Molecular sieve filling system for molecular sieve adsorbing device and filling process of molecular sieve filling system

A filling system and adsorption device technology, which is applied in the filling process field of the system, can solve the problems of molecular sieve life reduction, molecular sieve raw material failure, molecular sieve pulverization, etc., and achieve the effect of protecting adsorption performance, simple structure, and avoiding harmful friction and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

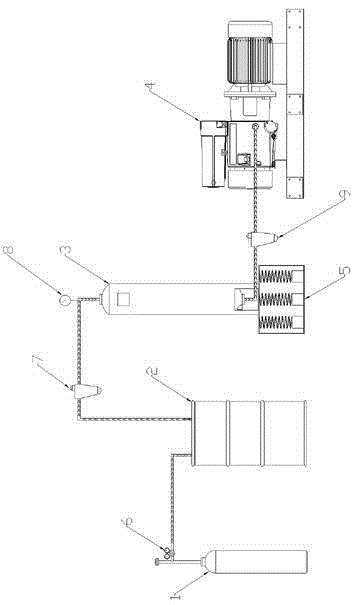

[0020] like figure 1 As shown, in this embodiment, the molecular sieve filling system used for the molecular sieve adsorption device includes a nitrogen cylinder 1, a molecular sieve raw material barrel 2, a molecular sieve adsorption tower 3 and a negative pressure machine 4 connected sequentially through pipelines. The molecular sieve filling system also includes A weighing vertical vibration table 5, on which the molecular sieve adsorption tower 3 is arranged.

[0021] In this embodiment, a pressure flow regulating valve 6 is provided between the nitrogen cylinder 1 and the molecular sieve raw material tank 2 .

[0022] In this embodiment, a primary dust filter 7 is provided between the molecular sieve raw material bucket 2 and the molecular sieve adsorption tower 3 .

[0023] In this embodiment, a negative pressure gauge 8 is provided between the primary dust filter 7 and the molecular sieve adsorption tower 3 .

[0024] In this embodiment, a precision dust filter 9 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com