Modified ABS special material and preparation method thereof

A special material and modification technology, which is applied in the field of ABS special material and its preparation, can solve problems such as difficulty in uniform dispersion, low ABS processing fluidity, and air quality impact, so as to overcome poor air quality, promote industrial application, and process flow sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

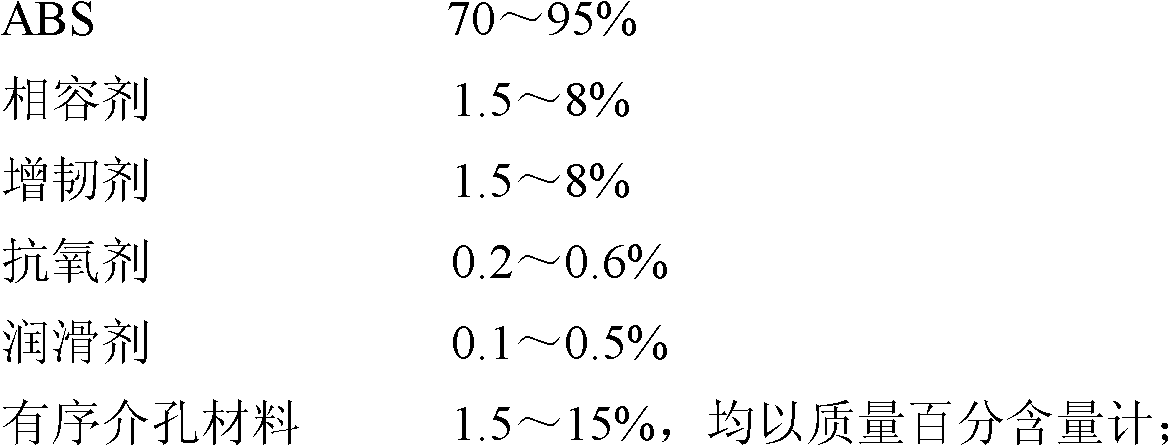

[0031] First weigh the raw materials (expressed in weight fractions) in the following proportions:

[0032]

[0033] ABS: The ABS T100 product produced by Toray Corporation of Japan. The ABS material is hygroscopic and requires drying before processing. Drying conditions are at least 2 hours at 80-90°C.

[0034] MCM-41 ordered mesoporous material: a product produced by Nanjing Xianfeng Nano Material Technology Co., Ltd., which is an ordered mesoporous material with hexagonal ordered pore structure and long-range order. Its pore diameter is 3.5nm and its BET specific surface area is ≥ 900m 2 / g, pore volume ≥ 0.6cm 3 / g.

[0035] Put the above raw materials into a high-speed mixer and mix fully, the mixing speed is 150-300 rpm, and the mixing time is 3-10 minutes; (3) Put the mixture obtained in step (2) into a twin-screw extruder to produce grain. The length-to-diameter ratio of the twin-screw extruder is 40:1, the screw speed is 150-700 rpm, and the working temperatur...

Embodiment 2

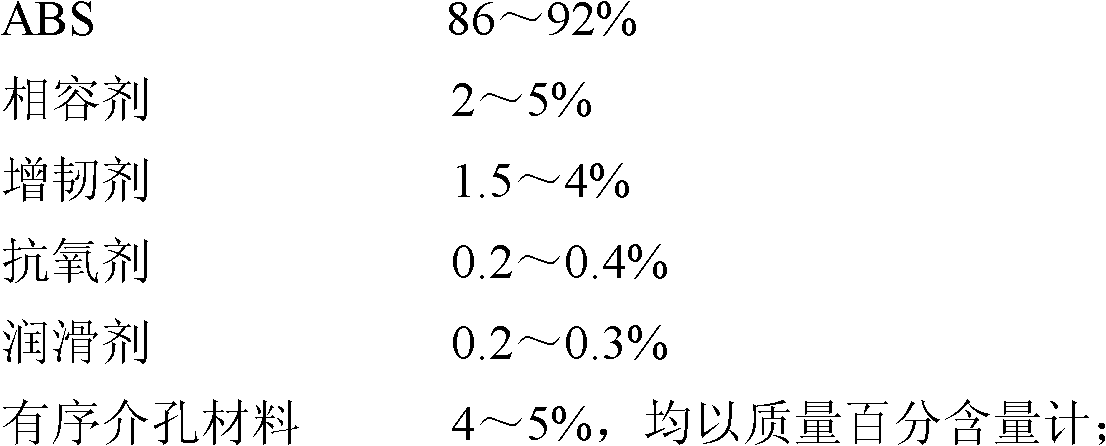

[0045] First weigh the raw materials (expressed in weight fractions) in the following proportions:

[0046]

[0047] MCM-48 ordered mesoporous material: a product produced by Nanjing Xianfeng Nano Material Technology Co., Ltd., which has a uniform pore size of about 2.6nm and two sets of independent three-dimensional spiral channel network structures. BET specific surface area ≥ 750m 2 / g, pore volume ≥ 0.6cm 3 / g.

[0048] Put the above raw materials into a high-speed mixer and mix fully, the mixing speed is 150-300 rpm, and the mixing time is 3-10 minutes; (3) Put the mixture obtained in step (2) into a twin-screw extruder to produce grain. The length-to-diameter ratio of the twin-screw extruder is 40:1, the screw speed is 150-700 rpm, and the working temperature of the twin-screw extrusion is 130-260°C in the first zone, 140-270°C in the second zone, and 140-270°C in the third zone. Zone 150-280°C, Zone 4 150-280°C, Zone 5 150-280°C, Zone 6 150-280°C, Zone 7 150-280°...

Embodiment 3

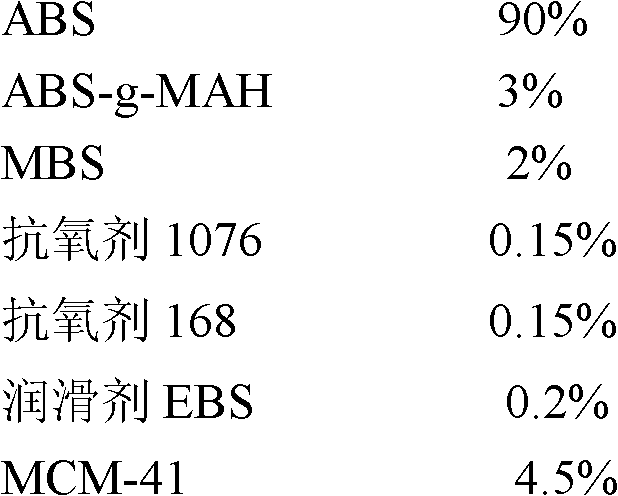

[0053] First weigh the raw materials (expressed in weight fractions) in the following proportions:

[0054]

[0055] SBA-15 ordered mesoporous material: a product produced by Nanjing Xianfeng Nano Material Technology Co., Ltd., which is a mesoporous silicon-based molecular sieve with a two-dimensional hexagonal structure synthesized under acidic conditions, with a pore size of 6-10nm and a BET specific surface area of ≥650m 2 / g, pore volume ≥ 1.2cm 3 / g. Compared with MCM-41, SBA-15 ordered mesoporous material has larger pore diameter, thicker pore wall and higher pore volume, and has better hydrothermal stability.

[0056] Put the above raw materials into a high-speed mixer and mix fully, the mixing speed is 150-300 rpm, and the mixing time is 3-10 minutes; (3) Put the mixture obtained in step (2) into a twin-screw extruder to produce grain. The length-to-diameter ratio of the twin-screw extruder is 40:1, the screw speed is 150-700 rpm, and the working temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com