Corrosion-resistant low-VOC high-flame-retardance halogen-free engineering plastic and preparation method thereof

A kind of engineering plastics, high flame-retardant technology, applied in the field of engineering plastics, can solve the problems that have not been seen in the reports of PX220 combined use, and achieve the effects of improved flame retardancy, less corrosive gas, and low odor level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

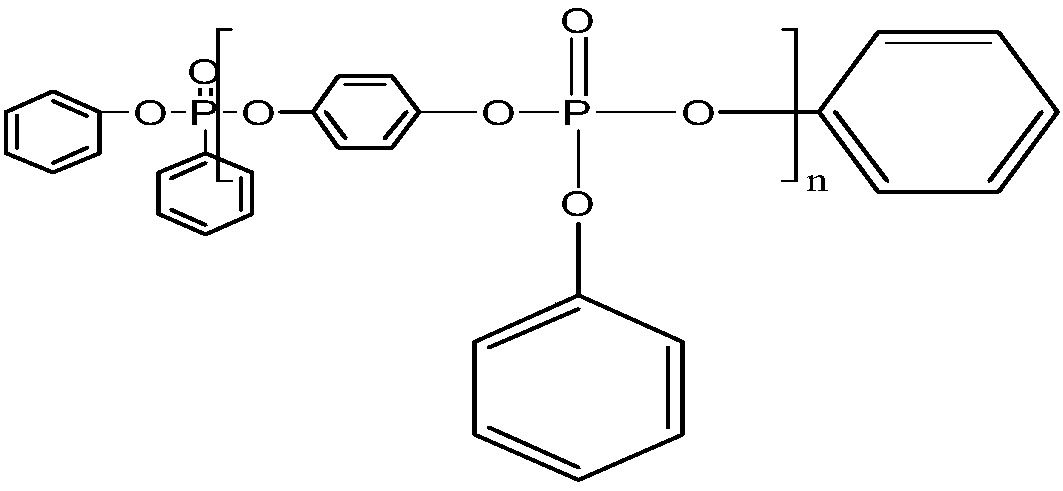

Method used

Image

Examples

Embodiment 1-8

[0044] Example 1-8: A corrosion-resistant and highly flame-retardant halogen-free engineering plastic

[0045] 1. Composition: See Table 1

[0046] Table 1: Compositions of Examples 1-8 (unit: g)

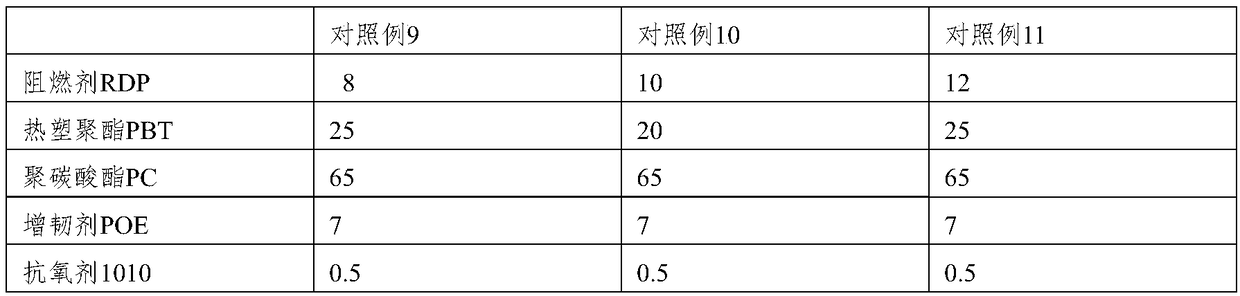

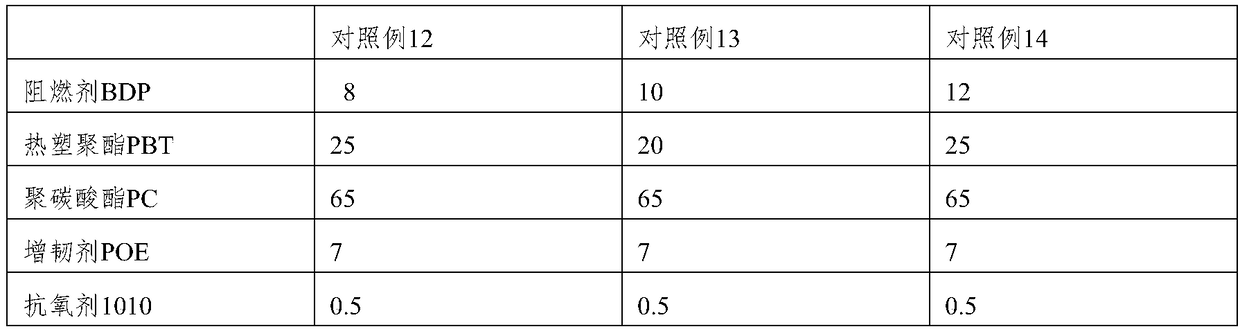

[0047]

[0048] 2. Preparation method: Plasticize and knead in a rotary variometer (parameters: temperature of each zone is 240 degrees, speed 50HZ), and then extruded by a twin-screw extruder to prepare samples.

experiment example 1

[0059] Experimental Example 1: Performance Testing

[0060] 1. Sample:

[0061] Sample 1-8 is respectively embodiment 1-8 (embodiment 6-8 is beyond the limited scope of the present invention);

[0062] Samples 9-11 are comparative examples 1-3;

[0063] Samples 12-14 are comparative examples 4-6;

[0064] Sample 15 was prepared according to Example 3 of CN103881319A (application number 201210561511.1), and its PBT dosage was 20%, PC48%, ethylene-octene copolymer (POE) 30% / triphenyl phosphite 15, ethylene bishard Fatty acid amide (EBS) 0.8%, hindered phenolic antioxidant 1076 and phosphite antioxidant 168 compound 0.2%.

[0065] 2. Detection method:

[0066] Oxygen index LOI test: test standard: GB / T2406-2009;

[0067] Vertical combustion UL-94 level test: test standard: GB / T2408-2008, where the combustion level is shown in Table 1 of the test standard;

[0068] Water resistance and corrosion resistance test method: UL746C;

[0069] Determination of VOC: according to VS-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com