Surface processing method of super-hydrophobic ice-covering-proof aluminum and steel with rough surface

An anti-icing and super-hydrophobic technology, applied in the direction of metal material coating process, can solve the problems of volatile organic solvent, difficult to coat, low service life, etc., to achieve simple process steps and equipment operation, easy industrial application, The effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

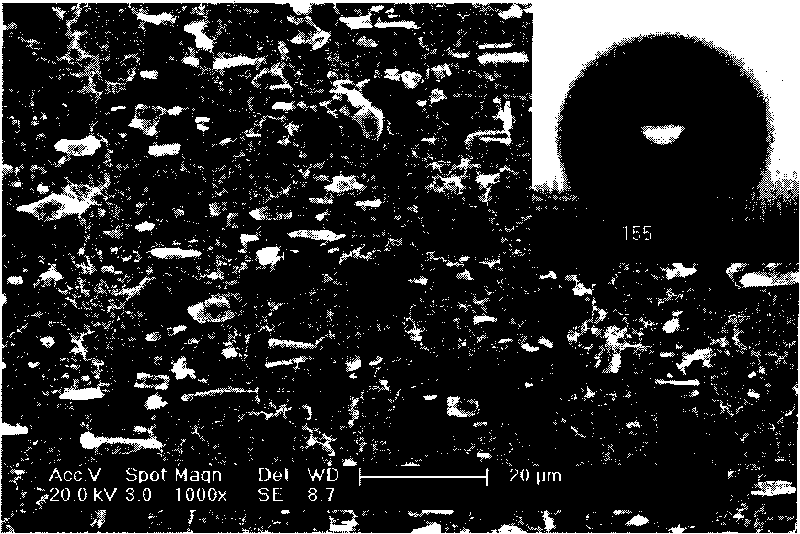

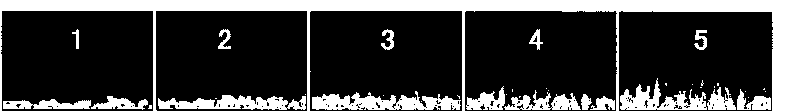

[0025]First, use acetone and deionized water to ultrasonically clean the aluminum sheet and dry it; then use a hydrochloric acid solution with a concentration of 40% in a closed container in a boiling water tank to steam-etch the aluminum sheet for 1 hour, take it out, rinse it with clean water, and dry it; Adjust the fluorosilane n-hexane solvent with an aqueous acetic acid solution with a pH value of 3, wherein the weight percent of fluorosilane and n-hexane is 2%, and the weight percent of acetic acid aqueous solution and fluorosilane n-hexane solution is also 2%; the etched aluminum The sheet was suspended above the above-mentioned fluorosilane n-hexane solution, sealed and placed together in a box-type electric furnace for 2 hours at 250°C to achieve fluorosilane modification on the surface of the aluminum sheet; then the sample was taken out and kept at 250°C for 0.5h to obtain The morphology of rough aluminum surface with superhydrophobic properties and the shape of wate...

example 2

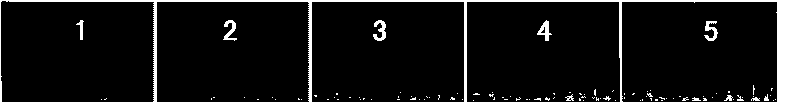

[0031] Clean the steel sheet sequentially with acetone and deionized water ultrasonically and dry it; put the 75% hydrochloric acid solution and the airtight container with the steel sheet suspended in the boiling water tank for 30 minutes, then take it out, rinse it with clean water and dry it; The acetic acid aqueous solution with a value of 3 adjusts the fluorosilane n-hexane solvent, wherein the weight percent of fluorosilane and n-hexane is 2%, and the weight percent of acetic acid aqueous solution and fluorosilane n-hexane solution is also 2%; the steel sheet after etching is placed Put the above-mentioned fluorosilane n-hexane solution into a closed container, and put them together in a box-type electric furnace at 250°C for 2 hours to realize the fluorosilane modification on the surface of the steel sheet; then take out the sample, and continue to hold it at 250°C for 0.5h, The surface morphology and surface water droplet morphology of the obtained rough steel surface w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com