Coke drying equipment

A technology for drying equipment and coke, which is applied in the direction of drying, dryers, lighting and heating equipment, etc. It can solve the problems of low drying efficiency, uneven heating of coke, uneven drying, etc., and achieve uniform heating, Improve the heat exchange efficiency and dry quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

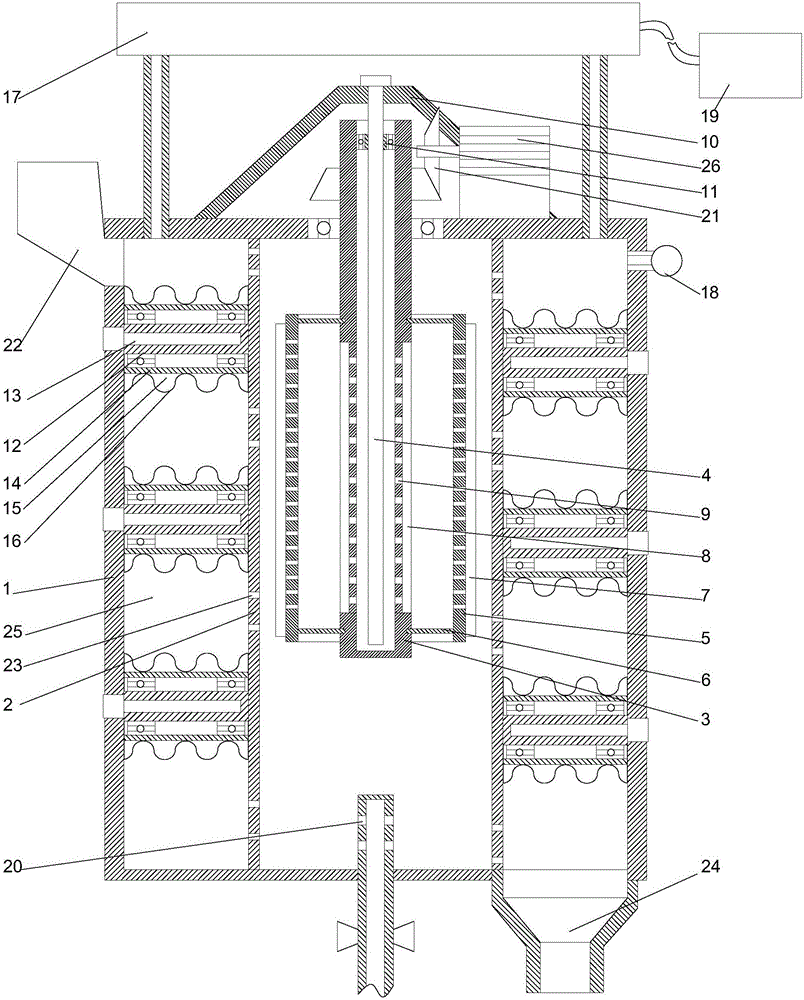

[0024] Such as figure 1 As shown, a coke drying equipment includes a box body 1 and a rotating shaft 3 arranged in the middle of the box body, an air cylinder 5 is arranged on the rotating shaft, and intervals are arranged on the outer wall of the air cylinder. The blade 7 is provided with an inner box 2 inside the box, a cavity 25 is formed between the inner box and the box, and a roller set is arranged inside the cavity , the roller set is arranged in a spiral along the height direction of the cavity, and a hot air input port 20 is arranged under the middle part of the box body, and a one-way valve is arranged on the hot air input port;

[0025] An input port 22 is provided on the outer wall of the box, a star valve is provided on the input port, an output port 24 is provided below the box body, and a Ventilation holes 23 arranged at intervals;

[0026] The roller set includes a fixed shaft 12 fixedly connected to the box body and the inner layer box body at both ends and ...

Embodiment 2

[0030] In this embodiment, on the basis of Embodiment 1, in order to facilitate the installation of the air cylinder, preferably, the inner sides of the upper and lower ends of the air cylinder are respectively connected to the shaft through the connecting rod 6, and the air cylinder A cavity is provided between the inner wall and the rotating shaft. By setting a cavity between the rotating shafts in the air cylinder, the air in the cavity between the air cylinder and the rotating shaft will flow under the drive of the air cylinder during the rotation of the air cylinder driven by the rotating shaft, which can accelerate the mutual contact of hot air and water vapor, and make the Moisture can be drained more quickly.

[0031] In order to improve heat exchange efficiency, in this embodiment, preferably, a through hole is provided in the middle of the rotating shaft, and a heating wire 4 is provided in the middle of the rotating shaft. The middle part of the rotating shaft is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com