Low emission polypropylene composite material with low odor and preparation method thereof

A composite material and polypropylene technology, which is applied to polypropylene composite materials with low odor and low emission and its preparation. , Excellent low odor and low emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described through specific embodiments below, and the examples are only used to illustrate the present invention rather than limit the present invention.

[0023] The raw materials used in the embodiment of the present invention and comparative example:

[0024] PP: Korea SKBX3800, polypropylene copolymer, melt index MFR is 30g / 10min (230℃, 2.16Kg).

[0025] Antioxidant: Antioxidant Irganox 1010, BASF; Antioxidant Irganox 168, BASF.

[0026] Talc powder: Jintian Industry BHS-1250.

[0027] The first deodorant: polyethylene foam masterbatch loaded with 60-70% deionized water in mass ratio.

[0028] The second deodorant: 13X type zeolite molecular sieve loaded with 2,4-dinitrophenylhydrazine in a mass fraction of 5-20%.

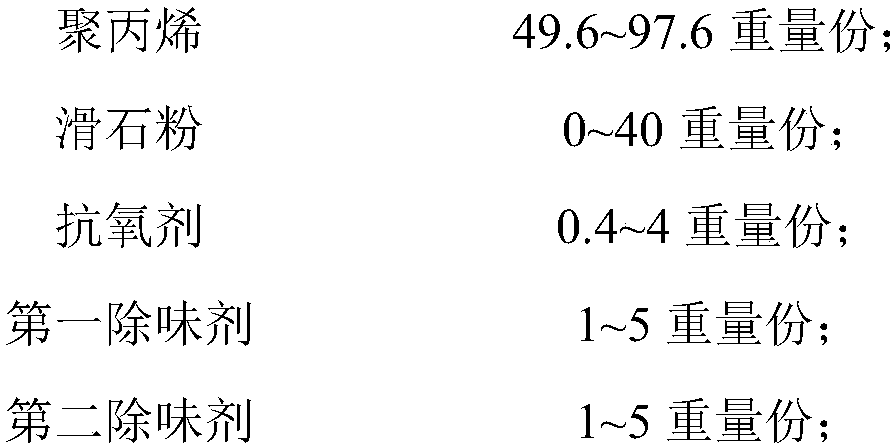

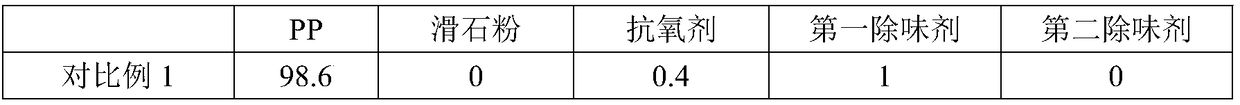

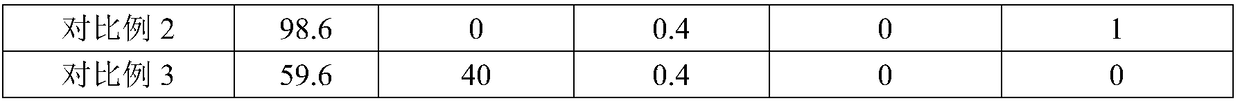

[0029] Wherein the following Table 1 and Table 2 are respectively the mass ratio of each component ratio in Examples 1-9 and Comparative Examples 1-3.

[0030] The component quality of each raw material in table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com