Low-odor automobile switch lubricating grease composition and preparation method thereof

A grease composition and low-odor technology, which is applied in the field of low-odor automotive switch grease composition and its preparation, can solve the problems of not meeting the smell requirements, easy to get stuck, poor low-temperature performance, etc., and achieve excellent colloidal stability, excellent Anti-shear performance, the effect of maintaining the integrity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

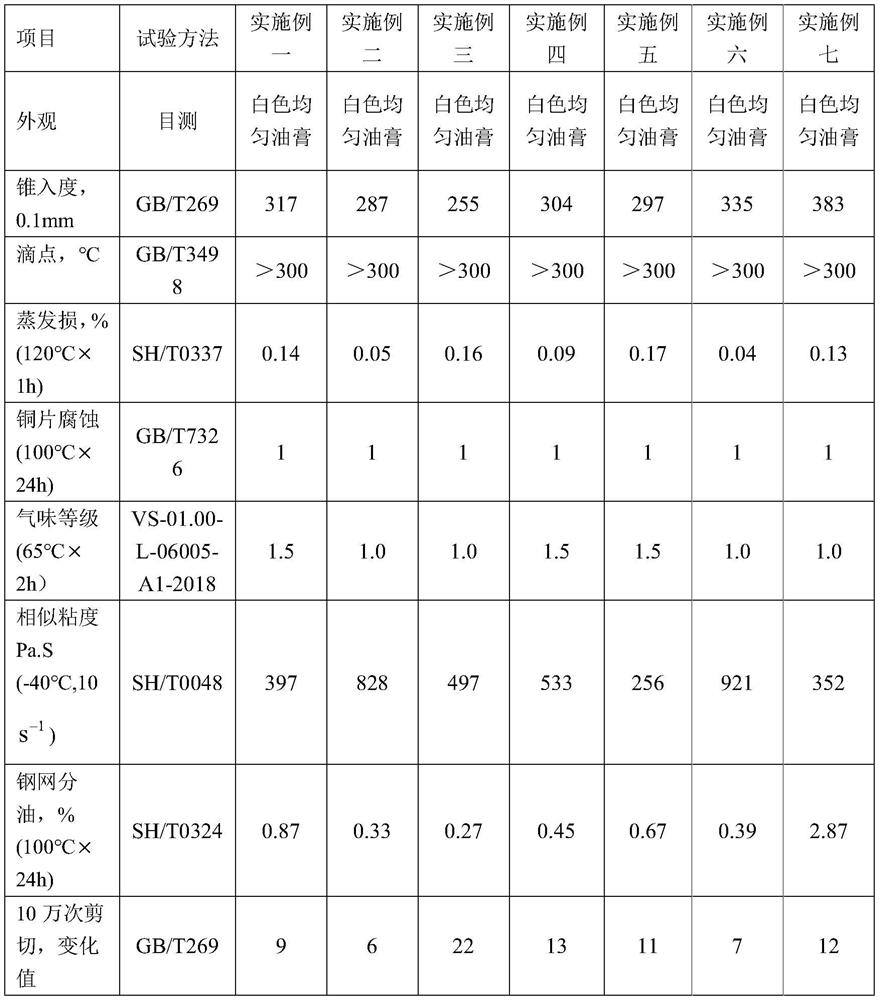

Examples

Embodiment 1

[0041] 86 parts of 40 degrees kinematic viscosity 46mm 2 / s poly-alpha olefin base oil into the cleaned reactor, heated and stirred to 80°C±5, then slowly added 4.5 parts with a specific surface area of 200m 2 / g of hydrophobic fumed silica and 4.5 parts with a specific surface area of 250m 2 / g of hydrophilic fumed silica, stir for 30±5 minutes; then add 2 parts of polytetrafluoroethylene micropowder, 3 parts of boron nitride, and then stir at constant temperature and evacuate for 120±10 minutes, vacuum degree ≤ -0.06Mpa, discharge into barrel.

[0042] Naturally cool to room temperature, then grind 3 times by three-roll mill to obtain the low-odor automotive switch grease composition

Embodiment 2

[0044] 83 parts of 40 degrees kinematic viscosity 95mm 2 / s poly-alpha olefin base oil into the cleaned reactor, heated and stirred to 80℃±5, and then slowly added 2.5 parts with a specific surface area of 300m 2 / g of hydrophobic fumed silica and 7.5 parts with a specific surface area of 220m 2 / g of hydrophilic fumed silica, stir for 30±5 minutes; then add 5 parts of polytetrafluoroethylene micropowder, 2 parts of fluorinated graphite, stir at constant temperature and evacuate for 120±10 minutes, vacuum degree≤ -0.06Mpa, discharge into barrel.

[0045] Naturally cool to room temperature, then grind 3 times by three-roll mill to obtain the low-odor automotive switch grease composition

Embodiment 3

[0047] 74.5 parts of 40 degrees kinematic viscosity 31mm 2 / s poly-alpha olefin base oil into the cleaned reactor, heated and stirred to 80℃±5, and then slowly added 12 parts with a specific surface area of 180m 2 / g of hydrophilic fumed silica, stirred for 30±5 minutes; then added 10 parts of polytetrafluoroethylene micropowder, 2.5 parts of boron nitride, and 1 part of fluorinated graphite, then stirred at constant temperature and vacuumed to disperse for 120 ±10 minutes, vacuum degree ≤-0.06Mpa, discharge into the barrel.

[0048] Naturally cool to room temperature, then grind 3 times by three-roll mill to obtain the low-odor automotive switch grease composition

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com