Low-odor masterbatch and preparation method thereof

A low-odor, masterbatch technology, applied in the field of low-odor masterbatch and its preparation, can solve the problems of personal injury in the car, decomposition and volatilization of harmful substances, etc., and achieve the goal of maintaining corrosion resistance, good mechanical properties, and reducing decomposition and volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

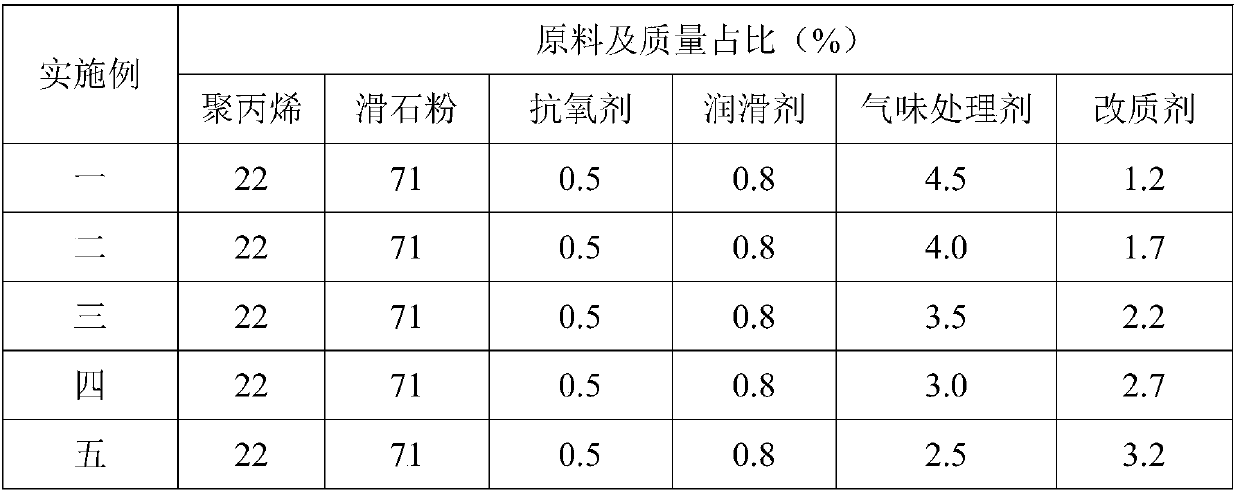

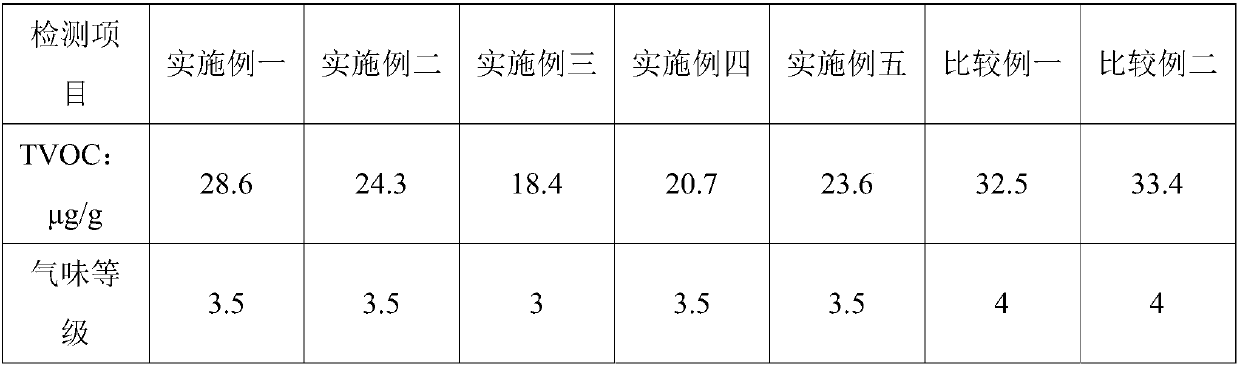

[0024] The present invention will be described in detail below by way of examples.

[0025] The polypropylene that uses in the embodiment is hp500N homopolypropylene, melt index 2-15g / 10min; Inorganic filler is the talcum powder of particle size scope 2000-2500 purpose; Antioxidant is antioxidant 1010 and antioxidant 1076 by mass A mixture of 2:1 ratio; the lubricant is a mixture of zinc stearate or calcium stearate in a mass ratio of 1:1; the odor treatment agent is a mixture of molecular sieves, synthetic zeolite and bentonite in a mass ratio of 1:1:1; The modifier is filler modifier LD-300P.

[0026] The preparation method of the masterbatch is as follows: After mixing polypropylene, talc powder, antioxidant and lubricant in proportion, stir in a high-speed mixer for 8 minutes, and mix thoroughly; when the temperature reaches 120°C, put the mixture into the banburying When the mixture reaches 180°C in the internal mixer, add odor treatment agent and modifier; when the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com