Metallic oxide/metal sulfide hollow nanospheres as well as preparation method and application thereof

A technology of metal sulfides and oxides, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as cost and resource reserve limitations, achieve simple methods, avoid compounding, and effectively compound Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

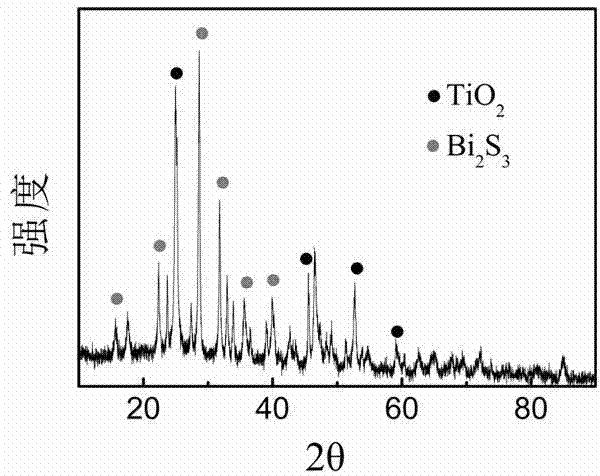

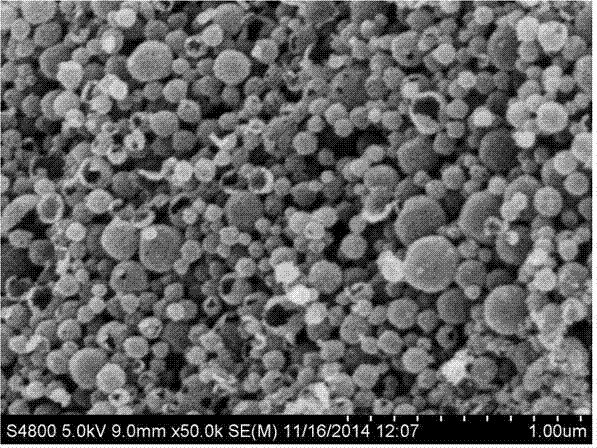

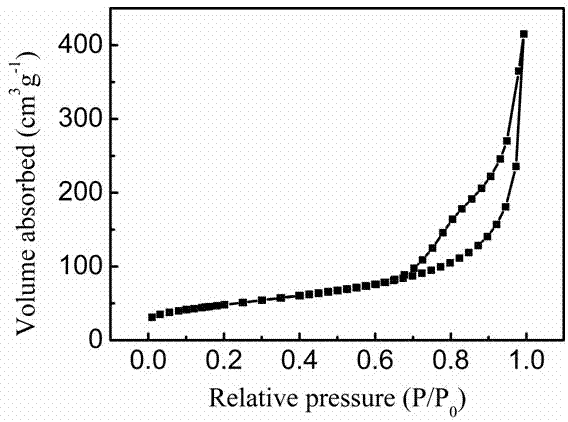

[0026] Titanium oxide (TiO 2 ) / bismuth sulfide (Bi 2 S 3 ) Core-shell heterojunction hollow nanospheres:

[0027] (1) Dissolve 0.34g of tetrabutyl titanate in 100mL of ethanol to obtain a titanium ion solution, then add 1g of carbon spherical templates with carboxyl and hydroxyl groups on the surface to the adsorption solution, ultrasonically disperse the spherical templates, and stir and adsorb for 12 hours After centrifugation, dry at 60°C for 12 hours to obtain the adsorbed spherical template;

[0028] (2) heat-treat the sample obtained in step (1) at 400°C for 6 hours to remove the carbon sphere template to obtain a titanium oxide hollow spherical shell;

[0029] (3) Add 20 mg of the above titanium oxide hollow spheres to 30 mL of 0.5 M glucose aqueous solution, ultrasonically disperse the hollow spheres, put them in a hydrothermal kettle, react at 160°C for 3 hours, cool to room temperature, centrifuge, Wash and dry at 60°C for 12 hours;

[0030] (4) Prepare a bismut...

Embodiment 2

[0035] Tungsten oxide (WO 3 ) / zinc sulfide (ZnS) core-shell heterojunction hollow nanospheres:

[0036] (1) Dissolve 0.4g of tungsten chloride in 60mL of deionized water to obtain a tungsten ion solution, and then add 0.7g of SiO with carboxyl and hydroxyl groups on the surface to the adsorption solution 2 Spherical template, ultrasonically disperse the spherical template, centrifuge after stirring and adsorbing for 8 hours, and dry at 70°C for 8 hours to obtain the adsorbed spherical template;

[0037] (2) Heat the sample obtained in step (1) at 400°C for 6h, then immerse it in a 5M NaOH solution at 80°C for 4h to remove SiO 2 Spherical template to obtain tungsten oxide hollow spherical shell;

[0038] (3) Add 30mg of the above tungsten oxide hollow spheres to 30mL of 0.4M glucose aqueous solution, ultrasonically disperse the hollow spheres, put them in a hydrothermal kettle, react at 170°C for 4h, cool to room temperature, and centrifuge , Wash and dry at 50°C for 8 hours...

Embodiment 3

[0043] Bismuth oxide (Bi 2 o 3 ) / cadmium sulfide (CdS) core-shell heterojunction hollow nanospheres:

[0044] (1) Dissolve 0.6g of bismuth nitrate in 80mL of ethylene glycol to obtain a bismuth ion solution, then add 0.9g of PS spherical templates with carboxyl and hydroxyl groups on the surface to the adsorption solution, ultrasonically disperse the spherical templates, and stir and adsorb for 48 hours After centrifugation, dry at 100°C for 2 hours to obtain the adsorbed spherical template;

[0045] (2) heat-treating the sample obtained in step (1) at 300° C. for 60 h to remove the PS spherical template to obtain a bismuth oxide hollow spherical shell;

[0046] (3) Add 30 mg of the above-mentioned bismuth oxide hollow spheres to 30 mL of 0.4 M glucose aqueous solution, ultrasonically disperse the hollow spheres, put them in a hydrothermal kettle, react at 180° C. for 3 h, cool to room temperature, centrifuge, Wash and dry at 100°C for 48 hours;

[0047] (4) Configure a ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com