Low-odor and low-VOC TPV material for automobiles and preparation method thereof

A low-odor, automotive-grade technology, applied in low-VOC automotive TPV materials and its preparation, and low-odor fields, can solve problems such as low production efficiency and production capacity, cumbersome and complicated procedures, and high equipment requirements, and achieve reliable quality, low self-odour, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

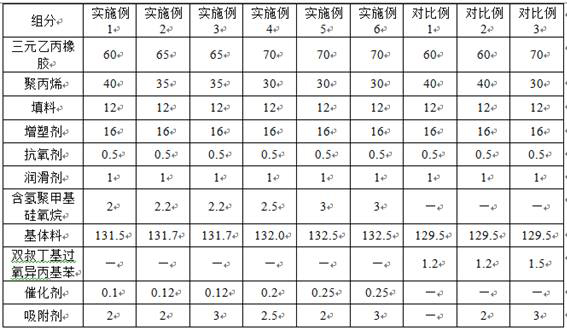

[0049] Embodiment 1~6: A kind of TPV material for automobile with low odor and low VOC

[0050] Preparation methods include:

[0051] The first step, pre-mixing: According to the weight ratio of Table 1, EPDM rubber, polypropylene, filler (nano calcium carbonate), plasticizer (white oil 323), antioxidant (antioxidant 1010), cross-linking agent (hydrogen-containing polymethylsiloxane, there are at least 3 silicon hydrogen groups in a molecular chain, and the silicon hydrogen content is between 1.2%), lubricant (silicone) after preparation, put into Mix evenly in an internal mixer, and then extrude and granulate through a single screw to obtain a base material; the mixing temperature of the internal mixer is 165-185° C., and the mixing time is 20 minutes. The extrusion temperature of single screw is 180~210℃.

[0052] In the second step, according to the proportioning by weight of Table 1, base material, adsorbent (using polypropylene as the microporous skeleton material, magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com