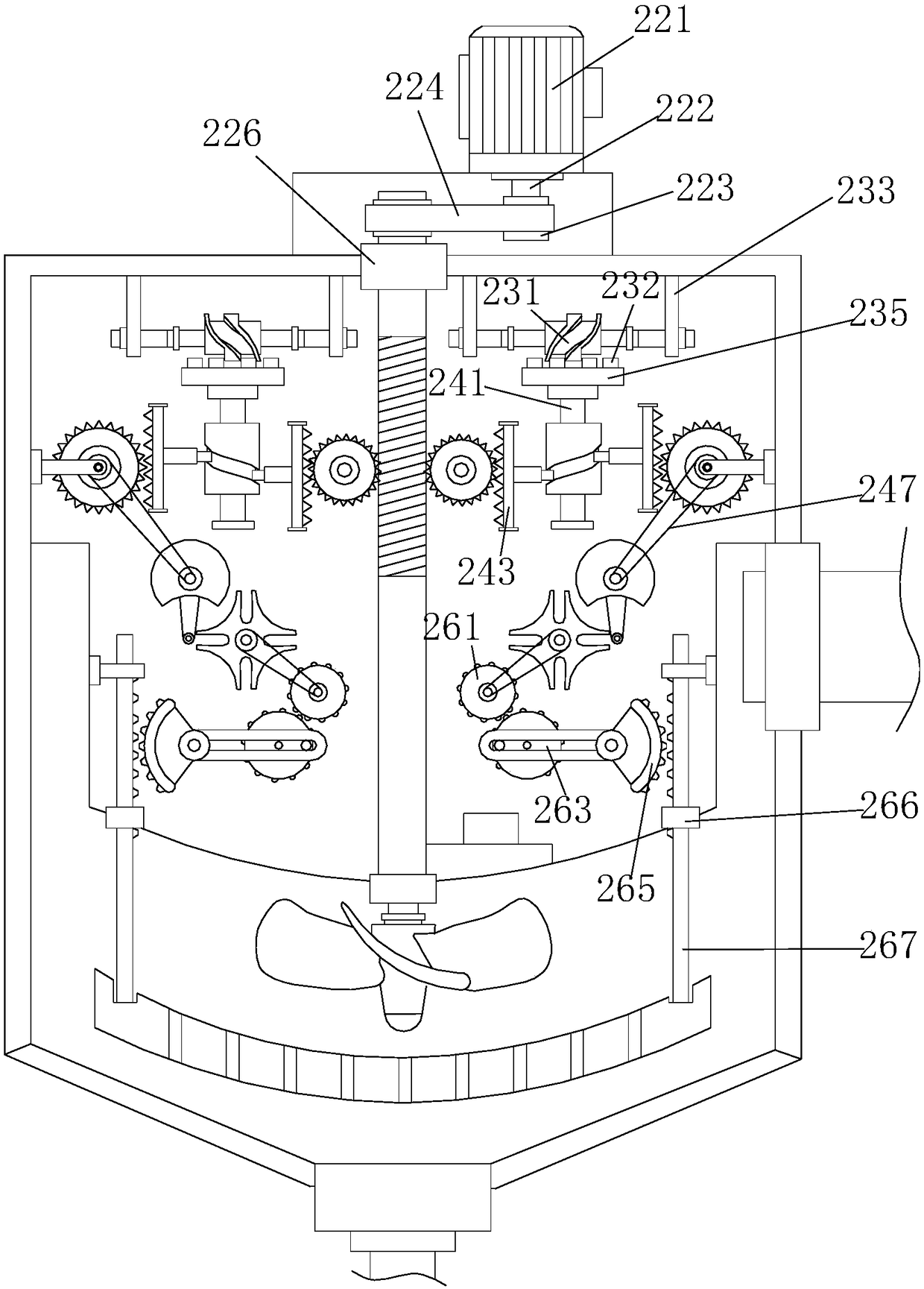

Boiler tea leaf dryer

InactiveCN108692542AHeat and dry evenlyImprove qualityPre-extraction tea treatmentDrying gas arrangementsAgricultural engineeringTea leaf

The invention discloses a boiler tea leaf dryer. The boiler tea leaf dryer comprises a boiler upper cover, an intermittent stir-frying device, a supporting seat, a guard ring, a boiler shell, a feeding inlet, a hot air pipe, a hot air fan, a hot air fan fixing seat and a discharging hopper, wherein the intermittent stir-frying device comprises a left cam mechanism, a driving mechanism, a right cammechanism, a right transmission mechanism, a right intermittent mechanism, a right stir-frying mechanism, a stirring paddle, a stir-frying movable plate, an air hole, a drying cavity, a left stir-frying mechanism, a left intermittent mechanism and a left transmission mechanism. According to the boiler tea leaf dryer, the intermittent stir-frying device is internally provided with the driving mechanism, the cam mechanism, the transmission mechanism, the intermittent mechanism and the stir-frying mechanism, the intermittent stir-frying of tea leaves during the boiler drying process is achieved,so that the tea leaves are uniformly heated and dried, and the quality of the tea leaves is improved.

Owner:刘钰婷

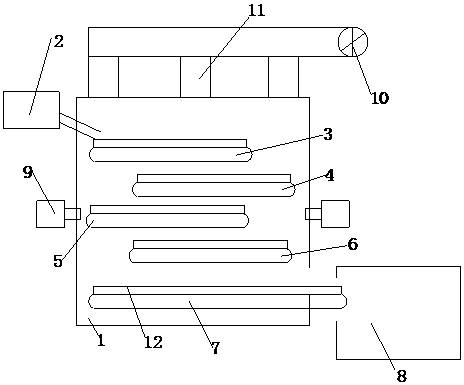

Simple and convenient drying device for traditional Chinese medicinal materials

InactiveCN108731453AHeat and dry evenlyReduce drying costsDrying gas arrangementsDrying machines with progressive movementsEngineeringElectric heating

The invention provides a simple and convenient drying device for traditional Chinese medicinal materials. The simple and convenient drying device comprises a drying box body, wherein a feeding hopperis arranged at the upper end of one side of the drying box body, a second conveying belt, a third conveying belt, a fourth conveying belt and a fifth conveying belt are sequentially arranged in a drying box from top to bottom, one end of the fifth conveying belt penetrates out of the drying box, the discharging end of the fifth conveying belt is connected with a discharging box, electric heating boxes are arranged on the left side and the right side of the drying box body respectively, and a plurality of pipelines connected with a dehumidifying fan are arranged at the upper end of the drying box body. According to the simple and convenient drying device, medicinal materials to be dried are placed in the feeding hopper, drying is carried out by staggering among the plurality of conveying belts in the drying box body, the turning of the medicinal materials is naturally realized in the process of falling between the conveying belts, the heating and drying uniformity of the medicinal materials is guaranteed, and the equipment is simple and low in drying cost.

Owner:陆应根

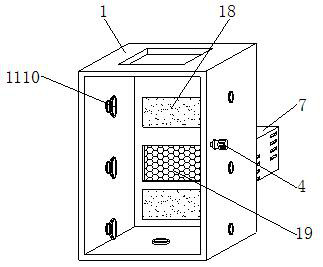

Ceramic drying device with dustproof function

InactiveCN112797769AImprove uniformityRapid drying moldingDrying solid materials with heatDrying chambers/containersActivated carbonRotational axis

The invention discloses a ceramic drying device with a dustproof function. The ceramic drying device comprises a drying box; a controller is bolted to the bottom part of the left side of the drying box; a box door is hinged to the front face of the drying box through hinges; a temperature sensor is embedded in the center of the right side of the drying box; and a supporting leg is bolted to each of four corners of the bottom part of the drying box. According to the ceramic drying device, with the cooperation of a sliding rail, a low speed motor, a rotating disc, sliding rods and a rotating shaft, ceramic can be driven by a holding frame and a blocking screen frame to uniformly rotate at a low speed, so that the ceramic is uniformly heated and dried, and the drying uniformity of the ceramic is improved, thereby being conducive to rapid drying and forming of the ceramic; with the cooperation of a dust suction pump, a dust suction tube and a dust outlet tube, dust particles floating in the drying box can be effectively sucked; and with the cooperation of a purification barrel, dust suction filter cotton and an activated carbon adsorption net, the sucked dust can be purified, to avoid that the dust is directly discharged to the outside to pollute the surrounding environment.

Owner:泗阳垠创运营管理有限公司

Synthetic fiber drying device used for oil refining

InactiveCN108224958AHeat and dry evenlyReduce work intensityDrying gas arrangementsDrying solid materialsCouplingPulp and paper industry

The invention relates to the technical field of oil refining and discloses a synthetic fiber drying device used for oil refining. The synthetic fiber drying device used for oil refining comprises a drying box; the middle portion of the bottom of the drying box is fixedly connected with a protective shell in which a motor is fixedly connected; an output shaft of the motor is fixedly connected witha rotating shaft through a coupler; a bearing is inlaid in the middle portion of the bottom of the drying box; the top of the rotating shaft penetrates the bearing and extends into the drying box; andthe top of the rotating shaft is fixedly connected with a rotating plate. According to the synthetic fiber drying device used for oil refining, due to the fact that the outer surface of a ring is provided with a through air exhausting hole, an air exhausting pipe is communicated with the air exhausting hole, and is communicated with an air inflow pipe, the air inflow pipe is communicated with anoutside hot air source, and therefore blown out air can be different in air direction, and therefore synthetic fiber can be dried at the same time in each direction, and can be uniformly heated and dried, the production cost is greatly reduced, and meanwhile, the work intensity of a worker is also relieved.

Owner:禹伟

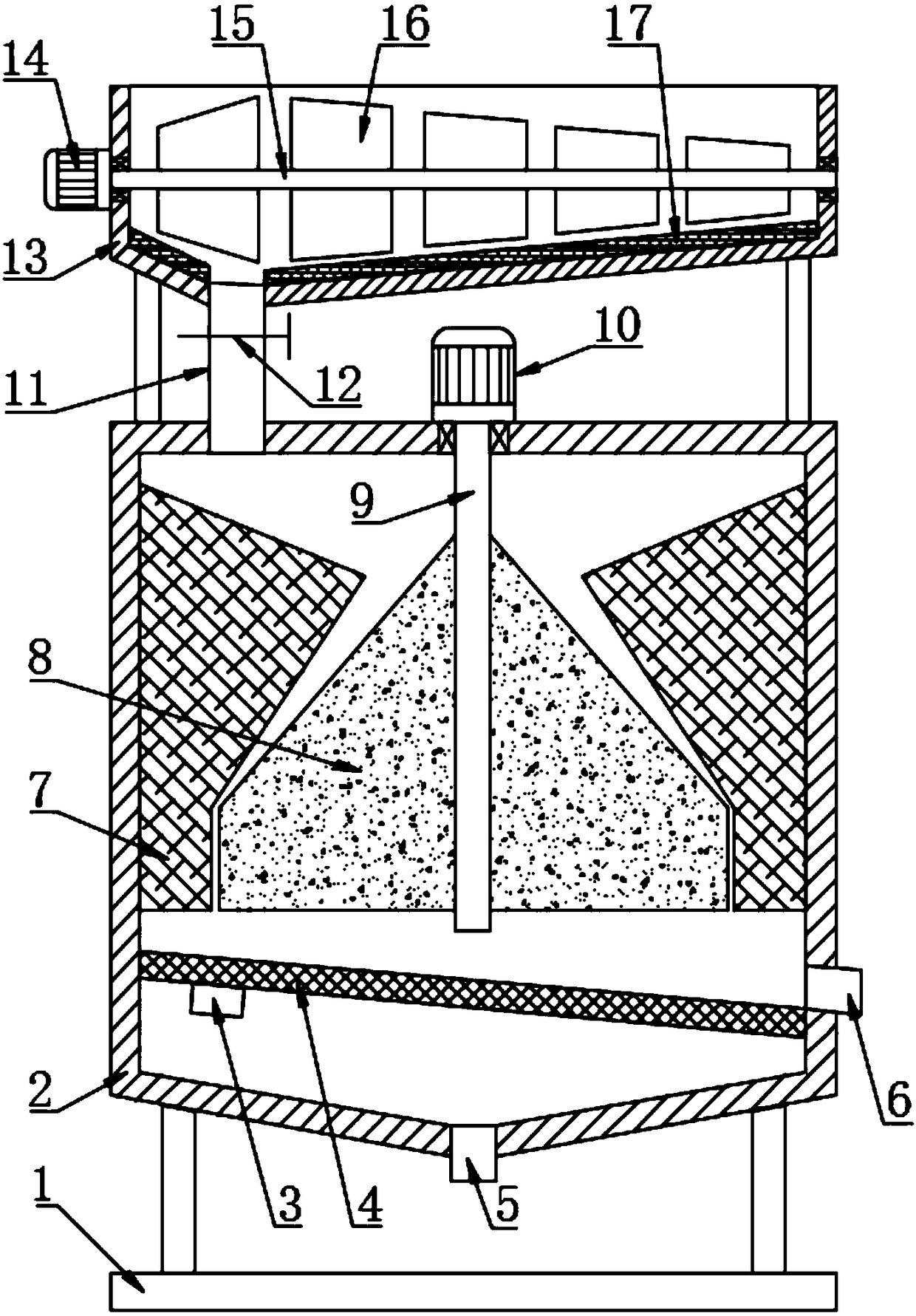

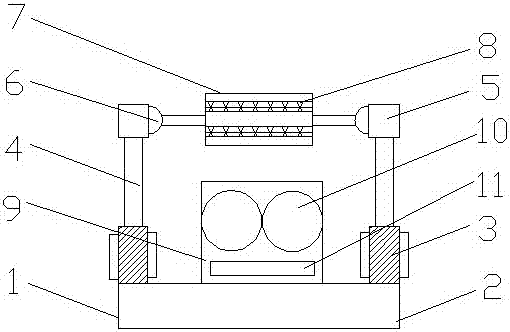

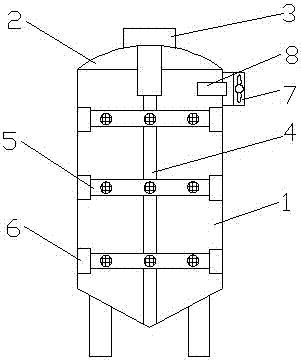

Plant feed drying equipment capable of drying uniformly

PendingCN107883711AEasy to eat and absorbHeat and dry evenlyDrying chambers/containersDrying machines with non-progressive movementsLivestockEngineering

The invention discloses plant feed drying equipment capable of drying uniformly. The plant feed drying equipment comprises a machine body, wherein the lower end of the machine body is equipped with abase in a supporting mode; two air cylinders are symmetrically arranged at the two sides of the upper end of the base; the two air cylinders are each vertically upwards guided out of a piston rod; theupper ends of the piston rods are connected with universal ball bases; a roller is horizontally arranged between the two universal ball bases; the two ends of the roller are movably connected with the two universal ball bases through two connecting rods separately; a plurality of gird plates are arranged inside the roller; electric heating wires are wound on the end surface of the grid plates; amaterial collecting hopper is arranged on the center of the upper end of the base; two rotary rollers are arranged at the upper end inside the material collecting hopper; the end surfaces of the two rotary rollers are tangential left and right; and a discharge slot is formed in the lower end inside the material collecting hopper. In this way, the plant feed drying equipment enables feed to uniformly heat and dry, further can perform cut-up treatment after drying, and is convenient for the poultry and the livestock to eat and absorb.

Owner:WUXI SHANGDE DRYING EQUIP CO LTD

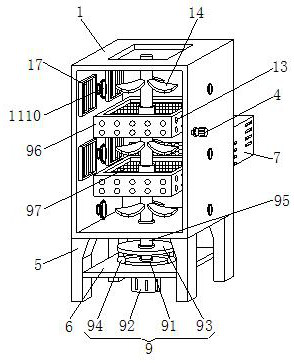

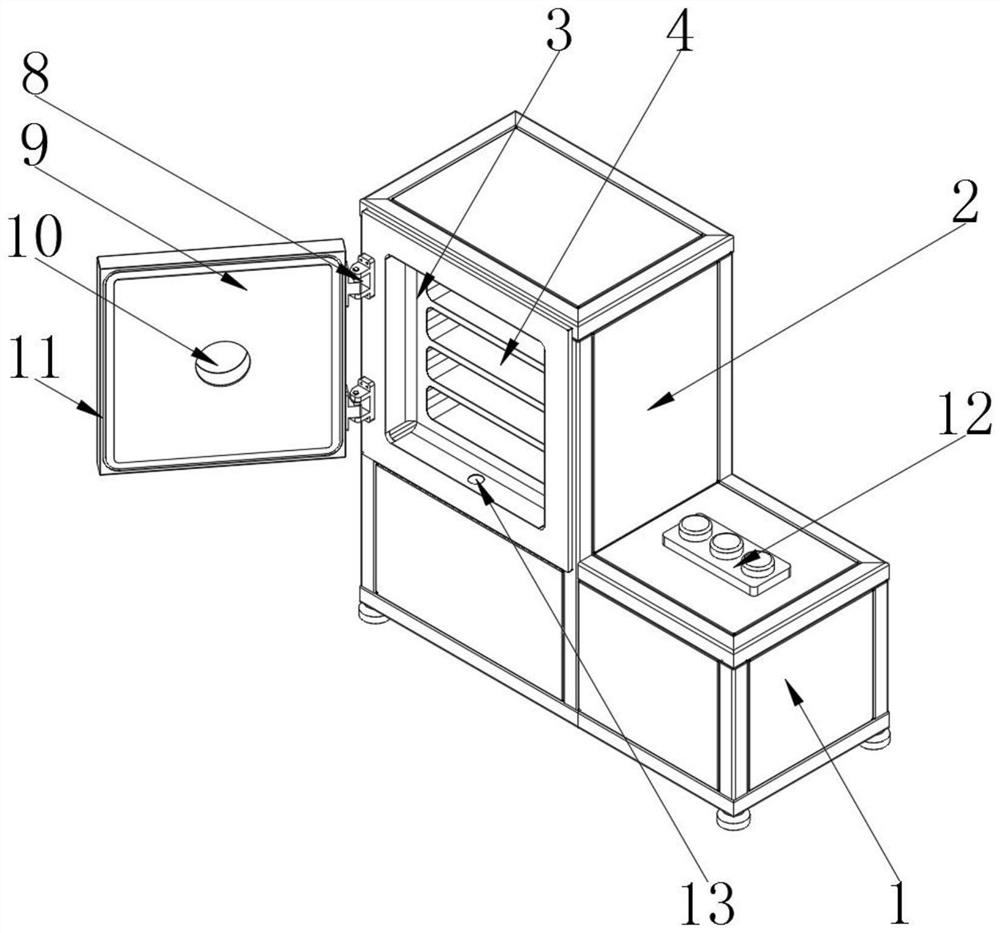

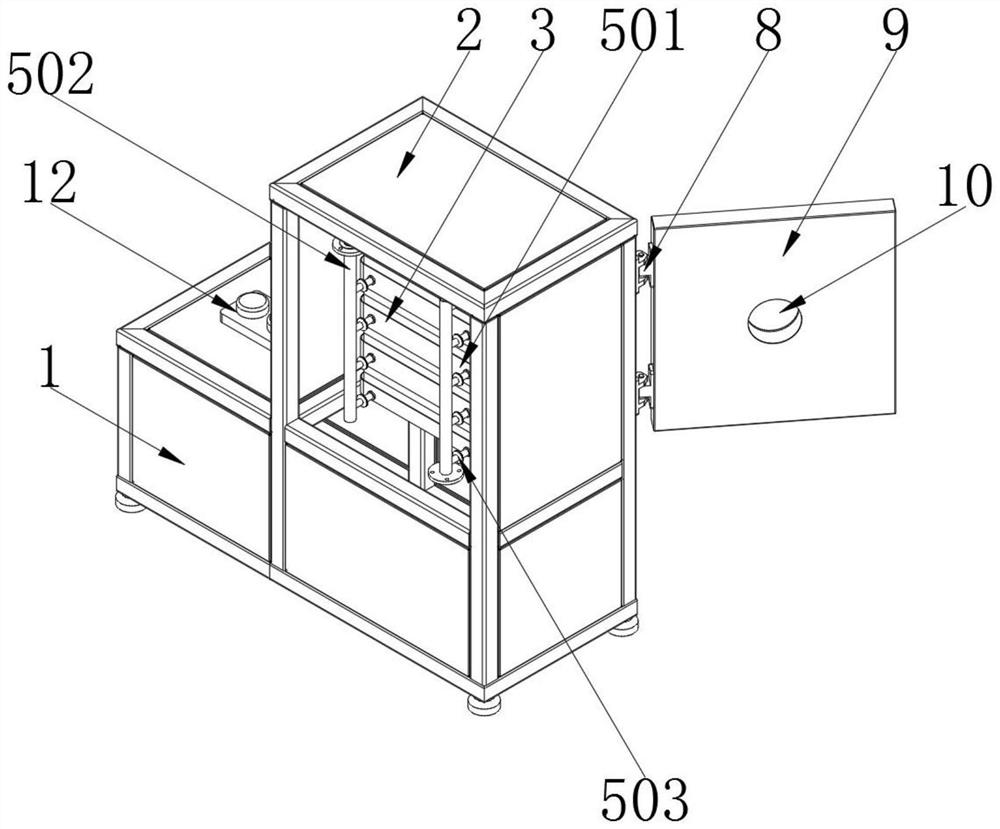

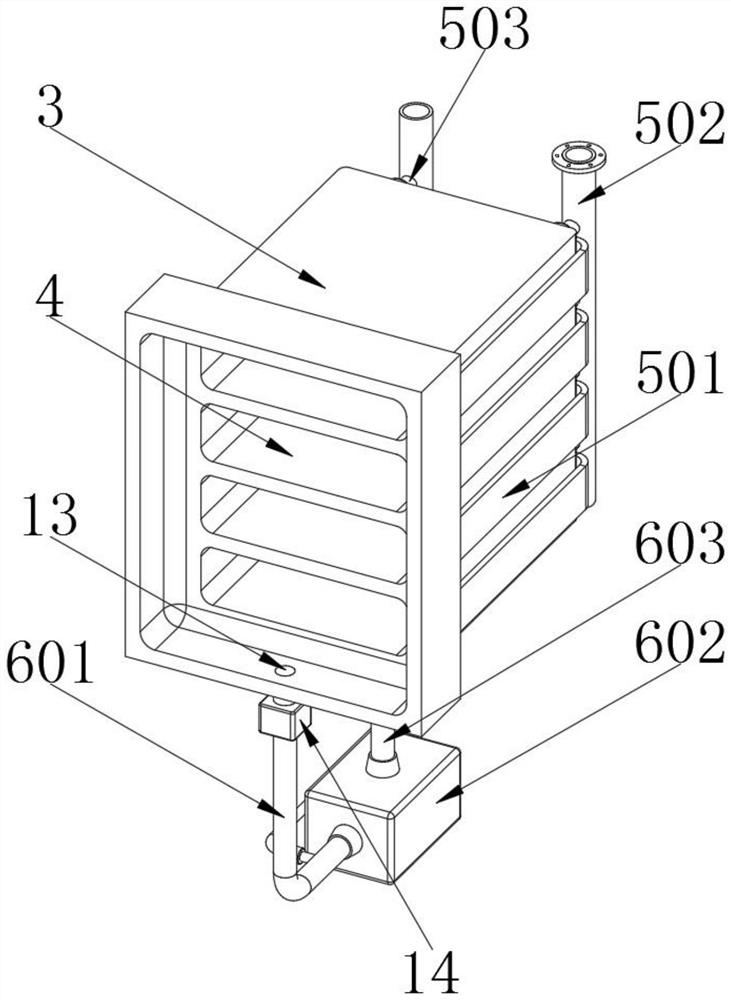

A vacuum drying oven

ActiveCN111637689BImprove heating efficiencyAvoid pollutionDrying solid materials without heatHollow article cleaningThermodynamicsEngineering

Owner:CHANGZHOU AOKAI DRYING EQUIP

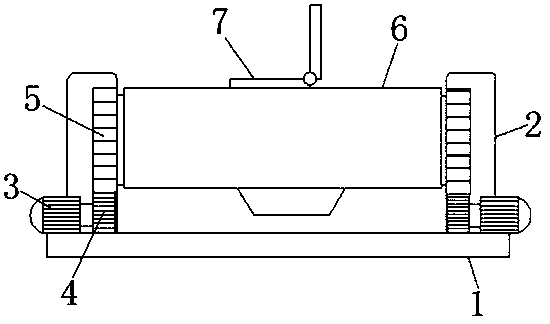

Cotton drier capable of drying cotton uniformly

InactiveCN108224945ADry evenlyEasy to useDrying gas arrangementsDrying chambers/containersElectric machineryEngineering

The invention discloses a cotton drier capable of drying cotton uniformly and relates to the technical field of cotton driers. The cotton drier capable of drying cotton uniformly comprises a bottom plate, wherein supporting columns are fixedly mounted on two sides of the upper end of the bottom plate; motors are fixedly mounted on two sides of the bottom plate; a first gear is fixedly mounted at the output end of each motor; the first gear is engaged to a second gear; a rotary drum is fixedly mounted at one end of the second gear; and a feed inlet is formed in the upper end of an inner cavityof the rotary drum. According to the cotton drier capable of drying cotton uniformly, by arranging the supporting columns, the motors, the first gears, the second gears, the rotary drums, the feed inlets, a drying barrel, an air inlet, a box body, an air blower, a heater, an air delivery pipe, a discharge pipe, a fixing column and an isolating net in a matched manner, when cotton in the drying barrel is dried, the rotary drum rotates by rotation of the motor, so that cotton can be also heated and dried uniformly while rotating.

Owner:胡和萍

Multi-layer uniformizing device of fiber particle rotary drum dryer

InactiveCN107421288AReasonable designDry evenly and fullyGranular material dryingDrying gas arrangementsFiberEngineering

The invention provides a multi-layer uniformizing device of a fiber particle rotary drum dryer. The multi-layer uniformizing device of the fiber particle rotary drum dryer comprises a rotary drum drying barrel, and the rotary drum drying barrel is provided with a feed inlet and a steam valve. A fixed drying charging barrel is connected in the rotary drum drying barrel through reinforcing ribs. Movable barrels are rotationally connected to the left end and the right end of the drying charging barrel, and the movable barrels are sleeved with fastening rings. Connecting arms extend from the fastening rings sequentially. The ends of the connecting arms are slidably fixed in sliding grooves of the drying charging barrel through universal bearings. The fastening rings are connected with a plurality of hangers correspondingly. Each hanger is rotationally fixed in a rotary ring groove in the inner wall of the rotary drum drying barrel through rollers. The multi-layer uniformizing device of the fiber particle rotary drum dryer has the beneficial effects that design is reasonable, materials are dried uniformly and sufficiently, the processing quality is ensured, and the work efficiency is improved.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

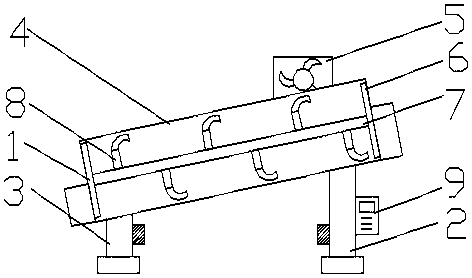

Stirring and speed-regulating dual-use drying machine

InactiveCN107906901AFully dryHeat and dry evenlyDrying gas arrangementsDrying solid materialsEngineeringHot blast

The invention discloses a stirring and speed-regulating dual-use drying machine. The stirring and speed-regulating dual-use drying machine comprises a machine body, and two supporting rods, namely, the high rod and the low rod are vertically arranged at the lower end of the machine body in a supported mode; both the high rod and the low rod are electric telescopic rods, a drying cylinder is connected to the position between the upper ends of the high rod and the low rod, and the drying cylinder is arranged in an inclined shape; a hot air machine is arranged on one side of the upper end of thedrying cylinder, a hot air guiding tube is introduced into the drying cylinder through the hot air machine, openings are formed in the two ends of the drying cylinder, and annular brackets are arranged at the openings; and a rotating shaft rod is connected between the two annular brackets, and a plurality of arc-shaped stir-fry plates are arranged on the end face of the rotating shaft rod and arearranged in a front-back staggered mode. In this way, the stirring and speed-regulating dual-use drying machine can stir materials during drying, so that the materials are evenly heated and dried, andthe feeding speed is regulated by controlling the angle of the drying cylinder, so that the materials are fully dried.

Owner:WUXI SHANGDE DRYING EQUIP CO LTD

Feed granulation device with mixing function

The invention discloses a feed granulation device with a mixing function. The feed granulation device comprises a device body, a mixing cylinder is fixed to one side of the top of the device body through fixing legs, a feeding port runs through one side of the top of the mixing cylinder, a first motor is arranged at the top of the mixing cylinder, the output end of the first motor penetrates through the top of the mixing cylinder and is connected with a stirring shaft, and stirring rods are fixed above the outer surface of the stirring shaft. The device is further provided with smashing blades, the smashing blades rotate quickly while stirring is conducted, large granules in raw materials are smashed accordingly, so that the size of the raw materials is more uniform, a good basis is laid for granulation in the later period, the granulation quality is improved, and the problem that through holes in a granulation plate are clogged is also solved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Using method of efficient, energy-saving and environmentally-friendly type tea drying equipment

InactiveCN110657642AImprove drying efficiencyHeat and dry evenlyPre-extraction tea treatmentDrying gas arrangementsElectric machineProcess engineering

The invention discloses a using method of efficient, energy-saving and environmentally-friendly type tea drying equipment. The using method comprises the following steps: placing a drying mesh disc ina drying box through a drying mesh disc base, and closing a sealing door to tightly connect a sealing groove and a sealing strip; starting a motor control switch arranged on a motor control panel, and observing whether a motor revolving speed display screen and a motor indicator lamp are in normal standby states; and when a control motor arranged in a master control box is in the normal standby state, starting a starting button arranged on a drying machine control panel. With adoption of the using method, the tea leaves can be uniformly heated and dried, the energy is saved and the environment is protected, and the popularization and application value is realized; an air returning pipeline arranged on an air returning pipeline inlet can discharge moisture in the drying box; a transparentwindow arranged on the sealing door can observe the tea leaf drying situation in the drying box; and in addition, the efficient, energy-saving and environmentally-friendly type tea drying equipment ishigh in drying efficiency, speed and stability and can meet the tea leaf drying demand excellently.

Owner:王兆举

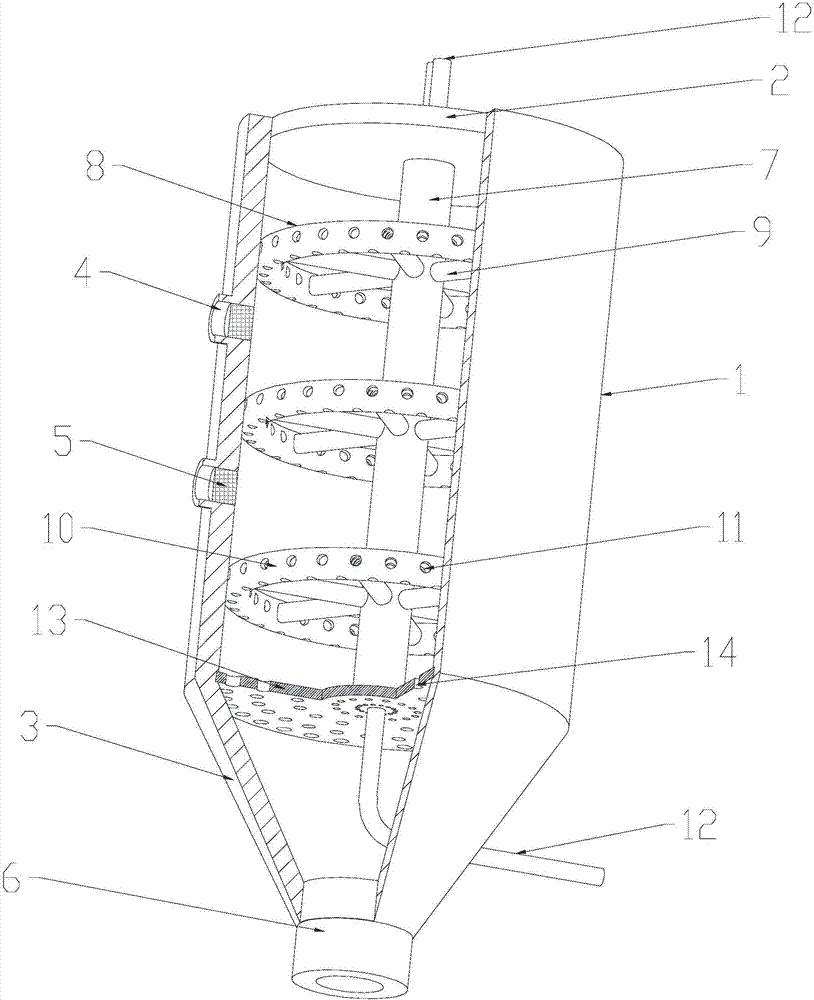

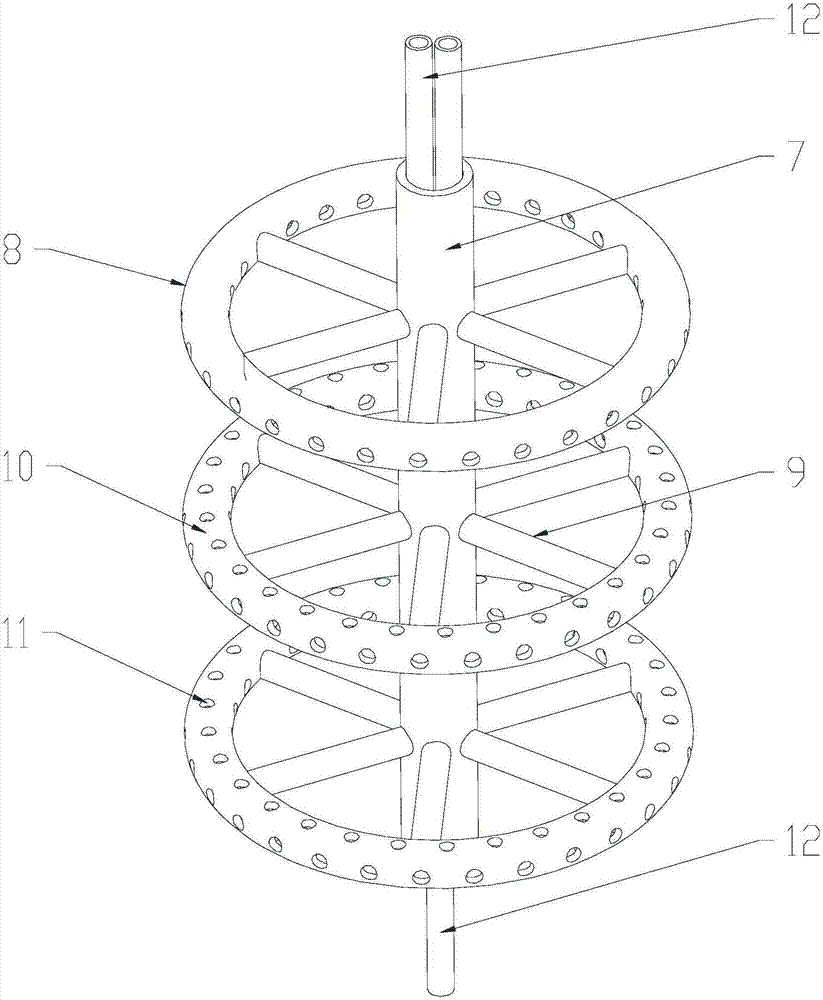

Drying apparatus for chemical fiber yarns

The invention relates to the technical field of processing of chemical fibers, in particular to a drying apparatus for chemical fiber yarns, comprising a drying kettle, an air diverting device for changing the direction of air entering the drying kettle, and a diffusion plate for diffusing the air entering a first air incoming pipe; the air diverting device comprises a fixing post, a plurality of circular air diverters, a plurality of vent pipes and second air incoming pipes as many as the circular air diverters, each circular air diverter includes a hollow circular body that is evenly provided with a plurality of diverting holes, one end of each vent pipe is communicated the corresponding circular air diverter, and the other end of each vent pipe is fixedly connected to the fixing post and is communicated with the corresponding second air incoming pipe. Air blown from the diverting holes of the circular air diverters provided herein goes in different directions, chemical fiber yarns can be dried from all directions; therefore, the problem that chemical fibers are heated unevenly is effectively solved.

Owner:江苏垶恒复合材料有限公司

Coke drying equipment

InactiveCN105698515AEvenly mixed with each otherHeat and dry evenlyDrying gas arrangementsDrying solid materialsPulp and paper industry

The invention discloses coke drying equipment. The coke drying equipment comprises a box body and a rotating shaft arranged in the middle portion of the rotating shaft. A wind barrel is arranged on the rotating shaft, blades which are arranged at intervals are arranged on the outer wall of the wind barrel, an inner layer box body is arranged on the inner side of the box body, and a cavity is formed between the inner layer box body and the box body; a roller set is arranged on the inner side of the cavity, and a hot air input opening is formed below the middle portion of the box body; a one-way valve is arranged on the hot air input opening; an input opening is formed in the outer wall of the box body, and an output opening is formed below the box body; and ventilation holes are formed in the inner layer box body at intervals. Coke passes through the cavity between the inner layer box body and the box body, and therefore in the gradual downward moving process of the coke, hot air passes through the ventilation holes in the inner layer box body to enter the cavity, and water in the coke is brought out; and the rotating shaft is used for driving the wind barrel provided with the blades to rotate, flowing of hot air and air is accelerated, and coke water removal and drying can be achieved.

Owner:丹东万通城市燃气有限公司

Special powder medicine drying barrel internally provided with sweeping device

PendingCN107883715AAvoid residueHeat and dry evenlyDrying gas arrangementsDrying machines with non-progressive movementsElectric machineStructural engineering

The invention discloses a special powder medicine drying barrel internally provided with a sweeping device. The special powder medicine drying barrel comprises a barrel body, the upper end of the barrel body is cylindrically arranged, the lower end of the barrel body is arranged in a taper shape, an end cover is hinged to the upper end of the barrel body, a rotating motor is arranged at the upperend of the end cover, a rotating shaft rod is vertically guided out from the lower end of the rotating motor and is guided into the barrel body, a plurality of annular surrounding rods are arranged inside the barrel body in an up-and-down parallel and equal-interval manner, the multiple annular surrounding rods surround the outer side of the rotating shaft rod, the inner side end faces of the annular surrounding rods are connected with the rotating shaft rod through connecting rods, the outer side end faces of the annular surrounding rods are evenly provided with a plurality of sweeping plates, the multiple sweeping plates are attached to the inner wall of the barrel body, an air inlet is formed in one side of the barrel body, and a hot-air blower is arranged at the air inlet. By means ofthe above manner, residual powder on the inner wall of the drying barrel can be swept away through the sweeping device after powder medicines are dried.

Owner:WUXI SHANGDE DRYING EQUIP CO LTD

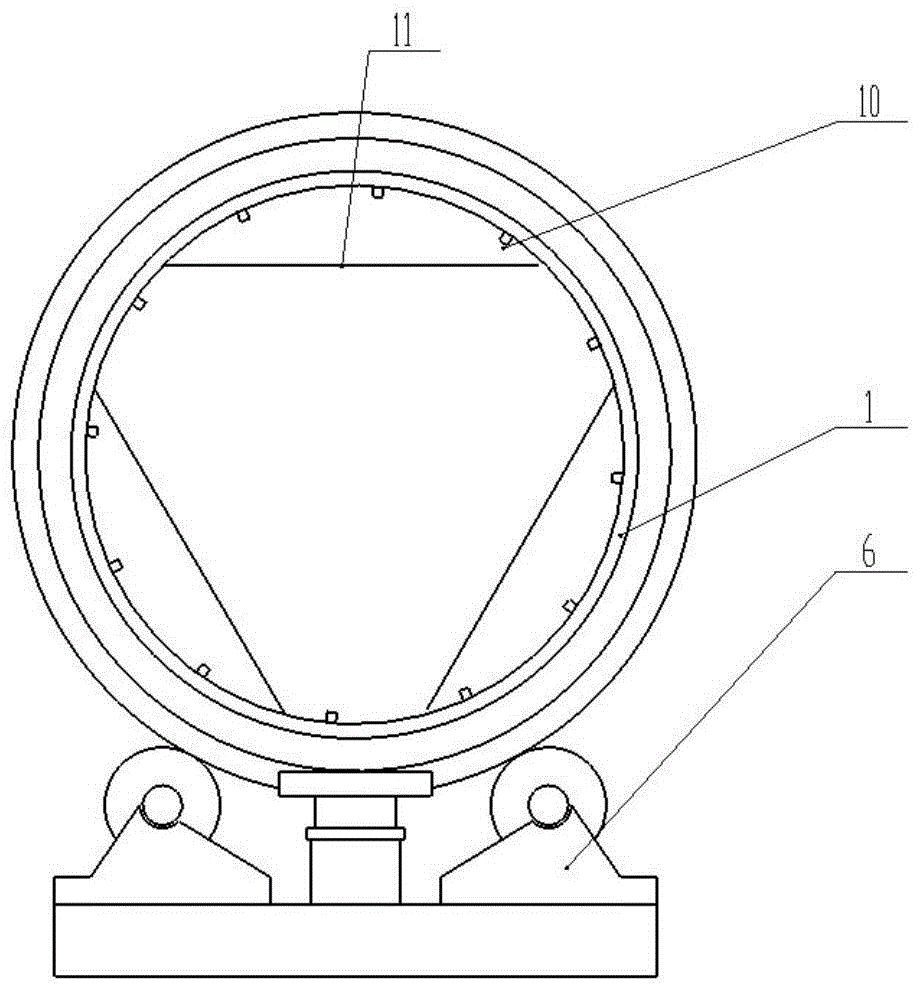

Stator paint dipping and drying device of permanent magnet motor

PendingCN114039466AHeat and dry evenlyImprove drying rateManufacturing dynamo-electric machinesElectric machineEngineering

The invention relates to the field of permanent magnet motor stator drying, in particular to a stator paint dipping and drying device of a permanent magnet motor. A motor stator is in an annular cylinder shape, and the drying device comprises a drying box, a chain type conveyor, chain accessories and clamps. The chain type conveyor comprises a chain and a meshing wheel; and the clamps are vertically installed on the top of the chain type conveyor at equal intervals through the chain accessories. After the motor stators are mounted on the clamps, the chain type conveyor is started to drive the clamps to regularly move in the drying box, so that the motor stators can be uniformly heated and dried, and the drying rate of the motor stators is increased; the internal space of the drying box can be well utilized through regular movement tracks to increase the drying number of the motor stators, and the motor stators cannot make contact with one another when the multiple motor stators are dried, so that the phenomenon that in the prior art, the motor stators are bonded together due to paint after drying, and are difficult to be seperated in the later period is prevented.

Owner:江西东涵科技协同创新有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com