A kind of low-odor wood-based panel and preparation method thereof

A wood-based panel, low-odor technology, used in the manufacture of tools, flat products, other household appliances, etc., can solve the problems of the decline of the mechanical properties of the board, the change of the production process, the decline of the mechanical properties of the wood, etc., to reduce the odor level, improve the quality, The effect of increasing acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Preparation of Sandwich Structure Odor Adsorbent:

[0060] Weigh 100g of γ-cyclodextrin and dissolve it in 500g of water, add 200g of Ti with a particle size of 60 meshes 3 C 2 , using ultrasonic treatment with a frequency of 100KHz for 90min, and then placing the mixture in a freeze dryer and drying at -40°C for 20h to obtain a sandwich-structured odor adsorbent.

[0061] Preparation of formaldehyde-free fiberboard:

[0062] Weigh 1000 g of eucalyptus wood fibers with a moisture content of 10% and 20 g of the sandwich structure odor adsorbent obtained in the previous step into a mechanical mixer to mix uniformly, and then apply 40 g of PMDI by aerosolization while stirring. Weigh 850g of sizing fibers, pave them into slabs in a 30cm*30cm mold, and send them to a hot press after pre-pressing. Fiberboard.

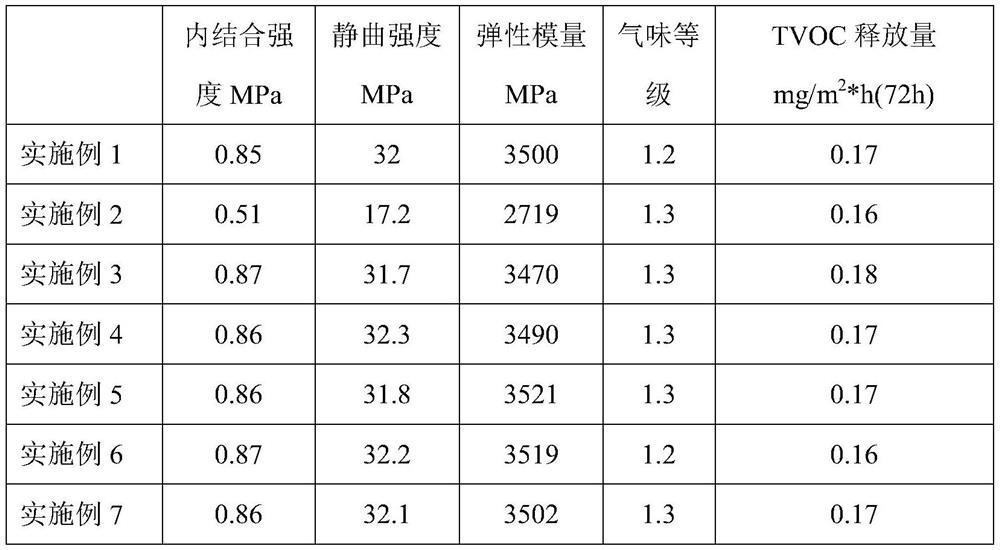

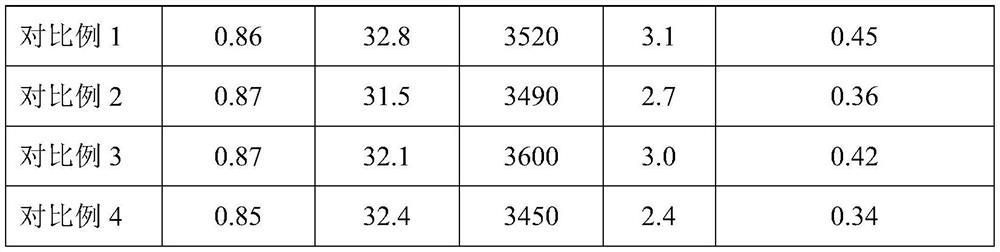

[0063] Sheet mechanical property test and odor grade evaluation, TVOC release test:

[0064] According to "GBT 17657-2013 Test Method for Physical and Chemical P...

Embodiment 2

[0067] The preparation of the sandwich structure odor adsorbent is as in Example 1.

[0068] Preparation of formaldehyde-free particleboard:

[0069] (1) Weigh 1000g of miscellaneous wood surface shavings with a moisture content of 17% and 20g of the sandwich structure odor adsorbent obtained in the previous step and put them into a mechanical mixer to mix uniformly, and then use aerosolization while stirring to apply 35g PMDI.

[0070] (2) Weigh 1000g of miscellaneous wood core layer shavings with a moisture content of 5% and 30g of the sandwich structure odor adsorbent obtained in the previous step and put them into a mechanical mixer to mix uniformly, and then apply 30g PMDI by aerosolization while stirring.

[0071] (3) Weigh 2 parts of surface shavings after sizing prepared in step (1) of 320 g and 1 part of core shavings after sizing of 970 g prepared in step (2), and pave them in a 35cm*35cm mold to have surface shavings-core The slab with layered shavings-surface shav...

Embodiment 3

[0074] Preparation of Sandwich Structure Odor Adsorbent:

[0075] Weigh 55g of γ-cyclodextrin and 5g of β-cyclodextrin and dissolve them in 500g of water, add 200g of Ti with a particle size of 80 mesh 2 N, ultrasonic treatment with a frequency of 28KHz for 30min, and then the mixed solution was placed in a freeze dryer and dried at -35°C for 40h to obtain a sandwich-structured odor adsorbent.

[0076] Preparation of formaldehyde-free fiberboard:

[0077] Weigh 1000g of eucalyptus wood fibers with a moisture content of 10% and 30g of the sandwich structure odor adsorbent obtained in the previous step, put them into a mechanical mixer and mix them evenly, and then apply 40g of PMDI by aerosolization while stirring. Weigh 850g of sizing fibers, pave them into slabs in a 30cm*30cm mold, and send them to a hot press after pre-pressing. Fiberboard.

[0078] The mechanical property test of the board, the evaluation of the odor level, and the TVOC release test are as in Example 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com