Patents

Literature

53results about How to "Lower odor level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-odor flame-retardant nylon 6 composite material and preparation method thereof

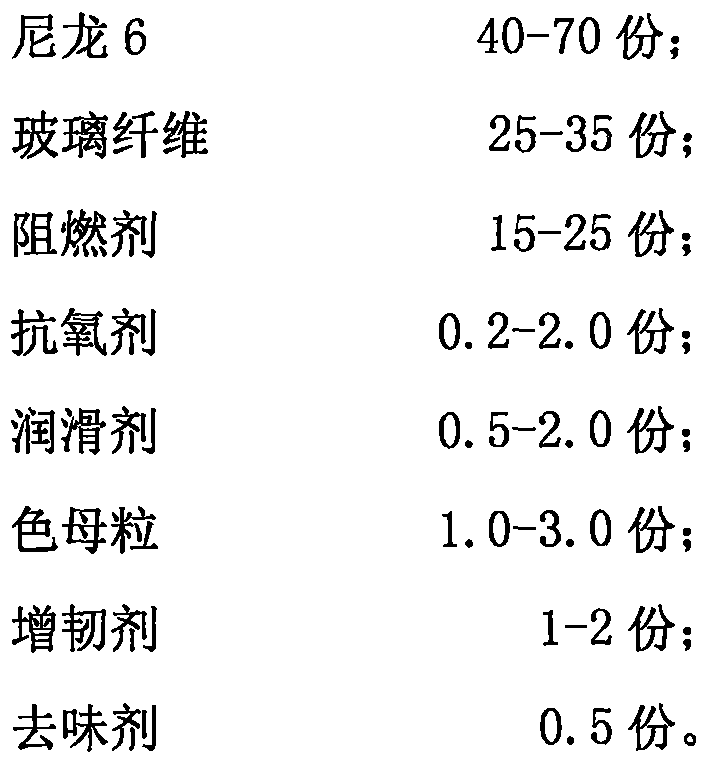

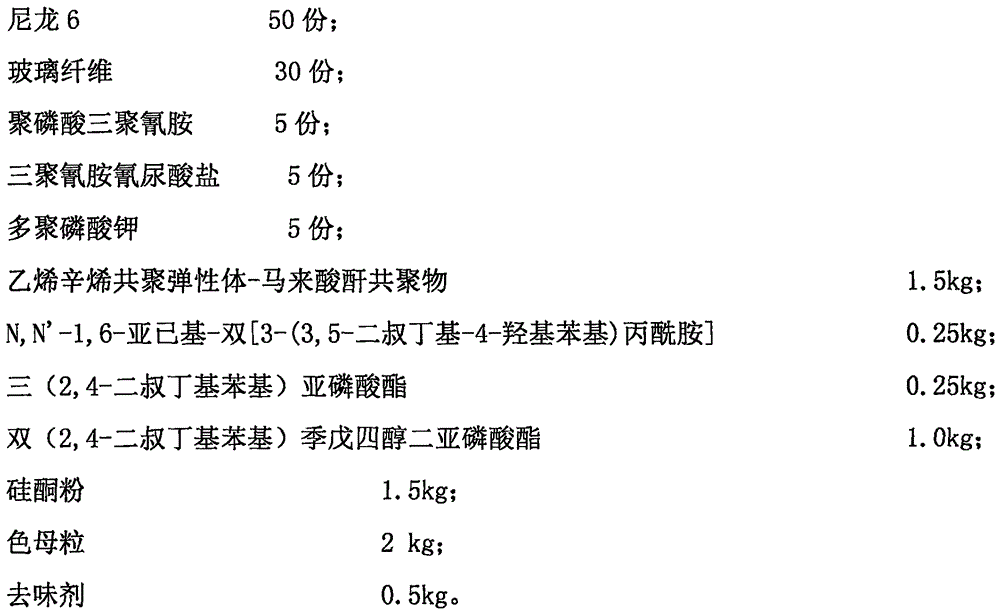

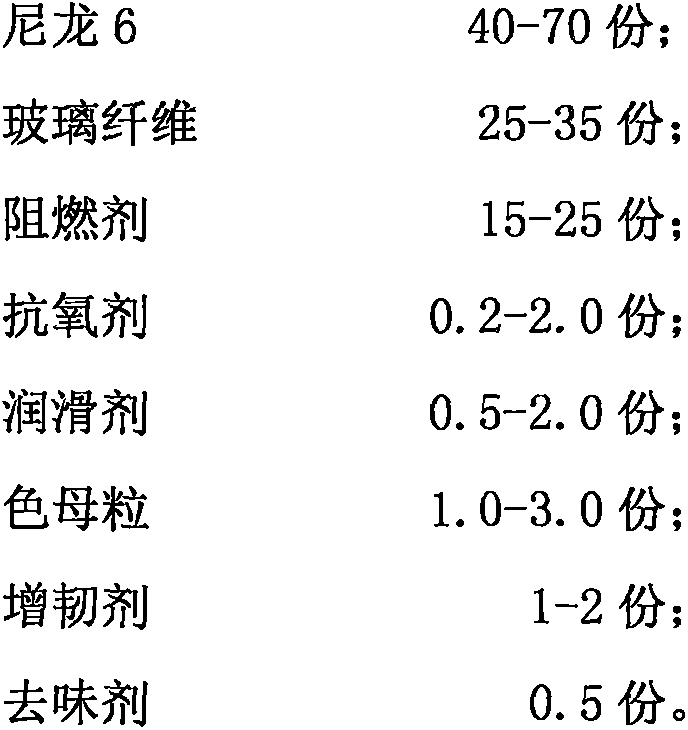

The invention relates to a low-odor flame-retardant nylon 6 composite material. The low-odor flame-retardant nylon 6 composite material is prepared from, by weight, 40-70 parts of nylon 6, 25-35 parts of glass fibers, 15-25 parts of a flame retardant, 0.2-2.0 parts of an antioxidant, 0.5-2.0 parts of a lubricating agent, 1.0-3.0 parts of color masterbatch, 1-2 parts of a toughening agent and 0.5 part of a deodorizing agent. The low-odor flame-retardant nylon 6 composite material is simple in preparation process, convenient to produce, good in flame-retardant effect, capable of meeting the requirement of a using environment where the odor grade is required to be lower than or equal to 3 and wide in market prospect. In addition, the invention provides a preparation method of the low-odor flame-retardant nylon 6 composite material.

Owner:NINGBO EAGLE NEW MATERIAL

Curable resin composition for convering a fingernail or artificial fingernail

ActiveUS20120276028A1Good lookingSuperior property in waterCosmetic preparationsToilet preparationsEmulsionPolyethylene glycol

The present invention provides a curable resin composition for coating natural or artificial nails, which in particular exhibits an excellent appearance after coating, high water and scratch resistances, and low levels of odor, damage to nails, and dermal irritancy, resulting in a high level of safety to human bodies and superior storage stability. The curable resin composition for coating a natural or artificial nail of the present invention comprises (A) an aqueous emulsion of a polymer having functional groups polymerizable by exposure to active energy radiation, (B) polyethylene glycol, and (C) a photo radical initiator containing no nitrogen atom in its molecule.

Owner:THREEBOND FINE CHEM CO LTD

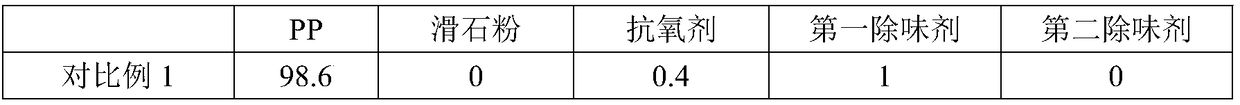

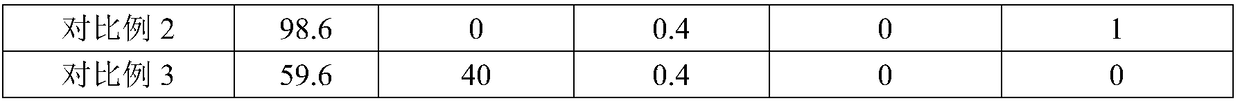

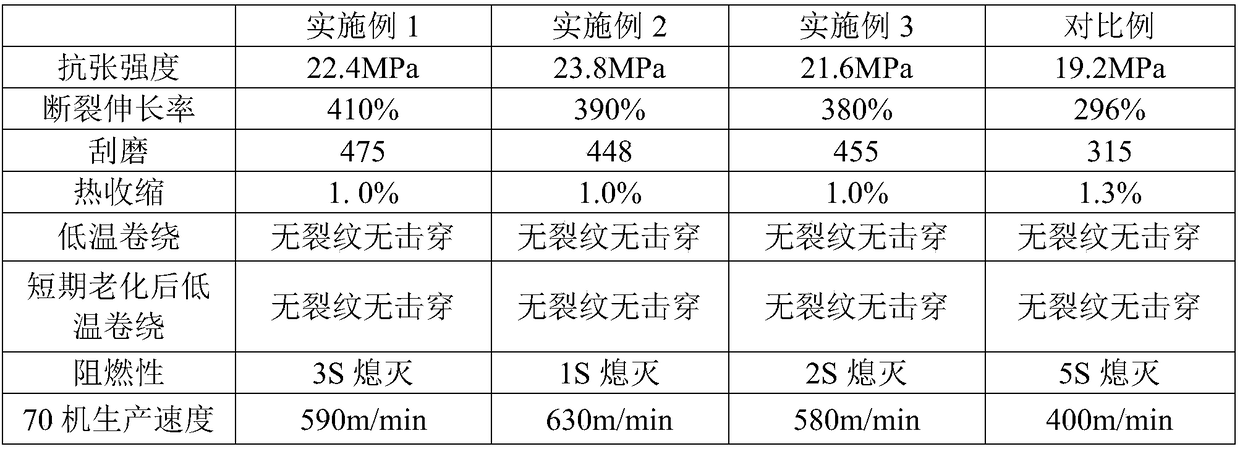

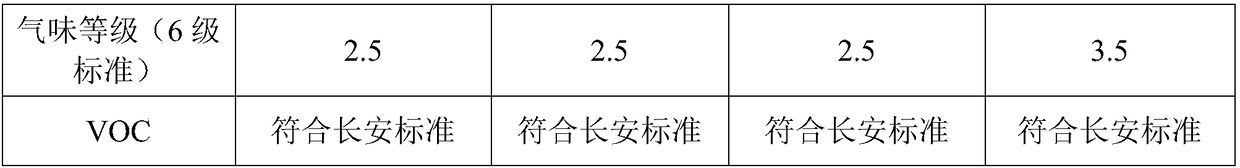

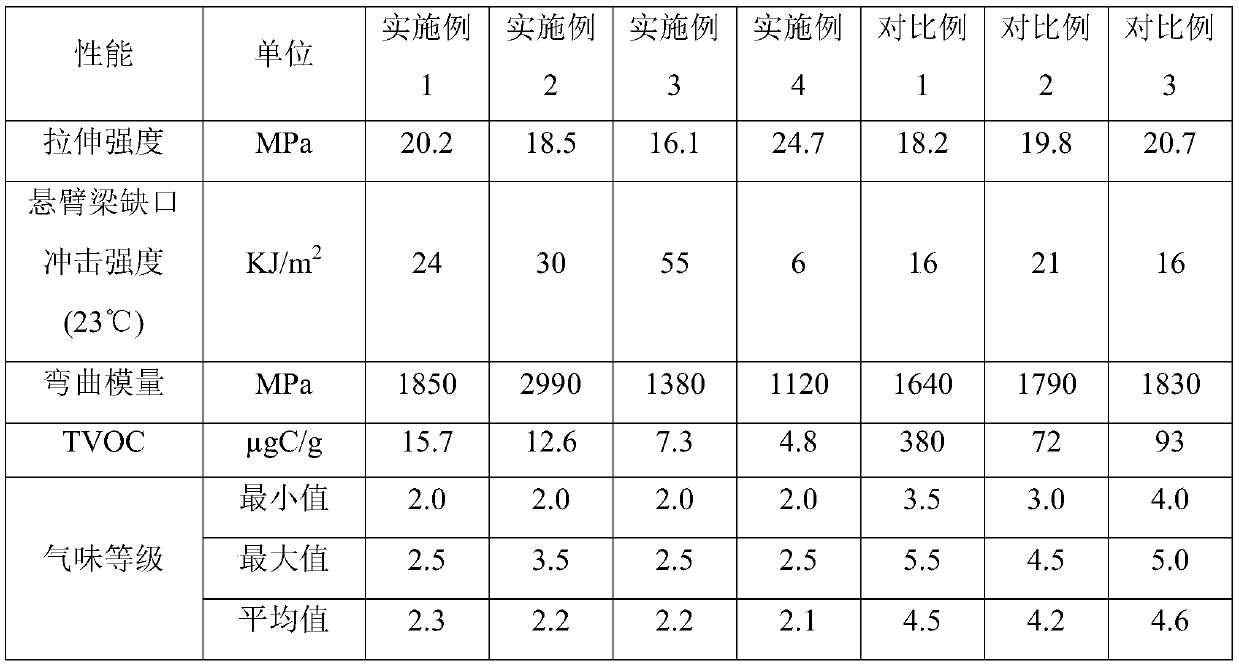

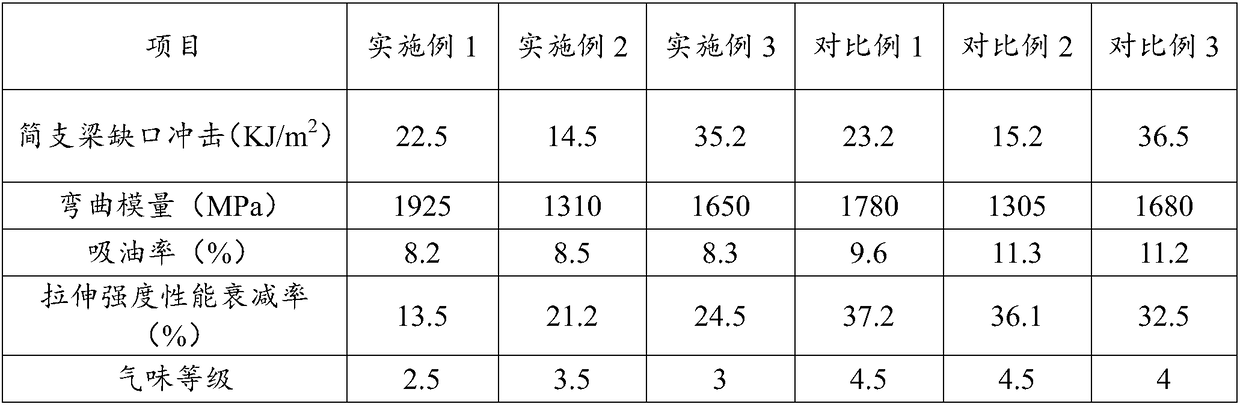

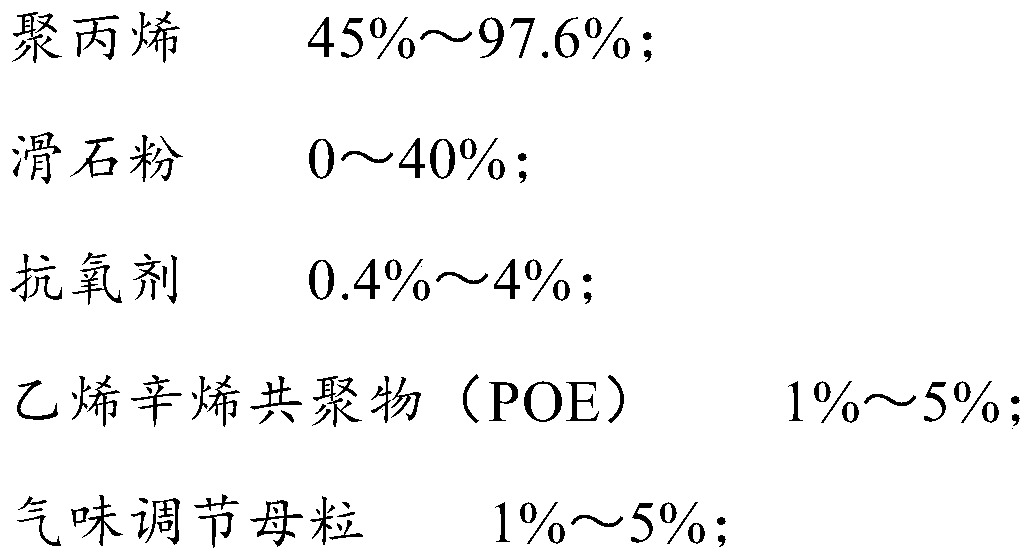

Low emission polypropylene composite material with low odor and preparation method thereof

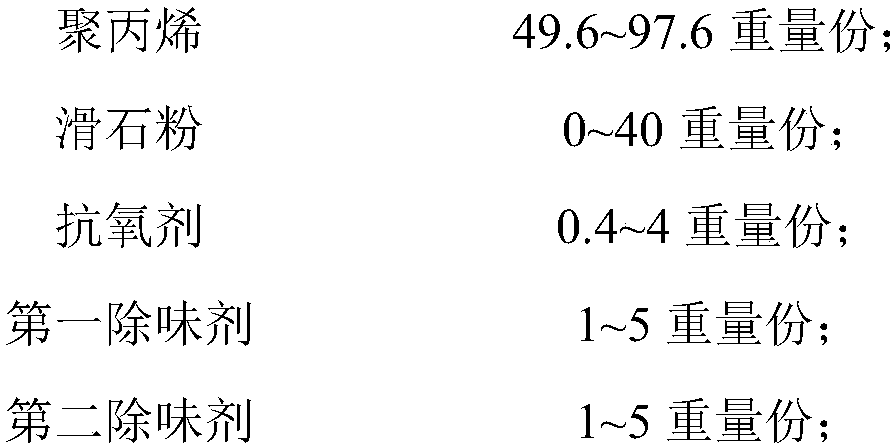

The invention provides a low emission polypropylene composite material with low odor. The composite material is prepared from following raw materials in parts by weight: 49.6 to 97.6 parts of polypropylene, 0 to 40 parts of talcum powder, 0.4 to 4 parts of antioxidant, 1 to 5 parts of first deodorant, and 1 to 5 parts of second deodorant. The first deodorant is an extraction type deodorant with aneffective component content of 40-85%. The second deodorant is an adsorption type deodorant with a loaded special substance. The invention also provides a preparation method of the polypropylene composite material. The preparation technology is simple, the cost is low, and moreover, the material has excellent mechanical properties, low odor, and low emission.

Owner:中广核俊尔(上海)新材料有限公司

Low-odor and low-VOC (Volatile Organic Compound) polyvinyl chloride composite material and preparation method thereof

The invention discloses a low-odor and low-VOC (Volatile Organic Compound) polyvinyl chloride composite material. The low-odor and low-VOC polyvinyl chloride composite material is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride resin, 35 to 45 parts of plasticizer, 5 to 8 parts of stabilizing agent, 0.3 to 0.8 part of lubricant, 2 to 4 parts of flame retardant, 20 to 40 parts of inorganic filler and 0.3 to 1.0 part of antioxidant. The low-odor and low-VOC polyvinyl chloride composite material and the preparation method thereof, disclosed by the invention, are used for the field of automobile insulating wire harnesses; odorous small molecule substances in the material are adsorbed through zeolite powder and anatase type nano titanium dioxide; a mixing and extrusion technology of PVC is improved aiming at the prior art; a feeding sequence and feeding time are adjusted; the odor grade of the PVC can be reduced when the PVC is produced according to the mixing technology; a special post-treatment technology is increased and finished-product mixing and heat circulating material drying treatment is increased; the obtained product meets basic performance requirements of the automobile wire harnesses and the odor and VOC of the whole automobile are reduced.

Owner:SUZHOU SILVER AGE TECH CO LTD

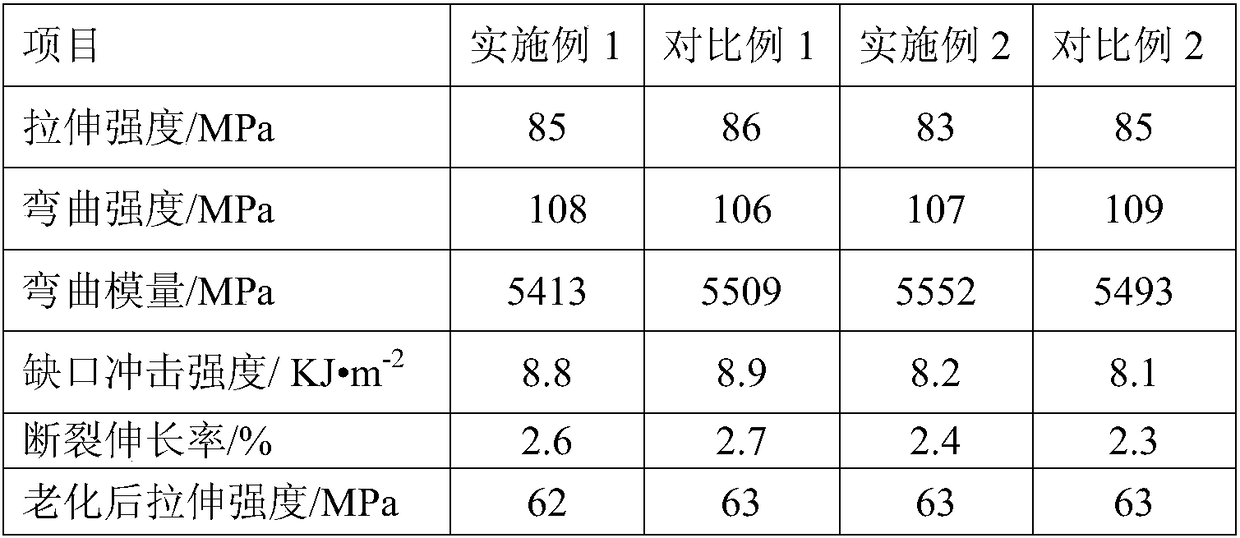

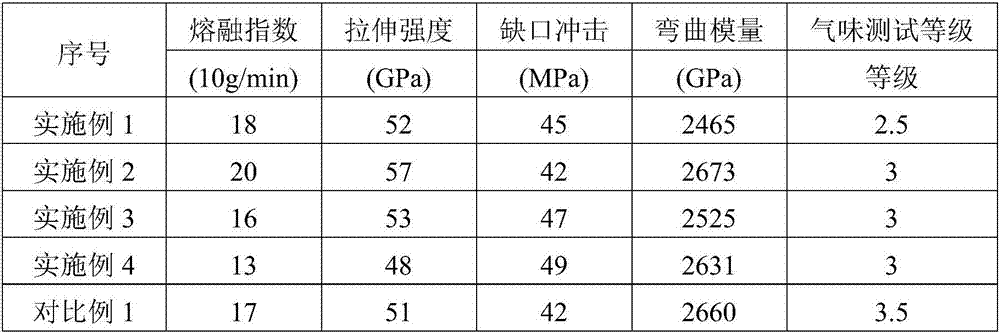

Low-emission low-odor glass-fiber-reinforced polypropylene composite material and preparation method therefor

The invention discloses a low-emission low-odor glass-fiber-reinforced polypropylene material and a preparation method therefor. The material is prepared from the following raw materials in parts by weight: 35-80 parts of polypropylene, 15-60 parts of glass fibers, 1.0-5 parts of compatibilizer and 0.1-1.5 parts of antioxidant. According to the material and the preparation method therefor, hindered phenol and hindered amine polymers are adopted as the antioxidant, an obtained sample has the same excellent aging resistance as that of a control sample, and the sample prepared by the method has alower odor level and lower emission performance.

Owner:CHONGQNG PRET NEW MATERIAL +4

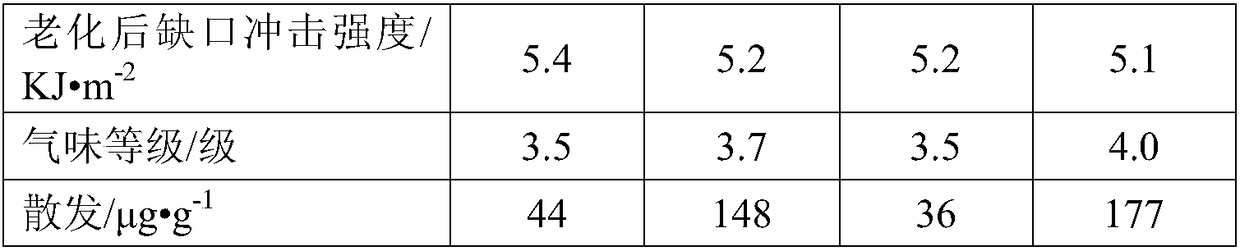

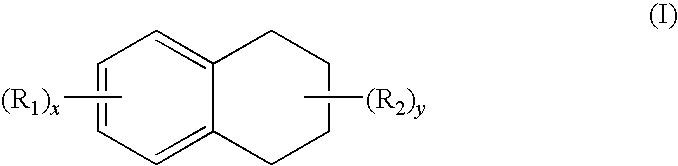

Solvent Composition

InactiveUS20090093588A1Improve securityLower odor levelOrganic compound preparationNon-surface-active detergent solventsHalogenSolvent composition

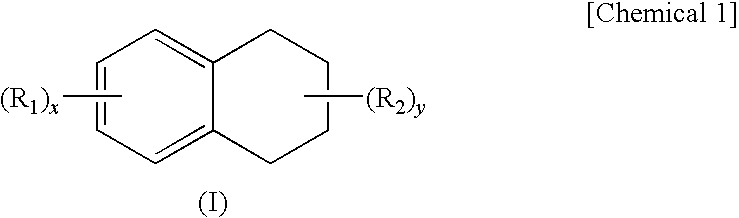

A solvent composition contains a tetralin compound (a) represented by the following general formula (I) and a polyether compound (b) represented by the following general formula (II). The solvent composition is excellent in safety and almost odorless, having a high capability of dissolving various organic materials, and also excellent in affinity to various substrates. The solvent composition is suitably used for various applications including various kinds of paints, adhesives, coating materials, detergents, and the like.wherein x is an integer of 0 to 4; y is an integer of 0 to 8; R1 and R2 each independently represent an alkyl or alkoxy group having 1 to 10 carbon atoms or an alkenyl or alkenyloxy group having 2 to 10 carbon atoms; these groups may be substituted by a halogen atom; and when a plurality of R1 or R2 exists, R1 and R2 each may be the same or different,wherein m is 1 to 10; p is 0, 1, 2, or 3; Prop represents 1,2-propylene group; R3 and R4 each independently represent an alkyl group having 1 to 10 carbon atoms; and when m is 2 or more, a methyl substituent in the 1,2-propylene group represented by Prop may be randomly positioned.

Owner:ADEKA CORP

Low odor and low VOC flame retardant modified HIPS material and preparation method thereof

Relating to the technical field of high polymer materials, the invention provides a low odor and low VOC flame retardant modified HIPS material and a preparation method thereof. The low odor and low VOC flame retardant modified HIPS material is prepared from the following raw materials: HIPS resin, a flame retardant, a toughening agent, a processing aid, an antioxidant and an odor absorbent. The invention adopts the flame retardant, the toughening agent and the odor absorbent for modification treatment of the HIPS main material, so that the material can have excellent flame retardant performance and low odor level, and the styrene monomer content is greatly reduced, thus lowering the odor of polystyrene. The material provided by the invention can be used for household electrical applianceshells, office electric appliance shells and other fields, and the use range of the material is improved.

Owner:ORINKO NEW MATERIAL CO LTD

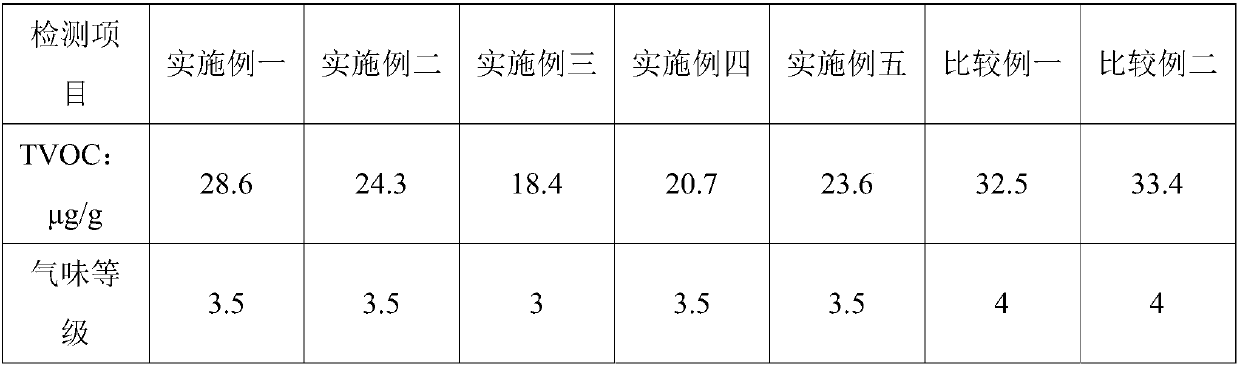

Low-odor low-TVOC polypropylene composite material and preparation method thereof

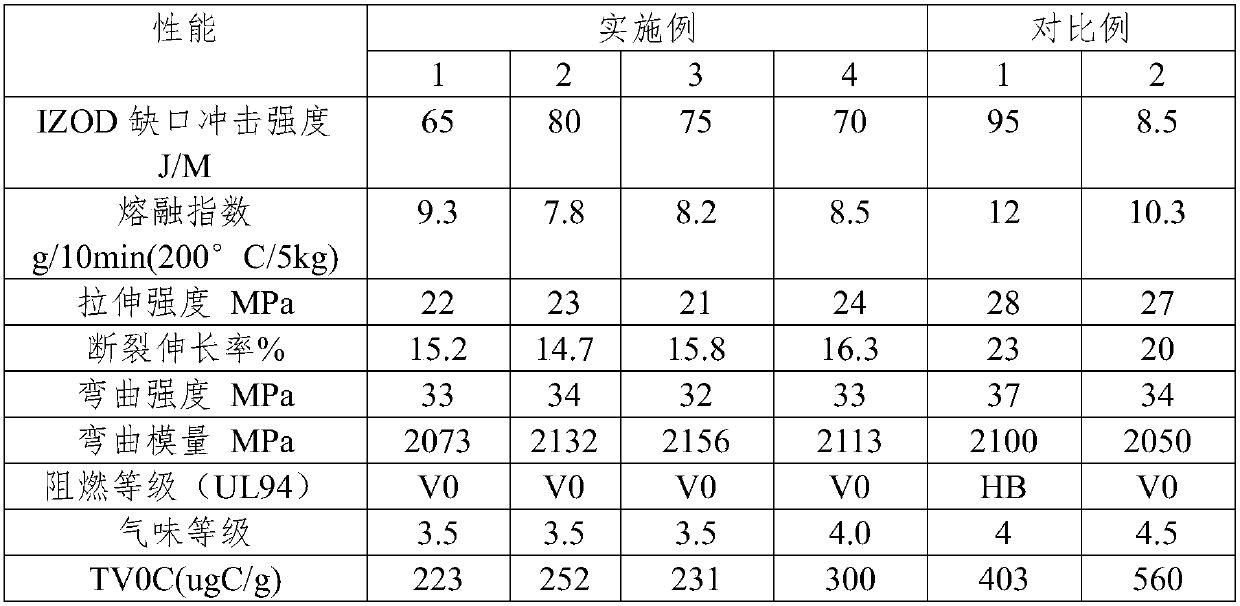

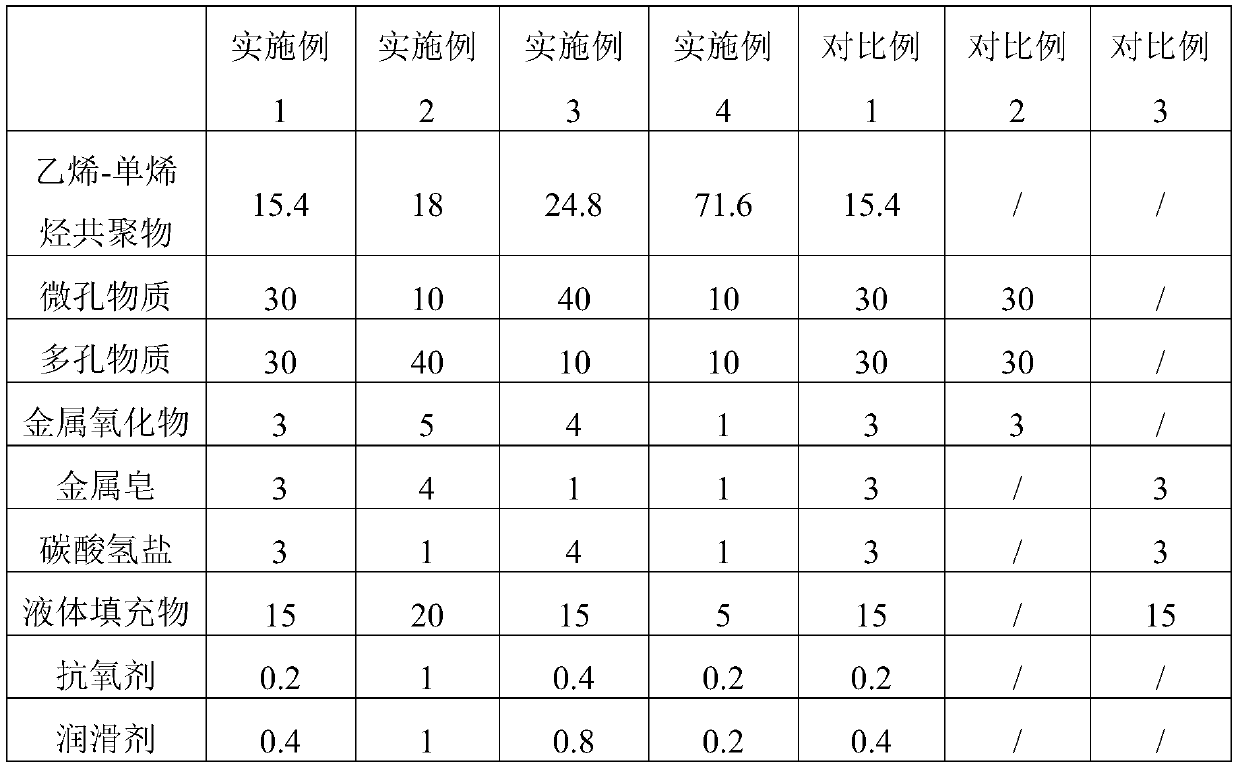

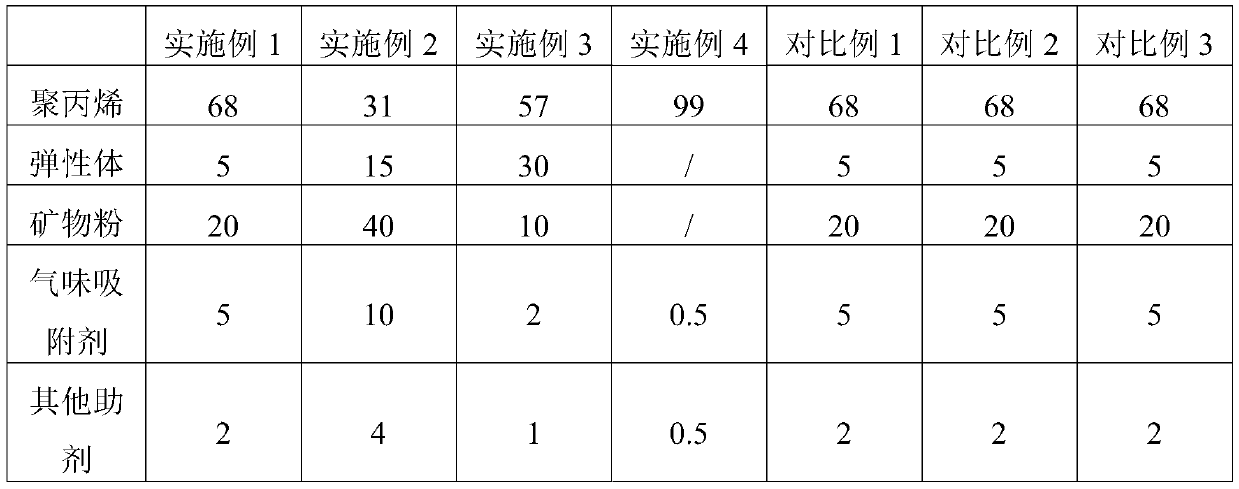

ActiveCN110964260ARemove completelyLower odor levelDispersed particle separationElastomerPolypropylene composites

The invention provides a low-odor low-TVOC polypropylene composite material and a preparation method thereof. The low-odor low-TVOC polypropylene composite material is characterized by comprising thefollowing raw materials in parts by weight: 30-99% of polypropylene, 0-30% of an elastomer; 0-40% of mineral powder; 0.5%-10% of an odor adsorbent; 0.5 to 4% of other auxiliary agents; wherein the odor adsorbent is prepared from the following raw materials in parts by weight: 10 to 75% of ethylene-monoolefine copolymer; 10-40% of a microporous substance; 10-40% of a porous substance; 1-5% of a metal oxide; 1-4% of a metallic soap; 1-4% of a bicarbonate; 5-20% of a liquid filler; 0.2 to 1.0% of an antioxidant; and 0.2 to 1.0% of a lubricant. The low-odor low-TVOC polypropylene composite material disclosed by the invention has relatively low odor and TVOC value.

Owner:TIANJIN KINGFA NEW MATERIAL

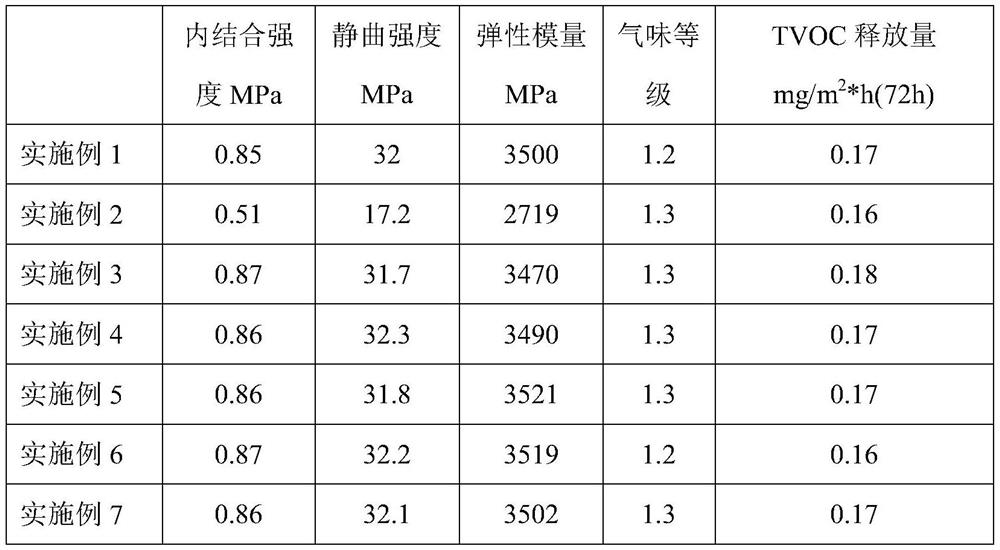

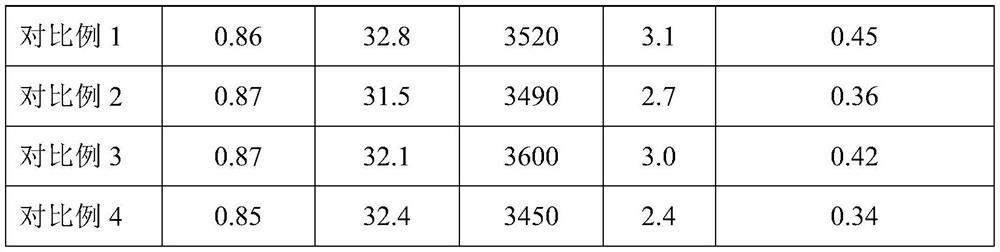

Low-odor artificial board and preparation method thereof

ActiveCN113150399AProtective AdsorptionNo chemical reactionFlat articlesDomestic articlesCyclodextrinMaterials science

The invention provides a low-odor artificial board and a preparation method thereof, the low-odor artificial board comprises an odor adsorbent, the odor adsorbent comprises a layered material and an adsorption material, the layered material is preferably MXene, and the adsorption material is preferably cyclodextrin. According to the low-odor artificial board, the odor grade of the artificial board can be reduced, the mechanical property of the artificial board is not affected, and the manufacturing method is simple.

Owner:WANHUA CHEM GRP CO LTD

Temperature-variable multi-color sponge for powder puff and preparing process thereof

InactiveCN110093027AEasy to operateReduce manufacturing costPackaging toiletriesPackaging cosmeticsWater basedTouch Senses

Temperature-variable multi-color sponge for a powder puff and a preparing process thereof are disclosed in embodiments of the invention, belonging to the technical field of polymer materials. The sponge includes two or more raw materials groups. Each raw material group includes an A component and a B component in a weight ratio of 1.5-2.5:0.8-1.2, wherein the A component includes, by weight, 40-50% of a filler, 1.7-4% of a surfactant, 1-2% of an emulsifier, 0.5-1% of temperature sensing toner powder, and 0.3-1% of water-based color paste, with the balance being water; the B component is a hydrophilic polyurethane prepolymer; and the sponge includes two or more types of temperature sensing toner powder. The sponge enables no dispersion of the toner powder, shows color of the added temperature sensing toner powder, has good physical properties, low smell grade, good environment protection performance, good shape recovery capability and touch sense, and is suitable for cosmetics.

Owner:雅丽日化实业(惠州)有限公司 +1

Low odor PC (polycarbonate)/ABS (acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

The invention belongs to the technical field of modified polymer materials, and discloses a low-odor PC / ABS alloy material and a preparation method thereof. The low-odor PC / ABS alloy material of the present invention comprises the following components in mass percentage: 62.7-81.4% of polycarbonate; 10-20% of polyacrylonitrile resin; 3-8% of styrene-butadiene rubber; 2-3% of toughening agent ; Zeolite 2-3%; Odor release agent 0.5-1%; Dispersant 1-2%; Processing aid 0.1-0.3%. The low-odor modified PC / ABS alloy material of the present invention has the characteristics of high modulus, high flow, high strength, high toughness, low odor, etc., and is especially suitable for manufacturing automotive interior parts, including eyeglass cases, decorative strips, central control Taiwan and so on. The present invention selects SAN and SBR blends as the rubber system, high molecular weight silicone compounds as the lubricant, and a compound system of zeolite and sodium oxalate to synergistically realize the low odor of the PC / ABS alloy material.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

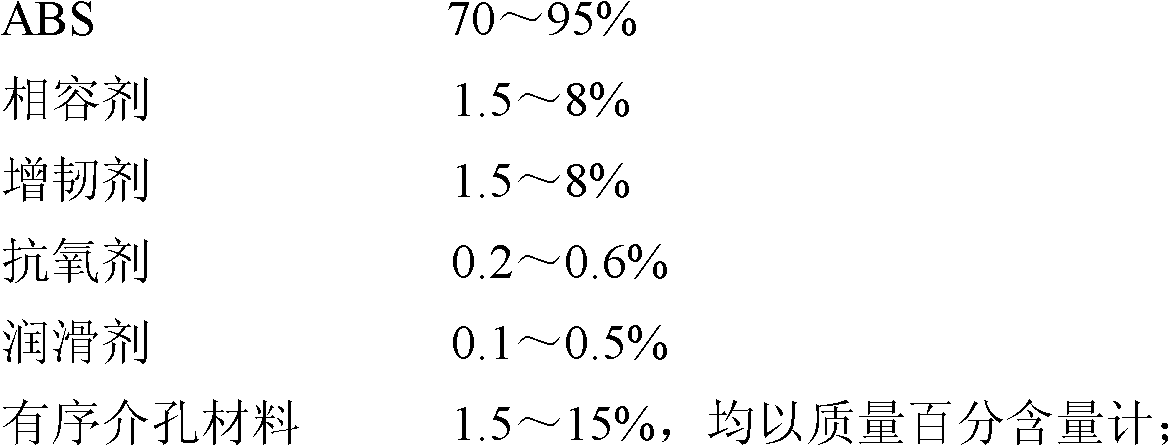

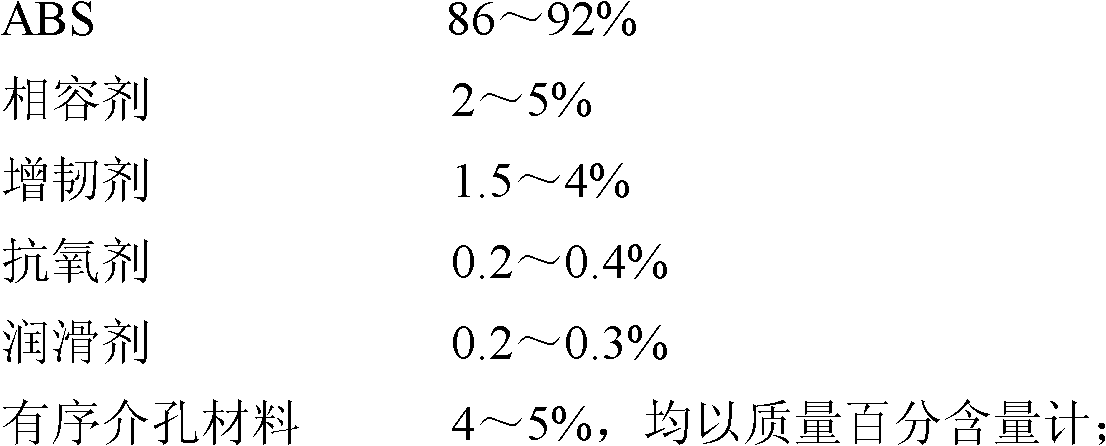

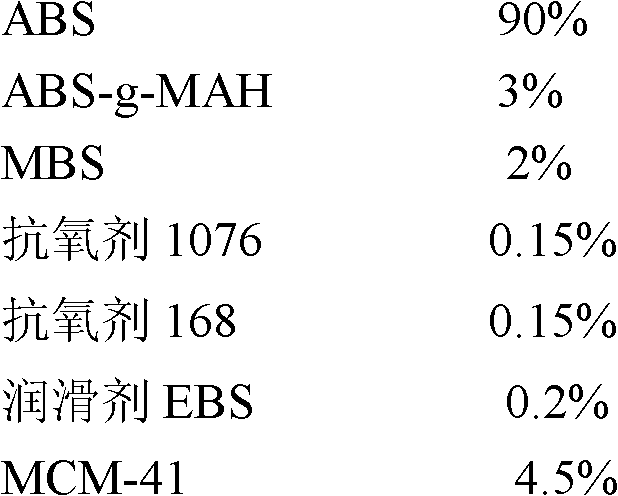

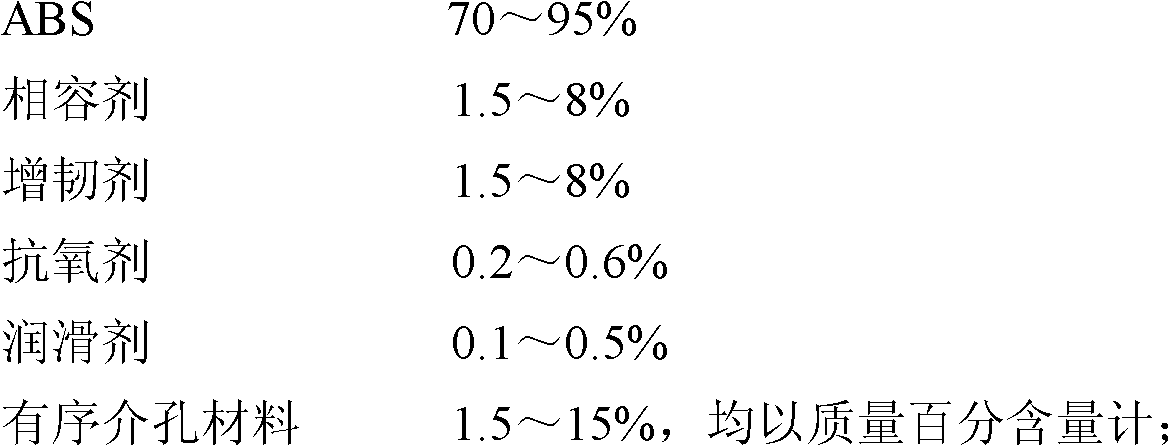

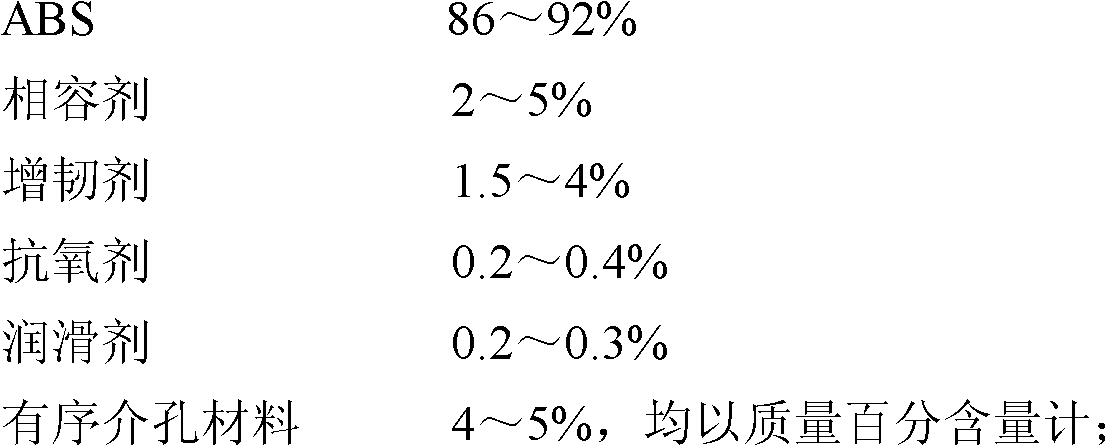

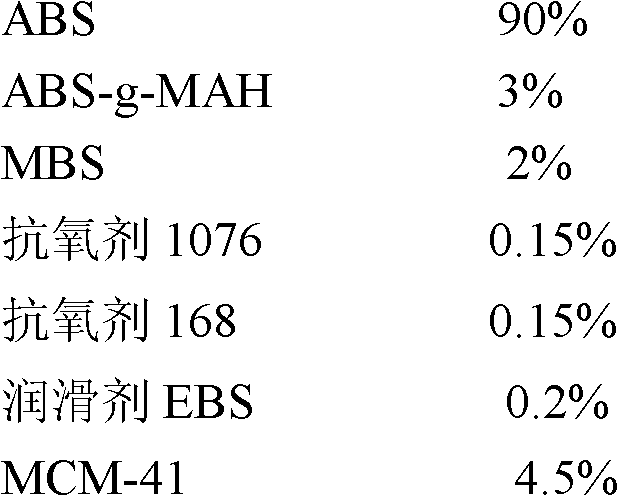

Modified ABS special material and preparation method thereof

InactiveCN102432977AEase of industrial applicationImprove processing fluidityAntioxidantAdditive ingredient

The invention provides a modified ABS (Acrylonitrile butadiene styrene) special material and a preparation method thereof; the ABS special material comprises the following components: 70-95wt% of ABS, 1.5-8wt% of compatilizer, 1.5-8wt% of flexibilizer, 0.2-0.6wt% of antioxidant, 0.1-0.5wt% of lubricant, and 1.5-15wt% of ordered mesoporous material, wherein the ordered mesoporous material is MCM-41, MCM-48, SBA-15 or SBA-16; the preparation method comprises the following steps of: weighing ingredients with certain proportions, putting into a high speed mixer and mixing fully, and then extruding and granulating by a double-screw extruder. The modified ABS special material and the preparation method thereof provided by the invention effectively improve MI (Moment of Inertia) value of the ABS and processing fluidity of the ABS as well as mechanical intensity; in addition, the modified ABS special material has the characteristic of low odour, and also has excellent comprehensive performances such as light weight, sound absorption, etc.

Owner:CHONGQING UNIV OF ARTS & SCI

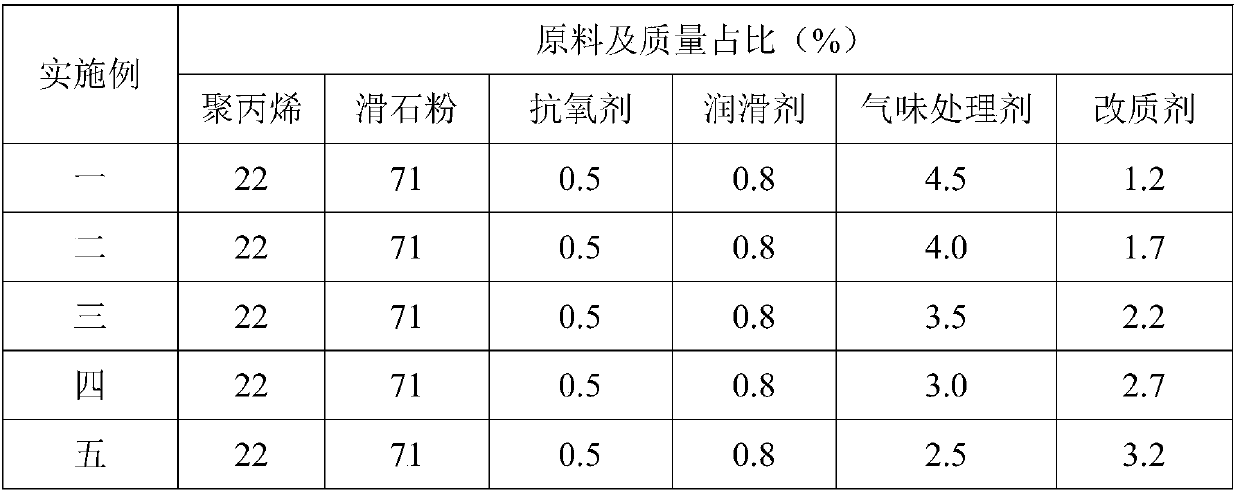

Low-odor masterbatch and preparation method thereof

InactiveCN108047545AReduce decomposition and volatilizationLower odor levelVolatile organic compoundPolypropylene

The invention discloses a low-odor masterbatch and a preparation method thereof, wherein the raw materials comprise 20-30% of polypropylene, 70-80% of an inorganic filler, 0.3-1.5% of an antioxidant,0.6-1% of a lubricant, 0.3-5% of an odor treatment agent, and 1-5% of a modifier. The preparation method comprises: preparing polypropylene, an inorganic filler, an antioxidant and a lubricant according to a certain ratio, stirring for 5-10 min in a high speed stirrer, completely mixing, pouring the mixing material into a mixer when the temperature is 120-130 DEG C, mixing, adding an odor treatment agent and a modifier when the temperature of the mixing material in the mixer is 150-190 DEG C, pouring the obtained mixture into a twin-screw extruder when the temperature is 160-210 DEG C, and extruding to prepare the product. According to the present invention, with the low-odor masterbatch, the easily volatile organic matters in polypropylene plastic can be effectively treated without the changing of the properties of the plastic product, such that the plastic product achieves the desired low odor level requirements.

Owner:江苏冠恒新材料科技有限公司

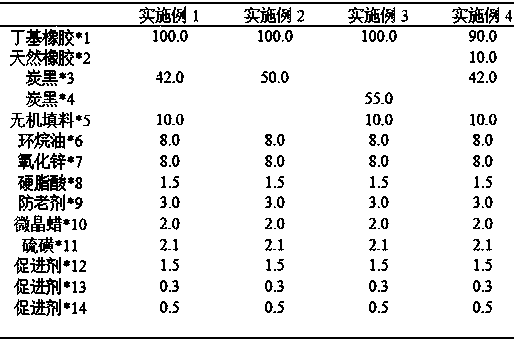

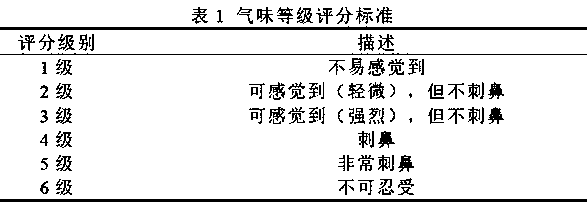

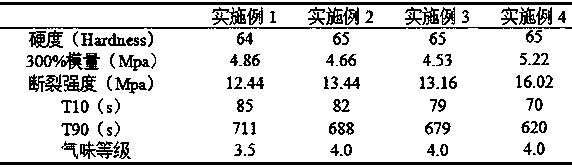

Rubber composition for low-smell tire and tire thereof

The invention belongs to the field of rubber tire manufacturing and relates to a rubber composition capable of effectively lowering tire smell grade. The rubber composition comprises, by weight, 90.0-100.0 parts of edible-grade butyl rubber, 30.0-80.0 parts of carbon black, 0-50.0 parts of softening oil, 0.5-4.0 parts of protective wax, 0.5-4.0 parts of antiager, 1.0-3.5 parts of sulfur and 0.3-2.5 parts of promoter. The rubber composition can effectively lower tire smell grade and is suitable for manufacturing low-smell tires, especially standby tires. Physical and mechanical performance of the rubber composition and high speed and durability of the tires can meet normal using requirements.

Owner:ZHONGCE RUBBER GRP CO LTD

Polypropylene composition and preparation method thereof

The invention belongs to the technical field of high polymer materials, and in particular relates to a polypropylene composition and a preparation method thereof. The polypropylene composition is prepared from the following raw materials in parts by mass: 60-80 parts of impact polypropylene, 10-30 parts of talcum powder, 3-10 parts of a toughening agent, 2-5 parts of white carbon black and 0.2-0.8 part of a composite antioxidant. The preparation method of the polypropylene composition comprises the following steps: firstly, performing uniform dry-mixing on the materials in parts by mass in a high-speed mixer, and performing extrusion pelletization by using an extruder at 180-120 DEG C, wherein the rotation speed of the mixer is 400-450 rpm, and the dry-mixing time is 5-8 minutes. The polypropylene composition provided by the invention is slight in odor, relatively high in rigidity and toughness and simple and feasible in preparation process. The polypropylene composition can be applied to production of automobile parts and household electric appliance components.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

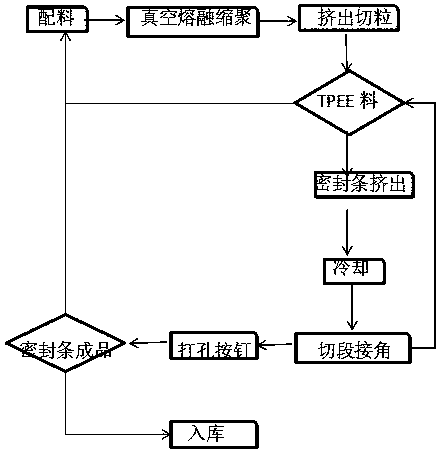

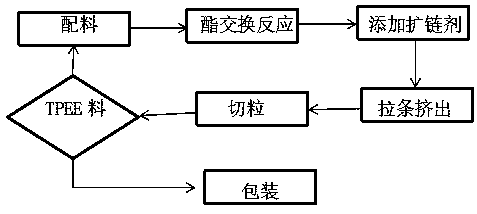

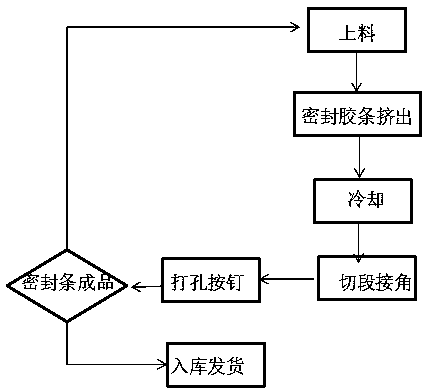

TPEE modified thermoplastic elastomer automobile sealing strip

The present invention relates to a TPEE modified thermoplastic elastomer automobile sealing strip. The sealing strip is prepared from the combination of a binder and an addition agent, wherein the binder is composed of the combination of PP and two thermoplastic elastomers, the PP is a resin, and the two thermoplastic elastomers are a polyene elastomer TPE-A and a polyester elastomer TPE-B. The preparation method comprises the steps that 1) automatic compounding, plastication, oil charge and pre-dispersion are carried out; 2) twin-screw plastication, liquation, compounding, extrusion and granulation are carried out; 3) product inspection of a sealing strip material is carried out; 4) extrusion processing of the sealing strip is carried out, and the processes of feeding, compounding, and underwater traction and extrusion are completed on a sealing strip extrusion processing production line; 5) finished strip inspection of the sealing strip is carried out, inspections of structural, physical and chemical properties of the sealing strip are carried out; 6) cutting and jointing are conducted on the sealing strip, according to the specification requirement of the sealing strip, cuttingis carried out, and a jointing mold is used for jointing; 7) packing and storage are carried out, the finished product of the sealing strip is tested again, and the qualified product is put into a warehouse. The TPEE modified thermoplastic elastomer automobile sealing strip has the advantages that the performances are excellent, the softness and hardness of the product are adjusted by PP content,the application range is wide, and the free lifting of the automobile sealing strip at an ultra-low temperature can be met.

Owner:HEBEI GUIHANGHONGTU AUTOMOTIVE COMPONENTS CO LTD

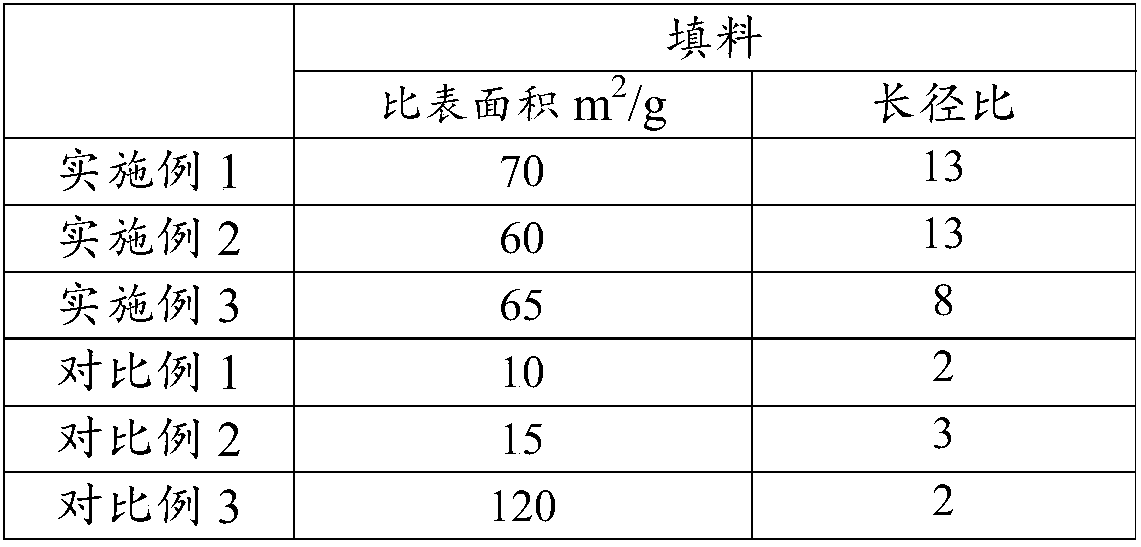

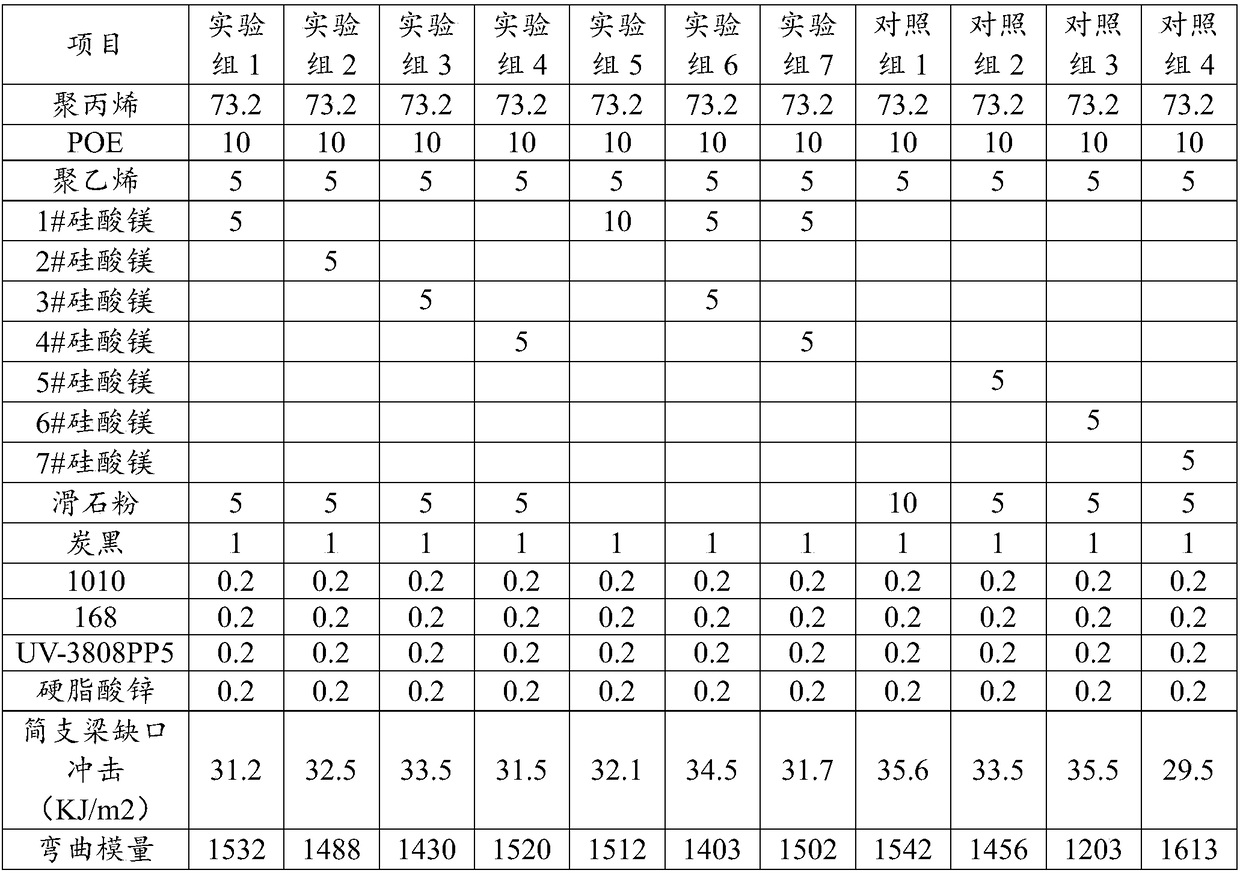

Chemical substance-resistant low odor polypropylene composite material and preparation method thereof

The invention discloses a chemical substance-resistant low odor polypropylene composite material. The polypropylene composite material comprises, by weight, 55-90 parts of polypropylene, 5-10 parts ofpolyethylene and 5-25 parts of a filler, and the filler comprises magnesium silicate. All components and contents thereof in the polypropylene composite material interact with each other, and the filler is selected reasonably, so the polypropylene composite material has good chemical substance resistance, low odor and other good comprehensive performances, keeps excellent mechanical performances,and is especially suitable for automotive interior parts. The invention also discloses a preparation method of the chemical substance-resistant low odor polypropylene composite material.

Owner:KINGFA SCI & TECH CO LTD

Preparation method of low-odor viscose fibers

ActiveCN112575402ALower odor levelPromote escapeArtificial filaments from viscoseTextile/flexible product manufacturePolymer scienceSpinning

The invention relates to the technical field of chemical fiber processing, in particular to a preparation method of low-odor viscose fibers. The preparation method comprises the following steps of selecting dissolved wood pulp with high whiteness, high methylcellulose content and low pentosan content as a raw material, preparing a viscose spinning solution, uniformly mixing with a titanium dioxidedispersion solution, feeding into a spinning machine, and solidifying to regenerate nascent fibers; and enabling the nascent fibers to be drafted and oriented to form fibers with certain strength, the fibers entering a fluff tank and a refiner after being cut off, and preparing the low-odor viscose fibers by adopting post-treatment processes such as desulfurization, water washing, bleaching, oiling, drying and the like. The low-odor viscose fiber prepared by the invention is relatively high in whiteness, extremely low in defect content, extremely low in residual sulfur content and low in odor, and can be applied to the fields of non-woven fabrics and medical sanitary materials with strict odor requirements; and the problem of peculiar smell generated when the viscose fibers are applied tothe field of dry tissues is solved, so that the application field of the viscose fibers is widened.

Owner:赛得利(福建)纤维有限公司

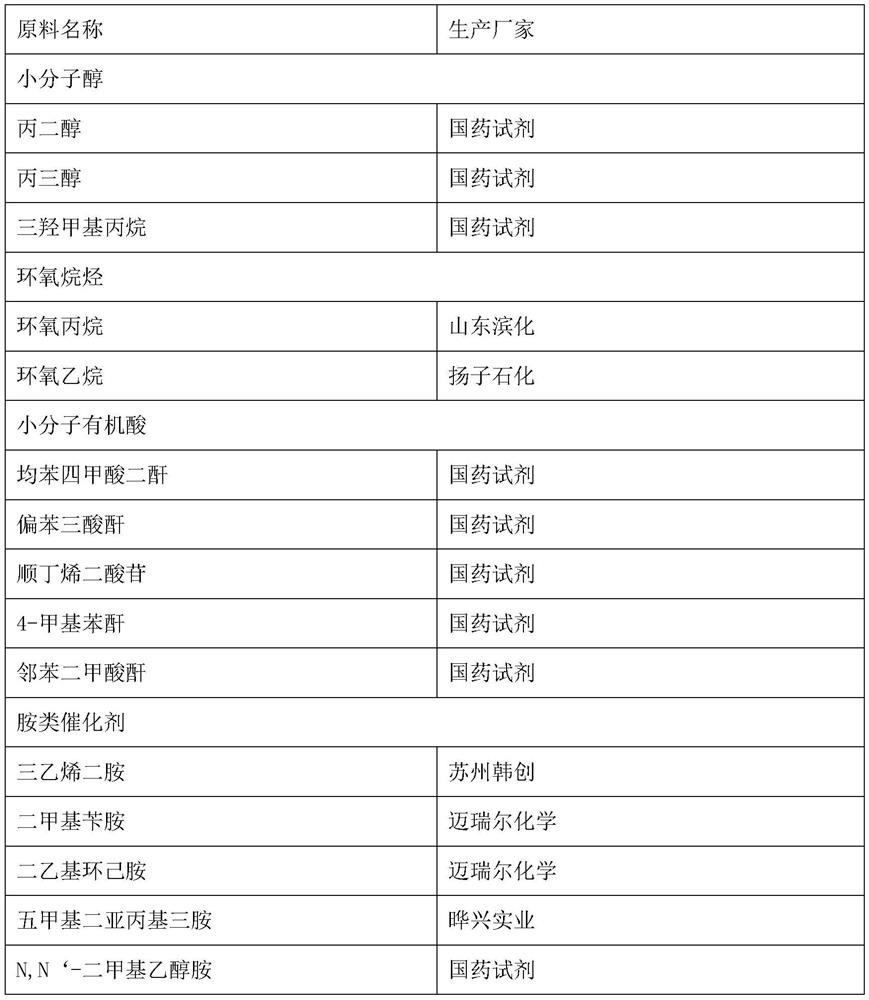

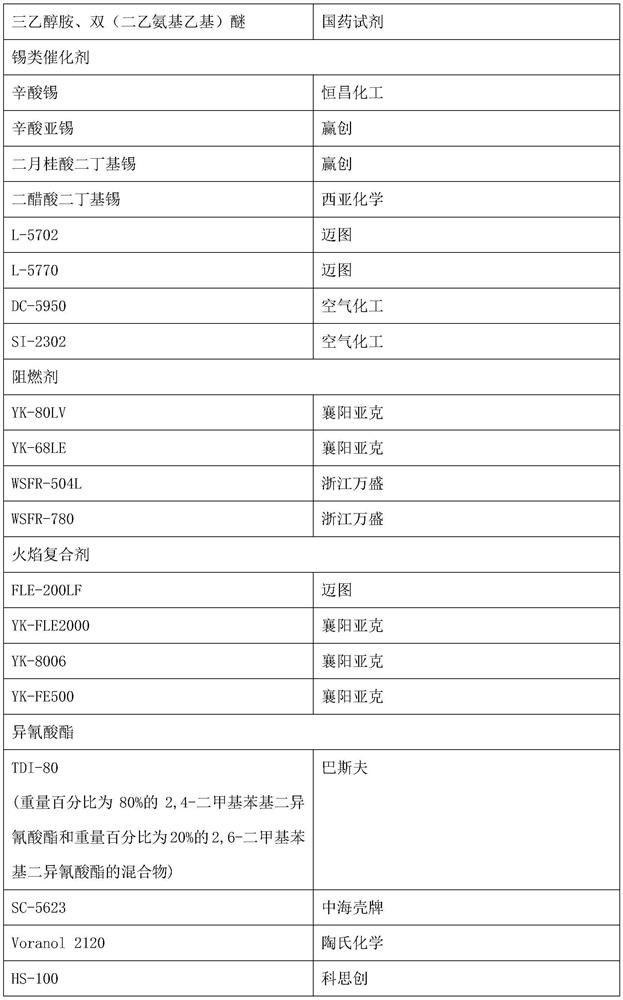

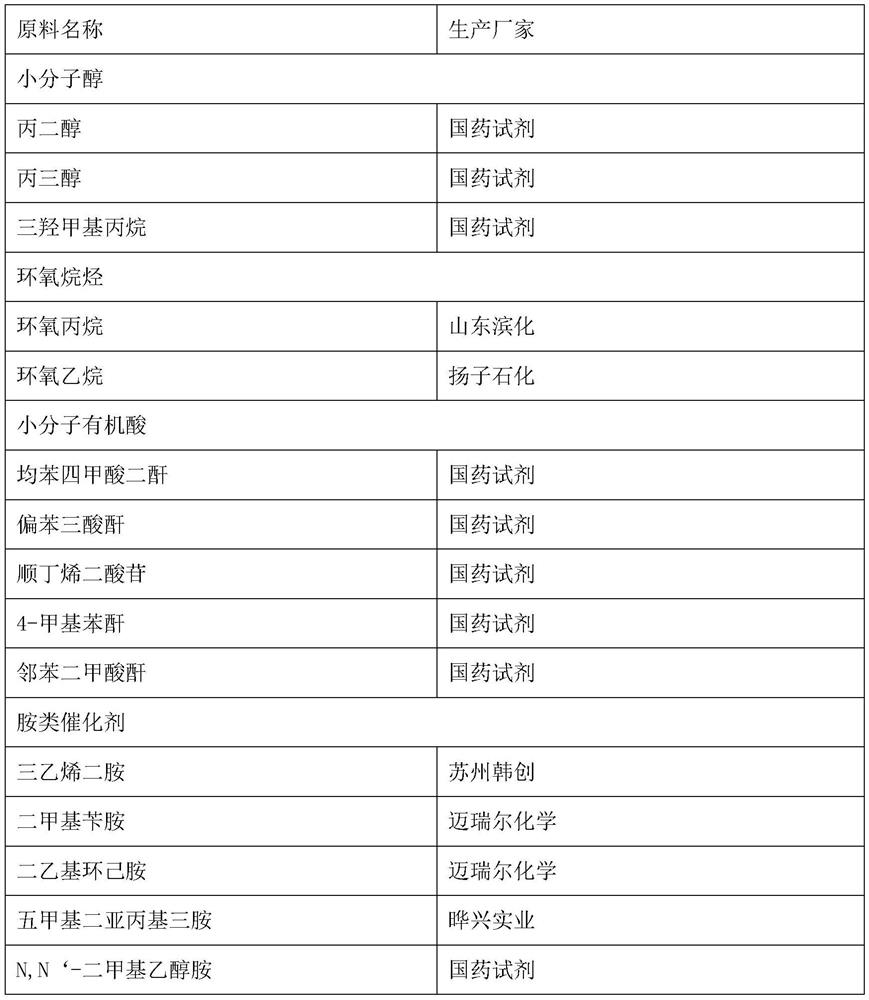

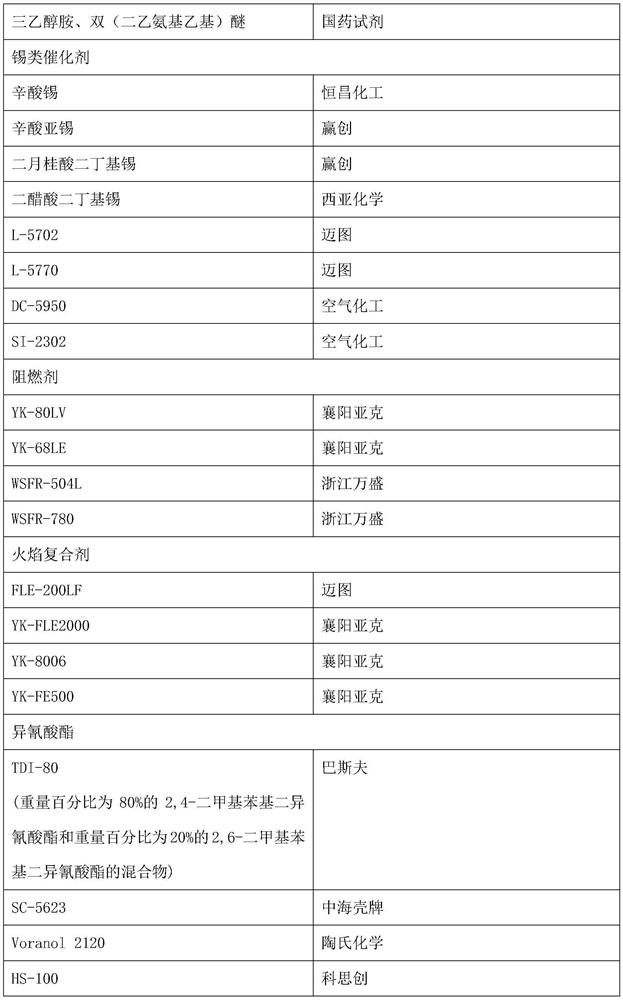

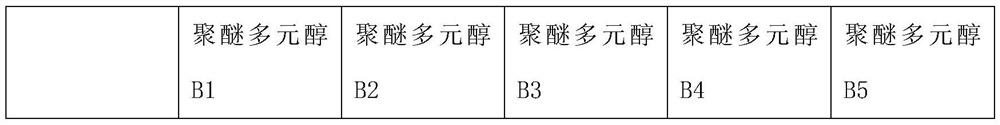

Composite material for automobile interior skin and its preparation method and use

The invention relates to a composite material for automotive interior skin and its preparation method and application, and mainly solves the problems of low composite fastness, large amount of flame compounding agent used and large odor of the composite material for automotive interior skin in the prior art during flame compounding question. The present invention adopts a composite material for automotive interior skin, which is composed of component I and component II, and the weight ratio of component I to component II is 100:20~60, wherein component I is expressed in parts by weight The count includes polyether polyol A: 30-60 parts, polyether polyol B: 30-60 parts, polymer polyol C: 10-40 parts, water: 1-5 parts, amine catalyst: 0.1-1 Parts, tin catalyst: 0.1 to 1 part, foam stabilizer: 0.5 to 2 parts, flame retardant: 2 to 12 parts, flame compounding agent: 0.5 to 5 parts; component II includes isocyanate 20 to 5 parts by weight 60 parts and the technical scheme of the preparation method thereof have achieved good technical effects and can be used in the industrial production of automotive interior skin composite materials.

Owner:江苏金智达新材料有限公司

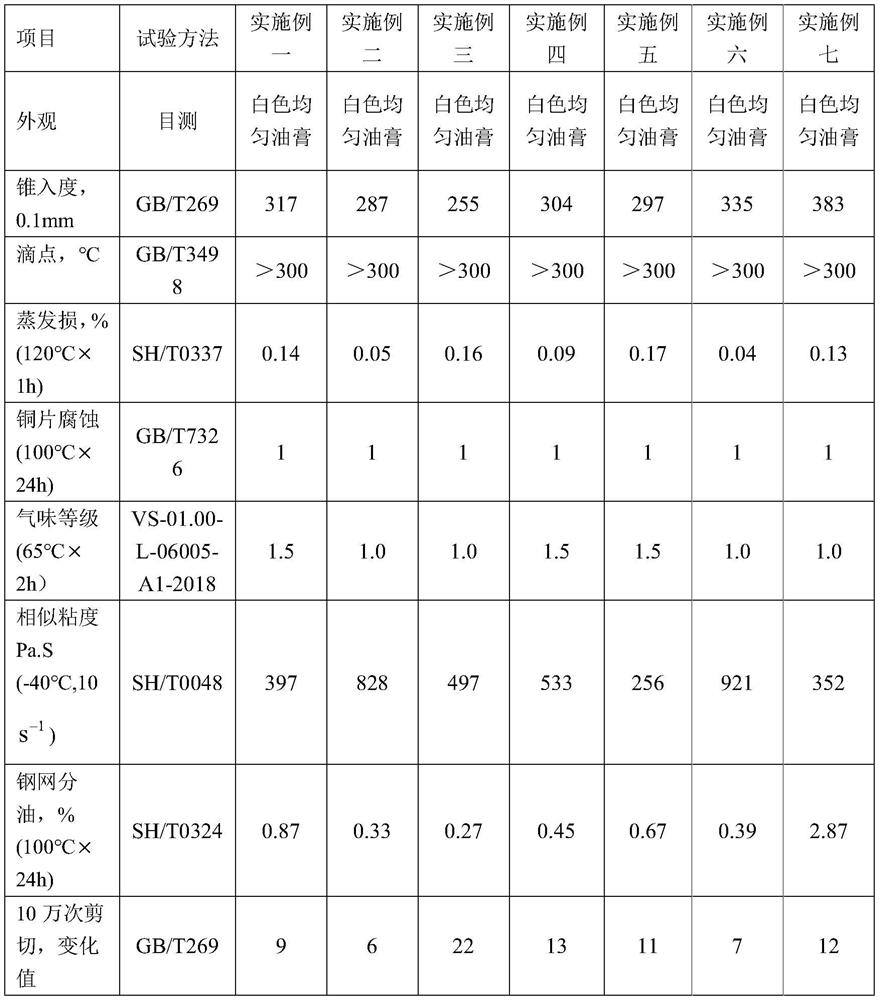

Low-odor automobile switch lubricating grease composition and preparation method thereof

The invention provides a low-odor automobile switch lubricating grease composition. The low-odor automobile switch lubricating grease composition comprises the following components in parts by weight:62-93 parts of base oil, 5-20 parts of a thickening agent and 2-18 parts of a solid lubricant. The invention also discloses a preparation method of the low-odor automobile switch lubricating grease composition. The low-odor automobile switch lubricating grease composition prepared by adopting fumed silica to thicken poly-alpha olefin base oil and adding the solid lubricant has an extremely low odor grade. Through the test of VS-01.00-L-06005-A1-2018 Test Specification for Odor of Nonmetallic Materials in Vehicles, the odor grade is 1.0-1.5 grade, which is reduced by one grade or more than onegrade compared with the odor of the lubricating grease in the prior art. The automobile switch lubricating grease composition disclosed by the invention also has good colloid stability, wear resistance, friction reduction, shearing resistance and excellent high and low temperature performance, is suitable for lubricating and protecting various switches, and is also suitable for lubricating various parts of an automobile cockpit.

Owner:武汉博达特种润滑技术有限公司

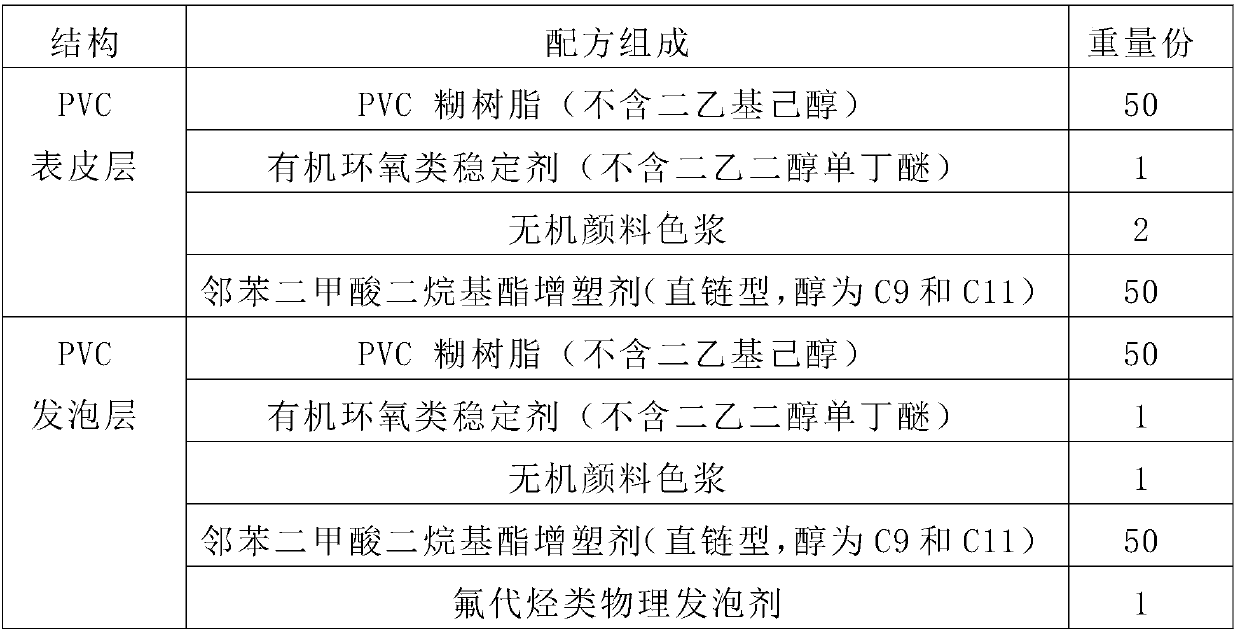

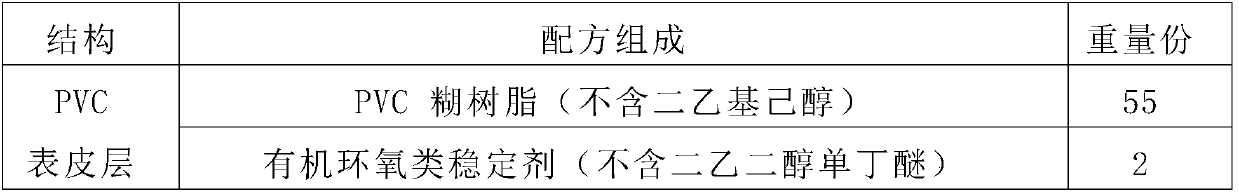

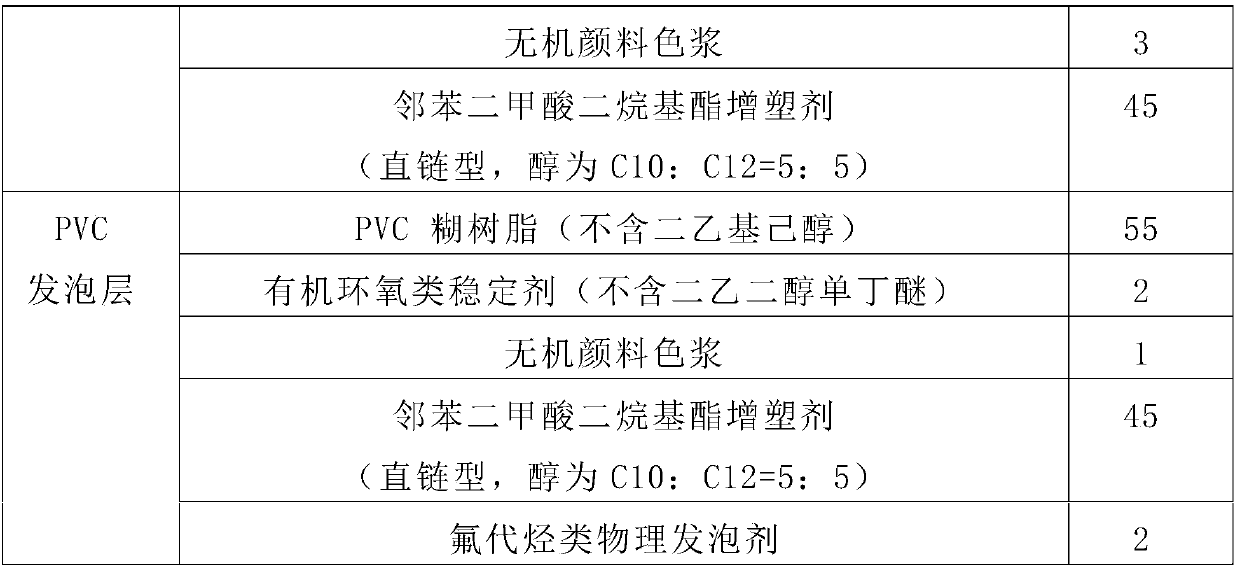

Skin layer composition, foaming layer composition and low-odor PVC artificial leather prepared from skin layer composition and foaming layer composition

PendingCN111058294ALower odor levelGuaranteed performanceTextiles and paperPolymer scienceFoaming agent

The invention relates to a skin layer composition for forming low-odor PVC artificial leather. The skin layer composition comprises PVC resin, a plasticizer and a stabilizer. The invention also relates to a foaming layer composition for forming the low-odor PVC artificial leather. The foaming layer composition comprises PVC resin, a plasticizer, a stabilizer and a foaming agent, wherein the plasticizer is selected from dialkyl phthalate, preferably alkyl alcohol forming the dialkyl phthalate is linear alcohol, preferably the linear alcohol has a carbon chain length of C9 to C13, particularly preferably C10 and / or C12, further preferably C10 and C12 mixed in a ratio of 10: 1 to 1: 10, particularly 8: 2 to 5: 5. The invention also relates to the low-odor PVC artificial leather. The low-odorPVC artificial leather comprises a skin layer formed by the skin layer composition and / or a foaming layer formed by the foaming layer composition. The odor level of the PVC artificial leather is effectively reduced, and the requirements of customers on product pleasure and health are met.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

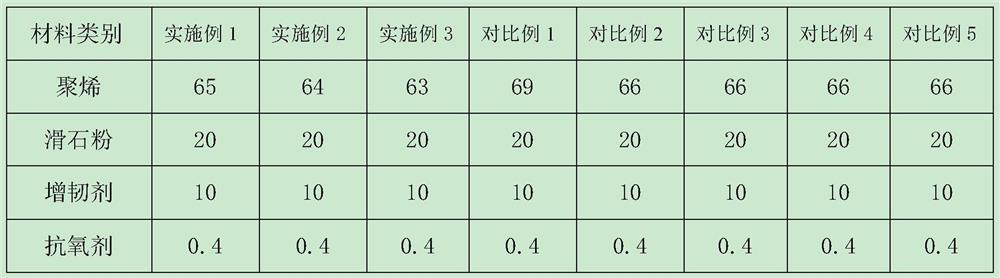

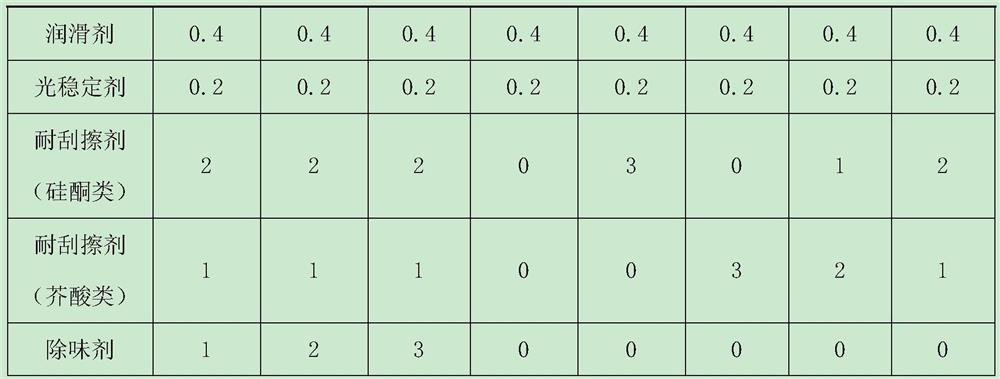

Low-odor, low-VOC and scratch-resistant polypropylene interior material for vehicle and preparation method of polypropylene interior material

The invention discloses a low-odor, low-VOC and scratch-resistant polypropylene interior material for vehicles and a preparation method of the polypropylene interior material. The low-odor low-VOC scratch-resistant polypropylene interior material for the vehicle comprises the following components: 63 to 66% of polypropylene, 18 to 22% of talcum powder, 8 to 12% of a flexibilizer, 0.3 to 0.5% of an antioxidant, 0.3 to 0.5% of a lubricant, 0.1 to 0.3% of a light stabilizer, 1 to 3% of a deodorant and 1 to 3% of a scratch-resistant agent. The pore diameter of the deodorant is 10 [mu] m and 50 [mu] m; and the scratch-resistant agent is formed by compounding silicone and erucyl amide according to a weight ratio of 1: 2-2: 1. By adopting the deodorant containing the microporous water-containing structure, the odor grade and VOC content of the material can be effectively reduced, so that the odor grade standard of automotive trim materials of various main engine plants is less than or equal to 3.0, and the VOC content standard is met.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

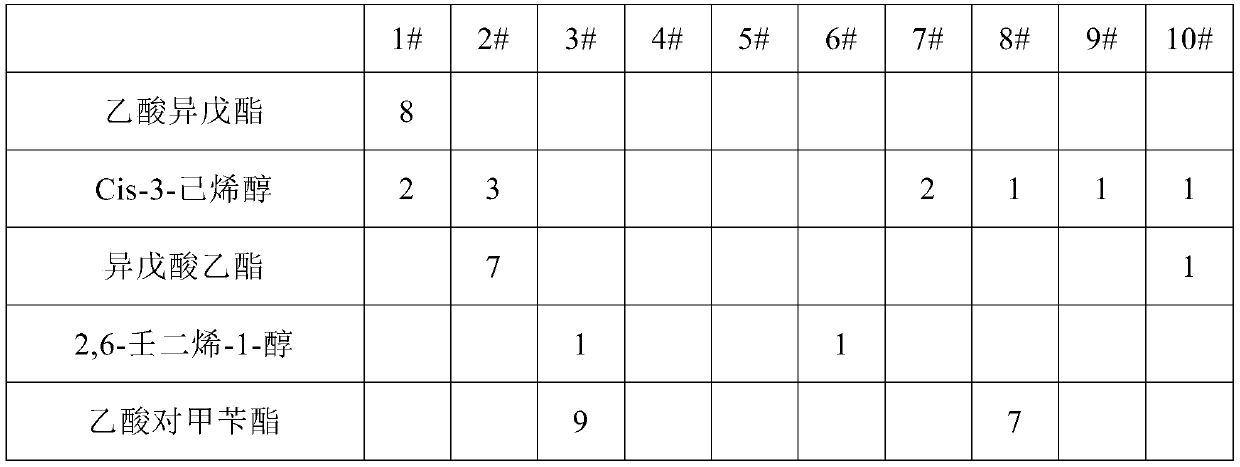

Low-odor polypropylene composite material and preparation method thereof

InactiveCN110317409AImprove the problem of special irritating odorLower odor levelPolypropylene compositesAlcohol

The invention provides a low-odor polypropylene composite material which is characterized by being prepared from, by mass, 45%-97.6% of polypropylene, 0-40% of talcum powder, 0.4%-4% of an antioxidant, 1%-5% of an ethylene octene copolymer and 1%-5% of odor regulating master batch. The odor regulating master batch is polypropylene particles supported with an odor regulator with the mass fraction of 0.01%-1.5%, the odor regulator is a mixture of alcohols, ketones, esters and phenols with a boiling point of 90-190 DEG C. The composite material is simple in preparation process and free of influence on performance and has special fragrance.

Owner:中广核俊尔(上海)新材料有限公司

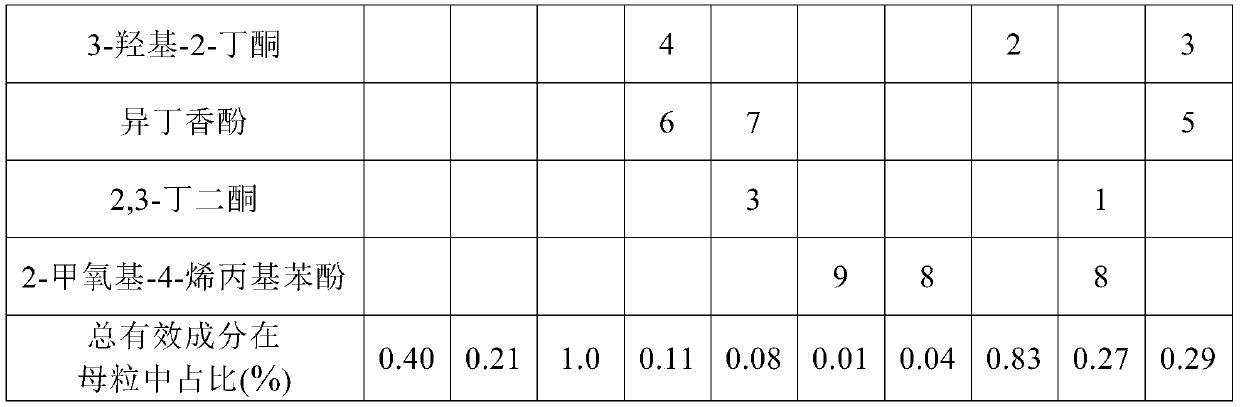

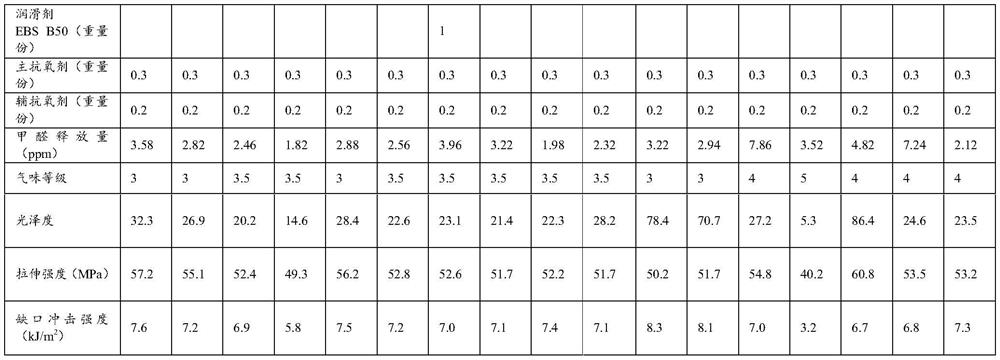

Polyformaldehyde composition and preparation method thereof

The invention discloses a polyformaldehyde composition and a preparation method thereof. The polyformaldehyde composition is prepared from the following components in parts by weight: 86-94 parts of polyformaldehyde resin, 6-12 parts of acrylate copolymer and 0.5-2 parts of amide lubricant. The acrylate copolymer is added into the system, so that the glossiness of the polyformaldehyde composition can be effectively reduced; and the amide lubricant is added into the system, so that the formaldehyde emission and the odor level of the polyformaldehyde composition can be effectively reduced. According to the invention, by optimizing the addition amount of the acrylate copolymer and the amide lubricant, a low formaldehyde emission (<5ppm), low odor (<=3.5 grades) and low gloss (the glossiness is less than or equal to 35), and is suitable for automotive interior parts.

Owner:KINGFA SCI & TECH CO LTD

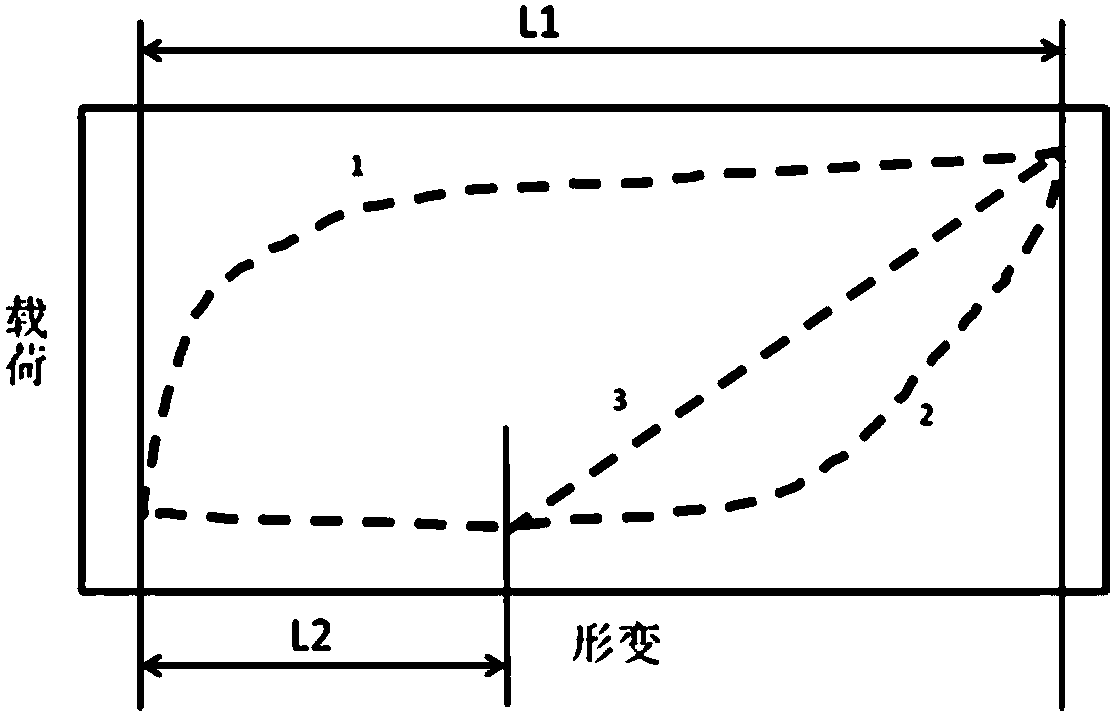

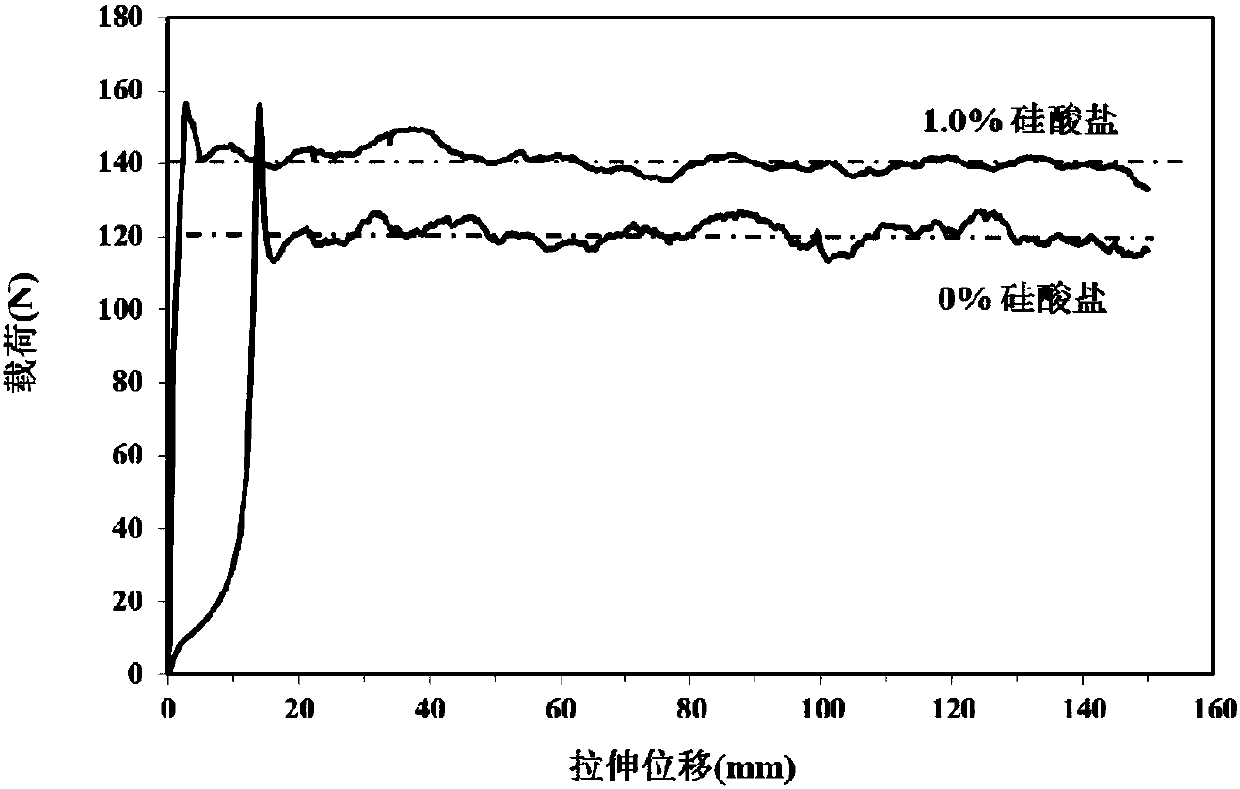

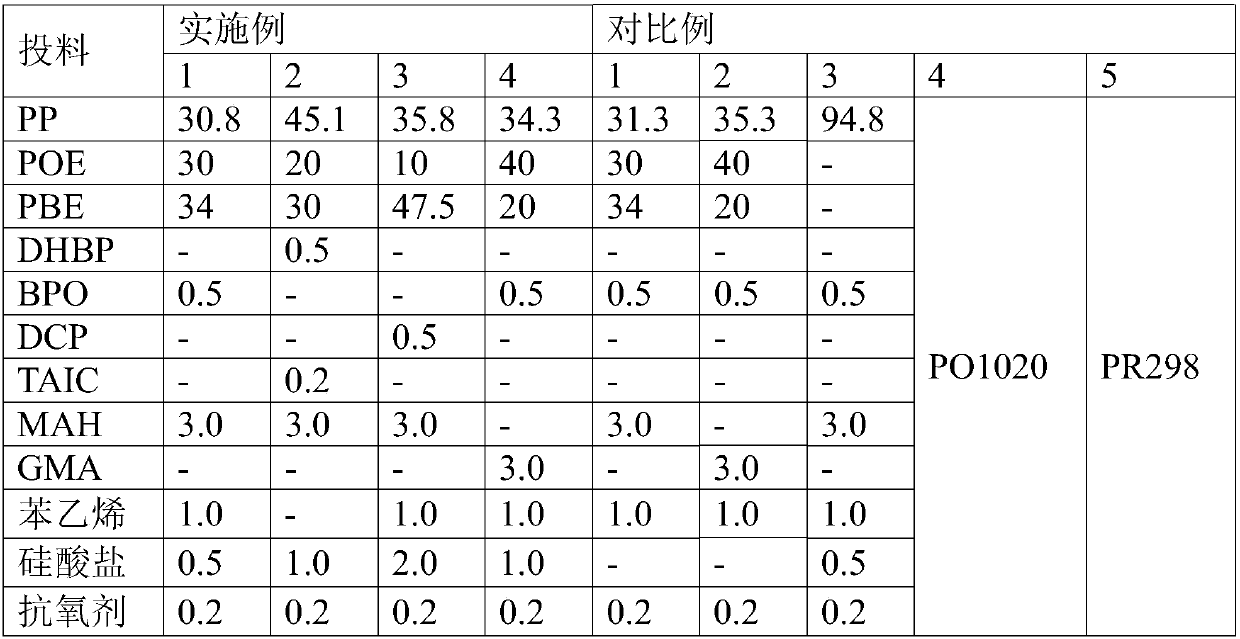

Poly(propylene-grafted polar monomer) composition and preparation method thereof

The invention relates to the field of a polypropylene-grafted composition, and discloses a poly(propylene-grafted polar monomer) composition and a preparation method thereof. According to the invention, the xylene insoluble substance content of the composition measured according to GB / T 18474-2001 is greater than or equal to 5 weight percentage; the peeling strength of the metal and the composition measured according to GB / T 2791-1995 is more than 50 N / 25mm; the VOC smell grade of the composition measured according to a German Volkswagen standard is less than or equal to 3.5; and the 100% tensile deformation recovery rate of the composition is more than 50%; by taking total weight of the composition as a reference, the silicate content is 0.1-5 weight percentage. The composition has high adhesion stress, high elasticity and little smell.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

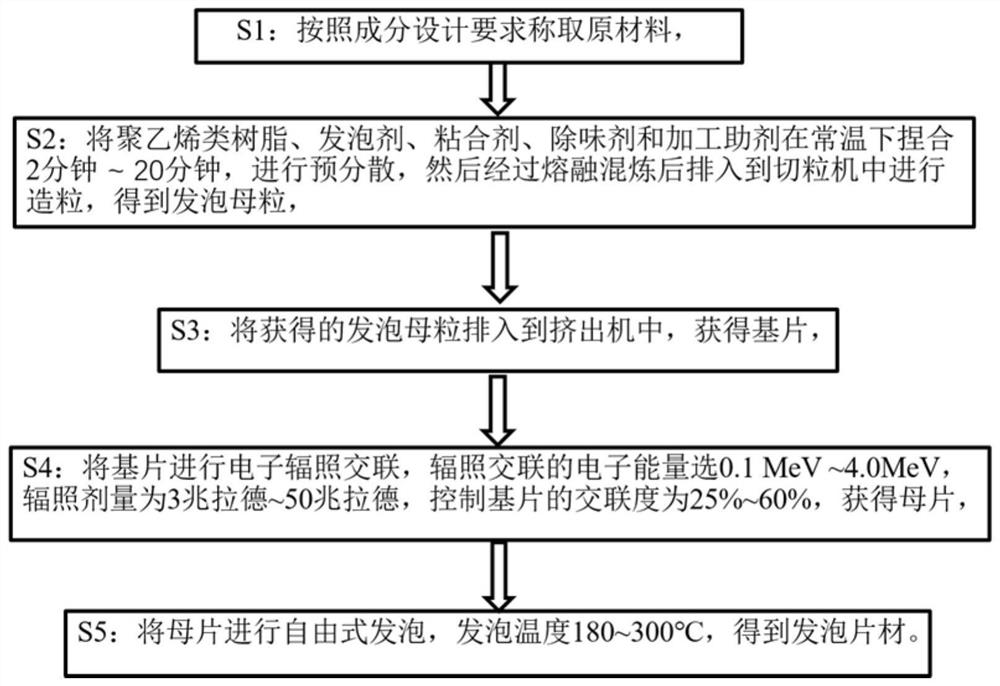

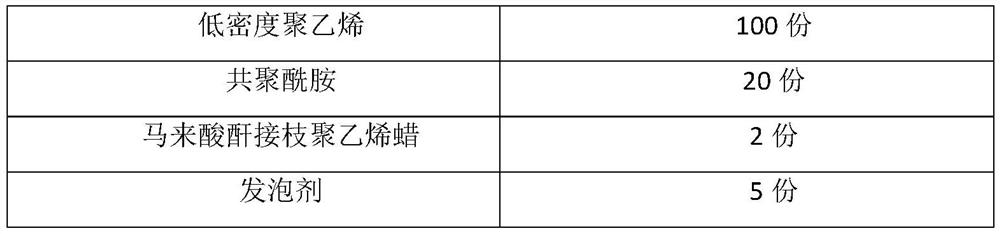

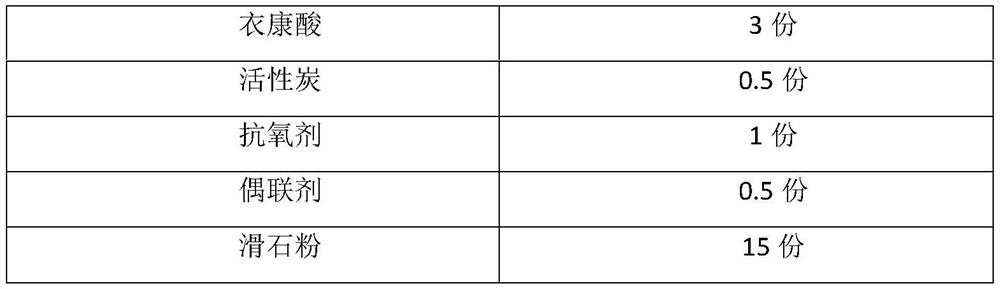

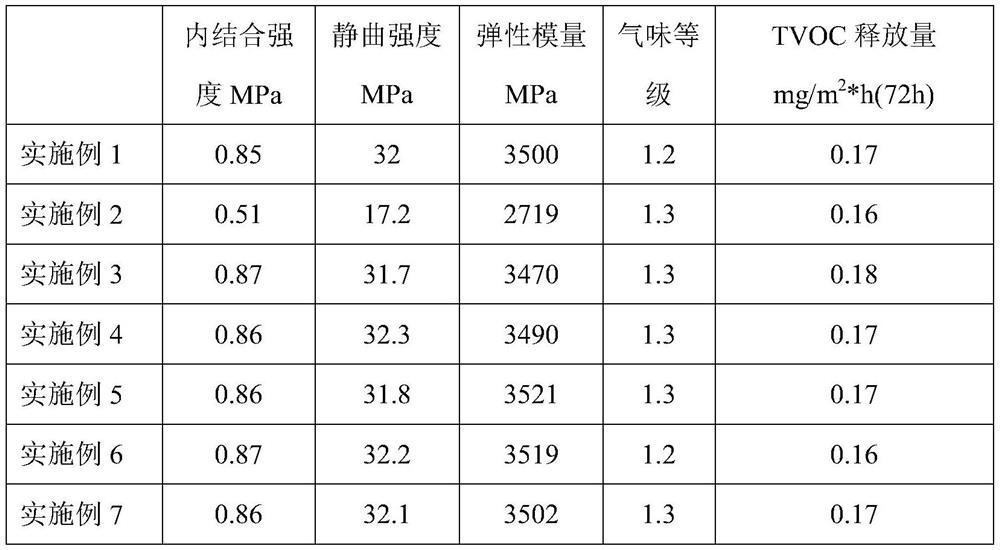

Low-odor polyethylene foam material with thermal bonding performance and preparation method thereof

The invention provides a low-odor polyethylene foam material with thermal bonding performance and a preparation method thereof, and belongs to the field of polyethylene foam materials. The density of the material is 0.05-0.18 g / cm<3>, and the hardness of the material is represented as 30-70 according to Shore C. The low-odor polyethylene foam material has uniform thermal bonding performance from inside to outside. After the low-odor polyethylene foam material is bonded with an external fabric, the peel strength is 1.5-2.6 N / mm. The odor grade of the low-odor polyethylene foam material is not greater than 2.5. The polyethylene foam material has no adhesive property at the temperature of 100-130 DEG C and has adhesive property at the temperature of higher than 180 DEG C. The polyethylene resin is resin obtained by polymerizing polyethylene monomers or polymerizing a polyethylene monomer with other monomers. The invention also provides a method for preparing the polyethylene foam material. The material provided by the invention has the advantages of thermal bonding performance, good processing technology and no pungent smell, and can be well compounded with fabrics made of other materials.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

A kind of low-odor wood-based panel and preparation method thereof

ActiveCN113150399BProtective AdsorptionNo chemical reactionDomestic articlesFlat articlesCyclodextrinEngineering

Owner:WANHUA CHEM GRP CO LTD

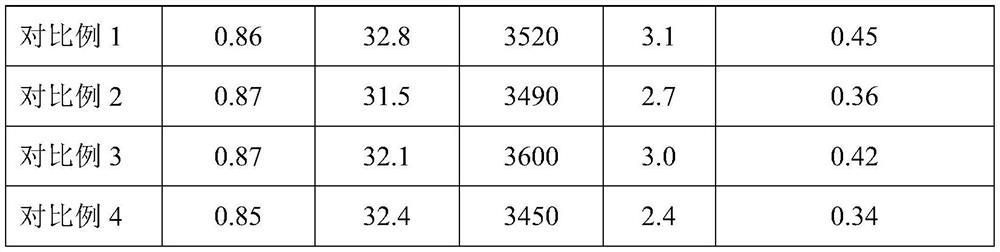

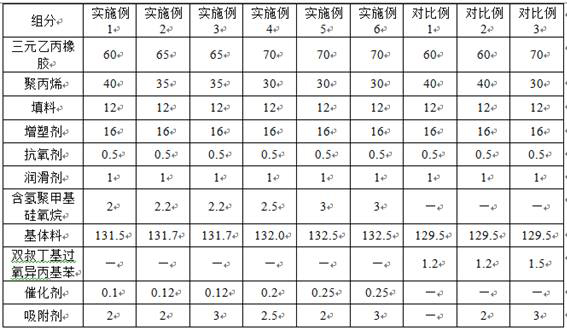

Low-odor and low-VOC TPV material for automobiles and preparation method thereof

The invention discloses a low-odor and low-VOC TPV material for automobiles and a preparation method thereof. The material comprises the following raw materials in parts by weight: 50-80 parts of ethylene propylene diene monomer, 20-50 parts of polypropylene, 10-30 parts of a filler, 5-20 parts of a plasticizer, 0.1-1 part of an antioxidant, 0.1-5 parts of a cross-linking agent, 0.1-5 parts of a catalyst, 0.5-1.5 parts of a lubricant, and 1-5 parts of an adsorbent. According to the invention, the cross-linking system belongs to a novel environment-friendly cross-linking system, and the defects that a peroxide cross-linking system is heavy in smell and high in volatile substance content can be effectively overcome; and the addition of the adsorbent can further reduce the odor and VOC of the elastomer material, so that the elastomer material meets the requirements of low odor and low VOC of the material for the automotive trim, and can be applied to automotive instrument panels, automobile door and window sealing strips and door panel trim.

Owner:中广核三角洲(江苏)塑化有限公司

Modified ABS special material and preparation method thereof

InactiveCN102432977BEase of industrial applicationImprove processing fluidityAntioxidantMoment of inertia

The invention provides a modified ABS (Acrylonitrile butadiene styrene) special material and a preparation method thereof; the ABS special material comprises the following components: 70-95wt% of ABS, 1.5-8wt% of compatilizer, 1.5-8wt% of flexibilizer, 0.2-0.6wt% of antioxidant, 0.1-0.5wt% of lubricant, and 1.5-15wt% of ordered mesoporous material, wherein the ordered mesoporous material is MCM-41, MCM-48, SBA-15 or SBA-16; the preparation method comprises the following steps of: weighing ingredients with certain proportions, putting into a high speed mixer and mixing fully, and then extruding and granulating by a double-screw extruder. The modified ABS special material and the preparation method thereof provided by the invention effectively improve MI (Moment of Inertia) value of the ABS and processing fluidity of the ABS as well as mechanical intensity; in addition, the modified ABS special material has the characteristic of low odour, and also has excellent comprehensive performances such as light weight, sound absorption, etc.

Owner:CHONGQING UNIV OF ARTS & SCI

Automotive trim skin composite material as well as preparation method and application thereof

The invention relates to a material for compounding an automotive trim skin as well as a preparation method and application of the material, and mainly solves the problems of low compounding fastness,high flame compounding agent consumption and strong smell of the material for compounding the automotive trim skin in flame compounding in the prior art. According to the technical scheme, the material for compounding the automotive trim skin is prepared from a component I and a component II, the weight part ratio of the component I to the component II is 100: (20-60), and the component I comprises, by weight, 30-60 parts of polyether polyol A, 30-60 parts of polyether polyol B, 10-40 parts of polymer polyol C, 1-5 parts of water, 0.1-1 part of amine catalysts, 0.1-1 part of tin catalysts, 0.5-2 parts of foam stabilizers, 2-12 parts of flame retartant, and 0.5-5 parts of a flame complexing agent; The component II comprises the following components in parts by weight: 20-60 parts of isocyanate and a preparation method of the component II. According to the technical scheme, a better technical effect is achieved, and the component II can be applied to industrial production of the material for compounding the automotive trim skin.

Owner:江苏金智达新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com